- Blogs

- The Essential UK Guide to Breathable Insulation: Enhancing Your Home's Health, Warmth, and Efficiency

The Essential UK Guide to Breathable Insulation: Enhancing Your Home's Health, Warmth, and Efficiency

Introduction: Why Breathable Insulation is Key for UK Homes

Effective home insulation is a cornerstone of comfortable and energy-efficient living, particularly in the United Kingdom. It promises not only significant savings on energy bills and a reduced carbon footprint but also a consistently regulated indoor temperature. However, a common pitfall in well-insulated homes can be the unwelcome build-up of condensation, often stemming from inadequate ventilation and the type of insulation used. This is where breathable insulation emerges as a vital solution, adept at managing moisture levels and allowing the building fabric to dry out when moisture ingress occurs.

The growing emphasis on breathable insulation within the UK is not merely a trend towards greater energy savings. It is a considered response to the specific challenges presented by the nation's climate, which is often damp, and its significant stock of older properties. Many of these older homes, particularly those constructed before the 1920s, feature solid wall construction. Such walls were traditionally designed to 'breathe', allowing moisture to permeate and evaporate naturally.

The application of modern, less permeable insulation methods to these structures can inadvertently trap moisture within the building fabric. This trapped moisture can lead to a host of problems, including dampness, mould growth, and even structural deterioration. Consequently, the adoption of breathable insulation represents a crucial adaptation for retrofitting these older homes in a sustainable and effective manner, suggesting a growing need for specialised materials and expertise.

Furthermore, the contemporary drive for heightened energy efficiency, often involving measures to make homes more airtight, can paradoxically worsen moisture-related issues if not complemented by breathable building solutions or meticulously planned ventilation strategies. As homes become increasingly sealed to conserve heat, moisture generated from everyday activities like cooking, showering, and even breathing has fewer pathways to escape.

If the insulation layers and general construction are not vapour permeable, this moisture can become entrapped. Breathable insulation systems facilitate the passage of this water vapour through the building's structure, thereby lessening the reliance on purely mechanical ventilation systems to manage humidity and crucially preventing interstitial condensation – the formation of condensation within the building fabric itself. This highlights an essential equilibrium that must be struck in modern construction and renovation: achieving airtightness for optimal thermal efficiency while ensuring breathability for effective moisture management.

Understanding Breathable Insulation: How it Works for Your Property ![]()

Defining "Breathability": Vapour Permeability Explained Simply

In the context of building construction, the term "breathable" primarily refers to a material's capacity to allow water vapour – moisture in its gaseous state – to pass through it. It is important to distinguish this from air permeability; breathable insulation is not about allowing air to leak through the building fabric, but specifically about managing moisture. This characteristic is technically known as vapour permeability. Materials classified as breathable permit the passage of moisture, encompassing both water vapour and, in some cases, liquid water, ensuring it does not become trapped within walls or other building elements.

The Science Behind Moisture Movement: How it Helps Prevent Condensation and Damp

Breathable insulation materials are designed to work in harmony with moisture, rather than creating a barrier against it. Water vapour naturally migrates from areas of higher concentration, typically the warm, moist interior of a heated building, towards areas of lower concentration, such as the cooler, drier exterior environment. Breathable materials possess a porous structure that facilitates this natural movement. By allowing water vapour to pass through, they enable the building's structure to dry out naturally and prevent moisture from accumulating and condensing into liquid water within the wall assembly (a phenomenon known as interstitial condensation) or on interior surfaces. This process is crucial for preventing dampness, mould growth, and associated structural damage.

Key Concepts: Hygroscopicity and Capillarity in Practical Terms

Beyond simple vapour permeability, many breathable insulation materials, particularly natural ones, exhibit two other important properties: hygroscopicity and capillarity.

Hygroscopicity is the ability of a material to absorb moisture vapour directly from the surrounding air and subsequently release it when the ambient humidity decreases. Materials like sheep's wool and wood fibre are notably hygroscopic. This characteristic allows them to act as a moisture buffer, helping to regulate internal humidity levels and reduce the risk of condensation by absorbing excess airborne moisture.

Capillarity refers to a material's ability to draw in and release liquid water through its porous structure, essentially wicking moisture away. This can be beneficial in helping to redistribute and dry out localised areas of dampness.

The hygroscopic nature of many breathable materials offers a significant advantage in the UK's often damp and variable climate. This "buffering" capacity is particularly beneficial in buildings where humidity levels can fluctuate, such as in kitchens and bathrooms, or in properties with intermittent occupancy. These materials can absorb peak moisture loads and release them gradually, maintaining a more stable and healthier internal environment compared to non-hygroscopic materials.

Breathable vs. Non-Breathable: The Role of Vapour Barriers and Vapour Control Layers

It is important to differentiate breathable insulation from non-breathable alternatives, such as rigid foam boards like Polyisocyanurate (PIR) or Polyurethane (PUR). These materials are dense and effectively block the movement of moisture. Consequently, when non-breathable insulation is used, it is typically essential to install a Vapour Control Layer (VCL) on its warm (internal) side. The VCL’s purpose is to prevent warm, moist air from the building's interior from entering the insulation, where it could cool, reach its dew point, and condense, thereby compromising the insulation's effectiveness and potentially damaging the structure.

Breathable insulation systems, due to their inherent ability to allow vapour to pass through, often do not require such a VCL, or they may utilise a "smart" VCL that can adapt its permeability according to humidity levels. However, breathable systems will almost invariably incorporate a breather membrane on the cold (external) side of the insulation. This breather membrane is vapour permeable, allowing moisture from within the wall structure to escape, but it is also water-resistant, preventing rainwater from penetrating from the outside.

The distinction between vapour permeability (related to moisture diffusion) and air permeability (related to air leakage) is fundamental yet frequently misunderstood. Effective breathable construction strives for air tightness to prevent draughts and convective heat loss, while simultaneously maintaining vapour permeability to allow for the controlled diffusion of moisture through the building materials themselves. Homeowners might incorrectly associate "breathable" with "draughty." In reality, a well-designed breathable system will be detailed to be airtight, controlling undesirable air movement through the use of appropriate tapes and membranes in specific locations, while still permitting moisture vapour to pass through the core materials. Achieving both these objectives demands careful design and meticulous installation.

