Similar Categories

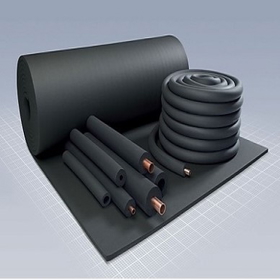

Types of Materials Used in Condensate Pipe Insulation Kits

Condensate pipe insulation kits utilise a variety of materials designed to enhance efficiency and protection.

Polyethylene is a popular choice due to its flexibility, lightweight nature, and ease of installation around different pipe shapes. It also resists moisture, aiding in the prevention of condensation issues.

Polyisocyanurate, a high-performance foam, can withstand high temperatures of up to 300°F and offers excellent fire resistance. It's durable and effectively manages moisture, making it suitable for demanding environments.

Polystyrene provides good insulation for low-temperature pipes, maintaining consistent thermal performance and resisting water absorption.

Polyurethane foam is prized for its high insulating properties and durability, particularly in refrigeration systems.

Lastly, fibreglass and mineral wool are fibrous materials that resist heat and flames, wrapping around pipes of various sizes while ensuring safety and efficiency.

Selecting the Right Insulation Kit for Your Needs

The environment also plays a significant role; outdoor or colder climates in the UK demand thicker or weather-resistant insulation to prevent freezing and withstand the elements.

Pipe size influences the required thickness—larger pipes need more insulation for optimal efficiency.

Additionally, the available installation space may limit your choices regarding thickness.

Compliance with standards such as BS 6798 ensures safety and effectiveness.

Finally, budget and performance goals will guide your selection—cost-effective options can provide a balance between insulation quality and ease of installation.

Benefits of Using Condensate Pipe Insulation

Using condensate pipe insulation offers numerous practical benefits that enhance overall system performance. Insulation helps maintain the right temperature by reducing heat loss, ensuring the system operates efficiently. It also prevents condensation, which can lead to water damage or mould growth, and protects pipes from freezing during cold weather. Additionally, insulated pipes function more smoothly, saving energy and lowering costs. Proper insulation can also extend the lifespan of pipes by minimising thermal stress. Thermal performance is optimized when pipes are properly insulated, which helps in maintaining consistent operation under varying conditions. - Maintains consistent temperatures in pipes for improved system control - Prevents water damage caused by condensation - Protects pipes from freezing and potential bursting - Reduces noise generated by running pipes - Lowers energy bills by enhancing efficiency

Common Applications and Uses

Condensate pipe insulation is widely used across various systems in the UK to enhance efficiency and prevent damage.

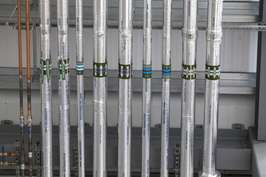

In HVAC and air conditioning systems, it insulates drain pipes to control moisture buildup and prevent freezing, thereby helping to maintain system efficiency by reducing energy loss. It also protects against corrosion caused by condensation on drainage pipes. Proper insulation installation can significantly extend the lifespan of piping systems.

For heat pumps, external insulation kits are designed to shield outdoor waste pipes from freezing, ensuring they operate smoothly during cold weather.

In plumbing applications, insulation is employed to reduce heat loss in hot water pipes and to prevent condensation on cold lines, thereby extending the life of the pipes.

In refrigeration and chilled water systems, insulation minimises energy loss and protects pipes from moisture damage.

Key Factors to Consider During Installation

Choosing the right materials and adhering to proper procedures are essential steps during the installation of condensate pipe insulation. Selecting suitable insulation types, such as foam tubes or fibreglass wraps, ensures effective temperature control and moisture protection.

It's crucial to verify compatibility with the existing HVAC system to avoid complications and to use durable materials that are appropriate for the environmental conditions. Insulation should be thick enough to prevent condensation by maintaining surface temperatures above the dew point, particularly for outdoor or exposed pipes.

Proper installation involves precise cutting, secure fitting, and addressing any gaps or bends. Additionally, safety measures such as switching off power and following manufacturer instructions are vital to avoid accidents.

Paying attention to these factors guarantees a reliable, long-lasting insulation solution that protects the system and optimises performance.

- Use quality insulation materials suited for the environment.

- Ensure insulation fits snugly without compression.

- Follow manufacturer instructions carefully.

- Check for gaps or exposed pipe areas after installation.

- Secure insulation at bends and joints properly.

Standards and Certifications for Insulation Kits

Standards and certifications play a vital role in guaranteeing the safety, quality, and effectiveness of insulation kits used for condensate pipes. They establish clear guidelines that manufacturers must adhere to, providing users with peace of mind. Certifications such as ASTM ensure that materials meet structural and performance standards, while ISO standards address environmental and acoustic concerns. Compliance with these standards indicates that insulation kits are safe, durable, and efficient.

| Standard/Certification | Focus Area | Relevance |

|---|---|---|

| ASTM C547 | Mineral wool insulation | Guarantees high-quality thermal performance |

| ISO 15665 | Acoustic insulation | Promotes noise reduction in industrial settings |

| ASHRAE 90.1-2010 | Energy efficiency | Guides insulation thickness for energy savings |

Adhering to these standards helps communities and professionals belong to a trusted, responsible network dedicated to safety and quality.

Conclusion

Choosing the right condensate pipe insulation kit depends on understanding the available materials, application needs, and installation factors. Proper insulation offers protection against leaks, heat loss, and damage, ensuring safety and efficiency. Considering standards and certifications helps confirm quality and reliability. By selecting suitable materials and following the correct installation steps, users can maximise the benefits of pipe insulation. Overall, informed decisions lead to effective, durable solutions that improve system performance and reduce maintenance costs.