- Blogs

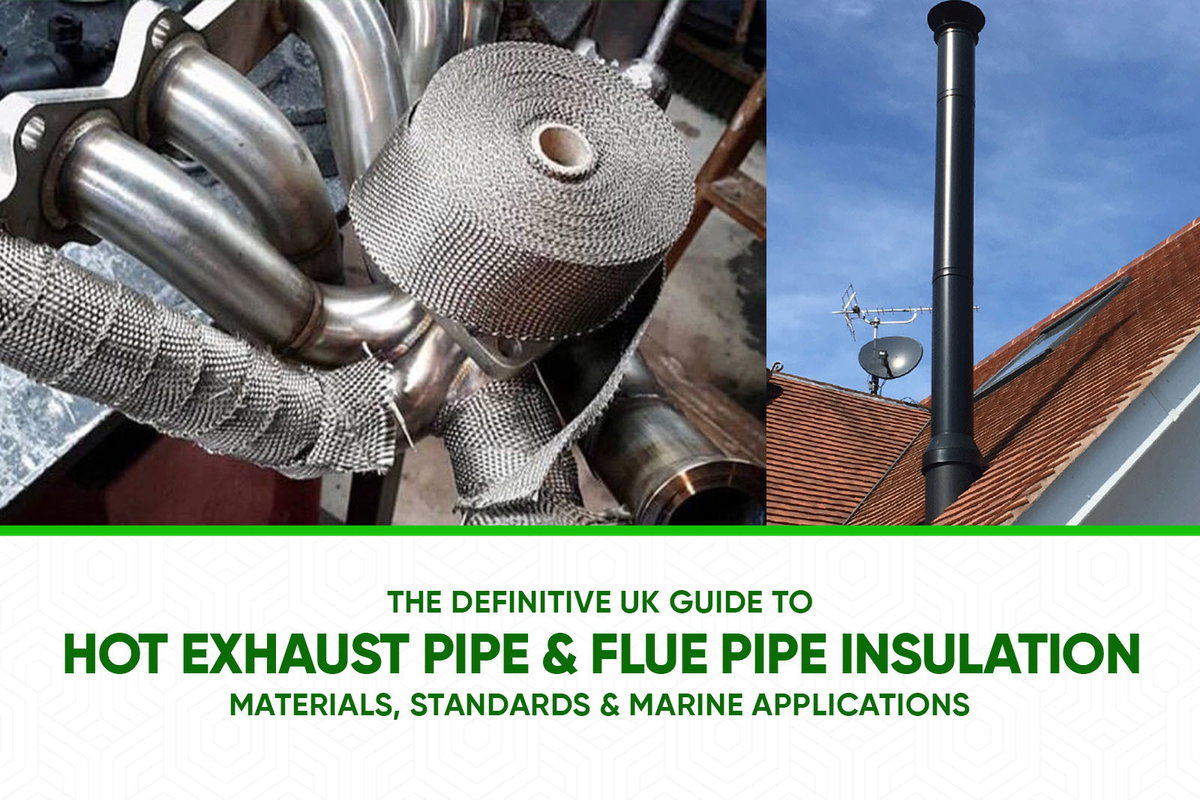

- The Definitive UK Guide to Hot Exhaust Pipe & Flue Pipe Insulation: Materials, Standards & Marine Applications

The Definitive UK Guide to Hot Exhaust Pipe & Flue Pipe Insulation: Materials, Standards & Marine Applications

Insulating hot exhaust pipes (on vehicles, generators) and flue pipes (for boilers, stoves) is a critical consideration for safety, efficiency, and system longevity in the UK. Proper insulation helps prevent burns, reduces fire risks associated with issues like creosote build-up in chimneys, and can lessen harmful emissions. It also improves the operational efficiency of engines and heating appliances, leading to better performance and potential fuel savings.

Furthermore, insulation protects adjacent components from heat damage, extending their lifespan, and can contribute to more comfortable ambient temperatures in surrounding areas. A variety of specialised materials are available, each suited to different temperature ranges and applications. Adherence to UK regulations, such as Approved Document J for building works and relevant British Standards, is essential for safe and compliant installations.

1. Introduction: The Importance of Insulating Hot Pipes in the UK

Hot pipes are a common feature in many systems, from vehicles to domestic heating. Understanding their function and the benefits of insulation is key to ensuring safety and operational effectiveness.

Understanding Exhaust Pipes and Flue Pipes

Exhaust pipes and flue pipes serve a similar primary function: to safely channel and expel hot, often noxious, gases produced by combustion processes.

Exhaust pipes are typically associated with engines – in cars, lorries, motorcycles, generators, and various industrial machinery. They carry the by-products of fuel combustion away from the engine and release them into the atmosphere. These gases are extremely hot and can contain harmful pollutants.

Flue pipes (or chimney flues) are components of heating systems in buildings. They vent combustion gases from appliances like boilers, wood-burning stoves, gas fires, and fireplaces. Similar to exhaust pipes, they must handle high temperatures and safely direct gases out of the living or working space.

Core Benefits: Safety, Efficiency, and Protection

Insulating these hot pipes offers a range of significant advantages, which can be broadly categorised into safety improvements, enhanced efficiency or performance, and protection of the system and its surroundings.

For exhaust pipes, insulation contributes to improved engine performance by maintaining higher exhaust gas temperatures, which can aid gas flow. It significantly reduces under-bonnet or engine bay temperatures, thereby protecting nearby sensitive components like wiring, hoses, and plastic parts from heat degradation. This also lowers the risk of fire. Personnel safety is another important aspect, as insulation reduces the temperature of exposed exhaust parts, lessening the risk of burns for those working on or near the machinery. Some evidence also suggests that by helping catalytic converters reach and maintain their optimal operating temperature more quickly, insulation can contribute to reducing harmful emissions.