The Advantages of Embracing Breathable Insulation

Choosing breathable insulation for a property offers a multitude of benefits that extend beyond simple temperature regulation, contributing significantly to the building's health, the occupants' well-being, and long-term sustainability.

Protecting Your Building: Reducing Risks of Damp, Mould, and Structural Decay

One of the most significant advantages of breathable insulation is its ability to manage moisture effectively. By allowing water vapour to escape from the building fabric, it prevents moisture from becoming trapped within walls, roofs, or floors. Trapped moisture is a primary cause of numerous problems, including unsightly damp patches, the proliferation of mould (which can have serious health implications), and the gradual decay of building materials, particularly timber components. Over time, this protection helps to preserve the structural integrity of the building.

A Healthier Living Environment: Improving Indoor Air Quality

The prevention of damp and mould directly translates to a healthier indoor living environment. Mould spores are known allergens and can trigger or exacerbate respiratory conditions. By minimising the conditions conducive to mould growth, breathable insulation helps to improve indoor air quality. Furthermore, some natural breathable materials, such as sheep's wool, have been noted for their capacity to absorb and neutralise airborne Volatile Organic Compounds (VOCs), further enhancing the quality of the air inside the home.

Boosting Thermal Performance: Lowering Energy Bills and Enhancing Comfort

While effective moisture management is a key characteristic, breathable insulation also provides excellent thermal resistance. This means it helps to keep homes warmer during the UK's colder months and can also contribute to keeping them cooler in summer. By reducing the amount of heat lost through the building envelope, breathable insulation lessens the demand on heating systems, leading to lower energy consumption and, consequently, reduced energy bills. This improved thermal efficiency also results in more consistent and comfortable indoor temperatures year-round.

The benefits of breathable insulation are often interconnected, creating a synergistic effect. For instance, improved moisture management directly contributes to better thermal performance. Damp insulation is significantly less effective at resisting heat flow than dry insulation. By keeping the building fabric and the insulation itself drier, breathable systems maintain their intended thermal performance more effectively over time. This, in turn, reduces the likelihood of material degradation, enhancing durability, and curtails mould growth, which is beneficial for air quality. This holistic improvement is a key advantage of adopting breathable insulation strategies.

Durability and Sustainability: The Long-Term Benefits for Your Home and the Planet

By safeguarding the building fabric against moisture-related damage, breathable insulation contributes to the overall longevity and durability of the structure. This means fewer repairs and a longer lifespan for the building itself. Many breathable insulation materials are derived from natural and renewable resources, such as sheep's wool, wood fibre, hemp, and cork. These materials often have lower embodied energy (the energy required to extract, process, manufacture, and transport them) compared to conventional synthetic insulation products. They are also often biodegradable or recyclable at the end of their service life, reducing their environmental impact.

While "breathability" is frequently discussed in the context of older properties, its underlying principles of moisture management are equally valuable for new-build constructions. As new homes are built to increasingly airtight standards to maximise energy efficiency, the effective management of internally generated moisture becomes even more critical. If this moisture cannot escape, it can lead to interstitial condensation and associated problems. Breathable construction systems offer a robust and often passive way to manage this internal moisture, potentially reducing over-reliance on mechanical ventilation systems or mitigating the risks associated with imperfectly installed Vapour Control Layers in non-breathable systems.

A Closer Look at Breathable Insulation Materials Popular in the UK

A diverse range of insulation materials, both natural and mineral-based, offer breathable properties. The selection of the most appropriate material depends on various factors, including the specific application (e.g., walls, roof, floor), budget constraints, the existing structure of the property, and desired thermal or acoustic performance.

Natural Fibre Champions

These materials are lauded for their environmental credentials and inherent ability to manage moisture.

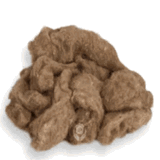

Sheep's Wool:

- Properties: Sheep's wool insulation is highly porous, offering excellent breathability and impressive thermal performance, with reported R-values around 3.5 - 4.5 square metres Kelvin per Watt and thermal conductivity (lambda) values ranging from 0.0359 Watts per metre Kelvin to 0.042 Watts per metre Kelvin depending on its density. It is naturally hygroscopic, meaning it can absorb and release moisture vapour, helping to buffer humidity levels. It is a sustainable and renewable resource, often recyclable, and is hypoallergenic. Some studies suggest it can also absorb certain airborne pollutants like VOCs.

- Applications: Commonly used in lofts, internal and external walls, and floors. Its properties make it particularly well-suited for insulating older, traditional properties.

- Considerations: It tends to be more expensive than some conventional insulations, with prices around £17.5 - £22 per square metre. Due to its high absorption capacity, adequate ventilation is crucial to prevent it from becoming saturated with moisture, which could damage the insulation. It must also be treated with a non-toxic agent (like borax) to protect against moths and other pests.

Wood Fibre (Boards & Loose Fill):

- Properties: Wood fibre insulation is a highly sustainable option, typically manufactured from waste sawdust and wood products. It is known for its effective moisture-wicking and transfer capabilities, which help to dry out moisture and reduce condensation. It offers good thermal and acoustic insulation, is hygroscopic, and vapour permeable. Reported thermal conductivity values range from 0.038 Watts per metre Kelvin to 0.050 Watts per metre Kelvin for generic wood fibre, with specific products like STEICOprotect L dry having a declared lambda value of 0.037 Watts per metre Kelvin.

- Applications: Versatile in application, it is used for External Wall Insulation (EWI), Internal Wall Insulation (IWI), in timber frame constructions, roofs, and floors.

- Considerations: The cost can vary, typically between £12 - £24 per square metre, depending on the thickness and type (board or loose fill). Rigid boards are generally preferred for vertical applications, while flexible batts or loose fill are suitable for other areas. Some wood fibre boards are treated to be water-repellent.

Hemp & Hempcrete:

- Properties (Hemp fibre): Hemp fibre insulation is a natural, sustainable, and breathable material offering good thermal and acoustic properties. Its thermal conductivity is typically in the range of 0.038 Watts per metre Kelvin to 0.040 Watts per metre Kelvin.

