- Blogs

- A Comprehensive Guide: Kingspan Minimal Profile Insulation Solutions in the UK

A Comprehensive Guide: Kingspan Minimal Profile Insulation Solutions in the UK

TLDR: Rapid Summary of Kingspan 10mm Context Insulation

The search term '10mm Kingspan insulation' typically refers to two distinct, high-performance, space-saving solutions within the UK market, both designed to minimise construction thickness while achieving stringent thermal targets. Firstly, the Kingspan Kooltherm K106 Cavity Board is engineered for full-fill cavity walls, crucially maintaining a 10 mm residual air gap to manage moisture and penetrating damp. Secondly, the Kingspan Kooltherm K118 Insulated Plasterboard is one of the thinnest internal wall insulation (IWI) solutions available, providing insulation, drylining, and vapour control in a single unit, ideal for older solid wall properties where space retention is critical. Both products utilise a premium performance, fibre-free rigid thermoset phenolic insulation core with an industry-leading thermal conductivity of 0.019 mathrm{W/mK}.

1. Introduction: Understanding Minimal Profile Insulation for UK Projects

1.1. Defining the Context: Addressing the Kingspan 10mm Search Term

The necessity for high-performance insulation that occupies minimal space is a constant constraint within the UK construction sector, especially during refurbishment projects where existing room dimensions are sacrosanct. The high volume of searches related to 'Kingspan 10mm insulation' is a reflection of this market need, although the interpretation of the '10mm' dimension varies depending on the application. For Kingspan, this dimension relates either to a critical gap maintained within a cavity wall system (K106) or the ambition to provide the thinnest practical solution for internal drylining (K118).

The insulation core that forms the foundation of these products is a premium performance fibre-free rigid thermoset phenolic material. This highly specialised material is the reason these boards are classified as minimal profile solutions. Their design is a direct response to the architectural challenge of achieving modern thermal compliance requirements without unduly compromising the usable floor area of a building, which is particularly vital in densely built urban environments.

1.2. The Kooltherm Advantage: Premium Performance Phenolic Technology

The core technical driver that defines the performance capability of the Kooltherm range is the exceptionally low thermal conductivity (lambda) of the phenolic foam. Both the Kooltherm K106 Cavity Board and the Kooltherm K118 Insulated Plasterboard possess a thermal conductivity of 0.019 mathrm{W/mK}.

This low thermal conductivity (lambda) is fundamental to the value proposition of the material. Thermal conductivity is a measure of a material's capacity to conduct heat; a lower figure indicates superior thermal resistance. Consequently, the high performance of the phenolic core means that the required thermal resistance for a specific application can be achieved with a considerably thinner profile compared to materials with higher lambda values. This is not simply a convenience; it directly enables specifiers and builders to adhere to strict energy efficiency targets while minimising intrusion into a building’s existing envelope. The high thermal resistance per unit of thickness ensures maximum thermal gain for the space sacrificed, which is often the decisive factor when selecting insulation for restricted spaces.

1.3. Why Minimal Thickness is Essential in UK Construction

The composition of the UK's building stock presents unique difficulties. Millions of homes feature solid brick walls or tight cavity walls, and renovation projects frequently face restrictions imposed by shared boundaries, conservation area status, or the high value placed on internal floor space.

The need for minimal profile insulation is often a regulatory necessity. Current UK Building Regulations (Approved Document L, Part L) stipulate stringent thermal performance targets for new construction and substantial refurbishments. Meeting these required U-values (e.g., 0.18 mathrm{W/m^2K} for new external walls ) would typically require substantial thickness if using less efficient materials. Minimal profile insulation allows designers to reconcile the conflicting demands of modern energy standards and the physical limitations of existing structures, particularly when working on refurbishments of solid walls where the installation of External Wall Insulation (EWI) is not feasible.

