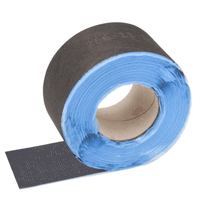

Uv Facade Tape

UV facade tape is a weather-resistant adhesive strip made from UV-stabilised polypropylene and acrylic coating, specifically designed for sealing building exteriors. It boasts a strong, durable bond, effectively resisting moisture, chemicals, and various outdoor weather conditions.

This tape adheres well to surfaces such as timber, masonry, and membranes, ensuring long-lasting seals that enhance the overall performance of buildings. To achieve optimal results, it is essential to apply the tape to clean, dry surfaces while paying careful attention to overlaps and corners during the sealing process.

Ongoing research indicates that the use of this tape can significantly improve the durability and longevity of building structures over time, making it an essential component in modern construction practices.

Characteristics and Composition of Uv Facade Tape

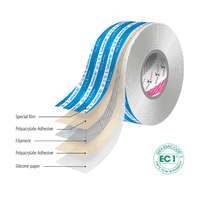

The characteristics and composition of UV facade tape are meticulously crafted to ensure durability and effectiveness in outdoor environments. The primary backing material is polypropylene (PP), which offers excellent UV stabilisation to prevent damage from sunlight. This makes it highly suitable for long-term exposure without degradation. A modified acrylic adhesive layer provides a robust, weather-resistant bond that effectively withstands moisture, wind, and the effects of ageing. This adhesive is formulated to maintain its tack and adhesion properties over time, even under harsh weather conditions. A siliconised paper serves as a protective release liner, simplifying the application process. Some variants of the tape feature scrim reinforcement, enhancing tensile strength and extending the life of the adhesive. Weighing approximately 300 g/m², the tape possesses a fabric-like structure that contributes strength without compromising flexibility. Its black colour aids in blocking UV rays and allows for a seamless integration with various facade surfaces.

Application Techniques and Best Practices

Proper application of UV facade tape requires meticulous preparation and precise techniques to ensure a robust, weatherproof seal. It is crucial to clean the surfaces thoroughly; substrate areas must be dry and free from dust, grease, and loose particles. Primers should be applied to rough or porous surfaces, and it is essential to maintain temperatures above minus five degrees Celsius to avoid condensation issues.

During the application process, the tape should be pressed firmly and evenly, utilising rollers to prevent any stretching or waviness. Overlaps need to be sealed tightly, with a sufficient amount of extra tape. Mechanical fixings, such as nails or screws, should be employed to support the tape and must be adequately sealed. For corners and openings, careful overlapping and sealing are vital to prevent leaks.

The table below outlines key application methods for a successful and durable installation:

Surface Preparation |

Application Process |

Fixing & Detailing |

| Clean and dry surfaces | Firm press and rollers | Seal overlaps and edges |

| Use primer on porous areas | No stretching during application | Seal fasteners with tape |

| Store tape in a warm area | Maintain consistent pressure | Wrap around corners |

| Temperature above minus five degrees | Avoid folds and creases | Properly support edges |

Following these guidelines will help to achieve a long-lasting and effective installation of UV facade tape, providing reliable protection against the elements.

Resistance to Weathering and Long-term Durability

UV facade tapes, such as Tyvek UV Facade Tape, are meticulously designed to withstand challenging outdoor conditions, ensuring prolonged performance. Their exceptional resistance to ultraviolet (UV) light helps maintain structural integrity when exposed to sunlight over extended periods. The acrylic adhesive paired with a UV-stabilised polypropylene backing effectively prevents degradation from UV rays, thereby avoiding any discolouration or loss of strength. These tapes are capable of enduring a wide range of temperatures, making them suitable for various climates. They offer robust resistance to water, humidity, and chemicals, thus ensuring airtight and watertight seals over time. The high tensile strength of the tape guarantees durability against wind and mechanical stresses. With proven stability after extended outdoor exposure, these tapes provide dependable protection, ensuring that buildings remain safeguarded and energy-efficient for many years. This makes them an ideal choice for construction and renovation projects in the UK, where weather resilience is paramount. This resistance to environmental factors guarantees long-term sealing performance, even in harsh conditions.

Suitable Surfaces and Integration in Building Systems

Multiple surfaces can effectively bond with UV facade tapes, making them versatile for various building applications. These tapes adhere well to materials such as Tyvek® membranes, plastic films, timber, metal, and masonry. Adequate surface preparation is essential, particularly on rough or contaminated surfaces, which may require priming to enhance adhesion. These tapes are engineered to endure outdoor conditions, providing a strong bond in temperatures above freezing, while maintaining their integrity against wind, moisture, and UV exposure.

Surface Type |

Best Practices |

Notes |

| Timber | Ensure cleanliness and dryness | Ideal for ventilated systems |

| Metal | Eliminate grease | Promotes durable seals |

| Masonry | Prime if textured | Guarantees surface stability |

| Plastic Films | Keep dry and dust-free | Suitable for building envelopes |

The adaptability of UV facade tapes makes them an excellent choice for various construction projects, ensuring reliable performance in the UK's diverse climate conditions. Proper application techniques will maximise their effectiveness, contributing to the longevity and durability of building structures.

Key Advantages for Modern Facade Construction

One of the primary advantages of UV facade tapes in contemporary construction is their exceptional resistance to environmental factors.

These tapes are crafted from UV-stabilised polypropylene or acrylate coatings, allowing them to endure prolonged exposure to sunlight without deterioration. They perform effectively across a wide range of temperatures, ensuring suitability for various climates.

Moreover, these tapes exhibit resistance to chemicals, humidity, and adverse weather conditions, guaranteeing long-lasting sealing solutions. Their UV resistance ensures durability even under prolonged sunlight exposure.

Enhanced with scrim or robust backing, they provide additional strength for outdoor applications. Their waterproofing and sealing capabilities significantly minimise water and vapour ingress, safeguarding the facade and enhancing durability.

In addition, these tapes offer excellent adhesion, even on cold or challenging surfaces.

Conclusion

UV facade tape provides robust, weather-resistant protection for building exteriors. Its formulation ensures strong adhesion and flexibility across a variety of surfaces, making it straightforward to install when proper techniques are employed. The tape's durability against weathering enhances its longevity, thereby supporting the long-term integrity of facades. When applied correctly, it contributes to modern building systems by preventing damage and minimising maintenance requirements. Overall, UV facade tape offers a reliable and cost-effective solution for preserving both the aesthetic appeal and durability of building facades.