For flue pipes in homes and commercial buildings, insulation is vital for several reasons. It enhances the chimney's "draw," meaning the upward flow of gases, by keeping the flue gases warmer. This ensures more effective expulsion of smoke and other combustion by-products. Critically, by maintaining higher temperatures within the flue, insulation helps prevent the condensation of these gases. When flue gases cool too much, water vapour and acidic compounds can condense, leading to the formation of creosote (a highly flammable tar-like substance, particularly with wood burning) and acidic condensates that can damage the flue liner and chimney structure.

Creosote accumulation is a primary cause of chimney fires. Proper insulation, therefore, significantly improves safety. It also contributes to energy savings by reducing heat loss through the chimney system, meaning more of the heat generated by the appliance is used effectively.

Furthermore, by effectively containing heat within the hot exhaust or flue pipes, insulation plays a significant role in reducing the ambient temperature of the spaces through which these pipes run. This is particularly beneficial in work environments or occupied areas, leading to more comfortable conditions for personnel. Lower ambient temperatures also protect other sensitive components or systems in the vicinity, such as cold water pipes, air conditioning ductwork, or chilled water lines, preventing them from unwanted heat gain which could impair their efficiency or cause condensation issues.

2. Insulating Hot Exhaust Pipes: For Vehicles, Generators, and Industrial Uses

Insulating exhaust systems on vehicles, generators, and other industrial equipment is a practice driven by the pursuit of better performance, increased safety, and improved component longevity.

Why Insulate Your Exhaust? Performance, Safety, and Longevity

The benefits of exhaust insulation are multifaceted:

-

Performance: Keeping exhaust gases hotter within the pipes helps to increase their velocity. This phenomenon, often referred to as the "scavenging effect," can improve the efficiency with which gases are expelled from the engine cylinders, potentially leading to modest gains in horsepower and torque. The principle is that hotter gases are less dense and flow more easily.

-

Safety: One of the most significant advantages is the reduction of radiant heat in the engine bay or surrounding areas. Modern engine compartments are often tightly packed with components, many ofwhich (like wiring harnesses, fuel lines, plastic sensors, and bodywork) are susceptible to damage or premature failure from prolonged exposure to high temperatures. Insulating the exhaust reduces this ambient heat, protecting these components and lowering the risk of fire. It also provides crucial protection against burns for mechanics, operators, or anyone who might come into contact with hot exhaust components during operation or maintenance.

-

Longevity: By moderating the extreme temperatures and rapid temperature fluctuations experienced by exhaust system components (manifolds, pipes, silencers), insulation can help to reduce thermal stress. This may contribute to a longer lifespan for these parts by minimising issues like cracking or corrosion.

-

Emission Control: For systems equipped with catalytic converters, maintaining a higher exhaust gas temperature can help the converter reach its optimal operating temperature more quickly and maintain it more consistently. This is important because catalytic converters are most effective at reducing harmful emissions when they are hot.

Common Insulation Materials for Exhaust Systems

Several types of materials are commonly used for exhaust insulation, primarily in the form of wraps, sleeves, and custom-fit heat shields. The choice often depends on the specific application, the temperatures involved, and budget.

Exhaust Wraps (e.g., Fibreglass, Basalt, Silica, Ceramic-based)

Exhaust wraps are flexible tapes that are wound tightly around exhaust manifolds and pipes.

-

Fibreglass wraps: These are a common and often cost-effective option. They provide good thermal insulation and can typically withstand continuous temperatures around 550°C.

-

Basalt wraps: Made from fibres of volcanic rock, basalt wraps generally offer superior heat resistance compared to standard fibreglass, often rated for continuous temperatures around 750°C, with some products claiming even higher direct heat tolerance (e.g., 1000°C). They also tend to be stronger and more durable, making them suitable for demanding applications, including those with turbochargers.

-

Silica wraps: These high-performance wraps are made from silica fibres and can endure very high continuous operating temperatures, for instance, up to around 1093°C. They are known for being soft, strong, and flexible, even after many heat cycles, making them a choice for racing or forced-induction applications where extreme heat is generated.

-

Ceramic fibre-based wraps/materials: Materials incorporating ceramic fibres can withstand exceptionally high temperatures, often in the region of 1260°C. These are used not only as wraps but also in the construction of rigid heat shields and blankets.

Heat Shields and Sleeves

Beyond wraps, other forms of insulation are also employed:

-

Heat Shields: These are often rigid or semi-rigid barriers, sometimes made from metal with an insulating backing, or from composite insulating materials. They can be purpose-made to clamp directly onto an exhaust pipe or to be mounted nearby to protect specific components from radiant heat.

-

Thermal Sleeves: These are pre-formed tubes of insulating material, such as knitted Basalt fibre or woven glass fibre, that can be slid over sections of exhaust pipe or over vulnerable hoses and cables running near the exhaust. They provide both thermal protection and abrasion resistance. These are frequently used in heavy goods vehicles, buses, and various industrial machinery where robust protection is needed.

Best Practices for Installing Exhaust Insulation

Proper installation is key to achieving the desired benefits of exhaust wrap and ensuring its longevity.

-

Preparation: Always work on a cool exhaust system. Clean the pipes thoroughly to remove any oil, grease, or road grime, as this will ensure better contact and prevent contaminants from being trapped. Remove any existing loose heat shields or obstructions.

-

Safety Gear: It is very important to wear appropriate personal protective equipment (PPE). This includes gloves (as the fibres can cause skin irritation), safety glasses, and a dust mask or respirator, especially when working with fibreglass or ceramic fibre wraps, which can release fine particles.

-

Wetting (for some wraps): Some exhaust wraps, particularly fibreglass ones, are easier to handle and conform more tightly if they are slightly dampened with water before application. This can also help to reduce airborne fibres. Always check the manufacturer's specific recommendations.

