Installation Process and Key Considerations

The installation of joist underfloor heating requires careful planning and adherence to specific procedures to ensure system efficiency and safety.

First, the layout of PEX tubing must be designed to promote uniform heat distribution, considering the size of the space and the desired temperature zones.

Insulation should be be correctly specified; typical solutions include rigid foam boards or other suitable insulants that prevent heat loss. Proper insulation helps prevent heat escaping into unheated spaces, ensuring more energy-efficient operation.

For heated spaces, insulation should be placed beneath the subfloor, while in unheated areas such as crawl spaces, higher-grade insulation materials are recommended to minimise heat escape.

Drilling precise holes in joists is essential to pass the tubing without damaging structural elements.

All tubing should be positioned securely within the joists, allowing for expansion and contraction, and fastened with appropriate clips or staples to prevent movement during operation.

Aluminium heat emission fins are installed to improve heat transfer efficiency.

Before completing the installation, all connections should be tested thoroughly for leaks to ensure the system functions safely and effectively.

Proper insulation helps to maximize the efficiency of the underfloor heating system by minimizing heat loss and ensuring the heat is directed upward into the living space.

Types and Suitable Applications of Between Joist Systems

Between joist underfloor heating systems can be categorised primarily into electric resistance mats and board or panel systems, each offering distinct advantages suited to various applications.

Electric resistance mats, such as SunTouch or QuietWarmth, utilise electrical resistance cables or conductive ink technology. They are suitable for retrofitting existing structures without the need to remove flooring. They're compatible with a wide range of floor coverings including hardwood, laminate, vinyl, carpet, and tiles, providing flexibility for renovations and embellishments. Proper installation and connections are essential to maximize their efficiency and performance.

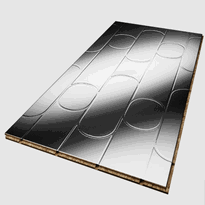

Board or panel systems, like Continal OneBoard, are prefabricated with integrated heating elements. They are designed mainly for new build projects or major renovations. Early planning in such projects allows for seamless integration of these systems into the floor structure. These panels are particularly prevalent in high-end developments and are widely used across European markets. Their quick installation and high performance make them especially popular in projects requiring efficiency and quality. Incorporating these systems can also involve considerations of energy efficiency, helping reduce overall heating costs in the long term.

Both types of systems serve residential retrofits, light commercial spaces, and specialised areas. They offer effective and energy-efficient heating solutions adaptable to specific project requirements. Their varied suitability ensures that there's a practical option for almost any situation requiring underfloor heating within the UK.

Benefits and Maintenance of Underfloor Heating Between Joists

Utilising underfloor heating between joists offers several tangible benefits that enhance both comfort and efficiency within a building. It provides uniform heat distribution by warming the floor directly, resulting in consistent comfort, especially in colder climates. The system’s concealed installation maintains a clean aesthetic, free from visible radiators or vents. Additionally, integrating insulation boards can significantly improve heat retention and system performance. It boosts energy efficiency through lower water temperatures facilitated by aluminium plates, allowing for zone-specific heating that reduces overall energy consumption. Maintenance involves proper insulation of the joist cavity, regular system checks for leaks or malfunctions, and cleaning the subfloor to prevent dust accumulation. The choice of materials, such as durable PEX tubing and aluminium plates, impacts the longevity and ease of maintenance of the system. Incorporating smart controls enables ongoing monitoring and adjustments, ensuring top performance and energy savings over time.

Conclusion

In conclusion, installing underfloor heating between joists in the UK requires careful planning, precise fitting, and strict adherence to manufacturer guidelines to ensure efficient operation and long-term performance. Different system types are suitable for specific applications, and correct installation helps minimise maintenance while optimising heat distribution. Understanding the key considerations involved enables confident decision-making and effective implementation, contributing to a safe, reliable, and energy-efficient heating solution. A systematic and informed approach will help maximise the lifespan and effectiveness of the underfloor heating system over time.