- Blogs

- Acoustic Plasterboard: Your Comprehensive Guide to a Quieter Environment

Acoustic Plasterboard: Your Comprehensive Guide to a Quieter Environment

Introduction: The Quest for Quiet – What is Acoustic Plasterboard?

In today's bustling world, unwanted noise is an increasingly common intrusion in both our homes and workplaces. Whether it is the sound of traffic, noisy neighbours, or simply the activities within a busy household or office, excessive noise can affect concentration, increase stress levels, and diminish overall comfort. The search for effective solutions to mitigate sound transmission has led to the development of specialised building materials, among which acoustic plasterboard plays a pivotal role.

Acoustic plasterboard, also known by terms such as sound plasterboard, sound-resistant plasterboard, or often colloquially in the UK as "blue plasterboard" due to its typical facing paper colour, is a high-performance building material specifically engineered to reduce noise transmission through walls and ceilings. Sometimes also generally referred to as soundboard, its primary purpose is to enhance sound insulation in situations where greater levels of peace and quiet are desired or mandated. This makes it a favoured choice for a wide array of applications, including residential properties (particularly between flats or terraced houses to reduce neighbour noise or media sounds), commercial buildings, hospitals, schools, music studios, and home cinemas.

Fundamentally, acoustic plasterboards achieve their superior sound-dampening qualities through a higher density core compared to standard plasterboard. This increased density is crucial for impeding sound waves. The material is typically based on gypsum, like its standard counterparts, but is often reinforced with additional materials or manufactured using processes that augment its density and sound-absorbing characteristics. It is important to recognise that acoustic plasterboard is often most effective when used as part of a comprehensive soundproofing system, working in conjunction with other materials such as soundproofing insulation and acoustic sealants.

The growing demand for such materials reflects a broader societal trend. As urban living becomes denser and homes increasingly serve as spaces for work, education, and entertainment, the control of noise is transitioning from a luxury to a fundamental requirement for well-being and productivity. The pursuit of "peace and quiet" is a direct response to this environmental pressure. Beyond its primary acoustic function, the inherent higher density of acoustic plasterboard often brings secondary benefits, such as improved impact resistance and fire resistance. This multi-functional aspect can be advantageous, potentially simplifying material selection and streamlining construction in projects where these additional performance characteristics are also valued.

The Science of Silence: How Soundproof Plasterboard Actually Works

Understanding how acoustic plasterboard contributes to a quieter environment requires a basic grasp of how sound travels in buildings and the principles employed to counteract it.

Understanding Sound Transmission in Buildings

Sound typically travels through buildings in two primary ways:

- Airborne Sound: This includes sounds that originate in the air and travel through it, such as voices, music, or television noise. These sound waves can pass through lightweight or poorly sealed structures.

- Impact Sound: This type of sound is generated by a direct impact on a building element, such as footsteps on a floor, a door slamming, or objects being dropped. The vibrations from the impact travel through the building's structure.

A critical concept in soundproofing is flanking transmission. This occurs when sound bypasses a sound-insulated element (like a wall or floor) by travelling along alternative paths. These paths can include adjoining walls, floors, ceilings, and even voids within the structure. For instance, even if a wall is treated with high-performance acoustic plasterboard, sound might still travel from one room to another through the floor or ceiling, or via an uninsulated cavity above a partition. The effectiveness of any soundproofing treatment, including acoustic plasterboard, can be significantly compromised if these flanking paths are not adequately addressed. This underscores the necessity of a holistic design approach; treating a single element in isolation may yield disappointing results if sound can easily circumvent it.

A clear understanding of the dominant type of noise is essential before selecting a soundproofing strategy. Acoustic plasterboard is primarily designed to tackle airborne sound due to its increased mass. While it can contribute to reducing some structural vibration, it is generally less effective against direct impact noise unless incorporated into a more complex system designed for that purpose. Applying it without diagnosing the specific noise problem – for example, expecting it to solve heavy footfall noise from above without treating the floor structure itself – can lead to unsatisfactory outcomes and wasted resources.

Key Soundproofing Principles at Play

Acoustic plasterboard, particularly when used within a soundproofing system, leverages several scientific principles to reduce noise transmission:

- Mass and Density (Deflection): This is the cornerstone of how acoustic plasterboard works. The "mass law" in acoustics suggests that the heavier and denser a barrier, the more effectively it will reduce the transmission of airborne sound. Sound waves striking a high-mass surface cause it to vibrate less readily, and less sound energy is transferred through to the other side. Acoustic plasterboards are manufactured with a significantly higher density core than standard plasterboards. For example, some specialised acoustic boards can be up to 30% heavier than their standard counterparts of the same thickness. This increased mass provides a more substantial barrier to deflect sound energy.

- Sound Absorption: While acoustic plasterboard itself is primarily a reflective (sound-blocking) material due to its dense, non-porous surface, it is frequently used in conjunction with sound-absorbent materials. Porous materials, such as acoustic mineral wool or fibreglass (types of soundproofing insulation), are installed within wall or floor cavities. These materials work by trapping sound waves and converting their energy into tiny amounts of heat, thereby reducing sound resonance and reverberation within the cavity. This prevents the cavity from acting like a drum and amplifying sound.

