Similar Categories

Historical Origins and Early Uses

The origins of duct tape can be traced back to the early 20th century, when various materials and experiments laid the groundwork for its development.

In the 1920s, cloth-backed tapes made from cotton "duck" cloth were used for shoe reinforcement, cable protection, and decoration.

By 1902, steel cables coated in linseed oil and wrapped with cloth tape were employed to protect against corrosion.

During the 1910s, homemade tapes soaked in rubber and rosin were experimented with.

In hospitals, cloth tapes inspired by medical needs emerged in the 1930s, while electrical standards in 1936 specified duck tape for insulating power cables.

During World War II, these early uses showcased the tape’s versatility and laid the foundation for its future roles in both military and civilian applications in the UK.

Development and Innovations Over Time

Advances in materials and design have played a key role in transforming duct tape over time. These improvements include:

-

Enhanced Adhesives: Modern adhesives are stronger and more durable, ensuring the tape adheres better and lasts longer in various conditions. This has been made possible by advances in adhesive chemistry.

-

Waterproofing and Fire Resistance: Newer versions are waterproof, able to withstand moisture, and some are fire-resistant, capable of handling high temperatures without losing effectiveness.

-

Colour and Texture Options: Duct tape now comes in a variety of colours and textures, catering to aesthetic preferences and specific needs such as insulation and heavy-duty repairs.

These innovations have expanded duct tape’s role from basic repairs to specialised applications.

They've also made the tape more reliable and versatile, helping people feel connected through its widespread use in homes, crafts, and industries across the UK.

Military Applications and Field Uses

Duct tape plays a vital role in military applications and field uses, where quick and effective solutions are often required. It's used to seal ammunition boxes to keep supplies dry and secure, as well as to reinforce equipment during combat to prevent failures. Furthermore, soldiers frequently rely on duct tape for makeshift repairs, ensuring their gear remains functional in challenging environments. Duct tape's versatility extends to creating improvisational tools and solutions, making it an indispensable item in tactical situations.

Sealing Ammunition Boxes

Sealing ammunition boxes in military field conditions requires reliable and durable materials that can withstand harsh environments. Duct tape, originally developed during WWII, proved ideal for this purpose.

Its three key features are:

- Waterproof adhesive and cotton duck backing, which protect contents from moisture and humidity.

- Easy-to-tear design, allowing soldiers to quickly open or reseal boxes without tools.

- Strong, camouflage-coloured tape that secures seals and prevents tampering during movement.

This tape's resilience minimised equipment failures and delays in critical situations, especially in humid environments like the Pacific Theatre. During WWII, duct tape was recognized for its waterproof and adhesive qualities, making it essential for military use.

Its ability to withstand rough handling and harsh weather made it indispensable for sealing ammunition boxes.

Over time, duct tape became a standard issue, ensuring the safe transportation and readiness of ammunition in combat zones worldwide.

Fortifying Equipment in Combat

In combat situations, soldiers often rely on duct tape to strengthen and secure their equipment quickly and effectively. It reinforces handles and straps, making equipment more durable under harsh conditions. The tape also secures loose items in vehicles, preventing loss during transit. Additionally, it insulates cables against extreme temperatures and moisture, protecting vital communications. Duct tape shields sensitive electronics from dust and water, ensuring operational integrity. The tape’s water-resistant nature makes it ideal for harsh environments, allowing soldiers to adapt to unpredictable weather and terrain. The table below highlights its key uses:

| Fortification Use | Specific Application |

|---|---|

| Improved Durability | Reinforces equipment handles and straps, prolonging their lifespan |

| Security in Transit | Secures loose items in vehicles, preventing loss |

| Environmental Protection | Insulates cables and shields electronics from environmental damage |

| Rapid Field Adjustments | Allows quick fixes for equipment components needing immediate attention |

Makeshift Repairs in Fields

In the field, soldiers frequently encounter situations that require quick, effective repairs to maintain operational readiness. Military-grade duct tape is invaluable because of its strength, water resistance, and conformability, making it ideal for field fixes.

-

It can temporarily seal leaks in pipes or boats, ensuring equipment remains functional until proper repairs can be made.

-

The tape’s adhesive properties enable quick fixes to torn gear, broken cracks, or damaged windows.

-

Soldiers also use it for improvised solutions, such as reinforcing gear or creating makeshift tools when other materials are unavailable.

These applications help maintain safety and operational efficiency. Its durability and versatility make duct tape a reliable tool for field repairs, promoting unity and resilience among soldiers facing unpredictable challenges.

Industrial and Commercial Adoption

Duct tapes play a significant role in construction, manufacturing, and packaging industries, where their versatility guarantees quick repairs and secure sealing.

They're valued for their durability, moisture resistance, and cost-effectiveness, making them essential for everyday applications.

As industries continue to grow, the demand for specialised, high-performance duct tapes is expected to increase, further expanding their industrial use in the UK.

The increasing adoption of duct tapes across various sectors is also driven by their ability to handle extreme conditions, ensuring reliable performance even in challenging environments.

Utility in Construction

Duct tapes play a vital role in construction projects, particularly within industrial and commercial settings in the UK. They're valued for their versatility, quick application, and cost-effectiveness.

