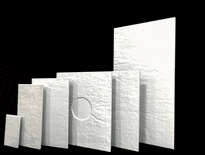

Vacuum Panels

Vacuum panels are exceptionally efficient insulation materials that utilise a sealed vacuum environment to significantly reduce heat transfer. They comprise a core material, such as silica or foam, which is encased in a vacuum-tight envelope to prevent the ingress of air and moisture. This design achieves remarkably low thermal conductivity, making them ideal for space-saving insulation in buildings, refrigeration, and aerospace applications.

The durability of vacuum panels relies on proper handling and sealing, which is essential for ensuring long-term performance.

A closer examination of these panels reveals their potential to greatly enhance energy efficiency, making them a valuable choice for those seeking effective insulation solutions.

Composition and Structure of Vacuum Insulated Panels

The composition and structure of Vacuum Insulated Panels (VIPs) are meticulously designed to optimise thermal insulation while ensuring durability. The core material must possess an open porous structure to facilitate the evacuation of air. It should also exhibit high compressive strength to endure atmospheric pressure, which typically hovers around 100,000 Pa. The core must also maintain minimal thermal conductivity to maximize insulation performance, with values around 0.004 W/(m·K) being ideal. Common core materials include microporous powders such as fumed silica, fibrous materials like glass, and specialised foams such as polyurethane. Low thermal conductivity is essential for effective insulation, with values around 0.004 W/(m·K) being ideal. Certain core types, like wood fibres, create porous and supportive structures that enhance both insulation properties and mechanical stability. The panels are encased in a vacuum-tight envelope made from laminated, metallised plastic or metal foils. This construction effectively prevents air and moisture ingress, thereby ensuring long-lasting performance and reliability in thermal insulation applications. With their advanced design and materials, Vacuum Insulated Panels provide outstanding solutions for energy efficiency in various settings.

How VIPs Enhance Thermal Performance

Vacuum Insulated Panels (VIPs) greatly enhance thermal performance due to their exceptionally low thermal conductivity. Typically, their conductivity values range from 0.004 to 0.007 W/m·K, significantly lower than traditional insulation materials. This superior performance means that VIPs effectively resist heat flow, achieving high R-values, with some panels equating to R-66.

Remarkably, even after years of use, their thermal conductivity remains low, ensuring enduring insulation. The slim profile of VIPs, often under 2 inches, allows for efficient space-saving and seamless integration into existing structures without requiring extensive modifications.

Additionally, these panels are equipped with moisture barriers, which prevent water damage and help maintain their performance over time. The airtight barrier collectively, these attributes contribute to making buildings warmer in winter and cooler in summer, resulting in substantial energy savings and enhanced comfort.

The use of VIPs is a sophisticated solution for modern insulation needs, catering to both residential and commercial applications across the UK.

Key Applications in Modern Building and Industry

Vacuum panels are extensively utilised in contemporary construction and industry to optimise space and enhance insulation. They offer exceptional performance in refrigeration systems and play a crucial role in thermal management within aerospace applications. These uses demonstrate how vacuum insulation panels (VIPs) facilitate compact and efficient solutions in environments where space and energy efficiency are of paramount importance. As insulation technology continues to evolve, the significance of VIPs becomes increasingly evident in a variety of sectors. From reducing energy consumption to ensuring optimal temperature control, the advantages of these panels are clear. Their lightweight nature and high thermal resistance make them ideal for innovative building designs and advanced industrial applications alike. The rising demand for energy-efficient solutions further emphasizes the important role VIPs play across industries.

Space-Saving Insulation Solutions

Vacuum insulation panels (VIPs) provide an exceptionally effective solution for space-saving insulation in contemporary buildings and various industries. They deliver thermal resistance significantly greater than conventional materials of the same thickness, making them particularly suitable for projects with restricted space. In the event of a vacuum failure, core fillers such as expanded perlite or nano-structured materials can maintain insulation efficiency that surpasses standard options. VIPs employ evacuated envelopes that reduce air pressure within the panel, thereby minimising heat transfer and ensuring superior insulation performance. Their slender design enables the construction of highly efficient walls, roofs, floors, and other architectural features without compromising interior space. This quality makes them ideal for retrofitting older buildings, fitting into narrow cavities, or addressing areas where traditional insulation might be overly bulky. The high thermal resistance of VIPs is achieved because the vacuum limits heat conduction and convection within the panel, enabling significant space savings without sacrificing insulation quality.

High-Performance Refrigeration Modules

High-performance refrigeration modules are vital components in contemporary building and industrial applications, where precise temperature control and energy efficiency are paramount.

These modules employ advanced materials and innovative designs to deliver exceptional results, instilling confidence among users.

Key features include:

Achieving significantly higher temperature differentials, ensuring reliable cooling for sensitive processes.

Enhancing heat pumping capacity, which reduces the number of modules required and improves overall efficiency.

Utilising shorter elements and dense packing to optimise heat transfer within compact environments.

Operating reliably at elevated temperatures, making them suitable for quiet, precise industrial and refrigeration requirements.

High CoP demonstrates the potential for reducing energy consumption and operational costs in large-scale systems.

These modules cater to a diverse array of applications, from microelectronics to cryotherapy, offering both durability and versatility.

They create a sense of community for users who prioritise performance, efficiency, and innovation in cooling technology.

Aerospace Thermal Management

Recent advances in insulation technology have greatly enhanced thermal management in aerospace applications. Vacuum Insulation Panels (VIPs) now offer thermal conductivity significantly lower than traditional materials such as glass wool. This innovation allows for ultra-thin, effective insulation in aircraft cabins and spacecraft, optimising space without compromising comfort. Due to their superior insulation properties, VIPs can significantly reduce heat transfer, leading to lower energy costs. VIPs contribute to reduced energy consumption by enhancing insulation in various areas, including galleys, air ducts, and electronic components. Constructed from porous core materials, like expanded perlite, and enclosed within gas-tight envelopes, these panels ensure durability and performance even under demanding conditions.

The use of VIPs elevates passenger comfort and system reliability, while supporting the design of lightweight and compact aircraft and spacecraft.

Application |

Benefit |

| Cabin insulation | Space-saving, energy-efficient |

| Electronic component protection | Minimises heat ingress |

| Spacecraft thermal control | Maintains temperature, lightweight |

Mechanical Characteristics and Handling Considerations

The mechanical characteristics of Vacuum Insulation Panels (VIPs) are essential for ensuring their durability and effectiveness. A thorough understanding of these properties, along with proper handling, is crucial to prevent damage that could compromise insulation performance.

Core strength is of utmost importance, as these panels must endure external pressure without collapsing, particularly during transportation and installation. Given their thin profile and limited structural composition, ensuring core strength is vital for maintaining panel integrity under various conditions.

Impact sensitivity indicates that panels are susceptible to punctures, which can significantly impair thermal performance.

Edge sealing is critical; robust and insulated borders help maintain the vacuum and prevent structural failure.

Protection against bending and puncturing is necessary to keep the panels intact, ensuring long-term efficiency.

To be part of a community that values quality, careful handling and proper installation are vital. Recognising these characteristics ensures that VIPs perform reliably and endure for longer in any application.

Factors Affecting the Longevity of VIPs

Factors influencing the longevity of Vacuum Insulation Panels (VIPs) include the quality of their gas barrier envelope, the effects of temperature and humidity, as well as the construction and handling of the panels themselves. High-quality barriers with effective sealing help to minimise gas leaks, thereby extending the life of the panels. Temperature is a critical factor, as elevated heat increases gas permeability, leading to pressure build-up and a decline in insulation performance over time. While humidity affects panels, its impact is generally less severe; water vapour can weaken materials and contribute to moisture accumulation. Proper edge sealing and construction techniques are vital, as most gas leaks occur at seams and edges. Furthermore, rough handling and exposure to external factors such as UV light or physical impacts can compromise the barrier, significantly reducing the effective lifespan of VIPs. Gas and water vapor permeability are critical parameters that determine how quickly gas can penetrate the barrier and affect the vacuum stability over time.

Environmental Benefits and Energy Efficiency Impacts

Vacuum insulation panels (VIPs) provide exceptional thermal performance, resulting in substantial energy savings. Their remarkably low thermal conductivity effectively minimises heat transfer compared to conventional insulation methods. Consequently, they help reduce energy consumption in homes and commercial buildings, leading to lower utility costs. The utilisation of VIPs also diminishes reliance on fossil fuels, thereby supporting initiatives to combat climate change. Their high thermal efficiency makes them a durable and sustainable choice for a variety of applications. Here are some key benefits of VIPs:

They facilitate superior insulation without increasing the thickness of walls or roofs, thereby preserving valuable interior space.

Their slim profile makes them particularly suited for refurbishment projects and areas where space is limited.

The reduction in energy use contributes to decreased greenhouse gas emissions, which is crucial for environmental protection.

VIPs encourage sustainable building practices by minimising material requirements and aiding in obtaining green certifications.

With these advantages, vacuum insulation panels stand out as a smart choice for energy efficiency and environmental sustainability in the UK.

Conclusion

Vacuum panels are a dependable insulator employed across various industries due to their exceptional thermal performance. These panels feature a robust, slender structure with a vacuum core that significantly reduces heat transfer. Although they are highly effective, factors such as mechanical handling and long-term sealing can impact their lifespan.

Utilising vacuum insulation panels (VIPs) contributes to energy savings and minimises environmental impact. They present a practical solution for enhancing insulation in buildings and equipment, making them invaluable in contemporary energy-efficient designs.

Their application spans a range of settings, from domestic properties to commercial enterprises, where improved insulation can lead to lower energy costs and reduced carbon footprints. Consequently, vacuum panels are increasingly recognised as a vital component in the pursuit of sustainability and efficiency in modern architecture and engineering.