B and Q Insulated Plasterboard

B&Q offers a selection of insulated plasterboards designed to enhance thermal performance and simplify installation in both residential and commercial projects. These boards are available in a variety of materials, including polystyrene-backed options such as EPS and XPS, as well as PIR and phenolic foam, each providing different levels of insulation and moisture resistance.

The installation process involves preparing surfaces by cleaning, then applying an appropriate adhesive before fixing the boards with suitable fasteners. Prices generally range from affordable to premium, depending on the material type and thickness selected.

A detailed examination of the products provides specific specifications and practical guidance to optimize insulation effectiveness. This ensures the right choice is made for individual project requirements, promoting energy efficiency and comfort.

Overview of B&Q Insulated Plasterboard Products

The B&Q insulated plasterboard products are engineered to enhance wall insulation and surface quality in both new builds and retrofit applications. These boards typically measure around 2400mm by 1200mm, covering approximately 2.88 square metres per sheet efficiently. The thickness varies depending on the insulation core and plasterboard layer, usually around 37.5mm when using PIR insulation or approximately 22mm with EPS insulation, offering flexibility to meet different thermal performance requirements. Designed with tapered edge profiles, these boards enable seamless jointing and achieve smooth surface finishes. Their lightweight construction, with typical weights close to 10kg per square meter for PIR types, simplifies handling and installation. Multiple packaging options are available, including single sheets and bulk packs, catering to a range of project sizes and ensuring adaptable application. These products are generally classified under Euroclass B fire ratings, complying with UK standards for fire safety. The materials used and their fire ratings ensure safety and compliance. Additionally, many B&Q insulated plasterboards incorporate high-performance insulation materials that contribute to improved thermal efficiency. Whether for refurbishments or new constructions, B&Q insulated plasterboard provides an effective solution to improve thermal efficiency and surface aesthetics, supporting sustainable building practices across the UK.

Types and Materials Available at B&Q

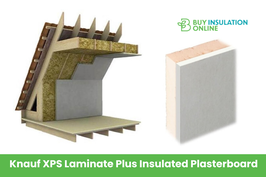

B&Q offers a comprehensive selection of insulated plasterboard types and materials, specifically tailored to meet various construction and renovation requirements across the UK. Standard insulated plasterboards generally consist of a plasterboard sheet bonded to an insulation core, making them suitable for a range of general applications. Insulated plasterboards can be bonded to different substrates to improve thermal performance and reduce heat loss.

For environments with higher humidity, moisture-resistant options are available. These incorporate rigid polyisocyanurate (PIR) foam with dual vapour barriers, providing enhanced moisture protection and thermal performance.

Polyisocyanurate (PIR) plasterboards feature a foam core with a low thermal conductivity of approximately 0.022 W/mK. They're highly effective at reducing heat transfer, making them ideal for energy-efficient building projects.

Polystyrene-backed plasterboards, available in expanded polystyrene (EPS) and extruded polystyrene (XPS) varieties, differ in their density and moisture resistance characteristics. EPS boards are lightweight and cost-effective, while XPS boards offer superior moisture resistance, suitable for more demanding environments.

Phenolic foam boards boast a fibre-free, thermoset phenolic core, delivering exceptional thermal insulation with a conductivity around 0.018 W/mK. These boards also include integrated vapour controls, making them suitable for use in highly insulated, moisture-sensitive areas.

All of these types and materials are available in a variety of sizes and thicknesses, designed to accommodate both domestic and commercial projects. The choice of core material impacts insulation performance and application suitability.

Whether seeking standard solutions or specialized insulation performance, B&Q provides materials to meet diverse building requirements across the UK.

Thermal Performance and Benefits of B&Q Insulation Boards

Insulated plasterboards are engineered to significantly enhance the thermal performance of internal wall systems, helping to reduce heat transfer and boost energy efficiency within buildings. These boards insulate much more effectively than standard wallboard, with the Thermaline PIR 28mm board featuring an insulant with a thermal conductivity of just 0.022 W/mK, resulting in a low U-value of approximately 0.50 W/m²K. This improved insulation capability reduces heat loss, maintains consistent indoor temperatures, and can lead to lower energy bills. Additionally, the Gyproc bonded polymer the boards contain acts as an effective barrier to heat flow, further enhancing their insulating properties. The table below highlights key differences:

Product Type |

Thermal Conductivity (W/mK) |

U-Value (W/m²K) |

| Thermaline Tapered Edge 22mm | 0.04 | 1.1 |

| PIR 28mm | 0.022 | 0.50 |

The boards’ moisture resistance also makes them suitable for damp environments, supporting the longevity and durability of the insulation system.

These features support energy savings and enhance indoor comfort, aligning with sustainable and energy-efficient building practices in the UK.

Installation Tips and Practical Uses

Proper installation of insulated plasterboard requires careful preparation, precise application methods, and attention to detail to ensure maximum thermal performance and structural stability. Using quality fixings and adhesives can significantly improve the durability of the installation and prevent future issues. Always verify that the materials used meet industry standards for insulation and fixation to achieve optimal results.

Ensure that wall surfaces are clean, dry, flat, and free of dust or debris before starting. This promotes proper adhesion and reduces the risk of future problems.

Use appropriate tools such as utility knives for cutting, spirit levels for ensuring accurate alignment, and screwdrivers for fixing. These tools help achieve a neat and secure installation.

Apply adhesive in a continuous zigzag bead or use the dot and dab method, depending on the irregularities of the wall surface. Once applied, press the panels firmly into place to minimize gaps.

Space screws between 150 mm and 300 mm along the edges and between 300 mm and 600 mm across the boards to maintain stability and support curing. Proper screw spacing ensures the panels are securely fixed and reduces movement over time.

Following these steps will facilitate effective insulation and help ensure long-lasting, energy-efficient results.

Price Range and Selection Guide

The cost of insulated plasterboard varies significantly depending on factors such as material type, thickness, and supplier, with retail prices generally ranging from approximately £38 to over £110 per sheet.

Lower-cost options include EPS bonded boards priced around £38, making them suitable for budget-conscious projects. These boards typically offer acceptable thermal performance, providing a cost-effective solution for basic insulation needs.

Mid-range options, such as extruded polystyrene (XPS) and polyisocyanurate (PIR) boards, usually fall between £48 and £105 per sheet. PIR boards are often regarded as offering a good balance of thermal efficiency and cost, making them popular for both retrofit and new-build applications in the UK.

Premium phenolic insulation boards, which provide superior thermal properties and lower U-values, can cost up to £69 or more per sheet, especially in thicker sizes. These high-performance boards are ideal where space is limited or where stricter thermal standards are mandated.

The price of insulated plasterboard also correlates directly with its thermal efficiency. Materials like phenolic panels, which exhibit better insulation capabilities or lower U-values, tend to be at the higher end of the price range.

Purchasing in bulk or through trade accounts can often reduce costs, particularly for large-scale projects requiring multiple sheets. This option is worth exploring for builders and contractors aiming to optimize their budget without compromising on quality.

Conclusion

B&Q insulated plasterboard offers a range of materials and types suited for various thermal insulation needs, providing effective energy conservation and cost savings. Its straightforward installation process, combined with reliable thermal performance, makes it a practical choice for both renovation and new build projects.

By selecting the appropriate product within the available price range, users can achieve desired insulation levels efficiently. Overall, B&Q insulation boards provide a durable, cost-effective solution grounded in clear specifications and practical application considerations.