-

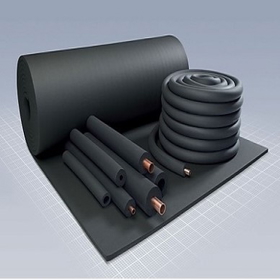

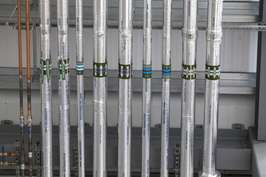

Sealing HVAC Systems: Duct tape is widely used to seal heating, ventilation, and air conditioning systems, preventing air leaks and improving energy efficiency.

-

Temporary Weatherproofing: It provides a reliable barrier against water and wind during construction, protecting materials and interiors from damage.

-

Material Reinforcement and Repairs: Duct tape is essential for bundling electrical wires, joining plasterboard, and making emergency fixes on-site.

These applications highlight the tape's essential role, driven by ongoing industry growth and the need for efficient, adaptable solutions in complex projects across the UK.

Manufacturing and Packaging

Manufacturing and packaging processes for duct tapes are highly specialised to ensure consistent quality and performance in industrial and commercial applications. These tapes are produced using two main methods: lamination, which bonds cloth to plastic backing, and co-extrusion, which combines backing, cloth, and adhesive in a single process. The backing, usually vinyl, is created through calendering, while adhesives utilise crosslinked polymers to withstand heat and stress. The adhesive is applied in liquid form and cured in ovens for stability. Innovative production techniques also enable the production of tapes with enhanced durability and strength. The finished tape is rewound onto jumbo rolls and stored in controlled environments to prevent degradation. During packaging, jumbo rolls are precisely slit into smaller consumer rolls on cardboard or plastic cores. This thorough process ensures that duct tapes meet high standards for strength, flexibility, and reliability.

Everyday Household and DIY Applications

In many households across the UK, duct tape is a go-to tool for a wide range of quick repairs and organisational tasks. It’s widely used for temporary fixes, sealing leaks, and mending appliances, particularly by husbands, children, and sons.

Duct tape works effectively on plastic, fabric, metal, wood, and glass surfaces, making it versatile for everyday needs.

-

It helps reinforce furniture, patch household items, and seal plumbing or car leaks.

-

People use it creatively for organising wiring, bundling tools, or even decorating event setups.

-

It quickly addresses emergency repairs, such as securing loose tiles, sealing drafts, or fixing hoses mid-crisis.

This affordable, portable solution promotes a sense of independence and resourcefulness in the home.

The Cultural Symbol of Ingenuity

Throughout history, duct tape has come to symbolise resourcefulness and ingenuity, particularly during times of crisis. Originally created to seal ammunition boxes during the Second World War, soldiers soon found it useful for repairing equipment and vehicles.

After the war, civilians adopted it for home repairs, recognising its durability and ease of use. Over time, duct tape became a cultural icon representing problem-solving under constraints, reflecting the wartime "make-do" attitude.

It's often seen as a symbol of human resilience and adaptability. The tape’s image as an improvised fix is reinforced through media, from television shows to films, where it's used as a quick solution.

Its widespread recognition makes duct tape a universal metaphor for creativity and the ability to overcome challenges with limited resources.

Marketing and Brand Evolution

As duct tape gained popularity beyond military use, companies in the UK began to develop strategic marketing efforts to position it as a versatile household product.

-

They emphasised durability for home repairs, shifting the focus from military origins to everyday uses.

-

Brands introduced branded packaging, colour options, and decorative patterns to appeal to consumers and foster a sense of belonging in DIY communities.

-

Manco, later acquired by ShurTech Brands, protected its trademarks and promoted Duck Tape® as a premium, recognisable brand.

These efforts helped transform duct tape into a household essential, encouraging people to trust it for quick fixes, creative projects, and general repairs.

Over time, marketing strategies reinforced its image as a versatile, dependable product that brings people together around common projects and solutions.

Creative and Unconventional Uses

Duct tape’s flexibility and strong adhesive properties have led to numerous creative and unconventional uses beyond traditional repairs.

In emergencies, it can protect blisters, stabilise fractures, reinforce shelters, or even assist in crafting emergency stretchers.

Outdoors, users have constructed boats, marked trails, and temporarily fixed gear such as tent poles or backpacks.

Around the home, duct tape aids in cleanup, secures toothpaste, stabilises bottles, and creates moulds or miniature furniture.

For crafting, it serves as a material for decorative art, custom phone cases, notebook covers, hammocks, and festive ornaments.

Historically, duct tape proved vital during the Apollo 13 mission, quickly repairing life-support systems.

Its versatility continues to inspire innovative solutions, making it a trusted resource in everyday life and extreme situations alike.

Conclusion

Duct tape has evolved from a practical military tool to a versatile household item. Its strength, durability, and adaptability have made it essential in many fields, from industry to creative projects. Over time, it has become a cultural symbol of ingenuity and problem-solving. Today, duct tape continues to inspire innovation and resourcefulness, proving that a simple adhesive can have a wide range of unexpected uses. Its history reflects a combination of practicality and creativity, resonating with the British penchant for making do and mending.