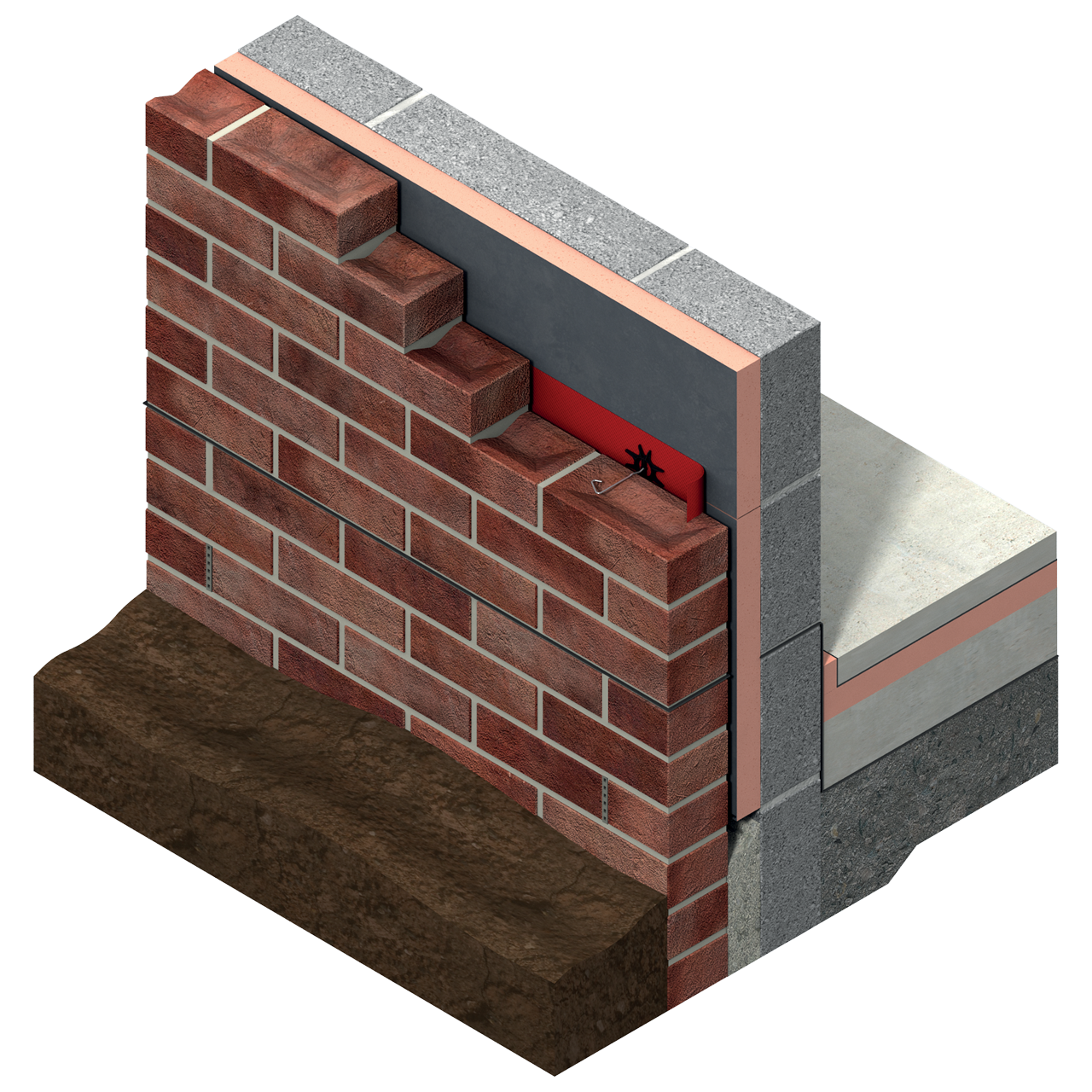

2. Kingspan Kooltherm K106 Cavity Board: Engineered for Full-Fill Cavities![]()

2.1. Product Profile and Composition

The Kingspan Kooltherm K106 Cavity Board is marketed as a premium performance solution specifically designed for full-fill cavity wall applications. The core is the fibre-free rigid thermoset phenolic insulation, providing the necessary thermal efficiency.

A key feature of the K106 product is its facing system. It incorporates a water-tight, vapour-open polypropylene fleece outer facing. This dual functionality is highly critical in UK cavity wall construction. The water-tight nature of the facing provides protection against liquid moisture penetration from the outer brick leaf, which is a common occurrence in exposed areas. Simultaneously, the vapour-open characteristic permits the diffusion and escape of water vapour, including residual moisture trapped within the wall structure following construction or slight atmospheric changes. This allows the wall to maintain breathability and long-term durability, protecting the inner leaf from moisture tracking and potential damage.

2.2. The 10 mm Residual Cavity Principle in Detail

While K106 is classed as a 'full-fill' solution, its design dictates that it is used to maintain a regulated 10 mm residual cavity between the insulation board and the outer leaf. This 10 mm gap is fundamental to the board’s function as a moisture management solution.

