Garage Conversion Floor Insulation

Effective garage floor insulation requires selecting a material suited to moisture resistance, thermal performance, and load capacity, such as rigid foam boards, closed-cell foam insulation, or mineral wool. Preparing the existing concrete involves cleaning thoroughly, repairing any cracks, and installing vapour barriers to ensure proper adhesion and prevent moisture issues. During installation, secure the insulation firmly, seal all seams with appropriate tape, and follow safety protocols, including wearing protective gear and ensuring adequate ventilation. These steps will help create a durable, efficient barrier that enhances comfort and energy efficiency in your garage. Continuing with detailed guidance will improve the success of your insulation project.

Selecting the Appropriate Insulation Material for Your Garage Floor

Choosing the right insulation material for a garage floor is an important decision that affects thermal efficiency, moisture management, and the overall durability of the space. In the UK, various materials are available, each with their own advantages and considerations.

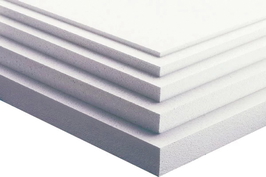

Rigid foam boards are a popular choice, typically ranging from 100 to 150 millimetres in thickness. They offer a high thermal barrier suitable for insulating concrete slabs. Polyisocyanurate (polyiso) foam, in particular, provides excellent thermal resistance, meaning less material is needed to achieve effective insulation. It also boasts strong compressive strength, making it suitable for supporting foot traffic and even vehicle loads. Rigid foam boards are also lightweight and easy to install, which can help reduce installation time and labor costs.

Mineral wool insulation, also around 100 to 150 millimetres thick, delivers effective sound dampening and moderate moisture resistance. It's a sustainable option, valued for its fire resistance and environmental credentials. However, in damp environments, mineral wool may require additional protective measures to prevent moisture absorption and mould growth.

Closed-cell foam insulations, including extruded polystyrene (XPS) and spray foam, excel in moisture resistance and durability. These materials are particularly well-suited for ground-contact surfaces where moisture ingress may be a concern, and they provide excellent thermal performance with relatively thin layers.

Fibreglass batts are a cost-effective and widely available option. However, they're more vulnerable to moisture absorption and may deteriorate over time if exposed to humidity, thus requiring protective measures such as vapour barriers or encapsulation in damp conditions.

Cotton insulation is an eco-friendly alternative, offering good insulation properties. Yet, it's less suitable for garages prone to moisture or water ingress, where the risk of mould and deterioration increases.

Ultimately, selecting the most suitable insulation depends on balancing thermal performance, moisture exposure, and the structural requirements of your garage. Proper installation and protection are crucial to ensuring long-lasting efficiency and durability.

Preparing Your Garage Floor for Insulation Installation

Proper preparation of the garage floor is essential to ensure a successful and durable insulation installation. This process involves several key steps that provide a stable and effective foundation for the insulation materials.

First, all items, debris, and equipment should be removed from the area to create a clear workspace. Sweeping and thoroughly cleaning the surface eliminates dust, dirt, oils, mould, grease, and chemical residues that could impair adhesion or lead to future issues.

Second, inspect the concrete slab for cracks, holes, or uneven areas. Any defects should be repaired using suitable patching compounds or by levelling the surface to ensure a smooth and stable base for the insulation layer.

Third, applying a vapour or damp-proof barrier is crucial to prevent moisture from penetrating the slab from below. This helps maintain dry conditions within the space and protects both the insulation and the structural integrity of the garage.

Additionally, adding a moisture barrier beneath the insulation can help prevent future water issues. Proper surface preparation not only enhances the effectiveness of the insulation but also reduces potential problems, ensuring the safety and longevity of the finished space.

Tips for Installing Floor Insulation Safely and Effectively

Installing floor insulation safely and effectively requires meticulous attention to detail and strict adherence to established safety protocols. First, individuals should always wear protective equipment such as durable gloves, safety goggles, and dust masks to minimise exposure to insulation particles and any potential fumes. Ensuring the work area is well-ventilated is essential to reduce inhalation risks and maintain a safe working environment. Proper ventilation reduces the risk of inhaling insulation fibers and fumes, particularly when working with materials that may emit off-gassing. Proper fastening of insulation materials is crucial to prevent shifting or gaps, which could compromise the insulation’s performance. Overlapping the insulation correctly and sealing the seams with suitable tape helps to establish a moisture- and air-tight barrier, enhancing overall thermal efficiency. It's vital to follow the manufacturer’s instructions precisely, as different types of insulation may have specific installation requirements and safety guidelines. Additionally, confirming that the chosen materials comply with local building regulations—particularly concerning fire safety, moisture management, and adequate clearance space—is fundamental. Adhering to these practices ensures a safe installation process that not only protects your health but also results in a durable, high-performing insulation system.

Conclusion

Proper selection of insulation materials, thorough preparation of the garage floor, and careful installation are essential for achieving effective floor insulation. Ensuring that materials are suitable for the specific environment, removing debris prior to installation, and adhering to safety guidelines will optimise performance and durability. Following these systematic steps provides a long-lasting, energy-efficient solution that enhances comfort and minimises heat loss. Precise execution and attention to detail are vital for successful garage floor insulation projects.