Similar Categories

How Do Intumescent Pipe Wraps and Collars Work in Fire Safety?

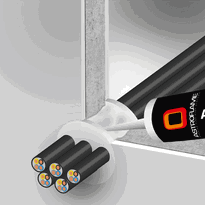

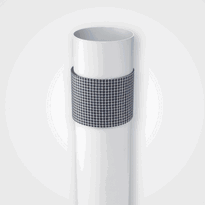

Intumescent pipe wraps and collars are essential components in fire safety because they help prevent the spread of fire and smoke through building openings. They function by expanding when exposed to heat, sealing gaps left by melted pipes or cables, and creating a barrier against fire and smoke. Made from materials such as graphite-based substances or synthetic polymers, they form a thick, protective char during a fire. This expansion fills the voids and blocks heat transfer, preventing flames and smoke from moving into other parts of the building. Proper installation is key, with wraps usually secured inside supportive structures. These products are compatible with many pipe types and are vital in maintaining compartment integrity during fires, helping to keep buildings safer for everyone inside. Intumescent materials are designed to expand rapidly and maintain their sealing properties during fire exposure.

Types of Intumescent Firestopping Products for Pipes

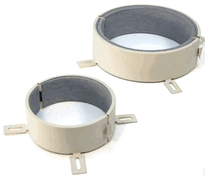

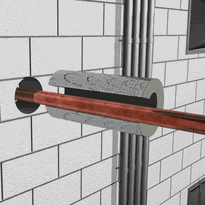

Different types of firestopping products are designed to protect pipes during a fire, ensuring that gaps and openings don't allow flames and smoke to spread. Intumescent fire collars, for instance, come in pre-sized options for plastic pipes up to 100 mm, and are factory-made to guarantee consistent performance. These collars seal pipe penetrations in walls and floors by expanding when exposed to heat. Factory fabrication ensures that each collar provides a reliable and uniform firestop solution. Graphite-based pipe wraps feature layered graphite sheets with self-adhesive strips, expanding up to 100 times to seal voids left by melted plastic pipes. Hybrid systems combine different materials to manage complex penetrations, such as mixed plastic and metal pipes, or cables. Specialist seals provide fire and smoke protection for irregular openings, adding extra safety layers for various building applications.

Proper Installation Methods for Optimal Fire Protection

Proper installation of intumescent pipe wraps and collars is essential for effective fire protection.

This process involves ensuring that the wrap fits tightly around the pipe and selecting materials compatible with the pipe type and installation environment. Ensuring the correct fire rating is chosen is crucial for compliance with safety standards. Adhering to the correct fitting techniques and choosing the right products helps maximise fire resistance and safety.

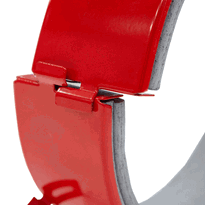

Ensuring Proper Fitting Techniques

Ensuring that insulation wraps and collars fit correctly is essential for delivering their full fire protection benefits. Proper surface preparation is key; the pipe surface and surrounding area must be clean, free of debris, and smooth. There should be no obstructions, such as concrete splashes or protrusions, in the penetration holes. Using vacuum tools in confined spaces helps remove residue effectively. Choosing the right size is critical—wrapping the pipe securely without gaps, and positioning the bottom edge flush with the concrete slab, ensures proper sealing. During installation, wraps should be tight, with no gaps, and applied gently without stretching. Sealing gaps with compatible, fire-rated sealant further enhances safety. Proper fitting techniques ensure the insulation performs at its best, maintaining its fire-resistant capabilities over time. Testing and certification of the products confirm they meet relevant fire safety standards, providing confidence in their performance during a fire.