The original design of cavity walls in the UK was based on the premise that the empty gap would interrupt the travel path of penetrating damp, preventing moisture that passes through the outer leaf from reaching the internal structure. Fully blocking this gap, even with insulation, introduces the risk of bridging moisture, compromising safety. The K106 system acknowledges this risk by insulating the maximum possible cavity width while deliberately retaining the critical 10 mm air gap. This continuous 10 mm space, combined with the protective fleece facing, acts as a continuous drainage and evaporation route, thus safeguarding the thermal integrity and the physical fabric of the inner wall from rain penetration in high-exposure conditions.

2.3. Achieving U-Value Targets in New Build and Extensions

The application of K106 is highly effective in helping construction projects meet or substantially exceed regulatory U-value targets. The U-value achieved by the wall system is not solely dependent on the thickness of the insulation, but also on the thermal properties of the surrounding construction elements, particularly the inner leaf blockwork.

For example, when using a 90 mathrm{mm} thickness of Kooltherm K106, the resulting system U-value can range from 0.18 mathrm{W/m^2K} when paired with a dense block inner leaf, down to 0.16 mathrm{W/m^2K} when paired with highly thermally efficient aerated blockwork (with a lambda value of 0.11 mathrm{W/mK}). This ability to achieve U-values substantially below the 0.18 mathrm{W/m^2K} new build target demonstrates the power of the 0.019 mathrm{W/mK} phenolic core.

Specifiers must conduct comprehensive U-value calculations specific to the entire wall assembly, ensuring that the selection of the inner leaf density maximises the overall thermal resistance of the structure, while the K106 ensures the insulation component itself contributes the highest possible thermal resistance per unit of thickness.

Table Title: Illustrative K106 U-Values (W/m^2K) for Varying Wall Systems

| Insulant Thickness (mm) | Inner Leaf: Dense Block (1.13 λ) | Inner Leaf: Medium Block (0.51 λ) | Inner Leaf: Aerated Block (0.11 λ) |

