Similar Categories

Polystyrene Insulation Board: A Guide to Choosing and Using the Right Product for Your Project

Polystyrene insulation is a popular and versatile material that can be used for various applications, such as building walls and roofs, refrigerators and freezers, industrial cold storage facilities, and underfloor heating systems. Polystyrene insulation is made from a synthetic polymer that has excellent thermal and sound resistance properties and is lightweight, durable, and resistant to water and moisture damage.

In this article, we will explain how polystyrene insulation works, what are the different types and forms of polystyrene insulation, and what are the benefits and drawbacks of using polystyrene insulation for your project. We will also introduce some of the products that you can find on our website, Buy Insulation Online, and how to use them effectively.

How Does Polystyrene Insulation Work?

Polystyrene insulation is a type of rigid, closed-cell foam insulation that is composed of either extruded (XPS) or expanded (EPS) polystyrene. Polystyrene insulation works by trapping air in millions of tiny bubbles inside the foam, which reduces the heat transfer and sound transmission through the material. The thermal performance of polystyrene insulation is measured by its R-value, which indicates how well it resists heat flow.

Polystyrene insulation is a type of rigid, closed-cell foam insulation that is composed of either extruded (XPS) or expanded (EPS) polystyrene. Polystyrene insulation works by trapping air in millions of tiny bubbles inside the foam, which reduces the heat transfer and sound transmission through the material. The thermal performance of polystyrene insulation is measured by its R-value, which indicates how well it resists heat flow.

The higher the R-value, the better the insulation. The R-value of polystyrene insulation depends on whether it is XPS or EPS, and on its density and thickness. Generally, XPS has a higher R-value than EPS, and higher density and thicker polystyrene insulation has a higher R-value than lower density and thinner polystyrene insulation.

For example, XPS board typically ranges from R-4.15 to R-5.2 per inch, while EPS ranges from R-3.85 to R-4.2 per inch. The R-value of polystyrene insulation also depends on the temperature and the moisture content of the material. Polystyrene insulation performs better at lower temperatures and lower moisture levels than at higher temperatures and higher moisture levels.

What Are the Different Types and Forms of Polystyrene Insulation?

Polystyrene insulation comes in two main types: XPS and EPS. XPS is produced by melting and extruding polystyrene resin through a die, forming a continuous sheet of foam that is cut into boards of various sizes and thicknesses. XPS has a smooth and uniform surface, and a higher density and compressive strength than EPS.

XPS is also more resistant to water and moisture absorption than EPS, making it suitable for applications where water exposure is expected, such as below-grade foundations, roofs, and exterior walls. However, XPS is also more expensive and less environmentally friendly than EPS, as it requires more energy to produce and contains ozone-depleting gases.

EPS is produced by expanding polystyrene beads with steam in a mould, forming blocks or shapes of foam that are cut into boards, panels, or other forms. EPS has a rough and porous surface, and a lower density and compressive strength than XPS.

EPS is also more susceptible to water and moisture absorption than XPS, making it less suitable for applications where water exposure is expected, such as below-grade foundations, roofs, and exterior walls. However, EPS is also cheaper and more environmentally friendly than XPS, as it requires less energy to produce and does not contain ozone-depleting gases.

Polystyrene insulation also comes in various forms, such as boards, panels, sheets, rolls, beads, or shapes. The form of polystyrene insulation depends on the type, the application, and the preference of the user.

For example, polystyrene boards are commonly used for wall and roof insulation, polystyrene panels are commonly used for underfloor heating systems, polystyrene sheets are commonly used for packaging and crafts, polystyrene rolls are commonly used for wrapping and cushioning, polystyrene beads are commonly used for filling and moulding, and polystyrene shapes are commonly used for decorative and artistic purposes.

What Are the Benefits and Drawbacks of Using Polystyrene Insulation?

Polystyrene insulation has many benefits and drawbacks that should be considered before choosing and using it for your project. Some of the benefits of polystyrene insulation are:

- It provides excellent thermal and sound insulation, reducing energy consumption and noise pollution.

- It is lightweight and easy to handle, transport, and install, saving time and labour costs.

- It is durable and resistant to water, moisture, mould, insects, rodents, and chemicals, ensuring a long lifespan and low maintenance.

- It is flexible and versatile, allowing for various applications and designs, as well as being easily cut and shaped to fit any space.

- It is inexpensive and widely available, making it an affordable and accessible option for insulation.

Some of the drawbacks of polystyrene insulation are:

- It is flammable and emits toxic fumes when burned, posing a fire hazard and a health risk.

- It is not biodegradable and difficult to recycle, contributing to environmental pollution and waste.

- It is sensitive to ultraviolet (UV) light and high temperatures, causing it to degrade and lose its insulation properties over time.

- It is not breathable and can trap moisture and condensation, leading to potential structural damage and mould growth.

- It can release volatile organic compounds (VOCs) and styrene, which are harmful to human health and indoor air quality.

What Are Some of the Products That You Can Find on Our Website, Buy Insulation Online, and How to Use Them Effectively?

On our website, Buy Insulation Online, you can find a wide range of polystyrene insulation products that suit your needs and preferences. Here are some of the products that we offer and how to use them effectively:

On our website, Buy Insulation Online, you can find a wide range of polystyrene insulation products that suit your needs and preferences. Here are some of the products that we offer and how to use them effectively:

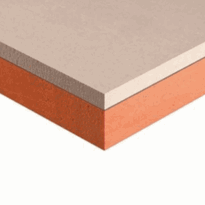

- Warmline EPS Insulated Plasterboard: This is a composite product that consists of an EPS board bonded to a plasterboard, providing both thermal and acoustic insulation, as well as a smooth and ready-to-finish surface. This product is ideal for internal wall and ceiling insulation, as it can be easily fixed to timber or metal studs, or directly to masonry walls, using mechanical fixings or adhesive. This product has an R-value of 2.25 per inch, and comes in various thicknesses, from 22 mm to 82.5 mm.

- Knauf XPS Thermal Laminate Plus Insulated Plasterboard: This is a composite product that consists of an XPS board bonded to a plasterboard, providing both thermal and acoustic insulation, as well as a smooth and ready-to-finish surface. This product is ideal for internal wall and ceiling insulation, as it can be easily fixed to timber or metal studs, or directly to masonry walls, using mechanical fixings or adhesive. This product has an R-value of 3.75 per inch, and comes in various thicknesses, from 27 mm to 67 mm.

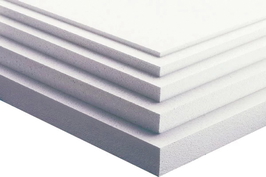

- Jablite Jabfloor EPS70 Polystyrene Insulation Board: This is a product that consists of an EPS board that is designed for floor insulation, providing thermal and sound insulation, as well as a stable and level base for screeds or chipboards. This product is ideal for ground floors, intermediate floors, and suspended floors, as it can be easily laid over concrete slabs, timber joists, or steel beams, using mechanical fixings or adhesive. This product has an R-value of 3.85 per inch, and comes in various thicknesses, from 25 mm to 150 mm.

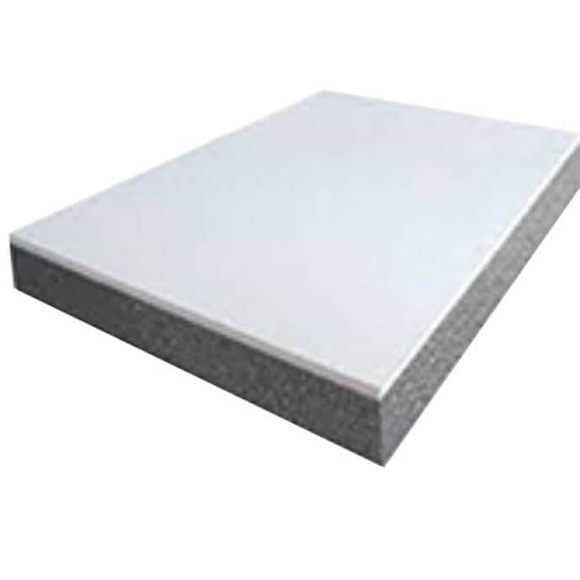

- Prowarm XPS Underfloor Insulation Boards: This is a product that consists of an XPS board that is designed for underfloor heating systems, providing thermal and sound insulation, as well as a high compressive strength and a low thermal conductivity. This product is ideal for underfloor heating systems, as it can be easily laid over concrete slabs, timber joists, or steel beams, using mechanical fixings or adhesive, and then covered with screeds, tiles, or laminates. This product has an R-value of 5 per inch, and comes in various thicknesses, from 6 mm to 50 mm.

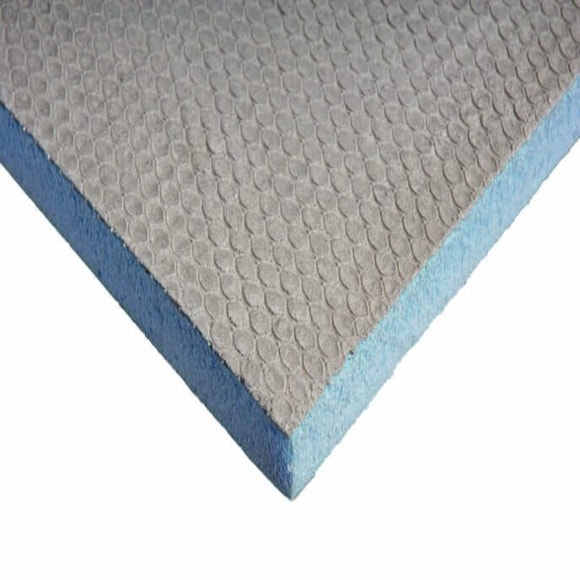

- Marmox Multiboard: This is a product that consists of an XPS board that is coated with a fiberglass mesh and a cementitious layer, providing thermal and sound insulation, as well as a waterproof and fire-resistant surface. This product is ideal for wet areas, such as bathrooms, kitchens, and swimming pools, as it can be easily fixed to timber or metal studs, or directly to masonry walls, using mechanical fixings or adhesive, and then tiled or plastered. This product has an R-value of 4.5 per inch, and comes in various thicknesses, from 4 mm to 50 mm.

- Stylite EPS70 Polystyrene Insulation Board: This is a product that consists of an EPS board that is designed for roof insulation, providing thermal and sound insulation, as well as a lightweight and durable material. This product is ideal for flat roofs, pitched roofs, and inverted roofs, as it can be easily laid over timber or metal decks, or directly to masonry walls, using mechanical fixings or adhesive, and then covered with membranes, tiles, or slates. This product has an R-value of 3.85 per inch, and comes in various thicknesses, from 25 mm to 250 mm.

How to Choose and Use the Right Polystyrene Insulation Product for Your Project?

Choosing and using the right polystyrene insulation product for your project depends on several factors, such as the type and size of your project, the location and climate of your project, the budget and availability of your project, and the performance and preference of your project. Here are some tips and guidelines to help you choose and use the right polystyrene insulation product for your project:

- Determine the R-value that you need for your project, based on the local building codes and the energy efficiency standards that apply to your project. The R-value that you need will depend on the type and location of your project, such as whether it is a wall, a roof, a floor, or an underfloor heating system, and whether it is in a cold, moderate, or warm climate. You can use online calculators or consult with professionals to estimate the R-value that you need for your project.

- Choose the type and form of polystyrene insulation that suits your project, based on the R-value, the application, and the preference that you have for your project. For example, if you need a high R-value, water-resistant, and fire-resistant product for your roof insulation, you may choose XPS board or Marmox Multiboard. If you need a low R-value, breathable, and environmentally friendly product for your wall insulation, you may choose EPS board or Warmline EPS Insulated Plasterboard. If you need a flexible and versatile product for your underfloor heating system, you may choose the XPS panel or Prowarm XPS Underfloor Insulation Board.

- Check the availability and the price of the polystyrene insulation product that you want for your project, based on the quantity, quality, and delivery that you need for your project. You can compare the prices and the reviews of different polystyrene insulation products on our website, Buy Insulation Online, and order the product that you want online. We offer a wide range of polystyrene insulation products at competitive prices and with fast and free delivery across the UK.

- Follow the installation instructions and the safety precautions of the polystyrene insulation product that you use for your project, based on the manufacturer’s guidelines and the best practices that apply to your project. You can find the installation instructions and the safety precautions of the polystyrene insulation product that you buy on our website, Buy Insulation Online, or on the product’s packaging or label. You may also need to use some tools and accessories, such as a utility knife, a tape measure, a straight edge, a hammer, a drill, a saw, nails, screws, washers, adhesives, sealants, tapes, membranes, or protective equipment, to install the polystyrene insulation product properly and safely. You can also find these tools and accessories on our website, Buy Insulation Online, or at your local hardware store.

Conclusion

Polystyrene insulation is a popular and versatile material that can be used for various applications, such as building walls and roofs, refrigerators and freezers, industrial cold storage facilities, and underfloor heating systems.

Polystyrene insulation provides excellent thermal and sound insulation and is lightweight, durable, and resistant to water and moisture damage. However, polystyrene insulation also has some drawbacks, such as being flammable, non-biodegradable, and sensitive to UV light and high temperatures.

Therefore, choosing and using the right polystyrene insulation product for your project is important to ensure the best performance and the lowest cost. On our website, Buy Insulation Online, you can find a wide range of polystyrene insulation products that suit your needs and preferences, as well as the tools and accessories that you need to install them effectively.

We hope that this article has helped you understand more about polystyrene insulation and how to use it for your project. If you have any questions or comments, please feel free to contact us or leave feedback on our website. Thank you for choosing Buy Insulation Online, and we look forward to serving you again soon.