Selecting Compatible Materials

Choosing the right materials for intumescent pipe wraps and collars is essential to achieve effective fire protection. Proper compatibility ensures the system performs reliably across different pipe types and environments. For example, graphite-based sheets like ROCKWOOL’s FirePro® CE work well with PVC, UPVC, and HDPE pipes, while thermoplastic composites such as Fischer’s FiPW are designed for non-metallic pipes up to 250mm. It's important to select systems that are UL-listed or CE-marked, depending on the region, to meet safety standards. Metal collars provide support in brick or block walls, and ablative coatings enhance fire resistance in rigid floors. The materials used should also be resistant to environmental factors such as humidity or chemicals, to maintain their integrity over time. Key considerations include: - Matching materials to pipe composition for chemical compatibility - Confirming that chosen systems meet UK installation standards - Verifying full-circumference fit to prevent flame or smoke leaks

Material Composition and Durability of Intumescent Collars and Wraps

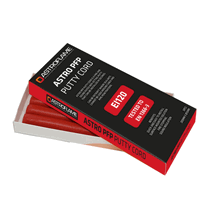

The materials used in intumescent pipe wraps and collars are meticulously chosen to provide effective fire protection and durability. Core components include graphite-based intumescent sheets that expand when heated, forming a barrier against flames.

A polythene sheath protects the material under normal conditions, while synthetic polymers such as silicone or epoxy bond the components and enhance heat resistance. Self-adhesive strips facilitate installation and securely fasten the wrap around pipes, while plastic wrap encapsulation prevents environmental damage.

These materials are designed to activate at approximately 200°C, expanding inward or outward to seal gaps and create a protective char. They're engineered to withstand humidity, minor chemicals, and thermal cycling, ensuring long-term stability without corroding or degrading prematurely, thereby offering reliable fire resistance over time.

Fire Resistance Ratings and Compliance Standards

Fire resistance ratings and compliance standards play an essential role in ensuring that intumescent pipe wraps and collars meet safety requirements.

These products are tested against specific standards to guarantee performance during a fire. For instance, BS EN 1366-3:2009 certifies up to a 2-hour fire resistance, while BS 476 Part 20 can achieve 4 hours for pipes under 200mm, such as PVC or ABS.

Additionally, products must carry CE/UKCA markings and undergo third-party validation, such as UL certification, to demonstrate they meet safety standards. Fire testing laboratories conduct rigorous assessments to verify compliance with these standards, ensuring reliability in real-world scenarios.

Key points include:

- Compliance with BS EN 1366-3 and BS 476 for fire resistance duration

- Certification markings like CE/UKCA and UL-EU for official approval

- Industry standards, including EN 13501-2 classification, validating fire performance

Applications Across Different Structures and Settings

Intumescent pipe wraps and collars are widely used across various building types in the UK to protect structures from the spread of fire through service penetrations. In commercial buildings, they help prevent flames from passing between floors or compartments, particularly around plastic pipes in offices, shopping centres, hospitals, and schools. Industrial facilities such as chemical plants, warehouses, and refineries utilise them to secure pipes carrying flammable substances or utilities, thereby maintaining safety and containment. Residential structures, including high-rise apartments, student accommodation, and hotels, rely on these firestopping solutions to limit vertical fire spread and comply with safety regulations. Critical infrastructure such as data centres, airports, and hospitals depend on collars to safeguard vital systems. In specialised structures like cleanrooms, tunnels, and heritage buildings, they ensure safety while preserving the building’s functionality and integrity. Proper installation of fire collars and wraps is essential to ensure their effectiveness during a fire event, and consistent maintenance checks are recommended to sustain safety standards.

Benefits of Using Intumescent Firestopping Solutions

Intumescent firestopping solutions offer several key benefits that make them a popular choice for building safety in the UK. These solutions swell when exposed to heat, creating a barrier that protects structural integrity and allows time for safe evacuation.

They also contribute to sustainability by reducing the environmental impact of construction materials and processes. Additionally, intumescent coatings provide a durable protective layer that maintains the building’s appearance while enhancing fire resistance.

They're straightforward to apply across various settings and adapt well to different shapes and materials. Furthermore, these solutions often improve their effectiveness over time, offering long-lasting performance.

Conclusion

Intumescent pipe wraps and collars are effective fire safety tools that expand when exposed to heat, sealing gaps around pipes to prevent the spread of fire. Proper selection, installation, and compliance with standards are essential for maximum protection. These firestopping solutions are versatile, durable, and suitable for various structures. Using them enhances safety by delaying the progression of fire, providing occupants with more time to evacuate and giving firefighters improved access for extinguishing fires.