- Properties (Hempcrete): Hempcrete is a biocomposite material made from hemp hurds (the woody inner part of the stalk) mixed with a lime-based binder. It acts as an insulator and an effective moisture regulator, is lightweight, and offers good fire resistance. A significant environmental benefit is its ability to sequester carbon during the growth of the hemp and within the material itself. Its thermal conductivity ranges from 0.05 Watts per metre Kelvin to 0.138 Watts per metre Kelvin, and it has a water vapour diffusion resistance factor of 5-25. However, it has a lower compressive strength compared to traditional concrete and is not suitable for load-bearing applications on its own.

- Applications (Hemp fibre): Used in walls and floors.

- Applications (Hempcrete): Primarily used for non-load bearing infill walls, as well as for roof, floor, and slab insulation, and as a breathable render.

- Considerations: Untreated hemp fibre insulation may have poor fire and moisture resistance. Hempcrete structures need to be protected from direct ground moisture, for example, by being built off a plinth.

Cork (Boards, Granules & Spray):

- Properties: Cork is a natural, biodegradable, and highly sustainable material harvested from the bark of cork oak trees. It offers excellent thermal resistance (R-value typically 3.6-4.0 per inch, lambda value 0.035-0.043 Watts per metre Kelvin), is naturally water-repellent, and resistant to mould and mildew. It also provides good soundproofing and is durable and fire-resistant.

- Applications: Available as rigid boards, granules, and in a sprayable form (e.g., SprayCork), making it suitable for internal and external walls, floors, roofing, and as a render.

- Considerations: The cost of corkboard insulation is around £17-£22 per square metre. Sprayed cork products offer the advantage of a thin application depth, which can be beneficial where space is limited.

Cellulose (Recycled Paper):

- Properties: Cellulose insulation is an eco-friendly option made primarily from recycled newspapers and other paper products, treated with fire retardants (often borates) for fire and pest resistance. It is effective at filling voids and irregular spaces, offers good thermal performance, and is hygroscopic. Its thermal conductivity is typically between 0.035 Watts per metre Kelvin and 0.040 Watts per metre Kelvin.

- Applications: Most commonly used as loose-fill insulation blown into lofts, stud wall cavities, and underfloor spaces.

- Considerations: If exposed to persistent damp conditions without adequate ventilation, cellulose insulation can sag or slump over time, potentially reducing its effectiveness. While treated for moisture resistance, it can be more prone to moisture issues than some other materials if not correctly managed. The cost is relatively low, around £10-£12 per square metre.

The increasing popularity of these "natural" insulation materials stems from a combination of factors. Their inherent breathability is a significant advantage, especially for the UK's older housing stock which often requires materials that can manage moisture effectively. There is also a growing environmental awareness among consumers, leading to a preference for sustainable materials with lower embodied energy. Furthermore, concerns about indoor air quality are driving interest in non-toxic materials, with some natural options even offering benefits like the absorption of VOCs. This convergence of building health, occupant well-being, and environmental responsibility suggests that the demand for natural insulation materials is likely to continue its upward trajectory, potentially fostering further innovation and, over time, greater affordability.

Tried and Tested Mineral Wools

Rock Wool & Glass Wool:

- Properties: Mineral wools (including rock wool, made from volcanic rock, and glass wool, made from recycled glass) are widely used and well-established breathable insulation materials. They are vapour permeable, offer good thermal insulation, excellent fire resistance (typically non-combustible and achieving Euroclass A1 fire rating), and effective acoustic dampening. For example, Rockwool Rainscreen Duo Slab has a declared thermal conductivity (lambda value) of 0.034 or 0.035 Watts per metre Kelvin. Unlike many natural fibres, mineral wools are generally not considered hygroscopic, meaning they don't actively absorb and release moisture vapour from the air to buffer humidity.

- Applications: Extremely versatile, mineral wool is available in rolls, batts (slabs), and as loose fill. It is used extensively for loft insulation, in cavity walls, for internal and external wall insulation (often within stud framing), under floors, and between rafters.

- Considerations: Handling mineral wool requires care, as the fibres can cause skin and respiratory irritation; appropriate personal protective equipment (PPE) should be worn during installation. It is a cost-effective option, with prices typically ranging from £10 - £17.5 per square metre. To function correctly within a breathable construction, it needs to be paired with effective vapour control strategies and adequate building ventilation.

Fibreglass

- Properties: Fibreglass insulation, typically supplied in blanket-style rolls or batts, is an affordable option known for its ability to trap heat. It is often treated with fire-retardant substances.

- Applications: Commonly used for insulating lofts and between rafters or joists.

- Considerations: Like mineral wool, fibreglass fibres can cause skin and lung irritation, so PPE is necessary during handling. A key consideration is its interaction with moisture; fibreglass is not very efficient at repelling water and can absorb it if exposed, which significantly reduces its R-value (insulating effectiveness) and can create conditions for mould growth if the area is not well-ventilated.

Specialised Breathable Systems

Insulating Lime Plasters & Renders (often with aggregates like cork, hemp, perlite, or aerogel):

- Properties: These systems combine the inherent breathability and flexibility of traditional lime with the thermal benefits of insulating aggregates. They are particularly suited for direct application to solid masonry and are often favoured for heritage buildings due to their compatibility with historic fabric. Insulating lime plasters help regulate moisture within the wall and can significantly improve U-values. For example, Cornerstone Insulating Lime Render has a K-value (thermal conductivity) of 0.12 Watts per metre Kelvin, and a 46mm thickness of Eden Hot Lime Mortar's insulating lime plaster has a tested lambda value of 0.113 Watts per metre Kelvin.

- Applications: Used as internal plaster or external render on solid brick or stone walls, especially in the restoration and refurbishment of older and historic properties.

- Considerations: Application is often a specialised skill and may require building up multiple coats with adequate drying time between each. Costs vary; for example, a basic lime render might be around £20 per square metre, but insulating variants with specific aggregates could be more.

It is evident that there is no single "best" breathable insulation material. The optimal choice is highly dependent on the specific context of the building project. Factors such as the required thermal performance (U-value), how the material needs to handle moisture (vapour permeability and hygroscopicity), installation practicalities, fire resistance, acoustic insulation needs, and, of course, budget, all play a critical role. For example, mineral wool offers a balance of good fire resistance and cost-effectiveness but lacks hygroscopicity. Wood fibre, while excellent for moisture buffering and sustainability, might be bulkier for an equivalent U-value compared to some synthetic options. Homeowners and specifiers must carefully weigh these trade-offs based on the unique requirements of their project, whether it's a listed building demanding high vapour permeability or a new construction aiming for the lowest possible U-value within a constrained space.

