Similar Categories

Plasterboard

What is plasterboard?

Plasterboard is a thin insulation board made of Gypsum. It is most commonly used for construction and insulation purposes. Plasterboards are also called wall boards, Gypsum boards, drylining, wall panels and so on.

What is plasterboard made of?

As mentioned above, plasterboard is made of Gypsum. Calcium sulfate dihydrate is the main component of gypsum. Gypsum is also used in fertilizers, paper, and textile industries.

What are the Advantages or Benefits of plasterboard?

- Plasterboard is lightweight, easy to use, carry and install.

- Plasterboards have a smooth finish, hence can be painted or decorated as required.

- Plasterboards give thermal and acoustic insulation.

What are the different types of plasterboard?

Plasterboards can be attached to insulation like PIR or XPS or can be specialised to fulfil a requirement, like fire insulation, acoustic insulation and so on. Some different types of plasterboards include:

Insulated Plasterboards:

The combination of plasterboard, usually a 12.5mm thick plasterboard, with a PIR insulation board or a polystyrene board gives insulated plasterboard. It provides superior thermal insulation at a low cost and uses less floor space.

We stock plasterboards with insulation or insulated plasterboards here at Buy Insulation Online from brands like Xtratherm and Celotex. We have written two extensive articles about plasterboard insulation which you can find here - Ultimate Guide to Insulated Plasterboard and How To Dot And Dab Insulated Plasterboard

Acoustic Plasterboards:

Acoustic plasterboard is a specialist insulation board. They are used in applications where you need to achieve significant soundproofing. They are made with high-density gypsum, perfect for sound insulation applications.

At Buy Insulation Online, we stock Knauf acoustic plasterboards like Knauf Soundshield Plus and Knauf Sound Panel. They help reduce impact and airborne noise, for an efficient workplace and a quieter, more relaxing home.

We've written a comprehensive article on the subject which you can find here - The Pros And Cons Of Acoustic Plasterboard

Fire Resistance Plasterboards;

Specialist plasterboards are made to offer superior fire insulation or fire resistance. It is ideal for use in high-risk locations. You can buy a Knauf fire board, here, at Buy Insulation Online at a low cost. Knauf Fire Panel has additional fire protection making it perfect for use as a fire barrier in domestic separating walls, garages, etc.

Moisture-resistant Plasterboards

Moisture-resistant Plasterboards are specialist plasterboards perfect for use in internal areas with high humidity like kitchens and bathrooms. Some moisture-resistant plasterboards, like Knauf Vapour Panels, have foil-facings. Foil in itself is moisture-resistant in nature and helps contribute to the application.

What are plasterboards used for?

Plasterboards are versatile in application. They can be used for

- Wall Insulation- separating walls, partition walls

- Roof insulation - ceilings, rafter level

- Kitchen, bathroom and other drylining applications.

How much plasterboard do I need?

Plasterboards are usually made in a standard size, which is about 2.4m long and 1.2m wide. Each board covers an area of 2.88 sq.m

To know the quantity of plasterboard you need, first off, you need to know the square meters you need to cover. Measure the length and width in meters and multiply them to get the square meters. For eg: If you have to cover 50 sq.m, you will need roughly 18 plasterboards

How to cut plasterboard?

Plasterboards are quite easy to cut. They are cut using a sharp knife, a Stanley knife or a fine-toothed saw.

How to fit or install plasterboard?

Mark the plasterboard for the area you intend to cut using a pencil. Now, you have to ensure that when you cut, you cut the plasterboard in a straight line, around 3mm along the cut line.

Stand the plasterboard, turned on its side and bent away from the cut. As you fold the board, it should split cleanly along the line you cut. Use your Stanley knife to cut through the plasterboard holding the board together and smoothen the edges.

If you plan on securing plasterboards to walls or ceilings through nails or screws, you need to insert the nails using a hammer at a distance of about 150-200mm and bout 12mm off the edges of the plasterboard.

For the dot-and-dab method, first, mix the plasterboard adhesive according to the manufacturer's instructions. Fix your pre-cut plasterboards to the wall using the adhesive applied, and press down firmly to secure the installation.

Difference between square edge and tapered-edge plasterboard

Square edge plasterboard has squared, flat edges are plasterboards that are intended to be firmly butted with surrounding boards. Taping or skimming the margins will be necessary. They are perfect for use on ceilings.

Tapered-edge plasterboard is ideal for wall applications. It has a slightly angled edge, which ensures a smooth finish. You can join, plaster, and paint both types of edges

Where to buy plasterboards?

You can buy plasterboards online here at Buy Insulation Online. We stock everything from specialist to regulate plasterboards to insulated plasterboards at a low cost.

What plasterboard can I use for the Ceilings?

You can use moisture-resistant plasterboard for ceilings. If you are looking to soundproof your roof, then we suggest using acoustic plasterboards for the application.

What plasterboard for a bathroom?

As mentioned earlier, for bathrooms and other places that have high humidity, you can use the Knauf moisture panel or other moisture-resistant plasterboards.

If you have any questions on Plasterboards or need help choosing plasterboard for your application, you can contact us via email or call.

Insulated Plaster board

Insulated plaster board, also known as insulated drywall or thermal plasterboard, is a type of building material that is used to insulate and finish the walls and ceilings of a structure.

It is made by glueing a layer of insulation to a layer of plasterboard, which is a type of gypsum board that is commonly used as a finish for walls and ceilings in construction. They are an effective way to meet modern building regulations.

Insulated plasterboards are mainly used to improve insulation and save installation time. Insulation-backed plasterboards also have superior moisture resistance owing to the fact that the materials themselves are usually closed cell and they have built in vapour barriers.

Plasterboards with insulation built in are an ideal choice for new builds and refurbishment projects. They help improve the energy efficiency of a building, save energy and money.

Plasterboards with insulation built in are an ideal choice for new builds and refurbishment projects. They help improve the energy efficiency of a building, save energy and money.

The cost of insulated plasterboard is a lot cheaper than external wall insulation on a square meter basis. They are a good option for those who don't have the budget nor the soffit width for EWS.

There are several different types of insulation like foam insulated plasterboards like PIR, XPS and Phenolic. You also have fibreglass and mineral wool however these are less common than foam backed plasterboard.

The type of insulation used will depend on the specific needs of the building and the climate in which it is located.

For example, foam insulation is a good choice for buildings in colder climates, as it provides a high level of insulation and is resistant to moisture.

What are insulated plasterboards?

Insulated plasterboards are basically insulation boards that combine the need for insulation and drylining. Typically insulated plasterboard is about 2.4m in length and 1.2 wide. It has a 12.5mm or a 9.5mm plasterboard on an insulating material which can be a PIR, extruded or expanded polystyrene.

Applications of plasterboard insulation

Insulated plasterboards can be used for;

- External wall insulation - To insulate external perimeter walls internally

- Internal wall insulation - To insulate partitions between rooms and party walls for building regs

- Ceiling Insulation - To insulate ceilings of rooms

- Room in roof and dormers for use on rafters and joists

- Any Other Applications where plasterboard can be used

Why use insulation backed plasterboard?

Thermal backed plasterboard's offer many advantages over the conventional two-part system of insulation board with plasterboard fitted separately. Here are just a few;

Thermal Backed Plasterboard Saves On Labour Installation Time

Insulation-backed plasterboard reduces installation time and can eliminate the need to install two separate products. Since labour costs constitute the most part of a project usually, it can mean big savings.

It is easy to work with, as it can be cut and shaped like regular plasterboard, and it is lightweight, making it easy to transport and install.

They lower energy bills

One of the main benefits of insulated plasterboard is its ability to improve the energy efficiency of a building.

By adding an extra layer of insulation, insulated plasterboard helps to reduce heat loss and keep a structure warm in the winter and cool in the summer.

This can result in significant energy savings over time, as well as a more comfortable living or working environment.

Insulated plasterboards are a low-cost way to stop heat loss and reduce your heating bills. Studies have shown that walls can lose as much as 16% to 25% of heat.

With its excellent insulation properties, this material can make a big difference in the heating and cooling efficiency of a building. By lining the walls with insulated plasterboard, you'll lower your heating bills and protect the environment.

Act as a vapour barrier

If you use foil backed insulation plaster boards, you can save even more time and hassle because the foil acts as a vapour barrier.

However, it can be difficult to make sure that the vapour barrier remains intact along the joints so care must be taken. Most Insulated plasterboards typically come with an in-built vapour layer and hence have superior moisture resistance.

Types of Insulated plaster boards

Insulated plasterboards can be of different types based on the type of insulating material:

PIR Plasterboard

This is the most common type of insulated plasterboard. Most insulation manufacturers make PIR-backed plasterboards. They have an extremely low thermal conductivity of 0.022 W/mK, which ensures that the heat stays in.

PIR-backed insulated plasterboards have zero GWP and ODP. PIR boards are backed on 12.5mm thick gypsum plasterboards with paper facings.

At Buy Insulation Online, we stock Celotex insulated plasterboards - Celotex PL4000 and Xtratherm - Xtratherm Thermal Liner at a low cost.

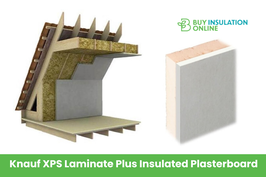

Expanded polystyrene-backed plasterboards:![Knauf XPS laminate plus]()

Plasterboard with polystyrene backing is extremely popular and there are 2 varieties, XPS thermal plaster boards and EPS polystyrene backed plasterboard too.

Here, expanded polystyrene boards of varying thicknesses, are backed on a 9.5mm plasterboard. They can be used for new builds and refurbishment projects alike.

Polystyrene backed plasterboards can be used to insulate walls and ceilings. At Buy Insulation Online, we stock Knauf thermal laminates, which are a range of EPS boards backed on plasterboards.

Extruded Polystyrene plasterboards

These insulated plasterboards combine the insulation efficiency and compressive strength of extruded polystyrene with the drylining applications of plasterboard.

Here the extruded polystyrene is backed on a 9.5mm thick, tapered edge plasterboard. It is possible to get 27mm thermal plasterboard by using Knauf XPS laminate plus, which is one of our best-selling insulation boards.

In our opinion, Knauf XPS laminate plus is the best plasterboard with insulation on the market when it's based on pure performance by cost.

Phenolic Backed Plasterboard

Phenolic foam is an extremely light-weight and effective insulator, providing excellent thermal performance as well as fire resistance. It delivers a level of performance that is unparalleled in the world of thermoset insulation materials, providing a thermal conductivity of only 0.018 W/mK across all thicknesses.

Phenolic insulated plaster boards can come as thin as 37.5mm. This thin insulated plasterboard is made up of a 25mm layer of phenolic foam with a layer of 12.5mm plasterboard bonded to it. This means less precious room space is taken up by walls.

How to install thermal insulated plasterboard?

Insulated Plasterboards can be fixed using the following methods;

- Dot and dab method using dollops of drywall adhesive on a brick wall. Check out our blog which talks about this method in more detail here - How to Dot and Dab Insulated Plasterboard

- Screwed to timber battens which are themselves screwed to the wall

- Screwed directly to the wall with wall plug and screws, although it must be said that screwing insulated plasterboards directly to the wall is not recommended due to the chance of thermal bridging through the screws.

- Floating wall method involves building a stud wall away from the current wall leaving an air gap between the 2 walls.

Things to consider before installing Insulated Plasterboard![installing insulated plaster board]()

Is the wall damp?

You will need to be careful if the wall you are intending to insulate is damp. This dampness could penetrate through the fixings and insulated plasterboard too. It is recommended you remedy the source of dampness first or in some cases, it is acceptable to build a floating wall out from the damp wall, but you will lose a lot more space this way.

You will lose room space

You will lose floor space by lining your walls because they will become thicker. The difference won't be noticeable in most cases except in very small cloakrooms, bathrooms and kitchens.Once all is said and done, you will lose around 65mm of space at a minimum using insulated plasterboard.

Mechanical and Electrical Services

Probably the biggest obstacle to retrofitting insulated plasterboard easily on existing walls is the fact that all of the heating pipes, radiators and electrical sockets and switches will all need isolating, removing and refitting once the insulation plasterboard is fitted. You will need to take this into consideration.

Hanging heavy fixtures

The same as above, in bathrooms and kitchens you will have to remove sinks and other fixtures to get to all of the wall behind them. It is important to plan carefully for remounting these fixtures in advance in order to ensure adequate support.

For stud walls, thick timber battens and noggins can be strategically positioned to align with fixing points before the insulation is installed. To provide a strong support in masonry walls, screw all the way through to the underlying brick.

What fixings for insulated plasterboard?

You can use standard drylining screws for insulated plasterboard, although if you are screwing directly into masonry walls you might want to use something like Insofast screws which help prevent thermal bridging. For dot and dab, you can use any kind of plasterboard adhesive.

Can you overboard existing plasterboard walls and ceilings with insulated plasterboards?

It is common practice to overboard ceilings and walls. Before using insulated plasterboard for ceilings, you must locate the ceiling joists.

In most UK houses, they are spaced at 600mm or 400mm centers and run along the shortest side. In order to find wall studs, you will need a stud detector. A professional builder is best consulted if the existing plasterboard has been dotted and dabbed.

Where to Buy Insulated Plasterboards?

You can buy insulated plasterboards right here at Buy Insulation Online, however they can be picked up from your local hardware store such as B&Q, Wickes and Homebase if preferred.

We offer delivery and click and collect for PIR insulated plasterboards, EPS and XPS insulated plasterboards with big name brands such as Kingspan and Knauf represented.

If your looking for plasterboard with insulation prices on larger projects, get in touch to see if we can offer you a further

What are standard insulated plasterboard sizes?

The standard size is usually 2400mm x 1200mm

What is the standard insulated plasterboard thickness?

There is no one standard thickness, although 50mm insulated plasterboard is a highly searched term although the actual size of most insulated plasterboard will be 62.5mm, which is 50mm thermal insulation board and 12.5mm drywall combined.

In Summary

Insulated plasterboards help save energy, money and much-coveted floor space (when used for internal wall insulation). If you need any help with your purchase or need to enquire about insulated plasterboards that we do not usually have in stock, email or call us and we will do our best to help you out.

Overall, insulated plasterboard is a versatile and effective building material that can help to improve the energy efficiency and comfort of a building. Whether you are building a new home or renovating an existing one, considering the use of insulated plasterboard can be a smart investment that will pay off in the long run.

More Resources On Plasterboards and Plasterboard Insulation

You can see some videos we have made on pipe insulation on our Youtube Channel here -

We have also written extensive articles on the subject which you can find here - Pipe Insulation Articles

Chilled Water Pipe Insulation - A Brief Guide / Everything You Need To Know About Phenolic Pipe Insulation / Soil Pipe Insulation: A Step-By-Step Guide / Tips On Preventing Condensation On Pipes / What Is Pipe Lagging? A Short Buyers Guide / Which Is The Right Pipe Lagging For You? / Insulate Pipes To Stop The Spread Of Legionnaires' Disease / Why You Need Pipe Insulation? / Benefits Of Using Nitrile Rubber Pipe Insulation / Why Pipe Insulation In Your Loft And Other Cold Spaces Is A Must. / How To Install Pipe Insulation Yourself? / 10 Things To Consider When Choosing Pipe Insulation Thickness / Are Your Pipes Winter- Ready? / Why Is Pipe Insulation Important?

Take a look at Isovers official website for their Fiberglass Pipe Insulation https://www.isover-technical-insulation.com/hvac-pipe-insulation

Insulating a Single Skin Block Wall with Insulated Plasterboard and Boxing in Windows: A Step-by-Step Guide

In this article, we will be discussing the process of adding insulated plasterboard to a single skin block wall and boxing in windows. We will cover the measurements, cutting, and installation of the plasterboard, as well as the importance of addressing moisture issues and preventing cold bridging. Additionally, we will explore the purpose of this insulation project and its role in resolving mould and condensation issues. So, let's dive into the details!

Step 1: Measurements and Diagram Creation

The initial step in this project is to take accurate measurements of the wall and create a diagram. This diagram will serve as a guide to cut the plasterboard to the correct size. The goal is to complete the entire wall with a minimal amount of boards to minimize costs.

Step 2: Cutting the Plasterboard

Using a straight edge, score the paper on the plasterboard to the desired depth. Once the score is deep enough, the board can be snapped along the line. The insulation boards used in this project are called Knauf Insulated Plasterboard, which consists of plasterboard mounted to a polystyrene insulation. Unlike other types of insulation, this particular product does not have a thin foil layer between the plasterboard and the insulation to act as a vapor barrier. The closed-cell structure of the foam acts as an integral vapor barrier.

Step 3: Addressing Moisture Issues

While retaining heat is not the primary objective of this project, it is essential to prevent moisture-related problems such as mold and condensation. In a previous video, a damp proof membrane (DPM) was applied to the floor to prevent moisture transfer. This was necessary because the damp proof course level had been compromised by a high concrete floor. By creating an air gap at the bottom of the plasterboard using glazing packers, any moisture from the ground is prevented from reaching the plasterboard.

Step 4: Ensuring Straightness and Levelness

To ensure the first board is fitted correctly, a laser level is used. The floor's unevenness is compensated for by adding extra packers to achieve a level installation. Additionally, any obstacles, such as a copper pipe, are marked and cut around to maintain a seamless fit against the wall.

Step 5: Marking and Cutting Window Openings

Using the laser level once again, the position of the windows is marked on the plasterboard. Precise cutouts are made using a multitool, speeding up the process of cutting through both the plasterboard and insulation. Air vents are also taken into account and marked for accurate cutouts, although these do not require as much precision.

Step 6: Installing the Plasterboard

With the first board in position and the adhesive applied, it is pressed firmly against the wall. The adhesive used is plasterboard foam adhesive, which creates a full bead around the perimeter to prevent cold bridging. The adhesive needs a few minutes to become tacky before pressing the board in place. A long spirit level is used to ensure the board sits true. The same process is repeated for subsequent boards.

Key Takeaways:

- Insulating single skin block walls with insulated plasterboard can help prevent mold and condensation issues.

- Knauf Thermal Laminate, is an insulation board consisting of plasterboard and polystyrene insulation.

- Creating a diagram based on accurate measurements ensures precise cuts and cost-effective use of materials.

- Addressing moisture issues, such as using a damp proof membrane, is essential to maintain the integrity of the insulation.

- Laser levels help ensure straightness and levelness during installation.

- Careful marking and cutting of window openings and air vents are necessary for a seamless fit.

Frequently Asked Questions (FAQs):

Q1. Why is single skin block insulation necessary?

A. Single skin block walls lack a cavity, which can make them prone to issues such as mold and condensation. Insulating these walls helps resolve these problems and improves overall comfort.

Q2. Does the absence of a vapor barrier foil affect the effectiveness of the insulation?

A. No, the closed-cell structure of the foam insulation acts as an integral vapor barrier in itself, eliminating the need for an additional foil layer.

Q3. What is cold bridging, and why is it important to prevent it?

A. Cold bridging refers to areas where heat can escape more easily, typically caused by gaps or uninsulated sections. To maintain an energy-efficient and comfortable space, it is crucial to prevent cold bridging by creating a continuous insulation layer.

Q4. How does an uneven floor affect the installation process?

A. An uneven floor can pose challenges during installation, as it may require additional packers or adjustments to ensure a level and seamless installation.

Q5. Are there any additional steps to address moisture issues besides using a damp proof membrane?

A. In cases where the damp proof course level has been compromised, cutting away a channel in the high concrete floor can help resolve moisture-related problems by preventing moisture from breaching the DPC.

Conclusion:

Insulating a single skin block wall with insulated plasterboard and boxing in windows provides an effective solution to regulate moisture, prevent mold and condensation, and improve overall thermal efficiency. By following the step-by-step guide outlined in this article, you can ensure a successful installation that contributes to a healthier and more comfortable living or storage space. Remember to take accurate measurements, create a diagram, address moisture issues, prevent cold bridging, and use the appropriate adhesive for a seamless and long-lasting insulation solution.