Hemp Insulation Slabs

Hemp insulation slabs are natural building materials that offer impressive thermal resistance, moisture management, and soundproofing qualities. Their low thermal conductivity helps minimise energy consumption for heating and cooling, contributing to a more sustainable and energy-efficient home. These slabs also act as effective moisture buffers, stabilising indoor humidity levels and reducing the risk of mould growth.

From an environmental perspective, hemp slabs are highly sustainable. They sequester carbon dioxide during growth, require minimal resources for production, and are fully biodegradable. Their affordability and straightforward installation make them an attractive choice for builders and homeowners seeking eco-friendly alternatives.

Practical applications of hemp insulation slabs include use within walls, floors, and ceilings, where they enhance thermal performance and acoustic comfort. Over the long term, they maintain their insulating properties, require little maintenance, and support healthier indoor environments by controlling humidity and preventing mould. Such benefits position hemp slabs as a versatile and beneficial choice for sustainable construction projects across the UK.

Thermal Performance and Energy Efficiency

Hemp insulation demonstrates significant thermal performance owing to its low thermal conductivity, typically ranging from 0.06 to 0.07 W/mK. This allows it to effectively minimise heat transfer through building envelopes, contributing to improved energy efficiency. For example, a 350 mm hempcrete wall can achieve a U-value of approximately 0.17 W/m²K, indicating excellent thermal resistance. Hemp fibre insulation panels also possess hydrothermal properties suitable for building applications, with thermal parameters comparable to traditional materials such as plant-based fibres and glass wool. These features help decrease the demand for heating and cooling, leading to lower operational energy costs. Additionally, hemp’s thermal mass allows it to store heat, damping temperature fluctuations and reducing the need for active climate control. Hemp insulation has been demonstrated to reduce energy consumption in buildings, leading to significant operational cost savings. This further enhances overall energy savings in both residential and commercial buildings in the UK, supporting sustainable and energy-efficient construction practices. Integrating hemp insulation panels can also contribute to sustainable construction materials and improve the overall environmental impact of building projects.

Moisture Control and Indoor Climate Benefits

Moisture regulation plays a crucial role in maintaining a stable and healthy indoor environment, especially in buildings striving for energy efficiency and durability. Hemp insulation’s hygroscopic nature allows it to absorb and release moisture without compromising its insulating properties, creating a natural buffer that helps stabilise indoor humidity levels. Hemp fibers’ ability to manage moisture contributes significantly to indoor air quality and building health. This moisture buffering reduces reliance on artificial humidity controls, minimises the risk of condensation within wall cavities, and prevents mould and mildew growth by managing dampness and enabling materials to dry out naturally. Furthermore, hemp’s vapour-permeability allows moisture to pass through walls, preventing trapped dampness that could cause structural damage or encourage biological growth. Insulation materials’ breathability also enhances the overall effectiveness of moisture management. These moisture control capabilities contribute to healthier indoor air quality, enhance the longevity of the building, and support consistent comfort for occupants throughout the year.

Soundproofing and Acoustic Advantages

The soundproofing and acoustic benefits of hemp insulation slabs originate from their naturally porous structure and fibrous makeup. These characteristics effectively absorb and disperse sound waves. This porous structure is a key factor in their sound absorption properties. Hemp fibres, particularly when incorporated at higher concentrations within composites, enhance sound absorption by trapping sound energy within their porous matrix. This process reduces transmission through building walls. The porous nature of hemp-based materials also diminishes sound transmission and improves acoustic insulation. As a result, environments become quieter—especially beneficial in urban areas or shared communal spaces. Hemp reinforcement—such as in hemp-lime or hemp-clay mixtures—further increases noise reduction capabilities without significantly compromising other structural properties. Additionally, sound insulation performance modelling of hemp composites’ acoustic performance aligns closely with experimental results, confirming their predictable and tunable sound insulation potential.

Environmental Impact and Sustainability

Because hemp cultivation requires fewer resources and has minimal environmental impact, it presents a sustainable alternative to conventional insulation crops.

Hemp absorbs substantial amounts of carbon dioxide (CO?) during growth, with hemp fields capable of sequestering approximately 3,000 kilograms per hectare, effectively reducing greenhouse gases.

Its cultivation demands minimal water, and it doesn't require the use of pesticides or chemical fertilisers, helping to prevent soil and water pollution while promoting soil health through natural nutrient cycling.

The manufacturing process for hemp insulation consumes less energy and produces less waste compared to traditional materials like glass fibre, which often rely on energy-intensive procedures.

Additionally, hemp insulation is considered carbon-negative, as it captures more CO? during production and installation than it emits, thereby supporting efforts to combat climate change.

Its durability and low maintenance needs further minimise resource consumption over its lifecycle, enhancing its environmental sustainability profile.

Hemp insulation also benefits from natural pest and mould resistance, further reducing the need for chemical treatments.

Practical Use and Cost Considerations

Hemp insulation slabs offer an effective and environmentally friendly solution for thermal regulation in building construction. They provide thermal resistance levels comparable to traditional batt insulation, with K-values typically around 0.035 W/m·K, ensuring good thermal performance.

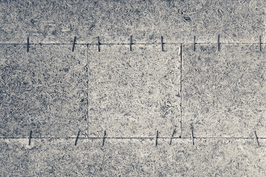

These slabs are suitable for in-wall cavity applications, with available thicknesses such as 100mm for certain ratings or thicker slabs reaching 150mm or more for enhanced insulation. Compared to other insulation options, hemp slabs are generally priced between approximately £12 and £27 per square metre, representing a mid-range cost with notable ecological benefits.

Handling and installation are straightforward; slabs should be stored in dry, sheltered conditions to prevent moisture absorption. Their flexibility allows for easy fitting around wiring and pipes, reducing installation time. Additionally, hemp insulation slabs are naturally biodegradable and can contribute to sustainable building practices.

Once installed, hemp slabs require minimal maintenance thanks to their natural resistance to mould and pests, leading to increased durability and sustainability for your property. Hemp insulation's biodegradability and chemical-free composition contribute further to their eco-friendly profile.

Conclusion

Hemp insulation slabs offer a sustainable, cost-effective solution for enhancing thermal efficiency, moisture regulation, and soundproofing in building applications. They contribute to maintaining a stable indoor climate while reducing environmental impact, making them suitable for a variety of construction needs within the UK.

Careful attention to installation procedures and budget considerations is essential to maximise performance. Overall, hemp insulation provides a reliable and environmentally responsible option, combining practical benefits with durability. It supports energy-efficient building practices and contributes towards more sustainable construction projects across the country.