Comparative Overview of Common Breathable Insulation Materials in the UK

To assist in navigating these choices, the table below provides a comparative overview of some common breathable insulation materials available in the UK.

| Material | Form(s) | Typical Thermal Conductivity (lambda value - Watts per metre Kelvin) | Vapour Permeability (water vapour diffusion resistance factor or Sd value) | Hygroscopicity | Key Pros | Key Cons | Indicative Cost (GBP per square metre) |

| Sheep's Wool | Rolls, Batts | 0.0359 - 0.042 | High | Yes | Excellent breathability, hygroscopic, natural, sustainable, good thermal performance, hypoallergenic | Higher cost, needs ventilation to prevent moisture saturation, pest treatment required | £17.5 - £22 per square metre |

| Wood Fibre | Boards (Rigid & Flexible), Loose Fill | 0.037 - 0.050 | High | Yes | Sustainable, excellent moisture management (wicking, buffering), good thermal & acoustic insulation | Cost can vary, may be bulkier than some synthetics for same U-value | Boards: £12 - £24 per square metre (depending on thickness); Rigid boards: £10-£30 per square metre; Flexible rolls: £5-£15 per square metre; Loose-fill: £8-£12 per bag |

| Hemp Fibre | Batts, Boards | 0.038 - 0.040 | High | Yes | Natural, sustainable, good thermal & acoustic properties | Can have poor fire/moisture resistance if untreated | Hemp wool: £10 - £25 per square metre (depending on density/thickness) |

| Hempcrete | Cast in-situ, Blocks | 0.05 - 0.138 (water vapour diffusion resistance factor 5-25) | High | Yes | Insulator, moisture regulator, lightweight, fire-resistant, carbon sequestering | Low compressive strength (non-load-bearing), needs protection from ground moisture | Varies by application |

| Cork | Boards, Granules, Spray | 0.035 - 0.043 | Medium - High | Limited | Natural, water-repellent, mould resistant, good thermal & sound insulation, durable, fire-resistant | Cost can be higher for some forms | Corkboard: £17 - £22 per square metre |

| Cellulose | Loose Fill | 0.035 - 0.040 | High | Yes | Eco-friendly (recycled), good gap-filling, good thermal performance, cost-effective | Can sag in damp if not ventilated, potentially more fire/moisture prone if not well managed | £10 - £12 per square metre |

| Mineral Wool | Rolls, Batts (Slabs), Loose Fill | 0.034 - 0.044 | High | No/Limited | Cost-effective, good thermal & acoustic insulation, excellent fire resistance (non-combustible) | Can cause irritation (handling), not hygroscopic, requires careful vapour control & ventilation | £10 - £17.5 per square metre (sheets/rolls) |

| Insulating Lime | Plaster, Render | 0.113 - 0.12 | High | Yes | Highly breathable, flexible, ideal for solid/historic walls, regulates moisture | Specialised application, can require multiple coats & longer curing times, potentially higher labour costs | Lime render (basic): £20 per square metre; Insulating versions vary |

| Fibreglass | Rolls, Batts | ~0.044 (similar to glass wool) | High | No/Limited | Affordable, traps heat, often fire-retardant treated | Can cause irritation (handling), can absorb water reducing R-value if not ventilated, not very moisture-repellent | £10 per square metre (for fibreglass sheets) |

Note: Costs are indicative and can vary based on supplier, brand, thickness, and market conditions. Vapour permeability and hygroscopicity are general characteristics; specific product data sheets should always be consulted.

Breathable Insulation in Action: Key UK Applications

The principles of breathable insulation find practical application across a range of building types and elements in the UK, each presenting unique challenges and requiring tailored solutions.

Tackling Solid Walls (Brick & Stone)

A significant portion of the UK's housing stock, particularly properties built before the 1920s, features solid wall construction (i.e., without a cavity). These walls were traditionally designed to manage moisture by allowing it to permeate through the permeable materials (like lime mortar and porous bricks or stone) and evaporate to the exterior or interior. Applying non-breathable insulation to such walls can disrupt this natural moisture balance, trapping damp within the wall structure. This trapped moisture can lead to a host of problems, including internal damp patches, mould growth, damage to decorative finishes, reduced thermal performance of the insulation itself, and, in severe cases, frost damage to the masonry (spalling) and decay of embedded timbers. Therefore, for solid walls, breathability is not just a desirable feature; it is often paramount.

Internal Wall Insulation (IWI) Strategies:

When insulating solid walls from the inside, breathable materials are strongly recommended. Options include:

- Breathable insulation boards: Wood fibre or cork boards can be fixed directly to the internal face of the wall, often with a breathable plaster finish.

- Framed systems: A timber or metal stud frame can be erected internally, with the space between the studs filled with breathable insulation batts or rolls, such as sheep's wool or hemp fibre. The frame is then typically covered with a breathable board (like wood fibre board or plasterboard with a breathable plaster finish).

- Insulating lime plasters: These can be applied directly to the masonry, offering a combined insulation and finish layer. They are particularly sympathetic to historic fabric. An example is ISO-THERM, a thin (around 4mm) polyester-based textile material supplied in rolls, which is vapour permeable and can be applied directly to plastered walls using an adhesive, then plastered over.

Key considerations for IWI include managing thermal bridging at junctions with floors, ceilings, and internal walls, and the inevitable loss of some internal room space. Uneven existing walls may require a parge coat of lime plaster to create a suitable surface for insulation boards.

External Wall Insulation (EWI) Systems:

EWI involves applying insulation to the exterior face of the walls. This approach can also be breathable if appropriate materials are chosen. Suitable options include:

- Mineral wool slabs or wood fibre boards: These can be mechanically fixed or adhered to the external wall and then rendered with a breathable render, such as lime-based or silicone-based renders. EWI is often considered more effective at eliminating thermal bridges compared to IWI, as it creates a continuous insulating envelope around the building. It also protects the existing masonry from weathering and allows the thermal mass of the wall to contribute to internal temperature stability.

For solid walls, the decision between IWI and EWI involves a complex balance of factors beyond just cost and aesthetics. It significantly influences moisture dynamics within the wall, the utilisation of the wall's thermal mass, and the risk of interstitial condensation. Generally, EWI, when executed correctly with breathable materials, is technically superior for moisture management as it keeps the original wall warmer and drier. IWI, even with breathable materials, can make the external wall colder, potentially increasing its moisture content and the risk of frost damage if not carefully designed and detailed. Homeowners need to weigh these technical considerations carefully.

Specific Considerations for Insulating Traditional Stone Walls:

Stone walls, common in many older UK properties, present particular challenges. They often have irregular surfaces, vary significantly in thickness, and possess high thermal mass. Breathability is absolutely crucial to preserve the integrity of the stone and the traditional mortars (often lime-based) used in their construction.

Recommended breathable insulation materials include mineral wool, fibreglass (with good ventilation), wood fibre boards, hemp boards, or specialised insulating lime plasters.

Installation methods for stone walls include:

- Direct application: Thinner insulation boards (e.g., calcium silicate, aerogel, or some wood fibre products) can sometimes be applied directly to the internal stone surface, often after a levelling parge coat of lime plaster.

- Framed systems: For thicker layers of insulation, a timber stud frame can be built internally, offset from the stone wall, with the void filled with flexible breathable insulation like sheep's wool or hemp batts.

- Insulated lime plaster/render: Applied directly to the stone, this can provide a modest thermal upgrade while maintaining high vapour permeability.

Retrofitting Period Properties & Listed Buildings

Insulating period properties, and especially listed buildings, requires a particularly sensitive and informed approach. The primary goal is to enhance energy efficiency while conserving the historic fabric, character, and special architectural interest of the building. Reversibility of any intervention is often a key consideration for listed buildings.

Favoured Materials: Natural, breathable insulation materials are generally preferred for period properties due to their compatibility with traditional construction methods and materials. These include sheep's wool, wood fibre, cork, hemp, and lime-based products (plasters, renders, hempcrete).

Techniques:

- Less intrusive methods: Where possible, techniques that minimise disturbance to historic fabric are favoured. This might include blowing loose-fill insulation (e.g., cellulose, perlite) behind existing lath and plaster walls if a suitable void exists and the linings are sound, though this requires careful assessment.

- Internal Wall Insulation (IWI): This is often the most feasible approach for walls, but it must be done with extreme care to avoid trapping moisture or damaging historic finishes. Breathable systems are essential.

- External Wall Insulation (EWI): Generally not considered acceptable for listed buildings due to the significant impact on their external appearance and character. Exceptions might exist for already rendered properties where a like-for-like breathable render system is used.

Navigating Historic England's Guidance:

Historic England provides specific advice on energy efficiency measures for historic buildings. Key points regarding insulation include:

- Loft insulation: Generally acceptable (e.g., using sheep's wool or hemp laid at joist level) and often does not require Listed Building Consent, provided it is not spray foam insulation applied directly to the underside of the roof covering (which is discouraged).

- Roof plane insulation (warm roof): May be acceptable in some cases, such as when converting a loft space, but often requires Listed Building Consent. Care must be taken not to obscure historic roof structures or lose historic plasterwork.

- Floor insulation: Generally acceptable, particularly if insulating between joists from below (e.g., in a cellar) or carefully lifting floorboards. May require consent. Insulating solid floors can be problematic if it disturbs historic surfaces or archaeology.

- Internal Wall Insulation (IWI): Acceptable only in some cases, as it can disrupt historic interiors (plaster, joinery, cornices). Listed Building Consent is almost always required.

- External Wall Insulation (EWI): Unlikely to be acceptable for listed buildings due to harmful visual impact.

Successfully retrofitting period properties with breathable insulation necessitates a holistic "whole building approach." This means considering the complex interplay between the chosen insulation materials, existing building fabric, ventilation strategies (both natural and mechanical), heating systems, and even occupant behaviour, rather than viewing insulation as an isolated intervention. Simply adding insulation without this broader understanding can lead to unintended negative consequences, such as shifting moisture problems to other areas or compromising the building's delicate equilibrium. A piecemeal approach is inherently risky, and a thorough assessment by a conservation-accredited architect or surveyor is vital before undertaking any work.

Insulating Between Rafters (Lofts & Pitched Roofs)

Insulating a pitched roof at rafter level is a common way to improve the thermal performance of a home, especially if the loft space is to be used as a habitable room (a "warm roof" design). Breathable insulation materials are well-suited for this application.

Warm vs. Cold Roof Designs:

- Cold Roof: Insulation is placed horizontally at ceiling joist level, leaving the loft space itself unheated and "cold". This is the most common and often simplest way to insulate a loft.

- Warm Roof: Insulation is placed between and/or over the rafters, following the pitch of the roof. The loft space is therefore within the insulated envelope of the building and becomes a "warm" space.

Materials: Common breathable choices for rafter insulation include mineral wool (rock or glass), sheep's wool, fibreglass batts, and rigid or semi-rigid wood fibre boards.

The Importance of Ventilation and Breathable Membranes:

Managing moisture is critical in roof constructions.

- Cold Roofs: It is essential to maintain clear ventilation pathways from the eaves to the ridge within the cold loft space to allow any moisture vapour that enters the loft to be vented away. This typically involves ensuring a gap at the eaves so air can flow over the insulation.

- Warm Roofs: In a warm roof design using breathable insulation:

- A breather membrane (also known as a vapour permeable underlay or VPU) is installed on the cold (outer) side of the insulation, directly beneath the tiling battens. This membrane allows any water vapour that passes through the insulation from inside the building to escape outwards, but it also prevents external water (rain or snow that might penetrate the roof covering) from reaching the insulation or roof structure.

- An Air and Vapour Control Layer (AVCL) may be required on the warm (inner) side of the insulation, beneath the internal finish (e.g., plasterboard). The AVCL's role is to minimise the amount of warm, moist air from the room passing into the roof structure (reducing the vapour load on the breather membrane) and, crucially, to provide an airtight layer, preventing heat loss through air leakage. Some modern "intelligent" AVCLs can vary their vapour resistance depending on humidity conditions.

