Design and Material Composition of UFH Polypipe Plates

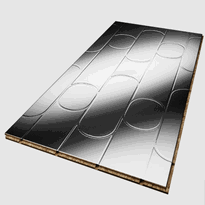

The design and material composition of UFH Polypipe plates are carefully engineered to maximise heat transfer, durability, and compatibility with underfloor heating systems suitable for properties in the UK. These plates are typically manufactured from high thermal conductivity materials such as aluminium, which effectively disperses heat across the floor surface to ensure consistent and efficient operation. Designed for efficient heat conduction, their dimensions are generally around 310 millimetres by 1000 millimetres, with a thickness of approximately 0.5 millimetres. Such sizing facilitates straightforward installation and contributes to the reliable performance of the heating system. Aluminium’s resistance to corrosion, coupled with the plates’ ability to maintain their shape under heat, enhances longevity and stability in a variety of environmental conditions. Designed specifically to accommodate standard 15 millimetre pipes, these plates enable seamless integration into existing underfloor heating layouts. The indented or channelled surface profiles promote even heat distribution, maximising system efficiency while fitting neatly into typical structural frameworks without increasing the finished floor height. This careful design ensures that comfort, performance, and ease of installation are all optimised for UK builders and homeowners. Additionally, the thermal conductivity of aluminium allows for rapid heat transfer, reducing warm-up times and energy consumption.

Installation Procedures and Compatibility Considerations

Proper preparation of the installation area is essential for a successful underfloor heating system using UFH Polypipe plates. The subfloor must be dry, clean, level, and structurally sound.

For suspended timber floors, insulation should be installed between the joists to optimise thermal performance. Address minor deviations or unevenness with suitable compounds, ensuring the surface is smooth before proceeding.

All other building services—such as electrical conduits and plumbing—must be positioned to avoid interference with the heating pipes, and work should be in accordance with relevant UK building regulations.

Panels are to be cut to size with precision, then aligned carefully to ensure a seamless fit. Bonding the panels with recommended adhesives in a brick bond pattern enhances stability and reduces movement during installation.

Insulation is to be tightly fitted beneath the spreader plates to prevent thermal bridging, and the plates should be secured firmly in place prior to laying the piping into the dedicated grooves.

The piping is to be laid into the grooves following the manufacturer's guidelines, ensuring an even and consistent layout. Once the piping is positioned, connections to the manifold are to be made securely.

Thorough leak and pressure tests should be carried out to verify system integrity before covering with the final floor finish.

The UFH system is compatible with most floor coverings when installed correctly, including tile, laminate, engineered wood, and carpet. It's important to follow the manufacturer's instructions for integration with specific floor types, ensuring optimal performance and durability.

Additionally, proper insulation plays a crucial role in maximizing energy efficiency by reducing heat loss through the subfloor [thermal performance](https://www.buyinsulationonline.co.uk/category/shop-by-material/pir-polyiso), and selecting the appropriate plates and pipes per manufacturer specifications ensures consistent and reliable operation.

Performance Benefits and Technical Specifications

Polypipe plates are predominantly manufactured from aluminium, a material selected for its exceptional thermal conductivity. This property ensures efficient heat transfer and uniform distribution of warmth across the floor surface, enhancing the overall performance of underfloor heating (UFH) systems. The aluminium construction increases system efficiency by maintaining consistent temperatures, reducing cold spots, and facilitating more effective heat spread, which results in lower energy consumption. These plates are designed to be compatible with 15mm diameter pipes and are suitable for various floor types, including suspended floors. Typical sizes include 390mm x 1m for double heat spreader plates, with pipe spacing generally set at 200mm centres to optimise heat coverage and system performance. To ensure reliable operation, the maximum circuit length usually doesn't exceed 100 metres. Features such as insulating panels and corrosion-resistant, durable materials further improve heat retention, system longevity, and energy savings. [Aluminium's thermally conductive properties contribute significantly to maintaining optimal heat transfer efficiency.](https://www.tdlonline.co.uk/Heating/Polypipe-Underfloor-Heating/Polypipe-Suspended-Floor/59361-/Polypipe-Double-Heat-Spreader-Plate-390mm-x-1m-PB240) The use of [thermal conductivity](https://www.buyinsulationonline.co.uk/product/rockwool-rwa45-mineral-wool-thermal-and-acoustic-insulation-slab-all-sizes) in these plates ensures rapid and even heating, which is vital for energy efficiency and comfort. Consequently, UFH systems incorporating these aluminium plates are more cost-effective and dependable for long-term use, offering consistent, energy-efficient warmth throughout the living space.

Conclusion

To summarise, UFH polypipe plates are engineered with specific design features and durable materials to ensure reliable performance in underfloor heating systems. Proper installation requires adherence to compatibility guidelines and procedural steps to optimise efficiency and longevity. Understanding the technical specifications and performance benefits enables professionals to select the appropriate plates for various applications, ensuring effective heat distribution and system stability. Implementing these practices supports the system’s overall functionality and sustained operational integrity.