Underlay for Underfloor Heating

Underlay options for underfloor heating in the UK typically include materials such as foam, insulation boards, vapour barriers, and rubber-based products. These materials are selected based on their thermal conductivity, moisture resistance, and compatibility with various subfloor types, including concrete and wooden structures.

Proper installation is essential to ensure optimal performance of the underfloor heating system. This involves selecting an underlay with low thermal resistance to facilitate efficient heat transfer, incorporating adequate moisture barriers to prevent dampness issues, and ensuring a stable and level surface. Correct installation not only improves heat efficiency but also contributes to the longevity of the system.

Choosing the most suitable underlay depends on the specific floor type and environmental conditions of the space. A thorough assessment of these factors will guide you in selecting the appropriate material and installation method. Continuing with this guide, you will find detailed advice on matching underlay options with different flooring types and best practices for installation, to help optimise your underfloor heating system effectively.

Types of Underlay Materials Suitable for Underfloor Heating

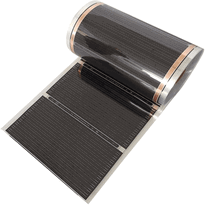

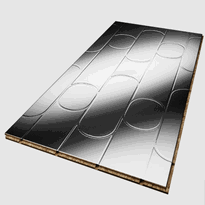

Choosing the appropriate underlay material for underfloor heating requires careful consideration of several factors, including the type of sub-floor, the thermal properties of the material, and its compatibility with the overall flooring system. [Hard surfaces like stone, ceramic tiles, and engineered wood are optimal due to their high thermal conductivity, facilitating efficient heat transfer. Polyfoam underlay provides a cost-effective solution suitable for wooden sub-floors. It is typically around 2 mm thick. It offers sufficient insulation while allowing efficient heat transfer, making it an excellent choice for a variety of residential applications. Foam underlays with vapour barriers are essential for concrete sub-floors. These barriers prevent moisture from building up, which could otherwise damage the flooring or reduce the efficiency of the heating system. Ensuring a good vapour barrier helps to protect your floor and maintain optimal performance. Recycled glass content from insulation products like Superglass supports sustainable building practices and can contribute positively to your environmental credentials. Fibreboard is another versatile option, providing good thermal insulation across different types of floors. Its properties help to enhance heat distribution and improve overall energy efficiency. Rubber underlays deliver durability and can incorporate vapour barriers to protect against moisture. They also maintain effective thermal conductivity, making them suitable for areas subject to higher wear and tear. Additionally, Dreamwalk Heatflow underlay is specifically designed for use with underfloor heating systems. Its small holes facilitate heat penetration through the layers, ensuring consistent and efficient heating performance. When selecting an underlay, always consider the specific requirements of your flooring and heating system to ensure optimal comfort and energy efficiency.

Key Features to Consider When Choosing Underlay for Underfloor Heating

When selecting an underlay for underfloor heating, it's crucial to assess several key features that directly impact the system’s performance, safety, and durability. One of the most important considerations is thermal resistance. A lower tog rating, such as less than 0.4, allows for effective heat transfer from the heating elements to the floor surface, ensuring optimal efficiency. Ensuring compatibility with the heat source is essential, as incompatible materials can lead to poor heat conduction or damage over time. Material compatibility must also be confirmed to guarantee that the underlay works seamlessly with both electric and hot water heating systems without compromising performance. Additionally, selecting an underlay made of materials that provide good insulation can further enhance energy efficiency and prevent heat loss.

Stability and smoothness are essential qualities to promote uniform heat distribution, prevent damage to the flooring, and facilitate a proper installation process. Ease of installation is another significant factor; many options offer no-glue or screw systems, which significantly reduce setup time and labour requirements. Furthermore, considering the moisture resistance of the underlay becomes critical in damp environments, helping to prevent moisture buildup that can impair the operation of the heating system and shorten its lifespan. Considering these features will help ensure that your underfloor heating system functions safely, efficiently, and has a long service life.

Compatible Floor Coverings and Their Flooring Considerations

Different flooring materials vary considerably in their suitability for underfloor heating systems, primarily due to differences in thermal conductivity, composition, and installation requirements. Ceramic and stone tiles are highly conductive, making them ideally suited for efficient heat transfer and quick response times.

Engineered wood can also be appropriate, provided that moisture content is carefully controlled to prevent warping or damage. Laminate flooring performs well, especially denser types, as thicker laminates tend to transfer heat more effectively than thin ones.

Vinyl and linoleum flooring have good thermal conductivity, making them suitable options for underfloor heating systems. Microcement offers exceptional heat transfer capabilities along with durability, making it an attractive choice for many applications.

When selecting flooring for use with underfloor heating, it's essential to consider the material’s thickness, moisture resistance, and maximum temperature limits to avoid damage or warping. Properly chosen flooring materials can optimize system performance and longevity.

Ensuring that each material’s properties are properly assessed will help maintain operational efficiency and extend the lifespan of both the underfloor heating system and the flooring itself. Proper planning and thoughtful choice of materials can provide consistent, efficient warmth while safeguarding the integrity of your flooring investment.

Installation Tips and Best Practices for Optimal Heat Performance

Proper subfloor preparation is essential for establishing a reliable foundation for underfloor heating installation, directly affecting the system's performance and longevity. A clean, debris-free surface helps prevent damage to heating elements and ensures smooth operation. Surface preparation, including the use of floor-leveling compounds, creates a flat surface, enabling efficient heat transfer across the floor. Priming the subfloor improves adhesion of the underlay, resulting in a secure and stable base for the heating system. It's crucial to check for moisture issues and address any dampness prior to installation, as excess moisture can cause problems over time. Supporting the subfloor with stable, well-supported structures allows the entire system and flooring materials to bear weight safely. When selecting an underlay, opt for materials with good thermal conductivity and insulation properties to minimise heat loss and enhance distribution evenly across the surface. Insulation boards should be installed evenly, with seams fully sealed, and secured using appropriate moisture barriers if necessary. Incorporating 3-ply class jointing tape can help reinforce surface seams and prevent cracks that might impact your underfloor heating system's efficiency. Following these best practices ensures the heating system operates efficiently, providing consistent warmth and long-lasting durability.

Conclusion

Selecting the appropriate underlay material for underfloor heating requires careful consideration of thermal conductivity, thickness, and compatibility with the chosen floor covering. Ensuring a proper installation is essential for optimal heat transfer, energy efficiency, and long-term durability.

Attention to manufacturer instructions, suitable floor coverings, and correct installation techniques can significantly minimise heat loss and enhance system performance. By prioritising these factors, homeowners and installers can achieve a reliable, cost-effective, and long-lasting underfloor heating solution that maintains consistent temperatures and maximises comfort throughout the space.