- A ventilated air gap of at least 50mm is often recommended between the top of the insulation and the underside of the roofing felt or breather membrane, particularly if the membrane is not highly vapour permeable or if there's a risk of condensation forming on its underside. However, some breathable membrane systems are certified for direct contact with insulation (check manufacturer guidance and BBA certification). BS 5250 provides detailed guidance on ventilation requirements for different roof types and membrane combinations.

Best Practices for Installing Breathable Insulation Systems

The successful performance of breathable insulation hinges not just on selecting the right materials, but critically on their correct installation. Meticulous attention to detail is required to ensure the system functions as intended, managing moisture effectively while delivering optimal thermal performance.

The Golden Rules: Ensuring Continuity and Avoiding Thermal Bridging

For any insulation to be effective, it must form a continuous thermal barrier around the heated envelope of the building. Gaps in the insulation, no matter how small, can significantly compromise its overall performance and create "cold spots". These cold spots are problematic because warm, moist indoor air can condense on these cooler surfaces, leading to localised dampness and potential mould growth. Studies have shown that even a 1mm gap in an insulation layer can lead to a substantial drop in thermal performance.

Thermal bridges are areas within the building envelope where heat can flow more easily from the inside to the outside due to a break in the insulation or the presence of more conductive materials. Common locations for thermal bridges include:Junctions between walls, floors, and roofs.

- Around window and door openings (reveals, sills, lintels).

- Where structural elements like floor joists or steel beams penetrate the insulation layer.

- Repeating thermal bridges can occur due to timber studs in a wall or joists in a floor if insulation is only placed between them.

Minimising thermal bridging requires careful design and detailing. This involves ensuring the insulation layer is continuous across these junctions or, where this is not possible, using materials with better insulating properties in these areas. For example, when installing Internal Wall Insulation (IWI), the insulation should be returned into window and door reveals right up to the frame. Similarly, where IWI meets an externally insulated wall, the internal insulation should wrap around the corner to overlap with the EWI.

Airtightness with Breathability: The Strategic Use of Vapour Control Layers (VCLs) and Breather Membranes

A common misconception is that "breathable" construction means it shouldn't be airtight. This is incorrect. While the building fabric needs to be vapour permeable to allow moisture diffusion, the overall construction should still aim for good airtightness to prevent uncontrolled air leakage (draughts). Air leakage can be a significant source of heat loss and can also carry moist air into the building structure, leading to condensation in unintended places.

Achieving both airtightness and breathability relies on the strategic use of specialised membranes:

-

Vapour Control Layers (VCLs) or Airtight Membranes: These are installed on the warm (internal) side of the insulation layer. Their primary functions are:

- To control the passage of water vapour from the warm, moist interior of the building into the cooler parts of the construction, thereby reducing the risk of interstitial condensation.

- To provide an airtight barrier, preventing air leakage through the construction. VCLs come in various forms, including standard polythene sheets, reinforced versions for greater durability, and "intelligent" or "smart" VCLs that can adapt their vapour resistance according to ambient humidity levels – becoming more resistant in winter when indoor humidity is high and more permeable in summer to allow drying inwards if needed. All overlaps and penetrations in the VCL must be meticulously sealed with appropriate airtight tapes and sealants.

-

Breather Membranes (or Vapour Permeable Underlays - VPUs for roofs): These are installed on the cold (external) side of the insulation layer. Their key functions are:

- To allow any water vapour that does find its way into the building structure (either from inside or from moisture in the construction materials) to escape outwards to the atmosphere.

- To provide a secondary barrier against external water (rain, snow, wind-driven moisture) penetrating the insulation and structure from the outside. Breather membranes are designed to be highly vapour permeable but water-resistant. In roofing applications, they are often referred to as VPUs. Some breather membranes are also air-open, contributing to ventilation, while others are air-tight but vapour permeable.

The correct selection and placement of these membranes are fundamental to the performance of any breathable insulation system.

Installation Specifics for Walls and Roofs

Walls (Internal Wall Insulation - IWI / External Wall Insulation - EWI):

- When installing IWI, if using rigid boards, they should be tightly butted together to avoid gaps. If using flexible insulation (like wool or hemp batts) within a stud frame, it must completely fill the voids without being overly compressed (which can reduce its effectiveness).

- For IWI on uneven solid walls (e.g., old stone or brick), applying a breathable parge coat (a thin layer of render, often lime-based) to the wall first can create a more even surface for the insulation and help to manage air movement behind it.

- Consider creating a service void on the warm side of the IWI (between the insulation/VCL and the final plasterboard finish) to accommodate electrical wiring and pipework. This avoids penetrating the crucial airtightness and vapour control layers.

- For EWI, insulation boards must be securely fixed to the wall (mechanically, adhesively, or both) and protected by a durable, weather-resistant, and breathable render system.

Roofs (Insulating Between Rafters):

- Ensure a snug fit of insulation between the rafters. It is sometimes recommended to cut flexible insulation batts slightly wider than the gap to achieve a compression fit and prevent gaps.

- If required by the specific roof design and materials (particularly with non-breathable roofing felt or certain types of breather membrane), maintain a clear, ventilated air gap (typically 50mm) between the top of the insulation and the underside of the roofing membrane/felt to allow for moisture to be vented away. This is a common requirement for "breathing roof" designs.

- Flexible insulation installed between rafters may need to be supported by netting or held in place by battens to prevent it from slumping over time.

Why Professional Installation is Often Crucial

While some simpler insulation tasks, like laying additional rolls in an accessible loft, can be undertaken by competent DIYers, the installation of comprehensive breathable insulation systems, particularly in older buildings or complex constructions, generally benefits from professional expertise.

Poor installation can negate the benefits of even the best materials and, in some cases, can lead to serious problems such as condensation, damp, and reduced thermal performance. Recent issues reported with government-backed insulation schemes highlight the consequences of substandard installation practices.

Professionals experienced in breathable construction will understand the nuances of moisture management, airtightness detailing, thermal bridge avoidance, and the correct application of membranes and tapes. They are also more likely to be aware of current Building Regulations and best practice standards.

The effectiveness of a breathable insulation system is truly determined by the quality of its installation. While the choice of materials is important, the overall performance of the building envelope relies heavily on meticulous attention to detail, especially at junctions between different building elements, around service penetrations, and at the overlaps of membranes. This underscores a potential need for more widespread training and upskilling within the construction industry to ensure installers are proficient in these often-specialised techniques. Investing in high-quality installation is just as critical as investing in high-quality materials.

Furthermore, achieving genuine "breathability" is a property of the entire construction system, not just of an individual material. It demands careful coordination of all components – the insulation itself, any membranes used, airtightness tapes and sealants, internal and external finishes (like plasters and renders), and the overall ventilation strategy for the building. These elements must all work harmoniously to manage heat, air, and moisture effectively. Simply choosing an insulation material labelled "breathable" is insufficient if it is not integrated into a thoughtfully designed and correctly installed system.

Navigating UK Standards and Building Regulations ![]()

When undertaking insulation work in the UK, it is essential to be aware of and comply with relevant Building Regulations and standards. These are in place to ensure buildings are safe, healthy, energy-efficient, and structurally sound.

Key Building Regulations: Part L (Conservation of Fuel & Power), Part F (Ventilation), and Part C (Site Preparation & Moisture Resistance)

Several parts of the Building Regulations for England and Wales (with similar standards in Scotland and Northern Ireland) are particularly pertinent to insulation projects:

-

Approved Document L (Conservation of Fuel and Power): This is a cornerstone of energy efficiency regulation. Part L aims to reduce carbon emissions from buildings by setting minimum standards for energy performance. This includes specifying target U-values (a measure of heat loss) for different building elements (walls, roofs, floors) in both new builds and existing buildings undergoing renovation. It also addresses overall fabric energy efficiency and, more recently, has introduced requirements for photographic evidence to demonstrate compliance with insulation and airtightness measures during construction.

-

Approved Document F (Ventilation): As buildings become more airtight to conserve energy, effective ventilation becomes crucial. Part F sets out requirements for adequate ventilation to ensure good indoor air quality for occupants and to control moisture build-up from activities like cooking and showering. This is vital regardless of the insulation type used, as trapped moisture can lead to condensation and mould.

-

Approved Document C (Site Preparation and Resistance to Contaminants and Moisture): This document provides guidance on protecting buildings from moisture from the ground and weather, as well as from contaminants in the ground. It has relevance for ensuring the durability of insulation materials and preventing damp problems that could compromise their performance.

Compliance with UK Building Regulations is not merely a procedural formality; it is fundamental to ensuring the long-term health of the building, its energy performance, and the safety and comfort of its occupants. The increased level of scrutiny, exemplified by the requirement for photographic evidence under the latest iteration of Part L, reflects a response to past shortcomings in installation quality and aims to bridge the often-observed "performance gap" between the designed energy efficiency of a building and its actual, as-built performance. Homeowners should be aware of these compliance requirements and ensure that any installers they engage are capable of meeting them.

Achieving Target U-Values with Breathable Insulation

A U-value measures the rate at which heat is lost through a particular building element (like a wall, roof, or floor). A lower U-value indicates better insulation and less heat loss. Achieving the target U-values stipulated in Approved Document L is a key objective of any insulation project.

The U-value of a construction element is determined by the thermal properties and thicknesses of all its constituent layers, including the insulation itself, structural materials, linings, and air layers. The thermal conductivity (often referred to as the lambda value, measured in Watts per metre Kelvin) of an insulation material is a measure of how easily heat passes through it. A material with a lower lambda value is a better insulator.

To achieve a specific target U-value, a thicker layer of insulation will be needed if using a material with a higher lambda value, compared to a material with a lower lambda value. For example, to achieve a U-value of 0.16 Watts per square metre Kelvin for an external wall in a new build, one might use 90mm of Expanded Polystyrene (EPS), 60mm of a high-performance PIR board, or 110-120mm of wood fibre insulation, depending on their respective lambda values.

Simplified UK Target U-Values for Key Building Elements (Watts per square metre Kelvin)

The following table provides a general guide to the U-value targets for common building elements under current Building Regulations in England. Specific requirements can vary, and the full Approved Documents should always be consulted for definitive guidance.

| Building Element | New Build Target U-value (Watts per square metre Kelvin) | Extension/Existing Building (Major Renovation) Target U-value (Watts per square metre Kelvin) |

| External Wall | 0.16 | 0.18 (Extension) / 0.30 (Refurbishment) |

| Pitched Roof - Rafters | 0.11 | 0.15 (Extension) / 0.16 (Refurbishment) |

| Pitched Roof - Joists | 0.11 | 0.15 (Extension) / 0.16 (Refurbishment) |

| Flat Roof | 0.11 | 0.15 (Extension) / 0.16 (Refurbishment) |

| Floor | 0.11 | 0.18 (Extension) / 0.25 (Refurbishment) |

There can sometimes be a tension between the drive to achieve extremely low U-values (to maximise energy efficiency) and the practicalities of managing moisture risks, especially in older buildings with inherently breathable construction. In certain circumstances, particularly when dealing with historic fabric, a balanced approach may be more appropriate. Building Regulations do allow for some flexibility, and it may be possible to make a technical case for using a slightly higher U-value if it can be demonstrated that this is necessary to ensure the breathability of the structure and prevent long-term damp problems. Historic England's guidance also often prioritises the preservation of historic fabric, which might mean that achieving the absolute lowest possible U-values is not always the primary or most suitable objective.

The Role of BS 5250 in Managing Moisture

BS 5250: "Management of moisture in buildings – Code of practice" is a key British Standard that provides comprehensive guidance on understanding and controlling moisture in buildings. It covers the causes and effects of condensation (both surface and interstitial), as well as other sources of moisture. The standard promotes a "whole-building" approach to moisture risk assessment and management, from design through to construction and operation.

BS 5250 is crucial when designing and installing breathable insulation systems, as it provides the technical basis for assessing condensation risks and ensuring that the chosen construction methods will effectively manage moisture and prevent detrimental build-up within the building fabric. It offers guidance on ventilation requirements, the appropriate use of vapour permeable and vapour resistant underlays (membranes), airtightness strategies, and the prevention of thermal bridging, all of which are critical for the success of a breathable insulation system.

Making the Right Choice: Selecting Breathable Insulation for Your Project

Choosing the most suitable breathable insulation for a specific property involves a careful evaluation of several interconnected factors. A one-size-fits-all approach is rarely effective, especially given the diversity of the UK's housing stock and the unique characteristics of breathable materials themselves.

Key Factors: Property Type, Budget, Existing Damp Issues, Acoustic Needs

A thorough assessment should consider the following:

- Property Type and Age: The construction of the property is a primary determinant. Is it a solid wall (brick or stone) Victorian or Edwardian house, a timber-framed building, or a more modern cavity wall construction? Older properties, particularly those with solid walls, generally have a greater need for breathable materials to manage inherent moisture movement. Listed buildings will have additional constraints related to preserving historic fabric.

- Budget: Insulation materials vary significantly in cost. Natural fibres like sheep's wool or corkboard can be more expensive upfront than mineral wool or some conventional rigid boards. The overall project budget will influence the choice of materials and the extent of the insulation work.

- Existing Damp Issues: It is crucial to identify and rectify any existing damp problems (e.g., rising damp, penetrating damp, condensation) before installing any insulation. Insulating over existing damp can trap moisture and exacerbate the problem. The choice of insulation may also be influenced by the property's susceptibility to damp.

- Acoustic Needs: If sound insulation is also a priority (e.g., for properties near busy roads or for internal party walls), some breathable insulation materials offer excellent acoustic absorption. Wood fibre, sheep's wool, hemp, mineral wool, and cork can all contribute to reducing noise transmission.

- Thermal Performance Requirements (U-values): The desired level of thermal performance, often dictated by Building Regulations or homeowner aspirations for energy savings, will influence the type and thickness of insulation required.

- Fire Resistance: The fire performance of insulation materials is an important safety consideration, particularly in certain applications or building types. Mineral wool, for example, is non-combustible. Many natural fibres are treated with fire retardants.

The increasing awareness among UK homeowners regarding breathable insulation is crucial. However, this awareness needs to be coupled with a sound understanding of the underlying principles. Many homeowners may not fully grasp the nuances of "breathability," the specific risks associated with using inappropriate insulation in their particular type of property, or the critical importance of system design (including membranes and ventilation) over the properties of an individual insulation material alone.

Recent issues with spray foam insulation causing mortgage problems and reports of poor-quality solid wall insulation installed under government schemes underscore the fact that incorrect choices or substandard installations have occurred, often impacting vulnerable households. This highlights a pressing need for clearer, impartial guidance, enhanced installer training and certification, and for homeowners to be more proactive in seeking expert, independent advice tailored to their specific circumstances.

The Importance of a Pre-installation Assessment

Before embarking on any significant insulation project, particularly with breathable systems in older or complex buildings, a thorough pre-installation assessment by a qualified and experienced professional is highly recommended. This assessment should:

- Identify the construction type and condition of the building elements to be insulated.

- Investigate and diagnose any existing moisture problems and their causes.

- Assess current ventilation provisions.

- Determine the most appropriate breathable insulation materials and installation strategy for the specific property.

- Ensure the proposed works will comply with all relevant Building Regulations.

- Consider any implications for heritage values if the property is historic or listed.

Energy suppliers or accredited assessors often conduct such assessments as part of grant-funded insulation schemes. For private projects, seeking advice from an independent surveyor, a specialist insulation consultant, or an architect with expertise in retrofitting older buildings is advisable. This upfront investment in professional assessment can prevent costly mistakes and ensure the insulation performs as intended.

Weighing Long-Term Value Against Initial Investment

While some breathable and natural insulation materials may have a higher initial purchase and installation cost compared to certain conventional options, it is important to consider the long-term value proposition. The benefits of breathable insulation, such as:

- Enhanced durability of the building structure due to better moisture management and reduced risk of damp-related decay.

- Sustained thermal performance, as the insulation is less likely to be compromised by moisture.

- Improved indoor air quality and a healthier living environment.

- Potential for lower long-term maintenance and repair costs associated with damp and mould issues.

- Increased property value due to improved energy efficiency and building health. can collectively outweigh a higher upfront cost over the lifespan of the building. Homeowners should look beyond the immediate price tag and consider the whole-life benefits and potential cost savings from avoided problems.

The "eco-friendly" credentials of many breathable insulation materials, such as their renewable sourcing, lower embodied energy, and biodegradability, are a significant attraction for many UK homeowners. However, it is essential that these environmental benefits are balanced with technical suitability and performance for the specific application.

A "green" material that is incorrectly installed or unsuited to the particular building's construction or exposure conditions can still lead to performance issues or even damage. Therefore, sustainability claims should always be evaluated alongside robust technical assessment and compliance with best practice installation for the UK context, considering its climate and diverse building stock.

Conclusion: A Breath of Fresh Air for Your Home

Embracing breathable insulation offers a pathway to creating homes that are not only warmer and more energy-efficient but also significantly healthier and more durable. By working in harmony with the natural movement of moisture, these specialised insulation systems help to protect the very fabric of a building from the detrimental effects of condensation and damp, issues that are all too common in the UK's climate and housing stock. The reduction in mould growth contributes to better indoor air quality, while the protection afforded to structural elements ensures longevity and reduced maintenance costs over time.

The selection of appropriate breathable materials, tailored to the specific needs of the property – whether it's a historic stone cottage, a solid-walled Victorian terrace, or even a modern timber-frame construction – is crucial. From the natural hygroscopic properties of sheep's wool and wood fibre to the robust performance of mineral wools and specialised lime-based systems, a growing range of options is available.

However, the journey to a successfully insulated and breathable home does not end with material selection. Correct installation, meticulous attention to detail in managing airtightness and thermal bridging, and adherence to UK Building Regulations and standards like BS 5250 are equally vital. The shift towards breathable solutions reflects a more sophisticated, building-science-led understanding of how buildings perform. It acknowledges the dynamic interplay of heat, air, and moisture within the building envelope, moving beyond a singular focus on thermal resistance to a more holistic approach that prioritises long-term building health and occupant well-being.

For UK homeowners, particularly those with older properties or those seeking sustainable and healthy living environments, exploring breathable insulation is a worthwhile endeavour. By making informed choices, based on a thorough understanding of their property and with guidance from qualified professionals, they can indeed bring a breath of fresh air to their homes, ensuring comfort, efficiency, and peace of mind for years to come.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *