- Blogs

- Fire Rated Pipe Insulation, Wraps & Collars: UK Guide to Standards & Safety

Fire Rated Pipe Insulation, Wraps & Collars: UK Guide to Standards & Safety

This is a long, comprehensive article on intumescent fire pipe wraps, collars and protection in the UK. For a quick summary, please see the TLDR section below, or use the section headings to navigate to topics of interest.

TLDR: UK Guide to Firestopping Pipes & Penetrations

- Why it matters: Fire-rated pipe insulation, intumescent wraps, and collars are vital for UK building safety. They seal pipe penetrations in fire-rated walls and floors, maintaining 'compartmentation' to stop fire and smoke from spreading, protecting escape routes and property.

- How they work: Products prevent heat transfer along metal pipes (insulation) or use 'intumescent' materials (like expandable graphite in wraps/collars) that swell with heat to crush melting plastic pipes and seal gaps. Solutions like fire batts and ablative coatings assist with larger or complex penetrations.

- Key to compliance: Correct selection (based on pipe material, fire rating needed), strict adherence to UK Building Regulations (Approved Document B), testing to BS EN standards (e.g., BS EN 1366-3 for penetration seals), and using third-party certified products (UKCA/CE marked) with proper installation are all essential for effective passive fire protection and life safety.

Section 1: Understanding Fire Rated Protection for Pipe Penetrations: An Essential Guide

Passive Fire Protection (PFP) is a cornerstone of modern building safety. Unlike active fire protection systems such as sprinklers or alarms, PFP measures are integrated into the very fabric of a building. They are designed to contain fires or slow their spread without requiring human intervention or external activation.

A critical component of PFP is fire compartmentation. This strategy involves dividing a building into a series of discrete, fire-resistant compartments using fire-rated compartment walls and floors. The primary purpose of compartmentation is to limit the spread of fire and smoke from one area to another.

This containment is vital for protecting lives by allowing occupants more time to evacuate. It also significantly reduces the overall damage to the property and enables firefighters to tackle the blaze more safely and effectively.

However, the integrity of these fire compartments is often compromised by the need for essential building services – such as plumbing, heating, and electrical cables – to pass through them. These service penetrations, if not adequately sealed, create breaches in the fire-resistant barriers.

In the event of a fire, these unprotected openings can become direct pathways for flames, hot gases, and toxic smoke to travel rapidly between compartments. This can potentially undermine the entire fire safety strategy of the building.

Even the most sophisticated active fire suppression systems or well-designed escape routes can see their effectiveness diminished if compartmentation fails due to unsealed penetrations. This illustrates that meticulous attention to the firestopping of service penetrations is not merely a minor compliance detail, but a fundamental requirement for ensuring overall building safety.

To address this vulnerability, specialised PFP solutions known as firestops are employed. Fire-rated pipe insulation, fire pipe wrap products, and pipe collars are specific types of firestops. They are engineered to reinstate the fire resistance of compartment elements where they are breached by pipework. These products are designed to seal the penetration effectively, thereby maintaining the compartment's integrity for a specified period during a fire.

The "passive" nature of these systems, meaning they do not require activation, is a key strength. However, this can sometimes lead to an underestimation of their importance during both the construction and ongoing maintenance phases of a building's life.

Because PFP elements like firestopping within voids or service risers are often concealed from view, they can be overlooked. This potential for "out of sight, out of mind" necessitates robust initial installation, thorough verification, and continuous diligence, especially when any modifications are made to the building or its services.

Section 2: What is Fire Rated Pipe Insulation and Why is it Crucial?

Fire-rated pipe insulation refers to specialised insulating materials meticulously designed to withstand high temperatures. Its purpose is to prevent the propagation of flames along or through pipework and, crucially, to limit the transfer of heat when pipes penetrate fire compartment walls and floors.

Its role is often twofold. Primarily, it serves to maintain the fire integrity of the compartment being breached, ensuring that the barrier continues to perform as intended for its rated duration. Secondarily, it can also provide thermal insulation for the pipe service itself, contributing to energy efficiency or preventing condensation, although its fire performance characteristics are paramount in this context.

The contribution of fire-rated pipe insulation to overall building fire safety is significant. It acts as a robust physical barrier, impeding the passage of fire and smoke through the penetration.

A critical function, particularly for metallic pipework (such as copper or steel), is its ability to slow down the transfer of heat along the pipe. Metal pipes are excellent conductors of heat. In a fire, an unprotected metal pipe can transfer sufficient heat from the fire-affected side of a compartment to the non-fire side to ignite combustible materials in an adjacent, otherwise safe, area.

Fire-rated insulation mitigates this risk by resisting heat transfer and protecting against excessive temperature rise on the unexposed side. Furthermore, these insulation systems are engineered to maintain their structural integrity and insulating properties for a specified fire-rated period. This ensures the penetration seal remains effective throughout the critical stages of a fire incident.

The term "fire-rated" when applied to pipe insulation signifies more than just the material's basic non-combustibility. It encompasses the performance of the entire installed system. This includes the insulation material itself, its thickness, how it is fixed, and its interaction with the pipe and the surrounding building element. The system must maintain both integrity (E) and insulation (I) properties under fire conditions for a designated duration (e.g., 30, 60, 90, or 120 minutes).

Materials are rigorously gauged by how long they can uphold these properties during a fire. Key characteristics include thermal stability, low flammability, and minimal smoke production. This means that while a core material might be classified as non-combustible (e.g., achieving an A1 rating under BS EN 13501-1), its overall performance as part of a fire-rated system is what determines its suitability and stated fire rating (e.g., EI60). This has profound implications for testing and certification, which must consider the entire assembly as it would be installed on site.

For metallic pipes, fire-rated insulation primarily addresses the failure mechanism of heat conduction. This is fundamentally different from the primary mechanism of intumescent wraps or collars when used with plastic pipes, which react to the pipe melting by expanding to crush and seal the resultant void. Therefore, the selection of a firestopping product must be appropriate for the pipe material (metal or plastic) and its behaviour in a fire; a generic firestop is often insufficient.

The engineering behind these materials ensures they can withstand intense heat and resist burning, forming a critical life-saving feature in modern building design.

Section 3: Intumescent Pipe Wrap: Sealing the Gaps Against Fire

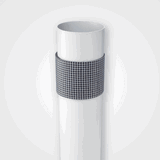

A fire rated pipe wrap, a key type of Intumescent Pipe Wrap, is an intumescent strip specifically designed to be wrapped around pipes at the point where they penetrate fire-separating compartment walls and floors. These fire wraps for pipework play a crucial role in maintaining the fire resistance of the building compartment.

For combustible plastic pipes, they achieve this by sealing the opening created when the pipe melts or softens under fire conditions. For metallic pipes (such as copper or steel) that are insulated with combustible materials (e.g., some foam insulations), these intumescent wraps work by compensating for the loss of this combustible insulation as it burns away in a fire.

The operational mechanism of a fire pipe wrap relies on the properties of intumescent materials, which are typically graphite-based in these products. When exposed to the heat of a fire, this intumescent material undergoes a rapid and significant expansion.

- For plastic pipes: This expansion exerts pressure, crushing the now softening or melting pipe and forming a robust, insulating char that effectively seals the penetration against the passage of fire and smoke.

- For metallic pipes with combustible insulation: As the combustible insulation burns away, the pipe wrap expands to fill the void created between the metal pipe and the surrounding structure, thus maintaining the fire seal. The metal pipe itself does not melt or get crushed.

Fire rated pipe wrap products are commonly applied to a variety of plastic pipes, including PVC, uPVC, PE, HDPE, and PP. They are also specifically designed for use with metallic pipes (copper, steel) that feature continuous combustible insulation. They are versatile and can be installed in diverse constructions such as drywalls, masonry walls, and concrete compartment walls and floors. Achieving a specific rating, such as a 2 hour fire rated pipe wrap performance, depends on the product and its tested application.