| 90 | 0.18 | 0.18 | 0.16 |

| 115 | 0.15 | 0.14 | 0.13 |

3. Kingspan Kooltherm K118 Insulated Plasterboard: Internal Wall Insulation (IWI)

3.1. K118 Composition and Integrated Functionality

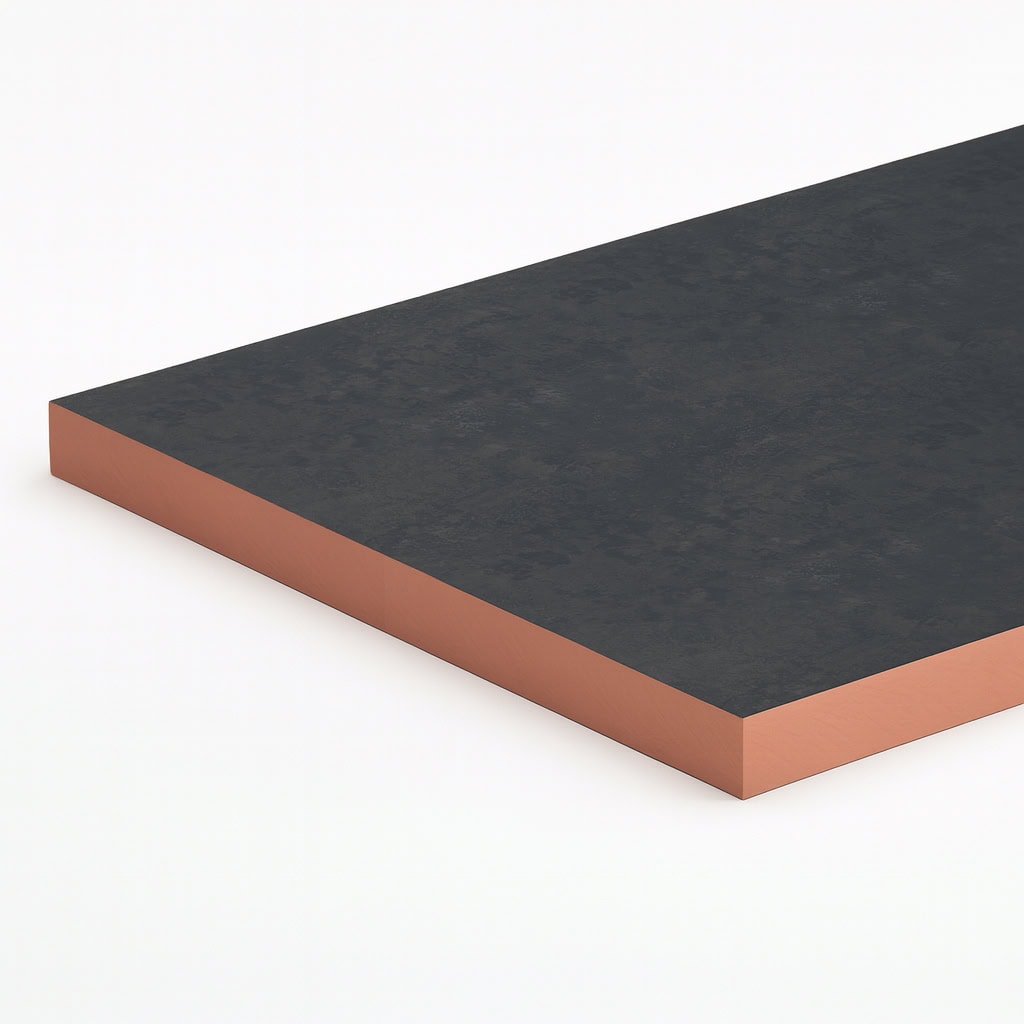

For applications where cavity insulation is impossible or where the structure is a solid masonry wall, the Kingspan Kooltherm K118 Insulated Plasterboard provides a solution for internal wall insulation (IWI). K118 is a composite board composed of the premium performance fibre-free rigid thermoset phenolic insulation core bonded to a 12.5 mathrm{mm} gypsum plasterboard face. The thermal conductivity of the insulation element is 0.019 mathrm{W/mK}.

Crucially, the K118 system integrates insulation, drylining, and vapour control into a single board. The reverse surface of the board features a low emissivity composite foil facing, which functions as an effective Vapour Control Layer (VCL). In IWI applications, installing a functioning VCL is paramount to the building's durability. By moving the temperature gradient inwards, the insulation increases the risk of interstitial condensation—moisture condensing within the wall structure. The integrated VCL in the K118 board mitigates this risk when the board is installed correctly, avoiding damaging moisture build-up within the wall.

3.2. Applications for K118: Solid Wall Refurbishment and Loft Spaces

The K118 insulated plasterboard is highly versatile, suitable for use with mechanically fixed or adhesively bonded drylining techniques on solid stonework, brickwork, and timber framing. It is also employed under rafters in pitched roofs to maintain headroom.

However, the primary strategic application for K118 is addressing the extensive solid wall stock in the UK, particularly in urban areas. This product is indispensable for buildings that cannot be insulated externally due to planning restrictions, heritage status, or access limitations. Its suitability for solid brickwork refurbishment provides a crucial method for improving the energy efficiency of the UK's dense, older housing stock, offering a compliant path towards reduced heating costs without altering the external façade.

3.3. Retaining Internal Space: K118’s Minimal Profile Advantage

The K118 range is recognised as one of the thinnest commonly used Internal Wall Insulation solutions. This minimal profile is the central advantage in refurbishment. While the plasterboard element is 12.5 mathrm{mm}, the overall board thickness starts from 32.5 mathrm{mm}.

The low thermal conductivity of 0.019 mathrm{W/mK} ensures that a significant thermal upgrade is achieved even with minimal thickness. For instance, increasing the total board thickness from 37.5 mathrm{mm} to 52.5 mathrm{mm} only sacrifices an additional 1.5 mathrm{cm} of internal space but delivers a disproportionately large improvement in the U-value potential. In small UK rooms, where every centimetre counts towards maintaining usable space, the minimal profile of K118 is a vital tool for preventing unacceptable spatial compromise during necessary thermal upgrades.

3.4. K118 Thermal Performance and U-Value Improvement

The selection of K118 thickness requires a careful balance between spatial retention and compliance ambition. An uninsulated solid brick wall may have a U-value exceeding 2.0 mathrm{W/m^2K}. Installing K118 provides a substantial reduction in heat loss.

As the thickness of the overall board increases, the system U-value decreases markedly. For a 37.5 mathrm{mm} total board thickness, the approximate system U-value is 0.87 mathrm{W/m^2K}. Moving to a 52.5 mathrm{mm} board significantly improves this performance to 0.56 mathrm{W/m^2K}. This improvement demonstrates that designers must consider how much space can be realistically sacrificed to approach the rigorous new build U-value targets of 0.18 mathrm{W/m^2K}. While minimal K118 boards offer excellent savings compared to the previous structure, reaching deep refurbishment targets often requires greater thickness, which must be justified against the practical constraints of the existing property.

Table Title: K118 Total Thickness and U-Value Improvement Potential (Approximate IWI Performance)

| Kingspan K118 Total Thickness | Thermal Resistance (m2K/W) | Approximate System U-Value (W/m2K) |

| 37.5 mathrm{mm} | 1.15 9 | 0.87 9 |

| 42.5 mathrm{mm} | 1.35 9 | 0.74 9 |

| 52.5 mathrm{mm} | 1.80 9 | 0.56 9 |

| 62.5 mathrm{mm} | 2.40 9 | 0.42 9 |

4. The UK Regulatory Environment: Compliance and Thermal Performance Calculation

4.1. Approved Document L (Part L): Targets for Thermal Efficiency

Compliance with Approved Document L (Part L) of the UK Building Regulations is mandatory for all new build projects and substantial renovations in England and Wales. The regulation sets demanding targets for energy efficiency, with external walls in new dwellings currently required to achieve a U-value of 0.18 mathrm{W/m^2K}.

The thermal conductivity of (0.019) mathrm{W/mK} achieved by the Kooltherm range is integral to meeting these demanding targets within the constraints of typical UK construction methods. High-performance insulation ensures that the thickness required to comply with Part L is minimised, maintaining the overall building envelope dimensions at an optimal level.

4.2. Refurbishment Flexibility and Technical Risk ![]()

For refurbishment projects, the application of Part L recognises that existing structures may face technical limitations that preclude meeting the new build targets. Approved Document L specifies that if meeting the target U-values in Table C1 is impractical, considering technical risk and the practicality of the work, then the U-value should be as close to the target value as practically possible.

This clause provides essential regulatory flexibility for IWI applications using K118 in older solid wall properties. Where a thick layer of insulation necessary to achieve 0.18 mathrm{W/m^2K} would result in unacceptable losses of internal space (e.g., compromising door clearances or staircase dimensions), the specifier can justify using a thinner, still highly effective K118 board. The requirement remains to use the best practical specification, necessitating thorough documentation of the physical constraints that prevent a thicker, fully compliant solution. The low lambda of K118 allows the maximum thermal improvement to be achieved under these spatial limitations.

4.3. Understanding Heat Loss Metrics and Product Efficacy

To understand why high-performance insulation is critical, it is necessary to consider the core metric of heat loss: the U-value, measured in mathrm{W/m^2K}. The U-value quantifies the rate of heat transfer through a structure, with lower values indicating better insulation performance. This calculation is derived from the material's thermal conductivity (lambda) and its thickness. Thermal Resistance, commonly referred to as the R-value, measures a material's capacity to impede heat flow. The relationship is inverse: higher thickness or lower thermal conductivity results in a higher R-value, leading to a lower system U-value. The use of insulation with a high R-value per millimetre, such as Kooltherm, is paramount for space efficiency.

5. Installation Protocols: Achieving Optimised Results with K118 (Dot and Dab)

The Kingspan Kooltherm K118 Insulated Plasterboard is suitable for installation using either mechanical fixing or adhesive techniques, frequently referred to as the 'dot and dab' method. Given the complexity of IWI, strict adherence to preparation and bonding protocols is necessary for system longevity and thermal performance.

5.1. Essential Pre-Installation Checks: Moisture and Alignment

Before any installation begins, a detailed survey and diagnosis of the property are mandatory. The presence of damp or mould growth must be identified, and the underlying cause (e.g., rising damp or penetrating damp) must be thoroughly investigated and remedied.

It is essential that the wall is dry, stable, and in a good state of repair before installation, as the K118 board should not be used in continuously damp or humid conditions or to attempt to isolate existing dampness. Failure to address existing moisture will lead to product failure. Furthermore, the structural alignment of the wall must be verified. The adhesive bonding method relies on a satisfactory background alignment where the deviation from the highest to the lowest point must not exceed a 5 mathrm{mm} gap when measured with a 2 mathrm{m} straight edge.

5.2. Preparation and Bonding Agent Application

For the drywall adhesive dab bonding method, it is a prerequisite that a bonding agent is applied to the composite foil facer of the K118 board. This step is critical because the foil facing is a low-emissivity material that is non-absorbent. Without the bonding agent, the standard gypsum-based adhesive blobs would lack sufficient mechanical key to the surface, significantly increasing the risk of bond failure and board delamination.

The bonding agent must be applied in continuous bands, a minimum of 150 mathrm{mm} wide, around the perimeter of the plasterboard and down the centre. These bands should coincide with the planned location of the adhesive dabs applied to the wall.

5.3. Applying the Adhesive Dabs and Perimeter Seal

When applying the adhesive dabs, a continuous band of adhesive must be run around the entire perimeter of the wall—vertically at corners and horizontally along the floor and ceiling lines, including the perimeter of all window and door openings. This continuous perimeter bond is crucial for establishing the integrity of the vapour control layer (VCL) system.

The adhesive dabs themselves should achieve a minimum coverage of 22% of the plasterboard area. Once the boards are fixed, a critical final step is sealing the perimeter. The perimeter of the K118 sheets and the 5 mathrm{mm} clearance gap maintained at the base of the wall must be fully sealed with a flexible sealant or equivalent. This sealing process prevents air infiltration, which could otherwise lead to thermal bridging and potentially allow moist internal air to bypass the VCL, causing condensation at the wall junctions.

5.4. Mechanical Fixing Requirements for Long-Term Security

The adhesively bonded method for K118 requires supplementary mechanical fixings to ensure long-term stability and security. These fixings are necessary to support the load of the board until the adhesive cures and to provide fail-safe mechanical support throughout the life of the building.

For a standard finish, such as a skim coat of plaster, no less than six supplementary nailable plugs are required per sheet of K118 Insulated Plasterboard, positioned approximately 15 mathrm{mm} in from each edge. Where the finished surface is intended to bear a heavy load, such as ceramic wall tiles, the fixing requirements increase significantly. The heavy dead load imposed by tiling requires no less than nine nailable plugs per sheet, typically applied in lines of three (top, middle, and bottom). This requirement for increased fixings is a safety measure to manage the increased sheer stress exerted on the board and the adhesive bond by the substantial weight added by the tiles, mitigating the risk of structural failure over time.

Table Title: Secondary Fixing Requirements for K118 Drylining (Per Standard Sheet)

| Wall Finish | Fixing Requirement | Minimum Fixings Required |

| Standard Plastered Finish | Supplementary Nailable Plugs | No less than 6 |

| Heavy Finish (Ceramic Wall Tiles) | Supplementary Nailable Plugs | No less than 9 |

6. Summary of Practical Benefits and Long-Term Value

6.1. Speed of Installation and Reduced Construction Time

The Kingspan Kooltherm K118 board offers substantial practical benefits on site by combining insulation, drylining, and vapour control into a single unit. This consolidation simplifies the procurement process and significantly reduces the complexity of installation compared to multi-layered solutions. By reducing the number of trades and processes required to complete the thermal upgrade, contractors working on refurbishment projects can minimise the construction timeline and realise cost efficiencies. Furthermore, the system is known to allow for quick response heating within the property, improving occupant comfort immediately after installation.

6.2. Durability and Stability of Phenolic Insulation

The fibre-free rigid thermoset nature of the phenolic core provides excellent dimensional stability. This material is resistant to the effects of air infiltration and is designed to maintain its high thermal performance over the operational lifetime of the building. This long-term durability is essential, ensuring that the thermal compliance achieved at the point of construction is sustained for decades, which is a critical consideration for building owners and mortgage providers in the UK.

UK Legal and Technical Disclaimer

This content is provided purely for general informational and educational purposes concerning the technical specifications and general application methodology of Kingspan insulation products within the UK construction context. This information is derived from public domain data and common industry practice. It does not constitute professional advice, specification advice, or legal guidance. Building regulations and specific material requirements are subject to constant review and depend entirely on the individual circumstances of a project, the existing structure, and local planning requirements. Before ordering, purchasing, or installing any materials, you must seek and rely solely upon advice from a qualified construction professional (such as a Chartered Surveyor, Architect, or Structural Engineer) who is competent to specify materials and ensure full compliance with the current edition of the UK Building Regulations and any applicable standards. Reliance upon the information provided herein is entirely at the reader’s own risk. Kingspan Insulation does not accept responsibility for issues arising from using products in applications different from those described in their official documentation or failure to correctly follow professional installation guidance.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *