Similar Categories

Overview of Foam Tape Types and Their Characteristics

Foam tapes are available in a variety of types, each designed for specific applications and offering unique characteristics.

Polyethylene (PE) foam tape is lightweight, durable, and resistant to moisture, making it ideal for sealing, insulation, and mounting tasks. PE foam tape is also environmentally friendly and easy to recycle.

Polyurethane (PU) foam tape is flexible and soft, allowing it to conform to irregular surfaces; it's often used for cushioning and soundproofing.

PVC foam tape withstands outdoor conditions with its UV and weather resistance, making it suitable for window sealing and HVAC insulation.

Acrylic foam tape provides strong bonds and high durability, making it a popular choice for industrial and automotive applications.

Neoprene foam tape offers excellent resistance to oils, solvents, and weather, which makes it perfect for harsh environments such as marine or HVAC use.

These variations ensure that foam tapes meet diverse needs, fostering a sense of community among users who value quality and reliability in the UK.

Core Properties That Make Foam Tapes Versatile

The core properties of foam tapes, such as temperature and UV resistance, play a key role in their durability across various environments. Conformability, which depends on the foam’s cell structure, allows the tape to adapt to uneven or complex surfaces while maintaining a strong bond. These features make foam tapes a versatile choice for a range of applications, from outdoor signage to automotive assembly in the UK. Properties like strength and flexibility further enhance their performance in demanding conditions.

Temperature and UV Resistance

Temperature and UV resistance are essential factors that determine the versatility of foam tapes in various applications. Different materials offer varying levels of endurance; for example, polyurethane foam tapes can withstand temperatures up to 160°C (320°F), while urethane-based options such as 3M™ 4016 can handle short-term exposure to 193°C (380°F). These tapes perform best between 21–38°C (70–100°F), yet they can flex in cold environments down to -30°C (-20°F) without cracking. Foam tapes are tested for elevated temperature resistance to ensure performance in demanding conditions. PVC foam, known for its strong UV resistance, is ideal for outdoor sealing, effectively resisting weathering and sunlight. Urethane tapes, tested in UV chambers, show no degradation after a week.

Conformability and Cell Structure

Conformability is a key property that makes foam tapes adaptable to a wide range of surfaces and shapes. Their sponge-like flexibility allows them to compress and expand, easily matching surface irregularities.

The viscoelastic foam core maintains its shape after deformation, ensuring long-lasting performance. Foam tapes such as 3M™ VHB™ are particularly effective at conforming to curved surfaces, making them ideal for irregular geometries.

They fill gaps and uneven textures without risking adhesive failure, thanks to their ability to adapt. Low modulus materials enable the tapes to bend around tight radii without delaminating.

Their cell structure, whether open or closed, balances compressibility and moisture resistance. The cell structure influences moisture resistance and compressibility, which guarantees that foam tapes provide reliable, versatile bonding in many applications across the UK.

Common Applications Across Industries

Foam tapes are extensively utilised across various industries for their versatile sealing solutions, offering dependable barriers against dust, moisture, and noise. They also assist in absorbing vibrations and shocks, thereby protecting equipment and enhancing performance. Furthermore, foam tapes accommodate thermal expansion, ensuring that joints remain secure even with fluctuations in temperature. Applications include use in automotive, electronics, and building components, demonstrating their adaptability and importance in maintaining structural integrity.

Industry-specific Sealing Solutions

Sealants made from foam tapes are widely utilised across numerous industries in the UK due to their ability to provide effective sealing solutions for diverse requirements. They help keep dust, moisture, and air out while enhancing durability and performance.

In the automotive industry, foam tapes seal gaps, reduce noise, and assist in bonding exterior components. Electronics manufacturers use foam tapes to secure components and protect against contaminants. The construction sector relies on foam for insulation and weatherstripping around windows and doors, which helps prevent energy loss. Foam tapes also offer excellent adhesion to a variety of surfaces, making installation easier and more reliable. adhesion to surfaces

- Ideal for sealing gaps in vehicle assemblies, electronic enclosures, and building joints.

- Provide thermal and acoustic insulation, enhancing comfort and safety.

- Are adaptable to various thicknesses for bespoke needs, from tiny gaps to larger spaces, making them versatile for many applications.

Vibration and Shock Absorption

Vibration and shock absorption are crucial functions that foam tapes can provide across various industries in the UK. They help protect equipment, enhance comfort, and reduce noise by isolating vibrating components.

Foam tapes utilise decoupling materials to create barriers between surfaces, preventing metal-to-metal contact. Their viscoelastic properties convert vibration energy into heat through internal friction, while high-density foams resist compression, maintaining stability under repeated stress. The compressive strength of foam tapes ensures their effectiveness over long-term use. These tapes also conform to uneven surfaces and are available in various thicknesses to target specific vibration frequencies. From automotive panels that mitigate resonance to electronics that absorb impacts, foam tapes offer versatile solutions.

They minimise damage, enhance durability, and ensure smooth operation, making them essential in industries that require reliable vibration control.

Thermal Expansion Compensation

Thermal expansion can cause problems in many industries, leading to gaps, warping, or damage if not properly managed. Foam tapes, particularly those with acrylic foam, offer an effective solution for thermal expansion compensation. They absorb the stress caused by temperature changes, maintaining the integrity of bonded components. Foam tape's flexibility further enhances its ability to accommodate movement caused by thermal expansion. Common applications include:

-

Automotive sealing: Ensures that doors and windows remain sealed despite temperature fluctuations.

-

Construction: Serves as a buffer between metal and wood in frames or facades.

-

Electronics: Protects sensitive components in displays and circuitry from expansion stress.

These foam tapes assist industries in managing the expansion and contraction resulting from sunlight, temperature variations, or operational heat. Their elastic recovery guarantees long-lasting bonds and helps prevent warping or cracking, providing peace of mind for manufacturers and installers alike.

Foam Tapes for Solar Panel Mounting and Renewable Energy

Foam tapes are increasingly vital in the renewable energy industry, particularly for mounting solar panels.

These tapes feature a 100% acrylic adhesive that bonds strongly without the need for mechanical fasteners, making installation cleaner and quicker.

The viscoelastic foam core absorbs vibrations and thermal expansion stresses, protecting panels over time.

Their UV-resistant formulation ensures durability outdoors, while their temperature tolerance allows them to perform well in extreme heat and cold.

Moisture resistance prevents bond failure in wet conditions, which is essential for outdoor setups.

Available in standard widths such as 50mm and 75mm, each roll is 33 metres long, supporting large projects.

These foam tapes are primarily used to securely bond solar panels, providing a reliable, long-lasting solution that reduces hardware costs and installation time for energy professionals and enthusiasts alike in the UK.

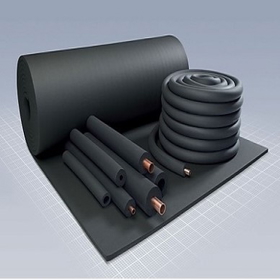

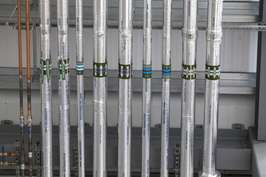

Sealing and Insulating Uses in HVAC and Building Envelopes

Foam tapes play an essential role in sealing and insulating in HVAC and building envelope applications, helping to improve energy efficiency and prevent air leaks. They're used to seal ductwork, roof curbs, pipes, and vibrations, reducing energy loss and noise. In building envelopes, foam tapes block drafts, fill gaps, and prevent condensation, supporting better thermal regulation. Many formulations include moisture-resistant and fire-rated options to meet safety standards. These tapes also accommodate material expansion and contraction, ensuring long-lasting seals. Foam tapes are available in various thicknesses and widths to suit different applications.

- Seal gaps around windows and doors for improved insulation.

- Protect against moisture infiltration with vapour barriers.

- Provide durable seals in building joints and penetrations to meet building regulations.

Automotive and Transportation Industry Applications

In the automotive and transportation sectors, foam tapes are extensively used to enhance vehicle assembly and performance. They securely fasten interior components such as dashboards, control panels, and infotainment screens without visible fasteners, resulting in a cleaner appearance within the vehicle.

Foam tapes also serve as a replacement for mechanical fasteners in lightweight headliner and door panel installations, contributing to a reduction in vehicle weight. Furthermore, they effectively dampen vibrations for electronic components, preventing any looseness during driving.

Externally, foam tapes are employed to bond exterior trim and emblems, eliminating the need for drilling and thereby preserving the car's aesthetic appeal. They're resistant to UV rays, humidity, and debris, which significantly extends the lifespan of various parts.

In addition, foam tapes create seals around doors, sunroofs, and windows to prevent the ingress of water, dust, and noise. Their capability to accommodate temperature fluctuations and thermal expansion renders them indispensable for ensuring safe, durable, and quiet transportation.

Material Selection: Choosing the Right Foam Tape for Your Needs

Selecting the right foam tape depends on understanding its material properties and how they match specific application needs. Different foam tapes offer unique advantages, so choosing the appropriate one is essential for success.

For example, polyethylene (PE) provides moisture resistance and cushioning, making it ideal for mounting or insulation. Polyurethane (PU) is flexible and absorbs vibrations, which makes it excellent for sealing irregular surfaces. PVC is durable and weather-resistant, perfect for outdoor sealing.

- Consider the environment: Will it be exposed to moisture, heat, or UV light?

- Match the material to the application: Is it intended for bonding, sealing, or insulation?

- Assess compatibility: Will the tape adhere well to your materials?

Understanding these factors will aid you in finding the perfect foam tape for the task at hand.

Advantages of Foam Tapes Over Traditional Bonding Methods

Traditional bonding methods, such as mechanical fasteners like screws and nails, often present challenges including higher costs, longer installation times, and potential negative impacts on appearance.

Foam tapes offer a more efficient alternative with a lower price point and quicker application, saving both time and effort. They create a sleek, seamless finish as they remain invisible once applied, enhancing aesthetic appeal.

Foam tapes distribute stress evenly across the entire bond area, thereby reducing the risk of damage and wear. Additionally, they provide superior insulation—both thermal and acoustic—compared to traditional fasteners.

The flexibility of foam tapes allows them to adhere to various surfaces, including irregular shapes, resulting in durable and waterproof bonds.

Tips for Proper Application and Maintenance of Foam Tapes

Proper application of foam tapes is essential to achieve strong and durable bonds. To guarantee success, surface preparation is key—clean and dry surfaces improve adhesion.

During application, careful alignment helps prevent wrinkles and uneven coverage, while applying firm pressure ensures a strong bond. It’s important not to overstretch the tape, as this can reduce effectiveness.

Regular maintenance includes inspecting the tape for damage or wear, cleaning surfaces before reapplying, and protecting it from moisture and sunlight to extend the tape’s lifespan.

Here are some helpful tips:

- Always follow manufacturer instructions for specific tape types.

- Store foam tapes properly to avoid damage before use.

- Reapply or replace the tape if it shows signs of deterioration or poor adhesion.

Conclusion

Foam tapes are versatile adhesives employed across various industries in the UK, offering benefits such as sealing, insulation, and bonding. Their diverse types cater to different requirements, ranging from renewable energy to automotive applications. Proper material selection and application are crucial for optimal performance and longevity. Foam tapes frequently outperform traditional methods, delivering easier, cleaner, and more durable solutions. By understanding their properties and uses, users can make informed decisions that enhance project quality and efficiency.