-

Wrapping Technique: Begin wrapping at the end of the pipe closest to the engine (e.g., at the manifold flange) and work your way along the pipe. Overlap each turn of the wrap consistently, typically by about 6mm (¼ inch). Too little overlap can leave gaps, while too much overlap can lead to over-insulation, trapping excessive heat within the pipe metal itself, which could potentially damage the pipe over time. Maintain firm tension as you wrap.

-

Securing the Wrap: Use stainless steel locking ties (cable ties) or stainless steel wire to secure the start and end of the wrap. It is also good practice to place ties at regular intervals along the wrapped pipe, especially at bends, to prevent the wrap from shifting or unravelling.

-

Curing: Most exhaust wraps require a curing process. This usually involves running the engine for a period (e.g., at idle, then for a short drive) to allow the wrap to heat up, smoke off any binders or impurities, and settle into its final form. Again, follow the manufacturer's instructions precisely. During this process, some smoke and odour are normal.

-

Consider Sharp Edges: Be mindful of any sharp edges on the exhaust system that could cut or damage the wrap during installation or due to vibration.

-

Allow for Expansion: If wrapping near sensors (like oxygen sensors) or other components, ensure a small gap is left to allow for thermal expansion and prevent direct contact that could lead to damage.

Key Considerations for UK Applications

In the UK, specific factors influence the need for and application of exhaust insulation. European emission standards, such as Euro 6, place stringent limits on vehicle pollutants. Efficient catalytic converter operation is key to meeting these standards, and exhaust insulation can play a role by helping the converter reach and maintain its optimal operating temperature more quickly, especially on short journeys or in cold weather.

The often damp UK climate and the use of road salt in winter mean that materials chosen should ideally offer good durability and resistance to moisture if exposed, although most exhaust wraps are installed in relatively sheltered under-bonnet locations. For industrial or generator exhausts that may be more exposed, the robustness of the insulation solution is a greater concern. Furthermore, the compact engine bays of many European vehicles make effective heat management crucial to protect the multitude of components packed into small spaces.

3. Insulating Flue Pipes and Chimney Liners: Essential for UK Homes and Buildings

For homes and commercial properties in the UK relying on combustion appliances like wood-burning stoves, multi-fuel burners, or certain types of boilers, the insulation of flue pipes and chimney liners is not merely an option but a critical aspect of safety, efficiency, and structural integrity.

The Critical Role of Flue Insulation: Preventing Fires, Condensation, and Improving Efficiency

The benefits of insulating flue systems are substantial:

-

Safety – Fire Prevention: A primary reason for insulating flue liners is to reduce the risk of chimney fires. When hot flue gases from burning fuel, especially wood, travel up a cool chimney, they can cool rapidly. This cooling causes condensation of unburnt volatile compounds, which then deposit on the inner surface of the flue as creosote. Creosote is a highly flammable, tar-like substance. If it ignites, it can lead to a dangerous chimney fire. Insulation keeps the flue gases warmer throughout their journey up the chimney, significantly reducing condensation and therefore creosote build-up. Additionally, insulation helps to maintain safe distances between the hot flue and any combustible materials within the building's structure (like timber joists or roof trusses), a key requirement of UK Building Regulations.

-

Efficiency and Performance: Insulation improves the "draw" of the chimney. A good draw, meaning a strong, consistent upward flow of air and smoke, is essential for the efficient operation of a stove or boiler. Warmer flue gases are less dense and rise more readily. By keeping the gases hot, insulation ensures they are expelled effectively, allowing the appliance to burn fuel more completely and efficiently. This can translate into better heat output from the appliance and reduced fuel consumption, leading to lower heating costs.

-

Condensation Control: Beyond creosote, general condensation within a flue can cause numerous problems. Moisture can combine with sulphur compounds in the flue gases (from coal or oil, for example) to form corrosive acids. These acids can attack and degrade the flue liner (whether metal or masonry) and the chimney structure itself, leading to costly repairs. Dampness within the chimney can also contribute to staining on internal walls and an unpleasant environment. Insulation is a key defence against such condensation by keeping the internal surface temperature of the flue above the dew point of the gases.

-

System Longevity: By reducing condensation and the associated corrosive attack, and by protecting the liner from extreme thermal shock (rapid temperature changes), insulation can extend the lifespan of the flue liner and the chimney system as a whole.

Common Insulation Materials for Flues and Liners

Various materials are used for insulating chimney flues and liners, chosen based on the type of flue, the chimney construction, and the specific requirements of the installation.

Loose-Fill Insulation (e.g., Vermiculite, Micafil/Perlite-like granules)

Loose-fill insulation is often used to backfill the void between a new flue liner (typically a flexible metal liner) and the existing masonry chimney structure.

-

Vermiculite: This is a naturally occurring mineral that expands when heated. In its exfoliated granular form, it is lightweight and has good insulating properties. It is commonly poured down from the top of the chimney, around the newly installed liner. It is particularly useful where the gap between the liner and the chimney wall is irregular or relatively small.

-

Micafil (or similar Perlite-based granules): These are also lightweight granular insulating materials. Some types are promoted as being less prone to compression if they become damp compared to vermiculite, offering more stable long-term insulation performance in such conditions. Like vermiculite, they are poured into the chimney void.

Insulation Wraps and Blankets (e.g., Mineral Wool/Rockwool, Glass Fibre, Aluminium-Coated)

These are flexible insulation materials that are wrapped around the flue liner before it is inserted into the chimney.

-

Mineral Wool (e.g., Rockwool): Stone wool or slag wool products are widely used due to their excellent thermal insulation properties and non-combustibility. They are available as flexible wraps or more rigid pre-formed sections. Rockwool is a well-known brand in this category, offering products specifically designed for chimney insulation.

-

Glass Fibre Felt/Blankets: These are often lightweight, non-flammable, strong, and durable options for wrapping flue liners. To improve their performance and ease of handling, they are frequently supplied with an outer facing, such as aluminium foil.

-

Aluminium-Coated Blankets: Glass fibre or mineral wool blankets with an aluminium foil facing offer additional benefits. The foil acts as a radiant heat barrier, reflecting heat back into the flue, and can also serve as a vapour control layer, helping to prevent moisture from reaching the insulation material. It also provides a more robust and easier-to-handle surface.

Pre-Insulated Flue Systems (Twin Wall Insulated Flues)

For new chimney constructions or where no existing chimney is present, twin wall (or double wall) insulated flue systems are commonly used. These consist of two concentric metal pipes (usually stainless steel) with a layer of high-density insulation (often mineral wool) packed between them. The insulation is an integral part of the pipe system. These systems are designed to maintain flue gas temperatures and ensure safe clearance to combustible materials without needing additional on-site insulation. Some flexible liner systems also come with a pre-applied insulation layer, such as triple-skin insulated liners, which combine inner and outer flexible metal layers with an insulating core.

Best Practices for Installing Flue and Chimney Liner Insulation

Correct installation is vital for flue insulation to perform effectively and safely.

-

Safety First: Always wear appropriate PPE, including gloves, safety goggles, and a dust mask, particularly when handling insulation materials (which can be irritant) and when dealing with soot and debris from an existing chimney. Ensure safe working access, especially when working at height.

-

Chimney Preparation: The chimney must be thoroughly swept by a qualified chimney sweep before any liner or insulation is installed. This removes soot, creosote, and any blockages like bird nests. The structural soundness of the chimney should also be checked.

-

Liner Installation (if applicable): If installing a flexible liner, a nose cone should be attached to the leading end to help guide it down the chimney and prevent it from snagging on rough masonry. For sectional rigid pipes, ensure that the female socket of each section faces upwards to contain any moisture or condensate within the system.

-

Wrap Application: If using insulation wraps or blankets, these should be securely fixed around the liner sections before they are lowered or pushed into the chimney. Ensure complete coverage and use appropriate fixings (like wire or high-temperature tape) as recommended by the insulation manufacturer. Aluminium foil tape should be used to seal joints between sections of foil-faced insulation to maintain the integrity of the vapour barrier and prevent heat leakage.

-

Loose-Fill Application: When using loose-fill materials like vermiculite, they should be poured carefully and evenly into the void around the liner from the top of the chimney. It can be beneficial to occasionally tap the sides of the chimney or gently poke down through the mixture (with a suitable rod, avoiding damage to the liner) to help the granules settle uniformly and prevent large air pockets. A register plate must be installed at the bottom of the chimney (e.g., above the stove or appliance connection) to contain the loose-fill insulation.

-

Securing at the Top: The top of the liner and insulation must be properly secured and weathered. This usually involves a top plate and clamp, with the area around the plate being flaunched (sealed with mortar) to prevent water ingress. A suitable chimney cowl or terminal should also be fitted.

-

Ventilation (for some backfills): Some guidance suggests that if backfilling with certain types of loose-fill insulation, a small amount of high-level ventilation should be maintained in the chimney void to allow any residual moisture to escape.

-

Professional Installation: Due to the safety implications and the need to comply with Building Regulations, it is often recommended, and in some cases required, that flue and chimney insulation work is carried out by a competent, registered installer (e.g., a HETAS registered installer for solid fuel appliances in the UK). They will be familiar with the current standards and best practices.

The pervasive issue of condensation in uninsulated flue systems cannot be overstated. It is not merely an efficiency concern; it directly impacts safety through creosote formation and potential chimney fires, and it affects the longevity of the chimney structure through corrosion and moisture damage. Addressing condensation by maintaining adequate flue gas temperatures via insulation is therefore a primary preventative measure with far-reaching benefits.

The choice between different insulation methods – loose-fill, wraps, or pre-insulated systems – often hinges on practical considerations such as the available space within an existing chimney, whether it is a new build or a retrofit, and the type of flue liner being used. While "efficiency" in the context of vehicle exhausts often relates to engine power output, for flue systems, efficiency translates more directly into optimal fuel combustion (thanks to a good chimney draw) and, crucially, the reduction of heat loss from the building itself, leading to tangible energy cost savings for the occupant.

4. A Closer Look at High-Temperature Insulation Materials

A variety of materials are engineered to withstand the high temperatures encountered in exhaust and flue systems. Their selection depends on the maximum operating temperature, the chemical environment, mechanical stresses, and the form required for the application.

Overview of Key Material Types

-

Ceramic Fibre: This category includes materials manufactured from inorganic amorphous glass fibres or alumino-silicate fibres, designed for very high-temperature applications. They offer excellent thermal insulation, low thermal conductivity, and good resistance to thermal shock and many chemicals. Ceramic fibre products are available in diverse forms such as blankets, boards, paper, ropes, and textiles. They can often withstand continuous temperatures up to 1260°C, with some specialised products rated even higher.

-

Mineral Wool (Stone Wool / Slag Wool): This is a widely used insulation material for both industrial and domestic pipes and flues. Produced from molten rock (stone wool) or blast furnace slag (slag wool), it is inherently non-combustible and provides good thermal and acoustic insulation. For pipe insulation, maximum service temperatures for some mineral wool sections can reach 650°C to 680°C. It is available as flexible rolls (often foil-faced), semi-rigid slabs or boards, pre-formed pipe sections, and loose wool for packing. Mineral wool is generally chemically inert and resistant to moisture.

-

Calcium Silicate: This is a rigid, high-temperature insulation material known for its high compressive strength and abuse resistance, making it suitable for industrial pipework that may be subject to mechanical impact or foot traffic. It is asbestos-free and composed of hydrous calcium silicate. Depending on the specific formulation and density, calcium silicate insulation can be used at service temperatures ranging from around 650°C up to 1050°C or even 1100°C. It is available in pre-formed pipe sections, blocks, and boards and offers good resistance to moisture and many chemicals.

-

Basalt Fibre: Derived from basalt rock, these fibres are used to create insulation products with excellent heat resistance and mechanical strength, often superior to standard E-glass fibres. Basalt fibre insulation, commonly found as wraps, tapes, and sleeves, is frequently used for vehicle exhaust systems, including high-performance and turbocharged applications. Continuous operating temperatures are typically around 750°C, with some products tolerating higher intermittent temperatures. Basalt fibres also exhibit very good chemical resistance to acids and alkalis.

-

Silica (Amorphous Silica / Silicon Dioxide based): High-purity silica fibres are used to produce textiles and wraps capable of withstanding extremely high temperatures, for example, continuous exposure at 1093°C or higher. These materials remain soft, strong, and flexible even after prolonged exposure to such heat, making them suitable for demanding applications like racing exhausts or furnace linings.

-

Glass Fibre (E-Glass): This is one of the most common materials for exhaust wraps and insulating textiles, particularly where temperatures are moderately high. Standard E-glass fibre products are generally rated for continuous temperatures up to around 550°C to 600°C. For flue applications, glass fibre blankets, often with an aluminium foil facing, are used as liners wraps. The foil facing improves thermal performance by reflecting radiant heat and provides a vapour barrier.

-

Vermiculite: As previously mentioned, this naturally occurring micaceous mineral is exfoliated to produce lightweight, fire-resistant granules. Its primary use in this context is as a loose-fill insulation poured around chimney liners to fill the void within a masonry chimney, offering good thermal stability.

Forms and Properties (Temperature Resistance, Fire Performance, Chemical Resistance)

These materials are available in various forms to suit different installation requirements:

- Wraps/Tapes: Flexible strips for winding around pipes (common for fibreglass, basalt, silica, ceramic fibre).

- Sleeves: Pre-formed tubular sections that can be slid over pipes (basalt, glass fibre).

- Blankets/Mats: Flexible sheets of insulation (ceramic fibre, mineral wool, glass fibre).

- Boards: Rigid or semi-rigid flat sheets (calcium silicate, ceramic fibre, mineral wool).

- Pre-formed Pipe Sections: Rigid, shaped sections designed to fit specific pipe diameters (mineral wool, calcium silicate).

- Loose-fill Granules: Particulate material for pouring into cavities (vermiculite, perlite-based).

Key properties influencing selection include:

-

Temperature Resistance: This is paramount. The chosen material must be able to withstand the maximum continuous and intermittent temperatures of the application without degradation. "High temperature" is a relative term; the specific operating temperature of the exhaust or flue system is the single most critical factor in material selection. Exceeding a material's service limit will lead to insulation failure and potential safety hazards.

-

Fire Performance: Many of these insulation materials are non-combustible (e.g., mineral wool, calcium silicate, basalt fibre) or have very high melting points (e.g., ceramic fibres, silica). This is crucial for safety and for compliance with building regulations, especially for flues within buildings.

-

Chemical Resistance: The ability to resist attack from chemicals is important in some environments.

- Mineral Wool: Generally chemically inert and not affected by most common industrial chemicals or moisture.

- Ceramic Fibre: Exhibits good chemical stability and is resistant to most oils, solvents, and corrosive agents, with notable exceptions being hydrofluoric acid, phosphoric acid, and strong concentrated alkalis.

- Basalt Fibre: Offers extremely high chemical resistance to both acidic and alkaline environments and is stable in contact with most liquids and gases, including saline solutions.

- Calcium Silicate: Known for good resistance to moisture and many chemicals, including dilute acids and alkalis.

- Glass Fibre (E-glass): Generally has good chemical resistance, though specific performance can vary depending on the chemical and exposure conditions.

It is also important to recognise that beyond just the base temperature rating, properties like mechanical strength (especially for materials subject to vibration, like in vehicles) and the form of the material (e.g., a rigid board for a flat surface versus a flexible wrap for a complex pipe bend) are vital for long-term performance and suitability. Some materials, like certain ceramic fibre products, may incorporate reinforcing media (such as glass filaments or wire) to improve their tensile strength and mechanical integrity, particularly at elevated temperatures. This indicates that even within a broad material category, specific product constructions can be tailored to meet demanding operational requirements.

Comparison of Common Insulation Materials for Hot Pipes

| Material Type | Common Forms | Typical Max Continuous Service Temp (°C) | Primary UK Use (Exhaust / Flue / Both) | Key Properties |

|---|---|---|---|---|

| Ceramic Fibre | Blankets, Boards, Paper, Textiles, Wraps | 1200 - 1400+ | Both | Very high temp resistance, low thermal conductivity, good chemical resistance (some exceptions), lightweight. |

| Mineral Wool | Pipe Sections, Slabs, Blankets (Rolls), Wraps | 600 - 750 (pipe sections up to 680°C) | Both (esp. Flues, Industrial Pipes) | Non-combustible, good thermal & acoustic insulation, moisture resistant, chemically inert. |

| Calcium Silicate | Pre-formed Pipe Sections, Boards, Blocks | 650 - 1100 | Both (esp. Industrial Pipes, Flues) | High compressive strength, abuse resistant, non-combustible, moisture & chemical resistant. |

| Basalt Fibre | Wraps, Tapes, Sleeves | 750 - 1000 | Exhaust | Excellent heat resistance, high strength, good chemical resistance (acids/alkalis). |

| Silica Fibre | Wraps, Textiles | 1000 - 1100+ | Both (esp. high-performance Exhaust) | Very high temp resistance, remains flexible, strong. |

| Glass Fibre (E-Glass) | Wraps, Tapes, Sleeves, Blankets (often foil-faced) | 550 - 600 | Both | Cost-effective, good thermal insulation at moderate temps, available with reflective facings. |

| Vermiculite | Loose-fill Granules | High (as refractory fill) | Flue | Lightweight, good insulator when dry, pours into cavities, fire resistant. |

Note: Temperatures are indicative and can vary significantly between specific products and manufacturers. Always consult manufacturer data for precise specifications.