Key characteristics often include being a cost-effective alternative to fire collars, ease of installation, and the ability to be cut to the required length on site to suit different pipe diameters. Many pipe wraps consist of layers of a graphite-based intumescent sheet encapsulated within a protective polythene cover, which is secured around the pipe using an integral self-adhesive strip.

It is important to note that this polythene cover or sleeve is an integral part of the system and should not be removed, as it likely protects the intumescent material or aids in its correct activation.

The effectiveness of a fire pipe wrap is critically dependent on its correct positioning within the wall or floor structure and the nature of the surrounding construction. Unlike fire collars, which typically have a metal shell to contain and direct the intumescent expansion, wraps often rely on the surrounding solid construction (e.g., concrete or masonry) or a fire batt system to channel the expansion inwards to crush a plastic pipe or effectively fill the void around a metal pipe.

While some may colloquially use terms like "fire collar wrap" due to both using intumescent material and being applied around pipes, it's important to distinguish between the flexible, strip-based pipe wraps and the rigid, cased fire collars; they are distinct product types.

Installation guidance frequently specifies that the wrap should be positioned so that its edge is left exposed to the face of the wall or the soffit of the floor. This exposure is crucial for the timely activation of the intumescent material. If the wrap is recessed too deeply or if the intumescent material is inadvertently insulated from the heat of the fire (for example, by incorrect shuttering during reinstatement of the surrounding area), its activation may be delayed or prevented. This can lead to a "product malfunction" and failure of the firestop, meaning improper installation could have catastrophic consequences for fire compartmentation.

While the cost-effectiveness of pipe wraps is an advantage, this should not lead to compromises in installation rigour or their selection for inappropriate applications. The reliance on the surrounding structure for containment and the precise positioning requirements underscore the paramount importance of installation expertise.

If cost considerations lead to unskilled installation or misapplication, such as using a wrap in a lightweight flexible partition without the necessary additional support (like a steel pipe band, as mentioned in some product literature), the firestopping system will inevitably fail. This highlights a potential risk if the perceived simplicity and lower cost of wraps lead to complacency in their specification or installation.

Buy Fire Rated Pipe Insulation

Section 4: Fire Rated Pipe Collars: Robust Protection for Pipework

Fire-rated pipe collars, also commonly referred to as firestop pipe collars or intumescent closure devices, are engineered components. They are designed to be fitted around pipes where they pass through fire-rated compartment walls and floors. Their construction typically features a durable metal shell, often made from stainless steel or powder-coated steel, which encases a high-performance, graphite-based intumescent material.

The primary function of fire-rated pipe collars is to prevent the spread of fire and smoke through openings.

- For combustible plastic pipes: They are particularly crucial for penetrations involving these pipes, which can soften and melt at relatively low temperatures in a fire scenario (approximately 93°C to 120°C, and largely gone by 180°C). The mechanism of a fire collar is a heat-activated process. When exposed to temperatures typically around 150°C to 200°C, the intumescent material housed within the collar expands dramatically. The robust metal shell of the collar plays a critical role by directing this powerful expansion inwards, towards the pipe. This action effectively crushes the softening plastic pipe, and the expanding intumescent material then forms a hard, insulating char plug that completely seals the void left by the consumed pipe. This char plug acts as a barrier to both flames and hot gases, maintaining the fire integrity of the compartment.

- For metallic pipes (copper, steel) with combustible insulation: Some fire collars have also been tested and approved for use with insulated non-combustible (metal) pipes. In this application, the collar's intumescent material expands to fill the void left by the burnt-away combustible insulation around the metal pipe, thereby sealing the penetration. The metal pipe itself remains intact. The metal shell of the collar is vital for containing and directing this expansion effectively.

Fire collars are predominantly used for a wide range of combustible plastic pipes, including PVC, CPVC, ABS, HDPE, and PP. As noted, their application can extend to certain configurations of insulated metal pipes.

Installation of fire collars is generally straightforward: they are surface-mounted and mechanically fixed to the face of the wall or the underside of the floor slab. This is often done on both sides of a wall penetration to provide protection from fire approaching from either direction. These fixing lugs are an integral part of the collar's design.

It is important to understand that while often referred to as "crushing collars" for plastic pipes, they work in synergy with the plastic pipe's reaction to heat. The intumescent material alone cannot crush a cold, rigid plastic pipe. Its effectiveness relies on the heat exposure causing the plastic pipe to soften and melt, allowing the expanding intumescent to then seal the opening. This nuance is important for appreciating the physics involved and ensuring correct application. For metal pipes, the "crushing" action is not relevant; the collar's role is to seal the gap formed by other materials burning away.

Although fire collars are robust devices, their ultimate effectiveness still hinges on correct and secure fixing to the substrate. If a collar is not securely attached using the manufacturer's recommended fixings, the pressure from the expanding intumescent or the dynamic forces within a fire scenario could dislodge it. This would thereby create a pathway for fire and smoke.

This highlights the critical importance of using the correct type and number of fixings, ensuring the substrate itself is sound and suitable for providing a secure anchor, and adhering strictly to the manufacturer's installation instructions. Common installation errors, such as missing fixings in the lugs, are a significant concern.

Section 5: How Do These Firestopping Solutions Work? The Science of Safety

The effectiveness of fire-rated pipe wraps, collars, and insulation in preventing the spread of fire through service penetrations is rooted in the science of specialised materials and their predictable reactions to heat. Understanding these mechanisms is crucial for appreciating their role in passive fire protection.

Intumescence Explained

At the heart of most fire rated pipe wrap solutions and collars are intumescent materials. These are substances specifically engineered to swell, or intumesce, when exposed to elevated temperatures, such as those encountered in a fire. As they expand, they also char, undergoing a chemical change that transforms them into a heat-resistant, insulating barrier. This process involves a significant increase in volume and a corresponding decrease in density.

A key active ingredient in many high-performance intumescent wraps and collar linings used for pipe firestopping is expandable graphite. Expandable graphite consists of graphite flakes that have had chemicals intercalated (inserted) between their layers. When heated, typically starting at temperatures around 150°C to 180°C or higher depending on the specific formulation, these intercalated compounds decompose, releasing gases. These gases force the graphite layers apart, causing the material to expand dramatically, sometimes up to 25 to 100 times its original volume.

This expansion creates a stable, resilient char that is an excellent insulator and effectively seals gaps and voids. The char formed is typically hard and robust, capable of resisting the passage of flames and hot gases.

The activation temperature of the intumescent material is a critical design parameter. It must be sufficiently high to avoid premature activation during normal service conditions or from ambient heat, yet low enough to react swiftly and effectively at the onset of a fire.

Beyond the expansion volume, the "pressure generation" of an intumescent is a vital characteristic, particularly for applications involving the crushing of plastic pipes. The material must not only expand but also generate sufficient force to overcome the resistance of the softening plastic pipe and form a tight, durable seal. For metal pipes with combustible insulation, the key is sufficient expansion volume and char stability to fill the void.

Mechanism for Plastic Pipes (Wraps & Collars)

When plastic pipes (such as PVC, uPVC, PE, HDPE, PP) are exposed to fire, they begin to soften and melt at relatively low temperatures, often between 93°C and 180°C. As this occurs, the heat triggers the intumescent material within the accompanying fire pipe wrap or collar to expand rapidly.

The expanding intumescent, directed by the collar's metal shell or the surrounding solid construction in the case of a wrap, exerts considerable pressure. This pressure crushes the now malleable, melting pipe, and the intumescent material itself fills the void completely. This forms an insulating plug that prevents the passage of fire and smoke through the penetration.

Mechanism for Metal Pipes (Copper, Steel) (Wraps, Collars & Insulation)

Metal pipes, such as copper and steel, behave differently in a fire; they do not melt at typical building fire temperatures but are very effective conductors of heat. Firestopping solutions for metal pipes must address these characteristics:

- Uninsulated Metal Pipes: For these, the primary concern is heat conduction. Fire-rated insulation, such as pre-formed sleeves made from mineral wool (e.g., Rockwool Insulated Fire Sleeves), is the main solution. This insulation acts as a thermal barrier, significantly slowing down the rate of heat transfer along the pipe from the fire-exposed side to the unexposed side of the compartment wall or floor. This prevents the pipe on the non-fire side from reaching temperatures high enough to ignite adjacent combustible materials. The insulation must maintain its integrity and insulating properties for the required fire-rated period.

- Metal Pipes with Combustible Insulation: If metal pipes are covered with combustible insulation (e.g., some types of foam insulation for thermal purposes), this insulation will burn away in a fire, creating a void or gap around the intact metal pipe. This void can allow fire and smoke to pass through the penetration.

- Fire Wraps: Intumescent wraps are commonly used in this scenario. When the combustible insulation burns off, the heat triggers the intumescent material in the fire pipe wrap to expand. This expansion fills the annular space left by the consumed insulation, sealing the gap between the metal pipe and the surrounding structure.

- Fire Collars: Some fire collars are also tested and approved for use with insulated metal pipes. Similar to wraps, the intumescent material within the collar expands to fill the void created by the burnt-away combustible insulation, with the metal shell of the collar helping to direct and contain this expansion.

- Insulated Fire Sleeves: Products like Rockwool Insulated Fire Sleeves, which combine stone wool with graphite intumescent, can also be used. These provide both firestopping by sealing the void and continued thermal insulation for the pipe.

It is crucial to select a firestopping system that has been specifically tested and certified for the type of metal pipe (copper, steel), its diameter, the presence and type of any existing insulation (combustible or non-combustible), and the nature of the surrounding construction.

How Fire-Rated Pipe Insulation Prevents Spread (Especially for Metal Pipes)

Fire-rated pipe insulation, typically made from materials like mineral wool, prevents fire spread through several key actions:

- It acts as a physical barrier, resisting the direct passage of flames and hot gases through the penetration.

- Its high thermal resistance significantly slows down the rate of heat conduction along the length of the pipe. This is particularly critical for metal pipes (copper, steel) which are excellent heat conductors. By insulating the pipe, it prevents the unexposed end from becoming an ignition source.

- The materials used are often non-combustible (e.g., mineral wool is typically Euroclass A1), meaning they do not contribute significantly to the fire load or fire propagation.

- Crucially, these insulation systems are designed and tested to maintain their structural integrity and insulating properties for the duration of their specified fire rating, ensuring continuous protection.

The environment in which these products are installed can also influence their long-term performance. Many intumescent products are designed to be water-resistant or are encapsulated in protective sheaths (like polythene for wraps) to prevent degradation from moisture or other contaminants. This protection is vital for ensuring the product remains functional throughout its service life, ready to perform as intended in the event of a fire.

Table 1: Comparison of Fire Rated Pipe Wraps and Collars

| Feature | Fire Rated Pipe Wraps | Fire Rated Pipe Collars |

|---|---|---|

| Definition | Intumescent wraps / strips designed to be wrapped around pipes at penetrations. | Device with a metal shell containing intumescent material, fitted around pipes at penetrations. |

| Construction | Layers of intumescent material (often graphite-based) typically encapsulated in a polythene or polymer sheath. | Robust metal casing (e.g., stainless or coated steel) lined with intumescent material (often graphite-based). |

| Primary Mechanism (Plastic Pipes) | Intumescent expands when heated, crushing the softening/melting plastic pipe and forming a char plug to seal the void. | Intumescent expands when heated; metal shell directs expansion inwards to crush the softening/melting plastic pipe and seal the void. |

| Primary Mechanism (Metal Pipes with Combustible Insulation) | Intumescent expands to fill the void left by burnt-away combustible insulation around the intact metal pipe. | Some types are tested to seal around metal pipes by expanding to fill the void left by burnt-away combustible insulation. |

| Typical Installation | Wrapped around the pipe and inserted into the aperture; often relies on surrounding solid construction or fire batt for containment. | Surface-mounted to the wall or underside of the floor using mechanical fixings. |

| Key Advantages | Cost-effective; flexible for various pipe sizes (can be cut to length); low profile. Can include options like a 2 hour fire rated pipe wrap. | Robust construction; metal shell effectively directs intumescent expansion; often higher fire ratings available. |

| Key Considerations/Limitations | Effectiveness can depend on correct positioning and a solid surrounding structure (e.g., concrete, masonry) or specific detailing in lightweight partitions. Exposure to heat is critical. | More visible; may require more space for installation; secure mechanical fixing to a suitable substrate is essential. |

Section 6: Key Materials Used in Fire Rated Pipe Protection

The performance of fire-rated pipe insulation, fire wraps for pipework, and collars is intrinsically linked to the specialised materials used in their construction. These materials are chosen for their ability to react predictably under fire conditions, providing the necessary integrity and insulation to maintain compartmentation.

A. Intumescent Materials (Primarily for Wraps and Collars)

Intumescent materials are the active components in most pipe wraps (including fire pipe wrap products) and collars, responsible for sealing a penetration during a fire.

- Expandable Graphite: This is a widely used and highly effective intumescent.

- Properties: Expandable graphite is a halogen-free material that, upon heating, expands significantly – some products claim expansion up to 25 times or even 100 times their original volume. It generates good pressure upon expansion, which is crucial for crushing plastic pipes, and significant volume expansion to fill voids around metal pipes. Different grades have varying activation (starting) temperatures, typically from around 150°C upwards. It is generally unaffected by water or vermin and forms a stable, insulating char.

- Mechanism: The layered structure of graphite expands like an accordion due to the release of gases from intercalated compounds when heated. This forms a dense, stable char that acts as a fire barrier, insulating against heat and sealing the opening.

- Used in: It is the core component in the majority of intumescent wraps and the linings of fire collars. The trend towards halogen-free flame retardants, driven by concerns over the emission of toxic gases during a fire, has made expandable graphite a preferred choice due to its environmental and safety profile.

- Other Intumescent Formulations: While graphite is prevalent, other intumescent formulations exist. These may incorporate synthetic polymers, various resin binders (such as silicone or epoxy-based systems), or elastomeric thermoplastic polymers. Some of these formulations are also designed to be non-toxic and halogen-free.

B. Insulation Materials (Primarily for Fire Rated Pipe Insulation/Sleeves)

These materials are chosen for their inherent fire resistance and thermal insulation properties, especially critical for uninsulated metal pipes.

- Mineral Wool (Stone Wool/Rock Wool):

- Properties: Mineral wool is a non-combustible material, typically achieving the highest Euroclass A1 fire rating. It has a very high melting point, often exceeding 1000°C or 1100°C, which is well above typical building fire temperatures. In a fire, it acts as a barrier to flames and hot gases, and critically, provides thermal insulation to prevent heat transfer along metal pipes. Beyond its fire performance, it offers excellent thermal and acoustic insulation and is resistant to moisture and mould. It is manufactured from natural volcanic rock (basalt, diabase) or recycled industrial slag.

- Used in: Pre-formed pipe insulation sections (essential for uninsulated metal pipes), and as a key component in insulated fire sleeves (which may also incorporate intumescent for sealing around the sleeve itself or dealing with combustible elements). For instance, products like Rockwool Insulated Fire Sleeves combine stone wool with graphite intumescent to offer both fire stopping and thermal insulation.

- Fibreglass (Glass Wool):

- Properties: Fibreglass insulation is generally non-combustible or has a low flame spread, often achieving Euroclass A1 or B ratings. When exposed to fire, it tends to melt and fuse, which can help to form a barrier. Its melting point is lower than that of mineral wool, typically around 540°C. It's important to note that the binders used to hold the glass fibres together can be combustible at high temperatures.

- Used in: Pre-formed pipe insulation sections.

- Calcium Silicate:

- Properties: Calcium silicate is a non-combustible material (Euroclass A1) renowned for its performance in high-temperature applications, capable of withstanding temperatures up to around 1000°C. It also possesses high compressive strength.

- Used in: Specialised high-temperature pipe insulation, particularly in industrial settings, and can be suitable for fire-rated applications on metal pipes.

C. Structural/Containment Materials (Primarily for Collars and Wrap Coverings)

These materials provide physical support and protection for the active fire-resistant components.

- Steel (Stainless or Coated Mild Steel):

- Properties: Steel forms the robust outer casing of fire collars. This shell is crucial for containing the intumescent material and directing its expansion inwards towards the pipe (for plastic pipes) or into the void (for insulated metal pipes) during a fire. It also provides durability and corrosion resistance.

- Used in: The main body of fire-rated pipe collars.

- Polythene/Polymer Sheaths:

- Properties: These materials are used to encapsulate the intumescent layers in fire rated pipe wrap products. They offer protection to the intumescent material prior to and during installation, and often incorporate a self-adhesive strip to facilitate fixing around the pipe. The sheath is considered an integral part of the wrap system and should not be removed.

- Used in: The outer covering of fire rated pipe wraps.

When selecting materials, it is important to consider not only their fire resistance but also their compatibility with the specific application environment and any other building materials they might come into contact with. Factors such as humidity, potential chemical exposure, and interaction with the pipe material itself are crucial for ensuring long-term performance and safety.

Buy Fire Rated Pipe Insulation

Furthermore, while a material being "non-combustible" (e.g., Euroclass A1) is a highly desirable property, the overall firestopping system performance (often expressed as an EI rating for integrity and insulation) is what truly determines its effectiveness in maintaining compartmentation. This system performance is evaluated through rigorous testing of the complete assembly as it would be installed.

Table 2: Overview of Key Materials in Fire Rated Pipe Protection

| Material Category | Specific Material | Key Fire Safety Properties | Common Product Types Used In |

|---|---|---|---|

| Intumescents | Expandable Graphite | Halogen-free; Expands significantly (e.g., 25-100x volume); Forms stable insulating char; Good pressure generation & void filling. | Pipe Wraps (incl. fire pipe wrap, intumescent wraps), Pipe Collar Linings |

| Other Intumescent Formulations | May be polymer/resin-based; Some are non-toxic, halogen-free; Swell and char when heated. | Pipe Wraps, Pipe Collar Linings | |

| Insulation Materials | Mineral Wool (Stone/Rock Wool) | Euroclass A1 (Non-combustible); High melting point (e.g., >1000°C); Forms fire barrier; Excellent thermal insulation; Acoustic insulation. | Pipe Insulation Sections (metal pipes), Insulated Fire Sleeves, Fire Batts |

| Fibreglass (Glass Wool) | Euroclass A1-B (Non-combustible/Low flame spread); Melts & fuses to form barrier; Binders may burn. | Pipe Insulation Sections | |

| Calcium Silicate | Euroclass A1 (Non-combustible); Excellent for high temperatures (e.g., up to 1000°C); High compressive strength. | High-Temperature Pipe Insulation (metal pipes) | |

| Structural/Containment | Steel (Stainless/Coated) | Robust; Directs intumescent expansion in collars; Corrosion resistant. | Pipe Collar Casings |

| Polymer Sheaths (e.g., Polythene) | Encapsulates intumescent in fire wraps for pipework; Provides protection; Aids installation. | Pipe Wrap Coverings | |

| Coatings | Ablative Coatings | Water-based acrylic; Release water vapour on heating (cooling effect); Form protective char; Seal fire batts and penetrations. | Fire Batt Coatings, Penetration Seal Coatings |

Buy Fire Rated Pipe Insulation

Section 7: Ablative Coatings in Firestopping

Ablative coatings are a crucial component in passive fire protection, often used to enhance the fire resistance of various systems, including penetration seals for pipes and ducts. These are typically water-based acrylic coatings that can be applied by brush or spray.

The primary fire protection mechanism of an ablative coating involves a process of controlled erosion or consumption when exposed to fire. When heated, these coatings undergo a chemical reaction that often releases water vapour. This release of vapour has a cooling effect on the surface it protects and on the fire-rated application beneath it.

As the coating ablates (erodes), it forms a char or an insulating barrier that helps to slow down heat transfer and prevent the spread of fire and smoke. At standard temperatures, many ablative coatings remain flexible, allowing for thermal and mechanical movement of services, but during a fire, they form a resilient barrier.

Ablative coatings are commonly used to coat fire batts (high-density mineral wool boards) on one or both sides. This coating significantly enhances the fire batt's performance by sealing the porous surface of the mineral wool, preventing the passage of smoke and hot gases, and improving its integrity and insulation characteristics during a fire. The coating also provides a more durable and damage-resistant surface to the batt.

Beyond coating fire batts, ablative liquids are also used to:

- Seal joints and edges: When fire batts are cut and fitted around services or into openings, ablative coating (or a compatible ablative mastic) is applied to all cut edges and joints between batt sections, and between the batt and the surrounding structure, to ensure a complete fire and smoke seal.

- Reinstate damaged coatings: If the ablative coating on a fire batt is damaged during installation or subsequent works, liquid ablative coating can be applied on-site to repair the damage and maintain the system's integrity.

- Back-coat services or substrates: In some tested systems, ablative coatings may be applied directly to certain services or the surrounding substrate as part of a comprehensive firestopping detail. However, this is less common for direct pipe firestopping compared to their use with batts. Their primary role in pipe and duct penetrations is typically as part of a fire batt system.

Manufacturers like Rockwool, Astroflame, PFC Corofil, FSi, Nullifire, and Quelfire offer ablative coating products. These coatings are tested as part of penetration sealing systems to standards such as BS EN 1366-3. The assumed working life of these coatings can be significant, often cited as 25 years or more when applied correctly.

Section 8: Fire Batts for Complex Penetrations and Large Openings

Fire batts, also known as fire-rated boards or mineral wool boards, are a critical component in passive fire protection. They are particularly useful for sealing larger or more complex service penetrations and voids in fire-rated compartment walls and floors.

They typically consist of a high-density stone wool (mineral wool) core and are often pre-coated on one or both sides with an ablative coating. This ablative coating enhances the fire batt's performance by providing a smoke and gas seal, improving fire resistance, and offering a more durable surface.

How Fire Batts Work in Penetration Sealing

Fire batts are used to reinstate the fire resistance of a compartment wall or floor where larger openings have been created for multiple services (pipes, cables, ducts) or for single large services. Their function is to:

- Fill the void: The batt is cut to size and friction-fitted into the aperture, creating a physical barrier.

- Provide insulation and integrity: The dense mineral wool core offers inherent fire resistance, slowing heat transfer, while the ablative coating helps maintain integrity against flames and hot gases.

- Support other firestopping products: Fire batts often form the substrate or supporting structure for other firestopping components like pipe collars, intumescent wraps, or sleeves when dealing with service penetrations passing through the batt.

Using Fire Batts with Pipe and Duct Penetrations

When pipes (plastic or metal) or ducts penetrate an opening sealed with a fire batt system, the following general principles apply:

- Creating the Opening in the Batt: An aperture is carefully cut into the fire batt to accommodate the penetrating service. This cut should be as neat and tight to the service as possible.

- Installing the Service Firestop:

- Pipe Collars: Fire collars can be fixed directly to the surface of the ablative-coated fire batt. For example, Rockwool details show their FirePro Pipe Collar CE being secured through Ablative Coated Batt using steel pigtail screws. Similarly, FSi's PipeBloc PCP collars can be installed onto their Stopseal Batt System. The collar then functions as described previously, crushing plastic pipes or sealing around insulated metal pipes upon heat exposure.

- Pipe Wraps: Intumescent pipe wraps, including those designed as a fire rated pipe wrap for specific durations like 2 hours, can be installed within an aperture in a fire batt system. The wrap is fitted around the plastic pipe or the combustible insulation on a metal pipe. The surrounding batt (often with an intumescent sealant applied around the wrap within the batt) provides the necessary containment for the wrap to crush the plastic pipe or fill the void around the metal pipe effectively. Protecta FR Pipe Wraps, for instance, can be fitted within their FR Board system.

- Fire Sleeves (for pipes and ducts): Insulated fire sleeves (often mineral wool based, sometimes with intumescent components) or duct sleeves are installed around the pipe or duct where it passes through the fire batt. These sleeves often need to protrude a specific distance from the face of the batt, as per the manufacturer's tested details. For example, Rockwool Insulated Fire Sleeves, when used with Ablative Coated Batts, are required to extend beyond the face of the batt. A minimum width of batt material must be maintained between sleeves and the edge of the aperture or other sleeves. Quelfire QRS Duct Sleeves are also suitable for installation within their QuelStop Fire Batt system. For uninsulated metal pipes passing through a fire batt, specific lagging with mineral wool pipe sections (e.g., Rockwool Fire Tube or Pipe Section) for a defined length through and extending from the batt may be required to achieve the necessary insulation (I) rating.

- Sealing: All joints between batt sections, between the batt and the surrounding structure, and around the services or firestopping devices within the batt must be sealed with a compatible fire-rated sealant (typically an intumescent or ablative mastic) to ensure a complete smoke and fire seal. Cut edges of the batt itself are also typically coated with ablative sealant or coating.

Installation Considerations for Fire Batts:

- Friction Fit vs. Pattress Fit: Batts can be friction-fitted tightly into an opening or pattress-fitted, where the batt is larger than the opening and fixed to the face of the wall/floor, overlapping the aperture.

- Support for Services: Services passing through fire batts must be independently supported on both sides of the seal, ensuring no load is transferred onto the firestopping system. The first support is typically required within a specific distance from the face of the seal (e.g., 400mm).

- Multiple Services: When multiple services penetrate a fire batt, minimum spacing requirements between services and between services and the edge of the batt must be adhered to, based on tested configurations.

Fire batts are available from various manufacturers, including FSi (Stopseal), Astroflame, Nullifire (FB750 Intubat), Rockwool (Ablative Coated Batt), Quelfire (QuelStop), and Protecta (FR Board). These systems are tested to standards like EN 1366-3 and can provide fire resistance for up to 240 minutes (EI240), depending on the specific product, thickness, and application.

Buy Fire Rated Pipe Insulation

Section 9: Spotlight on Specific Manufacturer Solutions for Pipe and Duct Firestopping

Several specialised manufacturers offer a wide array of tested and certified firestopping products for pipes and ducts. Understanding the offerings from some of these key players can aid in selecting appropriate solutions.

A. Astroflame Firestopping Products

Astroflame provides a comprehensive range of passive fire protection items, including solutions for pipe and duct penetrations.

- Pipe Collars:

- Astroflame X Series CE Intumescent Pipe Collars / PFP Pipe Closers: These collars are primarily designed to reinstate the fire resistance of compartment walls and floors penetrated by combustible plastic pipes (PP, PE, PVC-U, ABS, SAN+PVC). They feature a mild steel case containing a graphite intumescent material that expands in heat to crush the melting pipe and seal the opening. These collars are CE Marked, Certifire Approved, and tested to EN 1366-3, offering fire resistance up to 240 minutes. They are available for pipe diameters from 32mm to 315mm, and some designs feature a reduced height for installations in tight spaces. The intumescent material typically begins to expand around 105°C. While primarily for plastic pipes, always check specific test data if considering for insulated metal pipes.

- Pipe Wraps:

- Astro PFP FR Pipe Wraps / X Series PFP Pipe Wraps: These consist of a graphite-based reactive intumescent strip, a type of fire rated pipe wrap. They are designed to be wrapped around plastic pipes (PVC-U, PVC-C, PE, LDPE, MDPE, HDPE, ABS, SAN+PVC, PP), conduits, or metal pipes (copper, steel) with continuous combustible insulation. When heated (minimum expansion temperature 150°C), the intumescent expands (approx. 28:1 ratio) to close the void left by the melting plastic or insulation around the metal pipe. They can provide fire classifications up to 240 minutes (e.g., a 2 hour fire rated pipe wrap performance or higher is achievable depending on the specific product and application) for integrity and insulation and are tested for U/U pipe end applications. These intumescent wraps are installed by securing them around the pipe with a self-adhesive tab. The annular space is then sealed with a product like Astro PFP FR EX Mortar or within Astro PFP FR Boards (fire batts).

- Duct Sleeves:

- Astro DS Duct Sleeve: These are intended for use where plastic ventilation ducts pass through fire-rated compartment walls. The sleeve contains an intumescent material that expands in a fire, crushing the duct and sealing the opening. They are tested to BS476 Part 22 / EN1366-3 and can offer up to 2 hours fire rating (some specific sizes, like 220x90mm, may be 1 hour). Astro DS Duct Sleeves are suitable for retrofitting, requiring access from one side only, and must protrude from each side of the partition (e.g., by 25mm or 40mm depending on the version). Any small gaps around the installed sleeve should be sealed with intumescent sealant.

Astroflame also offers other relevant products like fire-rated boards (PFP FR Boards), mortars (PFP FR EX Mortar), and various intumescent sealants (e.g., Astro PFP FR Acrylic, Astro HPE Sealant for pipes and cables).

B. Protecta Firestopping Products

Protecta, a brand by Polyseam, offers a wide range of firestopping solutions. These include products specifically for pipe and duct penetrations, often designed to work in conjunction with their FR Board (fire batt) and EX Mortar systems.

- Pipe Collars:

- Protecta FR Pipe Collars: These collars are designed to maintain the fire resistance of compartment walls and floors breached by plastic pipes and also some configurations of metal pipes (e.g., with combustible insulation). They consist of a coated circular steel shell (often red or white) with a fast-expanding graphite-based intumescent material. They are suitable for pipe sizes up to Ø315mm (and larger in some cases) and can achieve fire classifications up to 240 minutes for integrity and insulation. They are certified for various plastic pipe types (PVC-U, PVC-C, PE, HDPE, PP, etc.) and tested for U/U pipe end applications. For metal pipes, their function is to seal the void left by burnt-away combustible insulation. Installation involves fixing the collar to the substrate (drywall, timber, masonry, concrete) using standard screws.

- Pipe Wraps:

- Protecta FR Pipe Wraps: These comprise a plastic-wrapped, graphite-based intumescent material – a type of fire pipe wrap. They react to heat to seal openings left by melting plastic pipes (PVC, PP, PE, ABS, Alupex), bundles of pipes, or cables, and also for metal pipes with continuous combustible insulation. They can be used for plastic pipes up to Ø400mm and for metal pipes with continuous combustible insulation. Fire classifications up to 240 minutes are achievable, allowing for solutions such as a 2 hour fire rated pipe wrap. The wraps are secured around the pipe with an attached sticker and can be cast into compartment walls and floors or fitted within Protecta FR Board or EX Mortar. They are available as pre-made sizes or in rolls.

- Duct Fire Protection:

- Protecta FR Damper: These are fire-rated dampers for ventilation ducts passing through fire-rated compartment walls and floors (drywall, masonry, concrete, timber). They consist of a galvanised steel casing with horizontal steel blades treated with heat-expanding graphite. In a fire, the blades expand to seal off airflow, preventing fire and smoke spread inside and around the ventilation duct. They can achieve fire ratings up to EI 120 and are tested to EN 1366-12. Circular dampers are available up to Ø1250mm and rectangular versions up to 1200x1700mm.

- Protecta FD Service Transit: This is a rectangular duct with a lid, made of steel with a graphite intumescent lining, approved for square plastic ducts and other services.

- Service Transits:

- Protecta FR Service Transit / FF Service Transit: These are circular casings (high-temperature plastic or steel) with a graphite-based intumescent lining. They are designed for compartment walls and floors breached by continuous cables and plastic pipes. Ideal for situations where services might be added or changed later, or in tight spaces, they can be cast in, friction-fitted, or installed within larger apertures using FR Board or EX Mortar. Available in various lengths (150mm, 250mm, 400mm) to suit different construction depths and fire ratings up to 240 minutes.

Protecta also provides FR Board (fire batt), FR Coating (ablative), EX Mortar, and various sealants (FR Acrylic, FR Graphite) that are often used in conjunction with their pipe and duct firestopping solutions.

Table 4: Overview of Example Astroflame and Protecta Pipe/Duct Firestopping Products

| Manufacturer | Product Type | Product Name(s) | Key Features & Applications |

|---|---|---|---|

| Astroflame | Pipe Collars | X Series CE / PFP Pipe Closers | Steel shell, graphite intumescent. Primarily for plastic pipes (PVC, PE, etc.). Up to 240 mins. Sizes Ø32-315mm. |

| Pipe Wraps | PFP FR Pipe Wrap / X Series | Graphite intumescent wraps. For plastic pipes & metal pipes with combustible insulation. Up to 240 mins (e.g. 2 hour fire rated pipe wrap). Used with mortar/batts. | |

| Duct Sleeves | Astro DS Duct Sleeve | Intumescent sleeve for plastic ventilation ducts. Crushes duct in fire. Up to 2 hrs (some 1 hr). | |

| Protecta | Pipe Collars | FR Pipe Collar | Steel shell, graphite intumescent. For plastic pipes & some metal pipe applications. Up to 240 mins. Sizes up to Ø315mm+. |

| Pipe Wraps | FR Pipe Wrap | Graphite fire pipe wrap. For plastic pipes (up to Ø400mm) & metal pipes with combustible insulation. Up to 240 mins (e.g. 2 hour fire rated pipe wrap). | |

| Duct Dampers | FR Damper | Steel casing, graphite blades. For ventilation ducts. Up to EI 120. Circular (up to Ø1250mm) & rectangular. | |

| Service Transits | FR / FF / FD Service Transit | Circular or rectangular steel/plastic casing with graphite. For pipes/cables, allows future changes. Up to 240 mins. |

Section 10: Fire Rated Construction Boards and Penetration Sealing: The Case of Marmox Fireboard

Modern construction often utilises specialised boards that offer multiple benefits, including inherent fire resistance. Marmox Fireboard is one such product, designed for a variety of internal and external applications, including wall and ceiling linings.

Marmox Fireboard: Composition and Properties

Marmox Fireboard is constructed with a core of Marmox Stone Wool (a type of mineral wool), which provides fire protection, sound absorption, and thermal insulation. The board is coated on its faces with a fibreglass mesh embedded in a cement polymer mortar, often featuring a unique honeycomb surface finish similar to their Multiboard range.

Key properties relevant to fire safety and general use include:

- Fire Resistance: Marmox Fireboard is certified A1 non-combustible according to the Euroclass system (BS EN 13501-1). This is the highest classification, indicating it will not significantly contribute to a fire. It has passed rigorous tests including EN 1182 (non-combustibility), EN 1716 (calorific value), and EN 13823 (single burn test).

- Thermal Insulation: The mineral wool core provides good thermal insulation (thermal conductivity typically around 0.037W/mK).

- Acoustic Insulation: The fibrous nature of the mineral wool core also offers sound absorption and decoupling properties.

- Weatherproof and Moisture Resistant: The stone wool core does not absorb moisture, making the board durable and suitable for wet environments or external applications.

- Lightweight and Workable: Despite its robustness, it is relatively lightweight and can be cut with standard tools, making installation easier.

- Surface Finish: The surface is designed to be an ideal substrate for plaster or render without requiring pre-treatment.

Marmox Fireboards are available in various thicknesses, commonly 20mm, 50mm, and 100mm. They can be fitted to masonry, timber, and steel frame constructions and are used for internal and external compartment walls and floors, ceilings (to prevent fire spread between floors), fire surrounds, and as part of External Wall Insulation (EWI) systems, even on buildings over 18 metres in height where regulations are particularly stringent.

(It is important to distinguish Marmox Fireboard (A1 rated) from Marmox Multiboard, which, while fire resistant, is stated as a Class E material in some contexts. Multiboard would have different limitations regarding its use in fire-critical applications, especially externally on taller buildings or in escape routes without an appropriate fire-resistant coating like plaster or render.)

Buy Fire Rated Pipe Insulation

Firestopping Service Penetrations Through Marmox Fireboard

While Marmox Fireboard itself boasts an A1 non-combustible rating and contributes significantly to the fire resistance of a wall or ceiling assembly, it is crucial to understand that any service penetrations (for pipes, ducts, cables, etc.) made through a Marmox Fireboard-lined construction must be appropriately firestopped. This is essential to maintain the overall fire compartmentation. An A1 fire-rated board alone does not automatically make penetrations through it fire-safe without specific, tested firestopping solutions for those penetrations.

Currently, specific tested details from Marmox for firestopping various service penetrations directly through their Fireboard are not widely available in the provided information. Therefore, a general best-practice approach, aligned with UK regulations and standards, must be followed:

- Select Tested Systems: Any firestopping product (e.g., pipe collars, intumescent wraps, sleeves, intumescent sealants, fire batts used in conjunction) intended to seal a penetration through a Marmox Fireboard wall or ceiling must be third-party tested and certified (e.g., to BS EN 1366-3). This testing must be for that specific type of service, its size, the nature of the penetration, and within a supporting construction representative of the Marmox Fireboard assembly.

- Compatibility: The chosen firestopping solution must be compatible with both the service material (e.g., plastic pipe, metal pipe, insulated duct) and the Marmox Fireboard itself, including its surface coatings.

- Manufacturer Guidance: Always adhere strictly to the installation instructions provided by the manufacturer of the chosen firestopping product. Additionally, consult any specific guidance Marmox may provide regarding making penetrations in their Fireboard and suitable methods for sealing them.

- Overall Assembly Performance: The goal is to ensure that the entire assembly – the Marmox Fireboard-lined structure plus the firestopped penetration – achieves the required fire resistance rating (e.g., EI30, EI60) for the compartment line.

Typical Approaches (General Principles):

- For smaller, individual pipe penetrations, appropriately sized and rated pipe collars or fire wraps for pipework would likely be considered. These should be fixed securely to or within the Marmox Fireboard (potentially with additional support or framing if required by the firestop manufacturer for non-rigid constructions) and sealed with compatible intumescent sealant. The fixing method for collars would need to ensure a robust attachment to the Fireboard and potentially the underlying structure.

- For larger or multiple service penetrations, a common approach in many fire-rated board constructions is to use an additional fire batt system (like those described in Section 8). This creates a localised, robust fire seal within the opening in the Marmox Fireboard. Services would then penetrate this secondary fire batt, sealed with appropriate collars, wraps, or sleeves tested for use in such batt systems.

- All annular gaps around services and firestopping devices must be fully sealed with a compatible, fire-rated intumescent or ablative sealant.

Given the A1 rating and robust nature of Marmox Fireboard, it provides a solid basis for creating fire-resistant constructions. However, the responsibility for ensuring that service penetrations are correctly firestopped to maintain that resistance lies with the specifier and installer, using proven, tested solutions. When in doubt, always seek technical advice from both the firestopping product manufacturer and Marmox.

Section 11: Navigating UK Standards and Regulations for Pipe Firestopping

Ensuring the correct specification and installation of fire-rated pipe protection is not just a matter of good practice; it is a legal requirement in the United Kingdom. This is governed by a framework of Building Regulations and supported by detailed British and European Standards.

A. UK Building Regulations Overview

In England and Wales, the Building Regulations 2010 set out the overarching legal requirements for building work. Practical guidance on how to meet these requirements for fire safety is provided in Approved Document B (Fire Safety). This document is split into two volumes: Volume 1 covers Dwellings, and Volume 2 addresses Buildings other than Dwellings. While specifics can vary, the core principles of fire safety and compartmentation are consistent.

A key requirement pertinent to firestopping is Requirement B3: Internal Fire Spread (Structure). This mandates that "The building shall be designed and constructed so that, in the event of a fire, its stability will be maintained for a reasonable period." Critically, it also states, "The building shall be designed and constructed so that unseen fire and smoke within concealed spaces in its structure and fabric is inhibited."

This directly relates to the need for effective fire compartmentation and the sealing of any penetrations through compartment lines formed by compartment walls and floors. Approved Document B explicitly states that all fire-rated elements must have their fire resistance reinstated if they are penetrated by services. Openings for such services must be kept as few and as small as practicable, and they must be appropriately fire-stopped. This also applies to joints between fire-separating elements, which must also be fire-stopped.

It is important to recognise that Approved Document B provides guidance. While following this guidance is the most common way to demonstrate compliance, it is not the only way. The ultimate responsibility for compliance rests with those carrying out the building work. Alternative solutions can be used if they can be demonstrated to meet the functional requirements of the Building Regulations and are agreed with the relevant Building Control Body, ideally at an early stage in the project.

B. Key British and European Standards (BS EN)

A number of British and European Standards underpin the testing, classification, and specification of fire-rated products for pipe penetrations:

- BS EN 13501-1: Fire classification of construction products and building elements. Part 1: Classification using data from reaction to fire tests. This standard is fundamental for understanding how materials themselves behave in a fire. It establishes the Euroclass system (A1, A2, B, C, D, E, F) for reaction to fire performance, where A1 is non-combustible and F is easily flammable. It also includes classifications for smoke production (s1, s2, s3 – low, medium, high) and flaming droplets/particles (d0, d1, d2 – none, some, high).

- BS EN 1366-3: Fire resistance tests for service installations. Penetration seals. This is the primary European test standard for assessing the fire resistance of penetration sealing systems. This includes those used for pipes, cables, and ducts passing through compartment walls and floors. The test methodology involves subjecting a representative sample of the penetration seal, installed in a supporting construction (e.g., a wall or floor), to standardised fire conditions (following the ISO 834 cellulosic temperature-time curve) and pressure regimes. Performance is evaluated based on the time for which the seal maintains:

- Integrity (E): Preventing the passage of flames and hot gases, assessed by criteria such as no sustained flaming on the unexposed side, no ignition of a cotton pad, and no penetration by specified gap gauges.

- Insulation (I): Limiting the temperature rise on the unexposed surface of the seal and adjacent areas to prevent fire spread by conducted heat. Test durations typically range from 30 minutes to 240 minutes (4 hours). Compliance is not merely about selecting a product with a "fire rating"; it's about ensuring that the product has been tested to the correct standard for the specific application – in this case, BS EN 1366-3 for penetration seals. A product might have an excellent "reaction to fire" classification under BS EN 13501-1 (e.g., be non-combustible) but could still perform poorly as a penetration seal if not specifically designed and tested for that complex scenario, which involves interaction with various services and the surrounding structure.

- BS 476: Fire tests on building materials and structures. This is an older series of British standards. While many parts have been superseded by European Norms, some parts, such as BS 476-20 (Method for determination of the fire resistance of elements of construction (general principles)) and BS 476-22 (Methods for determination of the fire resistance of non-loadbearing elements of construction), are still referenced or provide a basis for assessing products, particularly if they were tested before the full adoption of EN standards.

- BS 5422: Method for specifying thermal insulating materials... and BS 5970: Code of practice for thermal insulation of pipework...: These standards are primarily concerned with the thermal performance of insulation but are relevant where fire-rated insulation also serves a thermal purpose. They provide guidance on material specification and application, which can intersect with fire safety considerations.

The transition from national standards (like parts of BS 476) to European Norms (EN) aims to harmonise testing and classification across Europe. This requires professionals in the UK construction industry to be familiar with the current EN terminologies and methodologies, such as Euroclasses for reaction to fire and EI ratings for fire resistance. This ongoing evolution underscores the need for continuous professional development to stay abreast of the latest standards.

C. Understanding Fire Ratings (Integrity & Insulation)

Fire resistance performance is typically expressed in terms of Integrity (E), Insulation (I), and sometimes Loadbearing Capacity (R), followed by a time in minutes (e.g., 30, 60, 120). For penetration seals in compartment walls and floors, E and I are the most critical:

- E (Integrity): This refers to the ability of the firestopping system to prevent the passage of flames and hot gases from the fire-exposed side to the unexposed side for the specified duration. For example, E60 means the product maintains its integrity for at least 60 minutes.

- I (Insulation): This refers to the ability of the system to restrict the temperature rise on the unexposed surface to below specified limits for the duration. This prevents fire spread by conducted or radiated heat that could ignite materials on the non-fire side.

- EI (Integrity & Insulation): When a product is rated EI (e.g., EI60), it means it satisfies both the integrity and insulation criteria for that period. This is generally the most stringent requirement for fire-separating elements and penetration seals, as it addresses both direct flame/gas passage and heat transfer. Common ratings encountered include EI30, EI60, EI90, and EI120.

Table 3: Key UK Standards for Fire Rated Pipe Penetration Seals

| Standard | Brief Description | Relevance to Pipe Firestopping |

|---|---|---|

| Approved Document B (Req. B3) | UK Building Regulations statutory guidance on fire safety, including internal fire spread and compartmentation. | Sets the fundamental legal expectation for maintaining compartmentation integrity where pipes penetrate fire-separating compartment walls and floors. |

| BS EN 13501-1 | European standard for the fire classification of construction products and building elements (reaction to fire). | Classifies the combustibility, smoke production, and flaming droplet characteristics of materials used in firestopping products (e.g., Euroclasses A1-F). |

| BS EN 1366-3 | European standard specifying fire resistance tests for service installations, specifically penetration seals. | The primary test method used to evaluate the fire resistance (Integrity 'E' and Insulation 'I') of pipe collars, wraps, and insulated sleeves. |

| BS 476-20 / BS 476-22 | British standards for determining the fire resistance of elements of construction. | Older test methods, still sometimes referenced for products tested prior to full EN adoption, providing integrity and insulation performance data. |

Section 12: Best Practices for Selecting and Installing Fire Rated Pipe Protection

The successful firestopping of pipe penetrations hinges on two critical phases: the correct selection of the firestopping solution and its meticulous installation in accordance with tested configurations. Failure in either phase can compromise the fire compartmentation of a building.

A. Factors for Selecting Appropriate Solutions

Choosing the right firestopping product requires careful consideration of several interconnected factors:

- Pipe Material: This is a fundamental distinction.

- Combustible pipes (e.g., PVC, PE, PP) will melt and deform in a fire, requiring a firestop (like a collar or a fire pipe wrap) that can crush the pipe and seal the void.

- Non-combustible pipes (e.g., steel, copper) will not melt but can conduct significant heat. If uninsulated, they require fire-rated insulation to prevent heat transfer. If they have combustible insulation, this will burn away, requiring a wrap or collar to seal the resulting void.

- Pipe Diameter: Firestopping products are manufactured and tested for specific ranges of pipe diameters. It is essential to select a product that is appropriately sized for the pipe being sealed.

- Pipe Insulation: If the pipe is already insulated for thermal or acoustic reasons, the firestopping solution must be compatible.

- Is the existing insulation combustible or non-combustible?

- Some products, like insulated fire sleeves, are designed to maintain the continuity of existing insulation while providing the fire seal.

- If the existing insulation is combustible (on either plastic or metal pipes), it may need to be removed at the penetration point and replaced with a fire-rated system, or a specific type of fire rated pipe wrap or collar designed for this scenario may be required.

- Required Fire Rating (Integrity & Insulation - EI): The firestopping system must achieve a fire rating (e.g., EI60, EI120, which could involve a 2 hour fire rated pipe wrap for relevant applications) that is at least equal to the required fire rating of the compartment wall or floor being penetrated.

- Type of Construction: The material of the compartment wall or floor (e.g., masonry, concrete, plasterboard drywall, timber construction, or specialised fire-rated boards like Marmox Fireboard) and its thickness will influence product selection. Some products, like certain intumescent wraps, are designed for installation within solid constructions, while others are suitable for drywall partitions or fire batt systems. The compatibility of the firestop with the specific construction substrate is paramount.

- Annular Space/Aperture Size: The size of the gap between the pipe and the edge of the opening in the structure must be considered. This annular space often needs to be filled with a compatible fire-rated sealant as part of the overall firestopping system. For larger openings, a fire batt system may be required.

- Service Conditions: The normal operating conditions of the pipe, such as temperature, exposure to moisture, or chemicals, should be considered to ensure the long-term durability and performance of the firestopping product.

- Third-Party Certification and Test Evidence: Crucially, the selected product must have been successfully tested to the relevant standard (e.g., BS EN 1366-3) for the specific application. This includes pipe type, size, orientation, supporting construction, and required fire rating. Always demand and review the third-party certification and associated test evidence.

B. General Installation Guidelines

While the manufacturer's specific installation instructions for a product are always paramount, some general best practice principles apply:

- Surface Preparation: Ensure the pipe surface and the surrounding substrate (compartment wall or floor) are clean, dry, and free from dust, grease, loose materials, or any contaminants that could interfere with adhesion or performance.

- Correct Sizing and Fitting: Use the correctly sized product for the pipe diameter. Insulation or sleeves should fit snugly. Fire wraps for pipework should have the correct overlap as specified by the manufacturer.

- Positioning: The correct positioning of the firestop is critical. For pipe wraps, this often means ensuring an edge is exposed to the fire side for timely activation. Collars should be installed flush against the surface of the compartment wall or floor. Insulated fire sleeves should be cut and installed flush with the faces of the compartment wall or floor, or protrude as per the manufacturer's specification for certain applications (e.g., when used with fire batts or PVC services).

- Fixing: Fire collars must be securely mechanically fixed to the structure using the manufacturer's recommended type and number of fixings. Pipe wraps are typically secured using their integral self-adhesive tape. When fixing to or through fire batts, specific fixings (e.g., pigtail screws) may be required.

- Sealing Gaps: Any remaining annular gaps around the pipe or the firestopping device itself must be sealed with a compatible fire-rated sealant (e.g., intumescent mastic or acrylic sealant) or firestop compound to ensure a smoke-tight and fire-tight seal. This includes sealing around fire batts and where services penetrate them.

- Multiple Penetrations: If multiple services pass through a single large opening in a compartment wall or floor, specialised solutions such as fire-rated batts used in conjunction with appropriate collars, wraps, or sleeves will be required. The spacing between services and from the edges of the aperture is critical and must follow tested details.

- Follow Best Practice Guidance: Adhere to industry best practice, such as the "Golden Rules" for penetration seals outlined by organisations like the Association for Specialist Fire Protection (ASFP). These often include early engagement with manufacturers, using third-party certified products and installers, and ideally using a single manufacturer's system within an opening unless compatibility is proven through testing.

The "as tested" principle is fundamental in firestopping. Products and systems are fire-rated based on specific configurations tested in a laboratory. Any deviation from this tested configuration – be it the product itself, the type or size of pipe, the nature of the supporting construction, or the installation method – can potentially invalidate the fire rating and compromise safety. Installers must strive to replicate the conditions under which the product achieved its certification.

C. Common Mistakes and How to Avoid Them

A significant number of firestopping failures are attributable to human error or a lack of knowledge during specification or installation, rather than inherent defects in the products themselves. Common mistakes include:

- Using Non-Compliant or Untested Products: Selecting products without appropriate third-party certification or test evidence for the specific application.

- Incorrect Product for Pipe Type: For example, using a solution designed for plastic pipes on an uninsulated metal pipe without considering heat conduction, or vice-versa.

- Poor Installation Practices:

- Incorrect positioning of wraps or collars (e.g., a fire pipe wrap recessed too far, collar not flush).

- Missing or incorrect fixings for collars.

- Inadequate sealing of annular gaps around the pipe or device, or around fire batts.

- Using inappropriate materials for sealing gaps, such as standard silicone or, notoriously, "pink" expanding polyurethane foam which is often not suitably fire-rated for penetration sealing and can release toxic fumes.

- Incorrect Spacing: Insufficient spacing between adjacent services or between services and the edges of the opening, which can prevent the firestop from performing correctly. This is particularly critical when using fire batt systems with multiple penetrations.

- Damage by Other Trades: Firestopping installations can be damaged by subsequent trades working in the same area if there is a lack of awareness or coordination.

- Lack of Coordination Between Trades: This can lead to services being installed in a way that makes compliant firestopping difficult or impossible.

- Failure to Follow Manufacturer’s Instructions: This is a primary cause of ineffective firestopping.

Avoidance Strategies: The most effective way to avoid these mistakes is through a combination of:

- Using Competent Personnel: Employing third-party certified firestopping installers who have demonstrated their knowledge and skill.

- Adherence to Documentation: Rigorously following the manufacturer's installation instructions, data sheets, and the scope of application defined by the test evidence.

- Training and Awareness: Ensuring all relevant site personnel are aware of the importance of firestopping and the need to protect installed systems.

- Supervision and Inspection: Implementing robust site supervision and inspection regimes to verify correct installation before areas are closed off.

The interface between different trades and the sequencing of work on site are critical risk factors. Firestopping is often installed after mechanical and electrical services are in place. This necessitates careful planning and coordination to ensure that services are routed in a manner that allows for effective firestopping and that installed firestops are not subsequently compromised.

D. Importance of Manufacturer's Instructions and Certified Installers

Firestopping products are tested as complete systems. Their performance is contingent upon being installed exactly as they were during the fire test. Manufacturer's instructions detail these critical parameters.

Certified installers undergo training and assessment to ensure they have the competence to understand these requirements and apply them correctly in practice. Relying on such expertise is crucial for achieving compliant and effective fire safety.

Section 13: Ensuring Compliance: Certification and Marking

In the UK, demonstrating that firestopping products for pipe penetrations meet the required safety and performance standards involves a system of regulatory marking and independent third-party certification. These provide assurance to specifiers, installers, building control bodies, and end-users.

A. UKCA (UK Conformity Assessed) Marking

Following the UK's departure from the European Union, the UKCA marking is the product marking used for goods being placed on the market in Great Britain (England, Wales, and Scotland). It covers most product areas that previously required the CE marking.

For fire safety products, including fire-rated pipe collars, intumescent wraps, and insulation, the UKCA mark signifies that the product meets the necessary UK standards, regulations, and conformity assessment procedures. Affixing the UKCA mark is a manufacturer's declaration of compliance and demonstrates a commitment to quality and safety within the UK regulatory framework.

B. CE Marking

The CE marking indicates that a product complies with EU safety, health, and environmental protection requirements. It means the product can be legally placed on the market within the European Economic Area (EEA). For construction products, it signifies that the product is "fit for purpose" and will enable the finished construction works to comply with the essential requirements of the Construction Products Regulation (CPR).

While the UKCA mark is now the primary mark for Great Britain, CE marking may still be relevant for products sold in Northern Ireland or the EU. For a transitional period, some products could carry both marks or rely on CE marking if placed on the GB market before specific deadlines. It is important to note that CE marking, like UKCA marking, denotes compliance with minimum performance requirements and should not be confused with voluntary third-party quality marks.

The co-existence or transition between UKCA and CE marking can present complexities for manufacturers who supply products to both the UK and EU markets. This may potentially require adherence to two, albeit often similar, sets of regulatory and testing protocols, which could have implications for product availability and cost.

C. Importance of Third-Party Certification (TPC)

Beyond the mandatory regulatory markings, independent Third-Party Certification (TPC) plays a crucial role. It provides enhanced confidence in the performance and quality of firestopping products and their installation. Schemes run by accredited bodies such as Certifire, LPCB (Loss Prevention Certification Board), IFC Certification, and BM TRADA offer a more in-depth assurance.

- Product Certification: TPC for products typically involves:

- Initial type testing of the product to relevant standards (e.g., BS EN 1366-3 for penetration seals).

- Audits of the manufacturer's Factory Production Control (FPC) systems to ensure consistent quality and that manufactured products match the tested specification.

- Ongoing surveillance, including re-testing or sample checking, to verify continued compliance. A third-party certified product gives specifiers and users greater confidence that it will perform as claimed in a fire.