- Decoupling (Isolation): This principle involves creating a physical separation between elements of a structure to break the path of sound vibrations. If plasterboard is fixed acoustic plasterboard directly to studs, vibrations can easily travel from the board through the studs and into the structure on the other side. Decoupling techniques, such as using resilient bars or acoustic clips, create a flexible connection between the plasterboard and the framing. This separation significantly reduces the amount of sound energy that can be transmitted structurally. This is particularly effective at interrupting flanking transmission paths.

- Damping: Damping involves the dissipation of vibrational energy within a structure, typically by converting it into heat. This can be achieved by using specialised damping compounds applied between layers of rigid material, such as two sheets of plasterboard. When sound waves cause the first layer of plasterboard to vibrate, the damping compound creates frictional forces that reduce the vibration transmitted to the second layer. While standard acoustic plasterboard isn't inherently a damping material in this specialised sense, its higher density can contribute to some reduction in resonance compared to lighter boards.

The most significant improvements in sound insulation are typically achieved when acoustic plasterboard is used as part of a system that intelligently combines these principles. For instance, a high-performance acoustic wall might consist of a stud frame with acoustic mineral wool in the cavities (absorption), resilient bars fixed to the studs (decoupling), and one or two layers of acoustic plasterboard fixed to the resilient bars (mass). The synergistic effect of these combined elements is far greater than relying on mass alone. While simply increasing mass by adding layers of plasterboard does provide some benefit (theoretically, doubling mass can improve sound insulation by up to 6dB), this "law of diminishing returns" can set in, especially if factors like structural stiffness or resonance are not managed. At a certain point, incorporating decoupling or absorption becomes more critical for achieving substantial improvements than merely adding more mass.

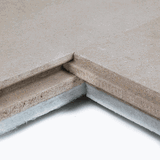

Inside Acoustic Plasterboard: Materials and Composition ![]()

The performance of acoustic plasterboard stems directly from its specific materials and construction.

The Core Components

The fundamental ingredient of acoustic plasterboard is gypsum, a naturally occurring mineral. The gypsum is processed to form a non-combustible core, which is a key safety feature. What distinguishes acoustic plasterboard is the higher density of this gypsum core compared to that found in standard plasterboard. This increased density is achieved through specific manufacturing processes and, in some cases, the inclusion of specialised additives within the gypsum mix. These additives not only contribute to the board's mass but can also enhance other properties such as surface hardness and impact resistance. The precise nature of these additives is often proprietary to the manufacturer, but their role in boosting density is crucial for the board's acoustic capabilities. As a direct consequence of this higher density, acoustic plasterboards are noticeably heavier than standard boards of the same dimensions; for example, Siniat's GTEC dB Board is stated to be 30% heavier than standard plasterboard.

Facing Materials

The dense gypsum core of acoustic plasterboard is typically encased in paper liners on both faces and along the long edges. For acoustic plasterboards, one of the most recognisable features is the colour of the front-facing paper. It is very commonly a distinctive blue (or sometimes green, though blue is more prevalent for acoustic grades in the UK). This has led to the widespread colloquial term "blue plasterboard." This colour-coding is not merely aesthetic; it serves as a practical, industry-wide visual cue that helps in the easy identification of the board type on busy construction sites and assists consumers and tradespeople in verifying they are using the correct specialised product. The paper facings are designed to provide a smooth surface suitable for direct decoration, such as plastering, painting, or wallpapering, after appropriate jointing and preparation. The long edges are typically a tapered edge, facilitating seamless jointing.

Layering

While the term "sandwich construction" is sometimes used, this typically refers to the basic structure of the gypsum core being encased between the two paper liners. The primary soundproofing benefit of an individual acoustic plasterboard sheet comes from the inherent high density of its core. However, in practical applications, sound insulation is often achieved by using multiple layers of acoustic plasterboard within a wall or ceiling assembly. For even greater performance, other materials like mass-loaded vinyl (MLV), which is a very dense, flexible material, or specialised damping compounds can be sandwiched between these layers of acoustic plasterboard. This layering approach further increases the overall mass of the partition and can introduce damping effects, significantly boosting its sound-blocking capabilities.

Choosing the Right Board: Types of Acoustic Plasterboard in the UK

The UK market offers a variety of acoustic plasterboard options, catering to different performance requirements and specific application needs.

Standard Acoustic Plasterboards (often "Blue Plasterboard")

These are the most commonly encountered types, primarily characterised by their high-density gypsum core and, typically, a blue paper facing for easy identification. They are available in a range of thicknesses, with 12.5mm and 15mm being the most prevalent for general acoustic applications. Some manufacturers also offer thicker boards, such as 19mm, or even more specialised composite boards like the Resonate ResoBoard series which can be 27mm or 30mm thick, designed for higher performance requirements.

The standard board dimensions are usually 2400mm x 1200mm, although some specialised boards may come in different sizes, for example, 1200mm x 1200mm. The edges of the boards are typically a tapered edge, which allows for effective jointing with tape and jointing compound to create a seamless surface ready for skimming or decoration. Square edge boards may also be available and are sometimes preferred for textured finishes, though less common for acoustic applications where a smooth, airtight finish is paramount.

Branded Product Lines

Several major manufacturers supply acoustic plasterboard in the UK, each with their own branded product lines:

- British Gypsum: A prominent name, offering products like Gyproc SoundBloc (a widely recognised acoustic board), Gyproc SoundBloc F (which combines acoustic performance with fire resistance), and Gyproc SoundBloc MR (offering both acoustic properties and moisture resistance). They also produce Gyproc DuraLine, which, while primarily focused on impact resistance, has a higher density that contributes to acoustic performance.

- Knauf: Another key supplier, with products such as Knauf Sound Panel and Knauf Soundshield Plus.

- Siniat: Offers the GTEC dB Board (also known as GTEC Sound Board), noted for its distinctive blue paper and specific acoustic performance data.

- Resonate Systems: Provides specialised, thicker acoustic boards like ResoBoard 3 and ResoBoard 4, often used where higher levels of sound insulation are required.

- Gypfor: Supplies products such as Gypfor Sound Acoustic Plasterboard.

Buy Acoustic Plasterboard Now!

Acoustic Performance (Rw values)

The acoustic performance of a material or partition is often quantified using the Weighted Sound Reduction Index (Rw), measured in decibels (dB). A higher Rw value indicates better airborne sound insulation – meaning less sound passes through the barrier.

It is crucial to understand that the stated Rw value for an acoustic plasterboard is highly dependent on the entire construction assembly in which it is used, not just the board in isolation. For example:

- A single layer system of 15mm Siniat GTEC dB Board is stated to achieve 49 Rw dB sound insulation and also provide 30 minutes of fire resistance.

- Systems using 12.5mm acoustic plasterboard on metal studs, incorporating acoustic mineral wool (AMW) – a type of soundproofing insulation – in the cavity, can achieve Rw values ranging from 43 dB (for a single layer of plasterboard on each side of 50mm studs) up to 56 dB (for two layers of plasterboard on each side of 146mm studs).

These examples clearly show that factors such as stud type and size, the presence and type of cavity insulation, and whether single or double layers of plasterboard are used, all significantly influence the final acoustic performance. Therefore, when comparing products or designing for a specific acoustic target, it is essential to refer to the Rw values for the complete tested system, not just an isolated board. While "blue plasterboard" is a common identifier, the actual acoustic performance can vary significantly between a standard 12.5mm blue board and a thicker, specialised product; checking specific product data sheets for performance metrics relevant to the intended application is vital.

Specialised Acoustic Plasterboards

The market has evolved to offer a spectrum of acoustic plasterboards that combine sound insulation with other desirable properties, catering to diverse and specific building needs. This indicates a mature market responding to complex project requirements, often simplifying specification and installation by reducing the need for multiple single-function board types. Key examples include:

- Fire-Resistant Acoustic Plasterboard: Products like British Gypsum's Gyproc SoundBloc F are engineered to provide both sound insulation and increased fire resistance, contributing to building safety.

- Moisture-Resistant Acoustic Plasterboard: Such as British Gypsum's Gyproc SoundBloc MR, these boards are designed for use in areas prone to humidity, like kitchens and bathrooms, where sound control is also a priority. They incorporate additives to resist moisture absorption.

- Impact-Resistant Acoustic Plasterboard: Boards like British Gypsum's DuraLine are designed for greater durability and resistance to impact, but their higher density also inherently improves acoustic performance. Gypfor Sound Acoustic Plasterboard also notes improved impact resistance as a feature.

- Insulated Plasterboard with Acoustic Properties: Some products, like Celotex PL4065 (an insulated plasterboard), combine thermal insulation with a plasterboard facing, which can offer some degree of acoustic benefit, although dedicated acoustic plasterboards typically offer superior sound insulation.

The following table provides a summary of common UK acoustic plasterboard types and brands:

Table 1: Overview of Common UK Acoustic Plasterboard Types/Brands

| Brand Name | Product Line(s) | Common Thicknesses (mm) | Typical Board Sizes (mm x mm) | Key Features | Indicative Acoustic Performance (System Dependent) |

| British Gypsum | Gyproc SoundBloc, SoundBloc F, SoundBloc MR | 12.5, 15 | 2400mm x 1200mm, other lengths | High density, Blue paper (SoundBloc), Fire-rated (F), Moisture-resistant (MR) | Up to 50+ Rw dB in specific systems |

| Knauf | Sound Panel, Soundshield Plus | 12.5, 15 | 2400mm x 1200mm | High density, Blue paper face | Performance varies with system design |

| Siniat | GTEC dB Board (GTEC Sound Board) | 12.5, 15 | 2400mm x 1200mm | High density, Blue paper face, Good acoustic and fire performance | 15mm board: 49 Rw dB (single layer system) |

| Resonate Systems | ResoBoard 3, ResoBoard 4 | 27, 30 | 1200mm x 1200mm | Composite board, High mass, Designed for acoustic isolation | Higher Rw values achievable due to thickness and composition |

| Gypfor | Sound Acoustic Plasterboard | 12.5, 15 | 2400mm x 1200mm | Surface hardness, Impact resistance, Blue paper | Performance varies with system design |

Note: Performance figures are indicative and highly dependent on the entire construction system. Always refer to manufacturers' specific system data.

The Upsides: Key Advantages of Using Acoustic Plasterboard

Employing acoustic plasterboard in construction and renovation projects offers several significant benefits, primarily centred around creating quieter and more comfortable indoor environments.

- Effective Noise Reduction: The most prominent advantage is its ability to significantly reduce noise transmission between rooms and from external sources. This creates a more peaceful and private atmosphere, which is particularly valuable in residential settings to minimise disturbances from neighbours or other household members, and in commercial spaces to improve concentration and confidentiality. Some sources also suggest that by providing a denser surface, acoustic plasterboard can help in managing noise within a room by reducing echoes and reverberation, thereby improving the overall acoustic performance, especially in larger spaces or those with many hard surfaces.

- Privacy and Comfort: By effectively blocking sound, acoustic plasterboard contributes directly to increased privacy and comfort. This is crucial for residential buildings such as flats and terraced houses, as well as in environments like offices, hotels, and healthcare facilities where a quiet and private atmosphere is essential for well-being and operational efficiency. The "comfort" and "privacy" benefits extend beyond mere technical performance to the overall quality of life and can even contribute to the perceived value of a property, especially in densely populated urban areas or multi-dwelling units where noise from neighbours is a common concern.

- Improved Fire Resistance: The higher density core inherent in many acoustic plasterboards often contributes to better fire resistance compared to standard plasterboard options. Gypsum itself is a non-combustible material, and the increased mass means it takes longer for fire to penetrate. Some acoustic plasterboard products are specifically engineered and tested as fire-rated boards, such as British Gypsum's Gyproc SoundBloc F or Siniat's GTEC dB Board, a single 15mm layer of which can achieve 30 minutes of fire resistance as part of a partition system. This dual benefit of acoustic performance and fire safety can be a significant advantage.

- Increased Impact Resistance: Some acoustic plasterboards also offer surface hardness and impact resistance due to their greater density and the inclusion of specialised additives in their composition. This makes them more durable and less prone to damage from everyday knocks and bumps, which can be beneficial in high-traffic areas.

- Versatility: Acoustic plasterboard is a versatile material suitable for use in a wide range of applications, including walls, ceilings, and partition systems across various building types, from residential to commercial and institutional settings.

The multi-benefit nature of some acoustic plasterboards – offering acoustic, fire, and sometimes impact resistance in a single product – can lead to material consolidation on projects. If a partition requires both sound insulation and a specific fire rating, using a board like Gyproc SoundBloc F or Siniat GTEC dB means that only one type of board needs to be sourced, handled, and installed. This can simplify logistics, potentially reduce labour time, and may even offer cost savings compared to installing separate layers of fireboard and standard acoustic board.

The Downsides: Potential Disadvantages and Considerations

While acoustic plasterboard offers substantial benefits, there are also potential disadvantages and considerations that need to be taken into account during the planning and execution of a project.

- Higher Cost: One of the primary drawbacks is that acoustic plasterboard is generally more expensive than standard plasterboard. This increased upfront cost can be a significant factor for budget-sensitive projects. However, this initial expense needs to be weighed against the long-term benefits of improved acoustic comfort, privacy, and potentially increased property value or productivity in a commercial setting. A careful cost-benefit analysis is often warranted.

- Increased Thickness and Weight: Acoustic plasterboards are typically thicker and, due to their higher density, considerably heavier than standard plasterboard sheets of the same dimensions. This increased weight can have several implications:

- It may necessitate adjustments to door frames, window reveals, electrical back boxes, and other fittings to accommodate the greater thickness.

- The additional load might require consideration of the existing structure's capacity, especially in older buildings or when adding multiple layers to ceilings. In some cases, additional structural support may be needed.

- Manual handling can be more challenging, potentially requiring two people to lift and fix boards, which can affect installation time and labour costs. These are not minor inconveniences and can have tangible knock-on effects on project timelines and overall budgets.

- Installation Complexity: Although the basic installation methods for acoustic plasterboard are similar to those for standard plasterboard, achieving optimal acoustic performance demands meticulous attention to detail. Simply substituting acoustic plasterboard for standard board without considering the entire system may yield disappointing results. Effective soundproofing relies on correct installation techniques, such as properly sealing all gaps and joints, and often involves the use of decoupling methods like resilient bars. Fixing acoustic plasterboard directly to the framing without such decoupling, while possible, offers significantly less sound insulation. Incorrect installation, such as creating "short circuits" by screwing resilient bars directly to framing or leaving unsealed air paths, can significantly reduce the board's effectiveness. The investment in premium acoustic plasterboard can be undermined if the system is not implemented according to best practices, highlighting the importance of skilled installers or thorough research for DIY applications.

- Potential for Overly Dampened Sound (Less Common with Plasterboard Alone): While this is more commonly associated with the excessive use of highly absorptive acoustic panels in a room, making a space sound "dead" or unnatural, it is a theoretical consideration. Acoustic plasterboard primarily functions by blocking sound transmission between spaces rather than absorbing large amounts of sound within a room. Therefore, the risk of over-dampening a room with acoustic plasterboard alone is relatively low unless it's combined with extensive soft furnishings and other highly absorptive surface treatments.

- Limitations Against Certain Frequencies and Noise Types: While effective against a broad range of airborne sound, particularly mid to high frequencies, acoustic plasterboard alone may struggle to mitigate very low-frequency noise (such as deep bass from music systems) or significant impact noise (like heavy footfall from above). These types of noise often require more specialised and comprehensive soundproofing strategies, such as dedicated bass traps, floating floors, or very high-mass constructions.

Best Practices for Installing Acoustic Plasterboard in the UK

To maximise the soundproofing potential of acoustic plasterboard, adherence to best installation practices is crucial. The effectiveness of the material is heavily reliant on how it is incorporated into a complete system.

Substrate Preparation

Before installation, ensure that the substrate (studwork, existing wall, or ceiling joists) is structurally sound, stable, clean, and capable of supporting the additional weight of the acoustic plasterboard. If installing onto an existing ceiling to add resilient bars, it may be necessary to first fix timber battens to the ceiling, ensuring these are securely screwed through to the joists and not just into the old plasterboard layer.

Decoupling with Resilient Bars (Highly Recommended for Optimal Performance)

For superior sound insulation, decoupling the acoustic plasterboard from the building structure is highly recommended. This is commonly achieved using resilient bars (also known as resilient channels):

- On walls, resilient bars should be installed horizontally, typically at 600mm centres, running from floor to ceiling. The narrow fixing flange of the bar should be positioned along the bottom edge, allowing the weight of the plasterboard to naturally pull it slightly away from the framing, enhancing the decoupling effect.

- On ceilings, the bars should be spaced at 400mm to 450mm centres and fixed across (perpendicular to) the joists or battens, as well as around the perimeter of the room.

- Crucially, when fixing the plasterboard to the resilient bars, the screws used must not penetrate through the bars into the studs or joists behind them. Doing so would create a rigid connection, or "short-circuit," bypassing the resilient bar and drastically reducing its decoupling effectiveness. It is advisable to carefully mark the positions of studs/joists and resilient bars before boarding.

Buy Acoustic Plasterboard Now!

Fixing the Plasterboard ![]()

- For best performance, using a double layer of 12.5mm (or thicker) high-density acoustic plasterboard is a common best practice.

- All joints in the plasterboard should be staggered, both between layers (if using a double layer) and between adjacent boards in the same layer. This helps to prevent continuous air paths for sound. This is easier to manage with boards featuring a tapered edge.

- Boards should be fitted to within approximately 3mm of surrounding walls, ceilings, and floors to allow for sealing.

- Secure the plasterboard to the resilient bars (or directly to studs if not using bars, though this offers lower performance) using the appropriate length of drywall screws or self-drilling screws. Screws should be fixed at specified centres (e.g., typically 230mm centres when fixing to resilient bars).

Airtightness: Sealing Gaps

This is a critical step often overlooked. Sound will readily travel through any air gaps.

- Thoroughly seal the perimeter gaps between the edges of the plasterboard and all abutting surfaces (walls, ceilings, floors) using a flexible, non-setting acoustic sealant.

- Carefully seal around any penetrations through the plasterboard for services such as pipes, cables, and electrical outlets. The underlying substrate should also ideally be made as airtight as possible before the plasterboard is installed. Even a very small unsealed opening, like a keyhole, can significantly compromise acoustic performance.

Layering Techniques

- As mentioned, using two layers of acoustic plasterboard with staggered joints is a standard method for improving sound insulation.

- For even higher performance, a constrained layer damping compound or a sheet of mass-loaded vinyl (MLV) can be sandwiched between the two layers of acoustic plasterboard. This adds mass and introduces a damping effect.

Cavity Insulation

It is highly recommended to fill any stud or joist cavities behind the acoustic plasterboard with dense soundproofing insulation such as acoustic mineral wool or fibreglass. This material absorbs sound energy within the cavity, prevents resonance (the cavity acting like a drum), and improves the overall sound insulation of the partition.

Finishing

Once the plasterboard is installed and all gaps are sealed, the joints should be finished using traditional methods (jointing tape and compound). The surface can then be skimmed with plaster if a very smooth finish is desired, or directly painted or wallpapered after appropriate priming.

Common Mistakes to Avoid

- Screwing through resilient bars directly into the framing (short-circuiting the decoupling).

- Leaving gaps unsealed around the perimeter or at joints and penetrations.

- Not staggering joints in single or multiple layers of plasterboard.

- Ignoring significant flanking paths (this is more a system design issue than just board installation, but critical for overall success).

- A lack of slight flex in the finished wall or ceiling surface when resilient bars have been used usually indicates that the bars have been short-circuited by incorrectly placed screws.

The effectiveness of an acoustic plasterboard installation is a testament to meticulous attention to detail. Small elements, such as ensuring every screw is correctly placed when using resilient systems or that every perimeter gap is thoroughly sealed, have a disproportionately large impact on the final soundproofing outcome. Sound behaves like water; it will find any weakness or path of least resistance. Therefore, the "weakest link" principle is paramount in acoustics. The method of attachment and the overall system design, particularly the incorporation of decoupling elements like resilient bars and addressing potential flanking transmission, are often more critical to achieving significant sound reduction than the choice of acoustic plasterboard itself. The board provides essential mass, but it is the integrity of the entire system and the quality of its installation that unlocks its full acoustic potential. Ensuring an airtight construction by sealing all potential air leakage paths is fundamental, as these can act as direct conduits for sound.

Meeting the Mark: UK Standards and Building Regulations for Sound Insulation

In the United Kingdom, the control of sound transmission in buildings, particularly residential ones, is governed by specific Building Regulations and supported by various British and European Standards. These provide a framework for achieving acceptable levels of acoustic comfort and privacy.

Part E of the Building Regulations ("Resistance to the Passage of Sound")

Part E of the Building Regulations for England and Wales, first introduced in its modern form in July 2003 and subsequently updated, is the key piece of UK government legislation concerning sound insulation. Its primary aim is to protect occupants from excessive noise by limiting sound transmission both between separate dwellings (e.g., flats, semi-detached or terraced houses) and within individual homes, thereby ensuring good living standards and maintaining privacy. Part E applies to all new-build houses and flats. It also applies to existing buildings that undergo a "material change of use" – for example, when a large single house is converted into multiple flats, or when a commercial building is converted to residential use. Extensions that create new rooms for residential purposes may also fall under its scope. In all such cases, developers and builders must demonstrate that the construction meets the required minimum standards for sound insulation as outlined in Approved Document E, which provides technical guidance on how to comply with Part E.

Approved Document E specifies performance requirements for both airborne and impact sound insulation:

- Airborne Sound Insulation: This relates to the reduction of sound transmitted through the air, such as speech or music.

- For new builds, separating walls and floors must achieve a minimum airborne sound insulation of 45 dB DnT,w + Ctr (for walls) or 45 dB DnT,w (for floors). The Ctr is a spectrum adaptation term that accounts for low-frequency sound like traffic noise.

- For conversions (material change of use), the minimum requirement for separating walls and floors is slightly lower at 43 dB DnT,w + Ctr (for walls) or 43 dB DnT,w (for floors). This slight relaxation acknowledges the practical difficulties that can be encountered when retrofitting sound insulation in existing buildings, where structural limitations or heritage considerations might make achieving new-build standards impractical or prohibitively expensive.

- Impact Sound Insulation: This relates to the reduction of sound caused by direct impacts on a floor, such as footsteps.

- For new builds, separating floors must achieve a maximum impact sound transmission level of 62 dB L'nT,w. (Lower L'nT,w values indicate better performance).

- For conversions, the maximum impact sound transmission level for separating floors is 64 dB L'nT,w.

Compliance with these performance standards is typically verified through Pre-Completion Testing (PCT). This involves on-site sound insulation tests conducted by an accredited acoustic testing body once the relevant building elements are complete but before finishes are applied. The results of these tests determine whether the construction passes or fails the Part E requirements. Alternatively, compliance can sometimes be demonstrated by precisely following Robust Standard Details (RSDs). These are pre-approved construction methods that have been shown to meet the performance requirements of Part E, and if used correctly, may negate the need for PCT.

Buy Acoustic Plasterboard Now!

Part E also includes provisions for controlling reverberation in common internal parts of buildings containing flats or other residential units (e.g., corridors and stairwells) and sets out requirements for acoustic conditions in schools, often referencing Building Bulletin 93 (BB93) "Acoustic Design of Schools". It is important to note that failure to comply with Building Regulations, including Part E, can lead to enforcement action. The Building Safety Act 2022 has introduced stricter penalties for non-compliance, and the enforcement period for non-compliant work has been extended from 12 months to 10 years after project completion. This underscores the critical importance of adhering to these acoustic standards. The mandatory nature of Part E is a significant driver for the specification and use of acoustic plasterboard and comprehensive soundproofing systems in the UK construction industry.

The following table summarises the key sound insulation performance standards from Part E:

Table 2: UK Part E Building Regulations: Sound Insulation Performance Standards (England & Wales)

| Type of Construction | Element | Airborne Sound Insulation (DnT,w + Ctr dB for walls, DnT,w dB for floors - Minimum) | Impact Sound Insulation (L'nT,w dB - Maximum) |

| Purpose Built Dwelling-Houses and Flats (New Build) | Separating Walls | 45 | Not Applicable |

| Purpose Built Dwelling-Houses and Flats (New Build) | Separating Floors | 45 | 62 |

| Dwelling-Houses and Flats formed by Material Change of Use (Conversion) | Separating Walls | 43 | Not Applicable |

| Dwelling-Houses and Flats formed by Material Change of Use (Conversion) | Separating Floors | 43 | 64 |

Source: Based on information from Approved Document E (England & Wales). Always refer to the latest official government documents for definitive requirements.

Relevant British and European Standards (BS EN)

Beyond Part E, several British and European Standards relate to the specification and testing of plasterboard and drywall systems, including those used for acoustic purposes:

- BS EN 520:2004+A1:2009 – Gypsum plasterboards. Definitions, requirements and test methods: This European Standard specifies the characteristics and performance of gypsum plasterboards. Acoustic plasterboards, such as British Gypsum's Gyproc SoundBloc, are typically classified as Type D under this standard. Type D boards are defined as having a controlled density, which enables improved performance in certain applications, including sound insulation.

- BS EN 16703:2015 – Acoustics. Test code for drywall systems of plasterboard with steel studs. Airborne sound insulation: This standard provides a specific test methodology for determining the airborne sound insulation (Sound Reduction Index, R or Rw) of non-load-bearing drywall systems constructed with plasterboard and steel studs. It works in conjunction with ISO 10140-2 (laboratory measurement of airborne sound insulation). The standard aims to ensure that such partitions are capable of blocking sounds with an intensity around 80 dB under laboratory conditions.

The existence of these specific testing and product standards provides a crucial framework for quality control and performance verification in the construction industry. They allow for more reliable comparisons between products and systems (when tested to these standards) and give specifiers, builders, and consumers greater confidence that the materials will perform as declared.

Making an Informed Decision: Is Acoustic Plasterboard Right for Your Project? ![]()

Choosing the right soundproofing solution requires careful consideration of the specific noise problem, the desired outcome, and the characteristics of the building. Acoustic plasterboard is a powerful tool, but its suitability depends on these factors.

Assessing Your Specific Soundproofing Needs

Before deciding on any soundproofing measures, a thorough diagnosis of the noise issue is paramount:

- Identify the type of noise: Is it airborne sound (e.g., voices, music, television) or impact sound (e.g., footsteps, dropped items, furniture movement)? Acoustic plasterboard is most effective against airborne noise. Impact noise usually requires treatment at the source (e.g., on the floor above) or specialised resilient floor/ceiling constructions.

- Identify the source and path of the noise: Where is the noise coming from, and how is it travelling into the affected area? Is it directly through a wall or ceiling, or are flanking paths (e.g., through floor voids, ceiling cavities, or around partitions) significant contributors?

- What level of sound reduction is desired?: Are you looking for a minor improvement in comfort, or do you need to achieve a significant reduction in noise levels, perhaps to meet Part E regulations or for a noise-sensitive application like a home recording studio?

A simple 4-point check can be useful: What is the construction of the separating element (e.g., timber joist floor, solid concrete)? Where is the noise coming from (above, below, adjacent)? Is the noise airborne or impact? How loud is the noise currently?. This initial assessment is crucial because applying a solution designed for one type of noise to a different problem will likely lead to ineffective results and wasted expenditure.

Considerations for Wall Applications

Acoustic plasterboard is commonly used for walls:

- Party Walls: These are walls separating adjoining dwellings (e.g., between flats or terraced houses). Effective sound insulation is critical here, both for occupant comfort and for compliance with Part E of the Building Regulations. Systems typically involve constructing or upgrading the wall using acoustic plasterboard (often in double layers), timber or metal studwork, soundproofing insulation (like acoustic mineral wool) within the cavities, and often resilient bars to decouple the plasterboard from the structure.

- Internal Partition Walls: Within a single dwelling, acoustic plasterboard can be used to improve sound insulation between rooms, such as bedrooms, home offices, bathrooms, or media rooms, enhancing privacy and reducing noise disturbance within the home.

Considerations for Ceiling Applications

Acoustic plasterboard is also frequently used in ceilings:

- Reducing Noise from Upstairs Neighbours: This is a common application, particularly in flats or houses with timber joist floors. A system comprising resilient bars fixed to the underside of the joists, soundproofing insulation in the joist cavity, and one or two layers of acoustic plasterboard fixed to the resilient bars can significantly reduce noise transmission (airborne) from the room above. However, for impact noise (footsteps), treatment will also ideally be required at the floor level in the room above (e.g., acoustic underlay beneath the floor finish).

- Home Cinemas or Music Rooms: To contain loud sounds within a specific room and prevent them from disturbing other parts of the house or neighbouring properties.

It is worth noting the distinction between materials that block sound transmission between spaces and those that absorb sound within a room. Acoustic plasterboard, as a dense form of drywall or soundboard, excels at blocking sound and isolating spaces. Acoustic ceiling tiles, on the other hand, are typically designed for sound absorption within a room to reduce reverberation and echoes, often seen in commercial or open-plan spaces.

When Acoustic Plasterboard Might Not Be Enough (or the Sole Solution)

While highly effective in many scenarios, acoustic plasterboard is not a universal panacea for all noise problems. There are situations where it may not be sufficient on its own, or where other solutions are more appropriate:

- Severe Impact Noise Issues: As discussed, heavy footfall or other impact noises are best dealt with at the source or with specialised floating floor systems or highly resilient ceiling constructions. Acoustic plasterboard on the ceiling below will help with the airborne component but may have limited effect on the structure-borne impact sound.

- Significant Low-Frequency Noise: Very low-frequency sounds (e.g., deep bass from subwoofers) are notoriously difficult to control. While the mass of acoustic plasterboard helps, effective reduction of these frequencies often requires very high mass constructions, specialised bass traps, or complex decoupled room-within-a-room designs.

- Severe and Unaddressed Flanking Transmission: If sound is predominantly bypassing the treated wall or ceiling via flanking paths (e.g., through uninsulated external wall cavities, interconnected floor voids, or poorly sealed junctions), even the best acoustic plasterboard system will underperform. These flanking paths must be identified and treated.

- Significant Air Gaps or Weak Points: Sound will readily pass through any gaps or weak points in a construction. If there are unsealed gaps around doors, poor-quality single-glazed windows, or unsealed penetrations for services, these will likely be the limiting factors for sound insulation, regardless of the wall or ceiling construction.

The selection of acoustic plasterboard should therefore be part of a holistic assessment of the building, the specific noise issue, and the desired outcome. It is a component within a broader soundproofing strategy, and its effectiveness is maximised when it works in concert with other essential elements like appropriate cavity insulation, effective decoupling mechanisms, comprehensive sealing of air paths, and careful attention to potential flanking transmission routes.

Conclusion: Achieve Peace and Quiet with Acoustic Plasterboard

Acoustic plasterboard stands out as a highly effective and versatile building material in the ongoing effort to create quieter, more comfortable, and more private indoor environments. Its principal benefit lies in its ability to significantly reduce noise transmission, a characteristic derived from its specially engineered high-density core. This makes it an invaluable asset in a wide range of applications, from ensuring peace between neighbours in residential settings to fostering concentration in offices and schools.

Beyond its primary acoustic function, many acoustic plasterboards offer the added advantages of improved fire resistance and impact durability, potentially simplifying material specification and contributing to overall building safety and robustness. However, to realise the full potential of acoustic plasterboard, it is crucial to recognise that it performs optimally not as a standalone product, but as an integral component of a well-designed and meticulously installed soundproofing system. Such systems typically leverage a combination of soundproofing principles – adding mass (with the plasterboard itself), incorporating absorption (with cavity insulation like acoustic mineral wool, a key type of soundproofing insulation), ensuring decoupling (often with resilient bars), and meticulously sealing all potential air paths to ensure airtightness.

For projects in the UK, particularly new builds and material change of use conversions, a thorough understanding of and compliance with Part E of the Building Regulations ("Resistance to the Passage of Sound") is essential. These regulations set mandatory minimum standards for airborne and impact sound insulation, and acoustic plasterboard frequently plays a key role in constructions designed to meet these legal requirements.

While the initial cost of acoustic plasterboard may be higher than that of standard plasterboard, this should be weighed against the long-term value it provides. The benefits of a quieter environment – reduced stress, improved sleep, better concentration, greater privacy, and increased property desirability – are significant. Choosing to invest in acoustic plasterboard and associated soundproofing measures is an investment in the quality of the indoor environment. By mitigating noise pollution, it can make a tangible positive impact on the health, well-being, and productivity of those who occupy the space, transforming buildings into more peaceful, functional, and enjoyable havens.

Legal Disclaimer

The information provided in this article is for general guidance and informational purposes only. It is not intended as, and should not be relied upon as, professional building or legal advice. All information is provided in good faith, however, we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability, or completeness of any information in this article.

Building regulations, standards, and best practices are subject to change and can vary depending on specific circumstances and location. Before making any decisions or taking any action based upon such information, you should consult with appropriate qualified professionals, such as a certified acoustician, structural engineer, or building control body, to ensure compliance with all applicable laws, regulations, and standards.

This content should not be used to specify materials for any construction project. The suitability of any material, including acoustic plasterboard, for a particular application should be determined by a qualified professional based on a thorough assessment of the specific project requirements and site conditions. We expressly disclaim all liability for any actions taken or not taken based on any or all of the contents of this article.

In Conclusion:

In conclusion, soundproof plasterboard can be an effective solution for soundproofing walls and ceilings in a variety of settings. It is designed to absorb sound waves and reduce noise levels, providing improved acoustic performance and additional thermal insulation.

However, there are also some drawbacks to consider, such as the higher cost, installation complexity, weight, and limited soundproofing. Ultimately, the decision to use sound-resistant plasterboard will depend on the specific needs and circumstances of the project, and it's important to weigh the pros and cons carefully before making a decision.

For top-rated soundproofing insulation solutions, acoustic underlay, soundproof boards, rolls and batts visit Buy Insulation Online. If you are in search of some Eco soundproofing insulation, we stock sheep wool, wood fibre and hemp wool insulation which are also known for their sound insulation.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *