Rockwool Foil Faced Insulation

Rockwool foil-faced insulation features a stone wool core made from basalt that offers high fire resistance, low moisture absorption, and excellent thermal insulation properties. The foil facing acts as a vapor barrier, enhancing moisture control and preventing mold growth within building structures.

Designed primarily for exterior cladding and fire containment, this insulation meets stringent safety standards thanks to its non-combustible core, which effectively limits the spread of smoke and flames. Its robust construction ensures durability and long-lasting performance in various environmental conditions.

From an environmental perspective, Rockwool foil-faced insulation is both recyclable and energy-efficient, supporting sustainable building practices across the UK. Continued research emphasizes its suitability for diverse applications, ensuring compliance with local regulations and standards.

Overall, it provides a reliable, versatile, and environmentally responsible choice for improving the thermal and fire safety performance of modern buildings.

Material Composition and Core Characteristics

Rockwool insulation is primarily composed of stone wool, a material renowned for its exceptional thermal insulating properties. These properties are achieved through the combination of mineral-derived fibers that trap air, thereby reducing heat transfer and improving energy efficiency.

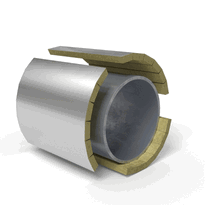

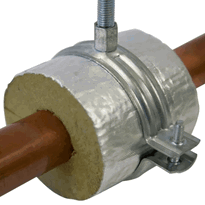

The core material, stone wool, is produced by melting volcanic rock or basalt at high temperatures. The molten rock is then spun into fine fibers, which assemble into a dense, semi-rigid structure. This structure provides excellent insulation qualities while maintaining flexibility for a variety of building applications. This process results in a noncombustible and fire-resistant core material that supports fire safety standards. Typically, the core may be faced with reinforced foil, which enhances vapor-retarding capabilities and helps to control moisture movement within the building envelope. Additionally, the mineral fibers' synthetic affinity helps to improve the moisture barrier and reduce the risk of condensation problems.

Stone wool’s chemical inertness ensures it doesn't react with other substances, contributing to its durability and safety.

Its low moisture sorption capacity allows it to effectively drain water away from exterior walls, helping to minimize the risk of damp or mold growth. Additionally, its non-corrosive and mold-resistant properties make it suitable for use in diverse environments, supporting the longevity and safety of the structure.

Fire Safety and Resistance Features

Fire safety and resistance are vital considerations in building design, and Rockwool insulation plays a key role in maintaining structural integrity and safeguarding occupants during fires.

Known for its non-combustible properties, Rockwool doesn't contribute to fire spread, offering fire resistance typically up to two hours depending on its specific application and fixing method.

The material’s composition limits smoke development, which is crucial for visibility and reducing inhalation hazards during an emergency.

Furthermore, Rockwool has a flame spread rating of zero, meaning it doesn't facilitate the rapid growth of flames.

Its fire safety performance has been validated through rigorous testing programs by recognized certification bodies such as UL, ULc, and Intertek, ensuring compliance with the highest standards.

Particularly suited for perimeter fire containment in curtain wall systems, products like Curtain Rock 40 and 80 enhance fire resistance.

These products combine fire-resistant properties with moisture resistance, providing fortified protection to the building envelope.

This dual capability helps to prevent fire from spreading across structural elements and maintains compliance with UK building regulations aimed at safeguarding both property and life.

Additionally, cladding boards's Rockwool thermal insulation properties contribute to energy efficiency and help maintain temperature control during a fire, further supporting safety measures.

Environmental Benefits and Thermal Performance

The environmental benefits and thermal efficiency of insulation materials play a crucial role in promoting sustainable building practices and reducing energy consumption across the UK. Rockwool insulation, produced from recyclable materials, supports environmental sustainability by decreasing waste and lowering its carbon footprint during manufacturing compared to alternative options.

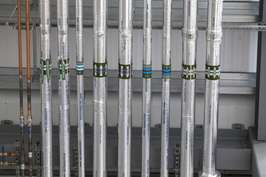

Its high thermal resistance per unit thickness ensures effective insulation, helping to maintain consistent internal temperatures and minimise the need for additional heating or cooling. The material’s dimensional stability and moisture resistance prevent deterioration over time, ensuring long-term performance and reliability. This durability reduces the frequency of replacements, further minimizing environmental impact. Furthermore, its low moisture absorption reduces the risk of mould growth and water damage, thereby helping to preserve the structural integrity of buildings. Collectively, these characteristics contribute to lowering greenhouse gas emissions, conserving vital resources, and achieving sustainability standards such as LEED credits.

This insulation solution promotes environmentally responsible, energy-efficient, and practical building design, benefiting all occupants and the wider community.

Conclusion

Rockwool foil-faced insulation combines a mineral wool core with a reflective foil barrier, offering enhanced thermal performance, fire resistance, and durability. Its material composition ensures effective insulation while contributing to fire safety standards, making it suitable for a range of building applications across the UK. Environmentally, it benefits from sustainable manufacturing processes and supports energy efficiency, helping to reduce carbon emissions. Overall, its technical advantages make it a reliable choice for superior insulation, safety, and environmental impact in construction projects.