5. Navigating UK Standards and Regulations for Pipe Insulation

In the United Kingdom, the installation and performance of insulation for hot pipes, particularly flue systems, are governed by a combination of building regulations, British Standards, and health and safety guidance. These frameworks aim to ensure safety, energy efficiency, and environmental protection. Compliance is often mandatory, especially for works subject to Building Regulations.

An Overview of Key UK Legal Frameworks

Several key documents and bodies of regulation are pertinent:

- The Building Regulations: These set out functional requirements for building design and construction in England (similar regulations apply in Wales, Scotland, and Northern Ireland). Approved Documents provide practical guidance on how to meet these requirements.

- British Standards (BS) and European Norms (BS EN): These are technical specifications and codes of practice developed by the British Standards Institution (BSI). While not law in themselves, they are often referenced in legislation or contracts as benchmarks for good practice and product conformity.

- Health and Safety Executive (HSE): The HSE provides guidance and enforces workplace health, safety, and welfare.

Approved Document J (Building Regulations): Implications for Flues and Chimneys

Approved Document J of the Building Regulations for England specifically addresses "Combustion appliances and fuel storage systems." It is highly relevant to the installation of flues and chimneys. Key implications include:

- Air Supply: It mandates that combustion appliances must have an adequate supply of air for combustion, to prevent overheating, and to ensure the flue works efficiently.

- Discharge of Combustion Products: Appliances must have adequate provision for the safe discharge of combustion products to the outside air.

- Protection Against Fire and Burns: Flues, fireplaces, and chimneys must be constructed and installed to reduce to a reasonable level the risk of people suffering burns or the building catching fire. This is a critical point where insulation plays a vital role. The document sets out requirements for the distance between flue pipes and combustible materials. For example, an uninsulated single-skin stove pipe typically needs to be at least three times its diameter away from combustible materials (e.g., a 150mm/6-inch pipe needs 450mm clearance). This distance can often be significantly reduced by using an insulated flue system, such as a twin wall insulated flue, sometimes to as little as 50mm, depending on the product's certification.

- Flue Construction: There are rules regarding the maximum number of bends in a flue (typically no more than four, with each bend no more than 45 degrees from the vertical, except for a short horizontal run from a rear appliance outlet), the minimum height of the flue for adequate draw and safe dispersal of gases, and the internal diameter of the flue (which must generally be at least equal to the appliance outlet).

- Notice Plates: A durable notice plate containing information on the performance capabilities of the hearth, fireplace, flue, or chimney must be fixed in a suitable place in the building.

While Approved Document J does not always explicitly mandate the type or thickness of insulation for the flue liner itself within an existing chimney, its stringent requirements regarding distances to combustible materials often make the use of insulation (either wrapped around a liner or as part of a pre-insulated system) an implicit necessity to achieve a safe and compliant installation in many domestic situations.

BS 5422:2023: Thermal Insulation for Pipework and Equipment

BS 5422 is a key British Standard titled "Method for specifying thermal insulating materials for pipes, tanks, vessels, ductwork, and equipment operating within the temperature range -40 °C to +700 °C." Its provisions are significant for a wide range of pipe insulation applications, including those in heating and hot water systems, and its temperature range makes it relevant for many flue systems and some lower-temperature industrial exhausts.

- Scope: It provides guidance on determining minimum insulation thicknesses to control heat loss or gain, and to prevent surface condensation.

- Material Properties: It specifies key performance criteria for insulation materials, including thermal conductivity, allowable operating temperatures, water vapour transmission rates, and fire performance.

- Energy Efficiency: The standard aims to strike a balance between economic considerations and CO2 savings, aligning with the objectives of Part L of the Building Regulations (Conservation of Fuel and Power).

- Thermal Bridges: It includes guidance on addressing thermal bridges, for instance, at pipe supports, to ensure the continuity and effectiveness of the insulation. Historically, wooden blocks were used at pipe supports, but these create a thermal bridge; BS 5422 encourages the use of insulated pipe supports.

- Application: While not exclusively focused on exhaust or flue insulation, its broad scope covering hot pipes up to 700°C means its principles and calculation methods are applicable to many such systems, particularly in ensuring energy efficiency and controlling surface temperatures. BS 5422 also covers limiting the effects of the system on indoor building temperature.

BS EN 1856 (Parts 1 & 2): Requirements for Metal Chimneys and Flue Liners

This European Standard, adopted as a British Standard, is crucial for metal chimney products:

-

BS EN 1856-1: Chimneys - Requirements for metal chimneys - Part 1: System chimney products. This part applies to factory-made, multi-wall (often insulated) rigid chimney systems. It specifies performance requirements for aspects like temperature rating (e.g., T600 for a maximum operating temperature of 600°C) and, critically, the distance to combustible materials, denoted by a 'G' value (e.g., G50 means 50mm clearance). Some insulated flexible liners may also be assessed against aspects of this standard if intended for use as a complete system under specific conditions.

-

BS EN 1856-2: Chimneys - Requirements for metal chimneys - Part 2: Metal flue liners and connecting flue pipes. This part is relevant for metal liners (both flexible and rigid) used to reline existing chimneys, and for single-wall connecting flue pipes. It specifies requirements for temperature class, pressure class, condensate resistance (W for wet, D for dry), corrosion resistance, material specification, and soot fire resistance (indicated by 'G' if resistant, 'O' if not). Products sold in the UK should be CE/UKCA marked to demonstrate compliance with these standards. HETAS, the UK body for solid fuel and biomass appliances, tests and approves products against these standards.

These standards ensure that flue products are fit for their intended purpose and can be installed safely when manufacturer instructions and relevant codes of practice are followed.

Health and Safety Executive (HSE) Considerations

The HSE's role is to prevent workplace death, injury, and ill health. Several areas of HSE guidance are relevant:

-

Burn Prevention: A primary concern with hot pipes is the risk of contact burns. While there isn't one single Approved Code of Practice (ACoP) specifically mandating insulation types for all hot industrial pipes to prevent burns, the Health and Safety at Work etc. Act 1974 places a general duty on employers to ensure, so far as is reasonably practicable, the health, safety, and welfare of their employees and others affected by their undertaking. This involves risk assessment. If a risk of burns from hot pipes is identified, insulation is a key engineering control to reduce surface temperatures to safe levels. HSE guidance for health and social care settings (HSIS6) states that where vulnerable people are at risk, hot surfaces (like radiators or pipes) should not exceed 43°C; insulation or covers are listed as precautions. This 43°C benchmark, while specific to care settings, provides a useful indication of a surface temperature considered safer for vulnerable individuals. General workplace thermal comfort guidance (HSG194) also suggests insulating hot plant and pipes as a way to control workplace temperature, which indirectly contributes to burn prevention.

-

Asbestos Awareness: In older buildings and industrial plants (generally pre-2000), asbestos was commonly used for pipe lagging. Asbestos insulation is extremely hazardous if disturbed, as the fibres can become airborne and cause serious lung diseases. Any work on or near suspected asbestos-containing materials (ACMs) must be approached with extreme caution. Removal or work on most asbestos pipe lagging must be carried out by an HSE-licensed contractor. It is crucial to assume asbestos may be present in older insulation systems unless a professional survey proves otherwise.

-

Hot Work: If the installation, repair, or removal of pipe insulation involves "hot work" processes such as welding, flame cutting, or grinding, then strict hot work procedures must be followed. This includes thorough checks for any flammable materials in the vicinity, ensuring appropriate fire-fighting equipment is readily available, and using correct personal protective equipment.

The regulatory landscape in the UK therefore often drives the need for insulation through performance-based requirements (e.g., preventing fires or ensuring safe distances to combustibles as per Approved Document J) rather than always prescribing specific insulation types or thicknesses for every scenario. However, to meet these outcomes practically and safely, insulation frequently becomes an essential component of the system design. There is an interplay between general building regulations, specific product standards like BS EN 1856 which ensure the components themselves are suitable, and broader codes of practice for thermal insulation such as BS 5422 which guide how insulation should be specified and applied for energy efficiency and safety. For those installing or specifying these systems, an awareness of all relevant layers of guidance is important.

Summary of Key UK Standards and Their Relevance

| Standard/Regulation | Primary Focus | Relevance to Exhaust Insulation | Relevance to Flue Insulation | Key Takeaway for User |

|---|---|---|---|---|

| Approved Document J (Building Regulations England) | Safety of combustion appliances, flues, chimneys, and fuel storage. | Indirectly, through general safety principles if exhaust passes through building elements. | Very high. Dictates clearances to combustibles, flue construction, air supply, discharge of gases. Often necessitates insulation to meet clearance rules. | Essential for anyone installing or modifying a solid fuel or gas appliance and its flue system in a building. Compliance is mandatory. |

| BS 5422:2023 | Specifying thermal insulating materials for pipes, equipment (-40°C to +700°C). | Applicable for industrial exhausts, generator exhausts for energy conservation, surface temperature control, condensation control. | Highly relevant for insulating flue liners and system chimneys to conserve energy, control condensation, and manage surface temperatures. | Provides methods for calculating insulation thickness for energy efficiency and condensation control. Key for meeting Part L (Energy Efficiency) of Building Regs. |

| BS EN 1856-1 | Requirements for factory-made metal system chimneys. | Not directly applicable to typical vehicle/generator exhaust wraps/sleeves. | Very high for new insulated metal chimney systems (e.g., twin wall). Specifies temperature ratings (T-class) and distance to combustibles (G-value). | Ensures system chimneys are tested and rated for safe operation, including how close they can be to building materials. Look for products certified to this standard. |

| BS EN 1856-2 | Requirements for metal flue liners and connecting flue pipes. | Not directly applicable to typical vehicle/generator exhaust wraps/sleeves. | Very high for flexible or rigid metal liners used to reline existing chimneys. Specifies performance like temperature, corrosion resistance. | Ensures flue liners are suitable for their intended use (e.g., solid fuel, gas) and meet safety criteria. Important for selecting the correct liner. |

| HSE Guidance | Workplace health and safety, risk assessment, burn prevention, asbestos. | High for industrial/generator exhausts in workplaces (burn prevention, noise, fume control). Asbestos awareness for older systems. | High for installers (asbestos in old chimneys, safe working). Burn prevention from hot appliance surfaces/connecting pipes. | Employers have a duty to protect workers from burns from hot pipes. Risk assessment is key. Extreme caution with potential asbestos in older insulation. Follow hot work procedures if applicable during installation. |

6. Installation and Maintenance: Ensuring Long-Term Performance

The benefits of hot pipe insulation – whether for an exhaust system or a flue – can only be fully realised if the insulation is installed correctly and maintained adequately throughout its service life.

General Best Practices for Safe and Effective Installation

While specific installation methods vary depending on the insulation material and the application, some general principles apply:

- Follow Manufacturer's Instructions: This is the most crucial rule. Insulation products are diverse, and manufacturers provide specific guidance on how their product should be installed to achieve optimal performance and safety. These instructions should always take precedence.

- Material Suitability: Ensure the chosen insulation material is appropriate for the maximum operating temperature of the pipe or flue it is being applied to. Also, consider the environmental conditions (e.g., exposure to moisture, chemicals, mechanical impact).

- Clean Surfaces: Pipes should be clean and dry before insulation is applied, unless the manufacturer specifies otherwise (e.g., some exhaust wraps are applied damp).

- Snug Fit, No Gaps: The insulation should fit snugly around the pipe with no gaps, voids, or excessive compression. Gaps can create thermal bridges, reducing the insulation's effectiveness and potentially leading to localised cold spots where condensation can occur (especially on flues or cold pipes).

- Continuous Insulation & Thermal Bridges: Pay close attention to pipe supports, hangers, and penetrations. Ideally, insulation should be continuous. Where supports interrupt the insulation, use insulated pipe supports or other methods to minimise thermal bridging, as recommended by standards like BS 5422.

- Sealing Joints and Seams: For sectional insulation or wraps with facings (like foil), all joints, seams, and edges should be properly sealed with the recommended tape (e.g., aluminium foil tape for foil-faced products) or sealant. This is vital to maintain the integrity of any vapour barrier and to prevent heat loss or moisture ingress.

- Safety During Installation: Always use appropriate Personal Protective Equipment (PPE) as recommended for the material being handled (e.g., gloves, dust masks, eye protection). Be aware of potential hazards such as sharp edges on pipes or existing hazardous materials like asbestos in older installations.

The Importance of Regular Inspections and Maintenance

Insulation is not always a "fit and forget" solution. Over time, it can degrade due to various factors:

- Physical Damage: Impacts, abrasion, or accidental tearing can compromise the insulation.

- Moisture Ingress: If the insulation or its protective jacketing is damaged, moisture can penetrate, significantly reducing its thermal performance (especially for open-cell materials) and potentially leading to corrosion under insulation (CUI).

- Compression: Insulation can become compressed over time, particularly around supports or if walked on, reducing its thickness and effectiveness.

- Temperature Cycling: Repeated heating and cooling can cause some materials to degrade or shrink.

- Vibration: In vehicle exhaust systems, vibration can cause wraps to shift or loosen if not properly secured.

Regular inspections are therefore important to identify any signs of damage or deterioration early. The frequency of inspection will depend on the application, the environment, the age of the insulation, and the potential consequences of insulation failure.

Key things to look for during an inspection include:

- Tears, punctures, or cracks in the insulation or its outer covering/jacketing.

- Signs of water damage, dampness, or mould growth.

- Areas where insulation has become compressed, sagged, or detached.

- Loose or damaged securing tapes, bands, or wires.

- Corrosion on the pipe surface if visible near insulation joints or damaged areas.

- For exhaust systems, listen for unusual noises or look for signs of exhaust leaks that might indicate a problem with the pipe or its insulation.

- If asbestos-containing insulation is present in older systems, its condition should be monitored regularly by competent persons to ensure it remains intact and undisturbed.

Minor damage, such as small tears in jacketing or loose tape, should be repaired promptly to prevent more significant problems from developing. More extensive damage may require replacement of the affected insulation sections. Keeping detailed records of inspections and any maintenance work carried out is good practice. Effective insulation is not solely dependent on the initial installation; its continued performance relies heavily on proactive maintenance to address the inevitable wear and tear that occurs over time. Neglecting this aspect can gradually erode the benefits the insulation was intended to provide. The repeated emphasis in guidance documents on following specific manufacturer's instructions also highlights that due to the wide variety of insulation materials and their unique product designs, generic advice has its limitations. Adherence to product-specific installation and maintenance protocols is therefore vital for achieving optimal, long-lasting results.

7. Conclusion: Selecting the Right Insulation for Your Needs

Insulating hot exhaust pipes and flue pipes offers a compelling array of benefits, centring on enhanced safety, improved operational efficiency, and greater protection for associated components and structures. From reducing the risk of fires and burns to optimising engine performance and home heating fuel usage, the advantages are clear.

The selection of an appropriate insulation material is paramount and must be guided by the specific demands of the application. Factors such as the maximum operating temperature, the nature of the environment (e.g., exposure to moisture or chemicals, potential for mechanical damage), and the physical form required (wrap, sleeve, board, loose-fill) will all influence the choice. There is no single material that suits all purposes; a fibreglass wrap suitable for a car exhaust will differ greatly from the vermiculite granules used to insulate a chimney liner, or the calcium silicate sections on industrial pipework.

Equally important, particularly in the UK, is a thorough understanding of and adherence to relevant building regulations and British Standards. For flue and chimney installations, Approved Document J of the Building Regulations sets out key safety requirements, while standards like BS EN 1856 ensure the suitability of metal chimney products. BS 5422 provides broader guidance on specifying thermal insulation for pipes and equipment to achieve energy efficiency and control condensation. Health and Safety Executive guidance also underscores the importance of risk assessment and taking precautions, such as insulation, to prevent burns and manage other workplace hazards like asbestos in older systems.

Given the technical nature of these systems and the safety implications of incorrect installation or material choice, seeking advice from qualified professionals or registered installers is always recommended if there is any uncertainty. By carefully considering the application, selecting the right materials, and ensuring compliance with UK standards, the full benefits of hot exhaust and flue pipe insulation can be reliably achieved.

8. Legal Disclaimer

The information contained in this article is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability with respect to the article or the information, products, services, or related graphics contained in the article for any purpose. Any reliance you place on such information is therefore strictly at your own risk. This content should not be used to specify materials or for making decisions regarding the installation or modification of any system. All advice, regulations, and standards should be thoroughly checked with relevant qualified professionals and official documentation before undertaking any work. The author or publisher will not be liable for any loss or damage, including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this article.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *