Similar Categories

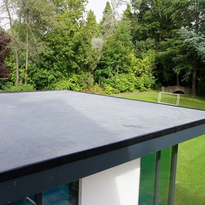

What Is EPDM Roofing and Its Key Components

EPDM roofing is a popular choice for flat and low-slope roofs due to its durability and flexibility. It's made from Ethylene Propylene Diene Monomer, a type of synthetic rubber that provides excellent weather resistance. The core of an EPDM system is a single-ply membrane that serves as the primary waterproof layer. This membrane is combined with adhesives to secure seams, flashings for edges and penetrations, and seaming tape to create watertight joins. There are also optional protective coatings available to reflect sunlight and reduce heat absorption. The materials are designed to withstand UV rays, ozone, hail, and thermal stress, ensuring reliability over time. EPDM roofing offers a lifespan of 50 years or more with proper maintenance, making it a cost-effective and long-lasting roofing solution. Proper installation of these components guarantees that the roof remains waterproof and durable, providing peace of mind for years to come.

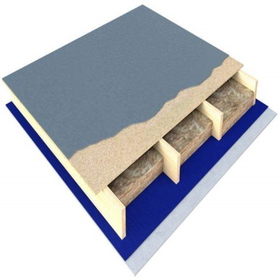

Physical Characteristics of EPDM Membranes

The physical characteristics of EPDM membranes are fundamental to their performance and suitability for roofing applications. These membranes are made from a blend of ethylene, propylene, and a diene monomer, combined with additives such as carbon black and stabilisers to enhance durability. EPDM is a thermoset elastomer that can stretch up to 300% and then return to its original shape, making it highly flexible. Reinforcement options add strength, while a uniform finish provides consistent protection. EPDM is available in black and white, which influences energy absorption and drying times. The typical thickness ranges from 45 to 90 mils, and sheets can be as large as 50 feet wide and 200 feet long, reducing seams and enhancing waterproofing.

| Aspect | Description |

|---|---|

| Thickness & Size | Ranges from 45-90 mils; sheet widths up to 50 feet, lengths up to 200 feet |

| Flexibility | Can stretch 300%, returns to shape, adapts to roof movements |

| Durability | Lasts over 30 years, resistant to UV, ozone, and weather damage |

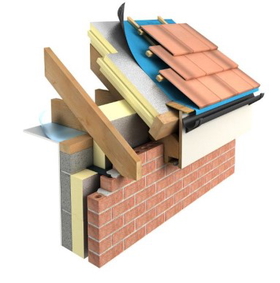

Various Techniques for Installing EPDM Roofs

Various installation techniques are employed to secure EPDM roofing membranes, each offering distinct advantages and suitable applications.

Mechanically attached systems use fasteners along the edges and seams, allowing for quicker installation and easier adjustments. These systems are versatile and can be used on a variety of roof types. Fully adhered systems bond the membrane directly to the roof deck with adhesive, providing the strongest resistance to wind uplift and excellent weather performance. Ballasted installations place gravel or paving slabs over the membrane, offering a cost-effective option with a smooth appearance, although they require careful handling of ballast materials. Loose-laid methods involve simply laying the membrane without fastening, making removal easier but less stable. Hybrid systems combine these techniques to enhance durability and performance, giving building owners flexible options based on their specific needs and roof designs.

Benefits of Choosing EPDM for Commercial and Residential Buildings

Choosing EPDM roofing offers a range of benefits for both commercial and residential buildings in the UK. Its durability means it often lasts over 30 years if properly maintained, reducing the need for future replacements. The material resists severe weather, including hail and strong winds, minimising damage and leaks. Additionally, EPDM’s flexibility in varying temperatures helps maintain its integrity over time. Long lifespan of 20 to 30 years; with proper installation, it can extend even further, providing a reliable roofing solution. Here are some key advantages:

- Long-lasting performance that lowers overall costs.

- Superior weather and environmental resistance, ideal for the diverse UK climate.

- Cost-effective installation with minimal maintenance requirements.

These qualities make EPDM a smart, reliable choice that fosters a sense of security and belonging, knowing your building is protected by a trusted, high-quality material.

How EPDM Performs in Extreme Temperatures and Weather Conditions

EPDM roofing performs exceptionally well in both extremely cold and hot weather conditions, making it a popular choice for diverse climates across the UK.

In cold temperatures, EPDM remains flexible, preventing cracking or shattering, even at lows of -45°C (-49°F). For optimal results, installation is recommended above 5°C (41°F), but its ability to withstand harsh winters is evidenced in colder regions. Its exceptional heat resistance ensures serviceability during the hottest days.

In hot weather, EPDM endures temperatures up to 150°C (302°F), acting as a barrier that reflects heat while retaining its structural integrity. Its flexibility allows it to cope with rapid temperature changes without damage, making it ideal for areas experiencing significant temperature fluctuations.

Understanding the Chemical and UV Resistance of EPDM

The durability of EPDM roofing isn’t just about how it handles extreme temperatures, but also how it resists various chemicals and ultraviolet (UV) rays from sunlight.

EPDM’s excellent UV resistance comes from specific additives that prevent damage and maintain colour and strength over time. Its chemical resistance varies; it can withstand ozone and some acids, but it's vulnerable to oils, petrol, and most organic solvents. O-ring materials are selected based on chemical resistance ratings, ensuring compatibility with specific environmental conditions. Here are three key points:

- UV resistance helps protect against weathering and prolongs the roof’s lifespan.

- Chemical resistance depends on factors such as temperature, concentration, and chemical type.

- Proper testing guarantees EPDM’s long-term performance in specific environments.

Understanding these properties helps confirm that EPDM roofing remains durable and reliable for outdoor use in the UK.

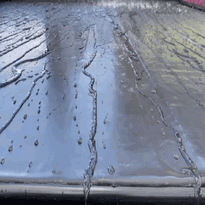

Common Challenges and Limitations of EPDM Roofing Systems

Many roofing systems encounter common challenges due to their material properties and installation requirements.

EPDM roofing, while known for its durability, presents some notable limitations. It's susceptible to high temperatures, which can result in shrinkage, stretching, and cracks that may lead to leaks. The rubber membrane can also be punctured or torn by sharp objects such as hail or branches, compromising its integrity. In addition, the thin layer of material is easy to damage, making it vulnerable to debris and foot traffic. Over time, EPDM tends to shrink, increasing the risk of seam failure and water infiltration. Furthermore, it's incompatible with asphalt-based products, which can weaken the material through chemical reactions.

Additionally, EPDM is less resistant to foot traffic, making it less suitable for walkable areas. Proper installation is crucial, as inadequate sealing or poorly constructed seams can result in leaks and premature failure, posing significant challenges for homeowners seeking a reliable roofing solution.

Maintenance and Repair Strategies for EPDM Roofs

Regular maintenance and timely repairs play a crucial role in extending the lifespan of EPDM roofs. Proper care helps prevent small problems from escalating into costly issues later on. Here are three essential strategies:

-

Routine inspections: Inspect the roof twice a year and after significant storms, looking for cracks, loose seams, or signs of leaks. EPDM's durability relies heavily on early detection of damage, making regular inspections vital.

-

Cleaning debris: Regularly remove leaves and dirt using soft tools, avoiding harsh chemicals or pressure washers that can damage the membrane.

-

Seam and flashing checks: Examine seals around vents and pipes, reapplying sealant when necessary, and promptly repair any damaged flashings.

Comparing EPDM With Other Single-Ply Roofing Materials

When comparing EPDM to other single-ply roofing materials, durability and resistance are key factors to consider. EPDM is known for being lightweight and cost-effective but tends to have lower puncture resistance and seam strength than TPO. EPDM's rubber composition provides flexibility and weather resistance, making it suitable for various climates, including the UK. Understanding these differences is essential for selecting the appropriate roofing material based on the UK climate and specific building requirements.

Durability and Resistance Differences

EPDM roofing is renowned for its durability and resistance to harsh weather conditions, making it a popular choice for many buildings across the UK. It typically lasts 20 to 30 years, and with proper maintenance, it can even exceed this lifespan.

When compared to other materials:

- Duro-Last often lasts 15 to 25 years longer than EPDM when conditions are ideal.

- PVC provides a lifespan comparable to or longer than EPDM, depending on the quality of materials and installation.

- TPO may not last as long due to concerns over longevity, particularly in extreme conditions.

EPDM excels in extreme temperatures, as well as UV and ozone resistance, while remaining flexible with an impressive stretch capability of up to 300%. It is also known for its excellent weatherproofing, which further enhances its suitability for the unpredictable climate in the UK. Although it can be susceptible to punctures, it remains a reliable, cost-effective, and easy-to-maintain roofing option for those seeking long-term durability in the UK.

Future Trends and Innovations in EPDM Roofing Technology

Emerging recycling methods are making EPDM roofing more environmentally friendly by enhancing end-of-life processes and reducing waste.

Simultaneously, smart membrane integration, including sensors and IoT technology, facilitates real-time monitoring and improves roof performance.

These innovations are shaping the future of EPDM roofing in the UK, rendering it more durable, efficient, and sustainable.

Emerging Recycling Methods

Recent advances in recycling methods are transforming how EPDM roofing materials are reused and repurposed in the UK. Innovations such as chemical recycling, pyrolysis, and devulcanisation are making it possible to process EPDM multiple times, even though repeated use can affect performance.

These methods involve breaking down EPDM into smaller parts or extracting useful ingredients, such as carbon black, for creating new products. Nationwide programmes now extend across the UK and parts of Europe, increasing access and collection.

Key emerging recycling methods include:

- Chemical and mechanical recycling techniques that restore EPDM’s properties.

- Pyrolysis, which decomposes EPDM into its basic components.

- Devulcanisation, breaking chemical bonds to improve material reuse.

These innovations help reduce landfill waste, support sustainability, and encourage a shared sense of progress within the roofing community.

Smart Membrane Integration

Innovations in membrane design are shaping the future of EPDM roofing in the UK by making membranes more durable, flexible, and environmentally friendly.

New manufacturing techniques produce thicker membranes with uniform surfaces, thereby increasing their lifespan. Smart designs enable EPDM to better resist weathering and environmental changes, while nanotechnology could soon enhance tensile strength and UV resistance.

Researchers are also developing self-healing coatings that reduce maintenance requirements over time. Furthermore, there's a focus on using sustainable materials, such as recycled rubber, to lessen environmental impact.

These advancements are complemented by integrating EPDM with green building technologies like improved insulation, solar panels, and green roofs. Such innovations create more efficient, resilient, and eco-friendly roofing systems, fostering a sense of community and shared responsibility for sustainable solutions.

Conclusion

EPDM roofing offers a durable, cost-effective solution for both commercial and residential buildings in the UK. Its strong resistance to weather, flexible installation options, and longevity make it popular among building owners. While it has some limitations, proper maintenance can extend its lifespan. As technology advances, EPDM is likely to become even more efficient and environmentally friendly. Overall, it remains a reliable choice for those seeking a long-lasting, weather-resistant roofing material.