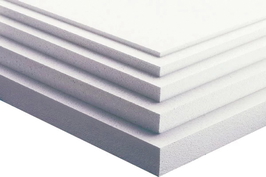

Foam Board Insulation

Foam board insulation includes types such as expanded polystyrene (EPS), extruded polystyrene (XPS), and polyisocyanurate (Polyiso), each offering distinct advantages like thermal resistance, moisture resistance, and strength. EPS is lightweight and cost-effective but less resistant to moisture; XPS provides higher moisture resistance and durability, making it suitable for damp environments; Polyiso offers some of the highest K-values and is often foil-faced to reflect heat. Proper selection depends on application specifics, environmental factors, and performance requirements. Exploring these options carefully can help optimise insulation effectiveness in a variety of settings.

Types of Foam Board Insulation and Their Characteristics

There are various types of foam board insulation, each with unique properties that influence their suitability for specific building applications. Expanded Polystyrene (EPS) is lightweight, straightforward to cut, and budget-friendly. However, it offers lower moisture resistance and a reduced thermal resistance per millimetre, meaning thicker panels are necessary to achieve effective insulation. EPS can be used in a wide range of applications, including roof, wall, floor, below grade, and geo applications. Extruded Polystyrene (XPS) provides greater strength and moisture resistance compared to EPS. It features a higher thermal resistance per millimetre, making it well-suited for environments exposed to humidity or water, such as beneath ground or in basements. Polyisocyanurate (Polyiso) insulation offers the highest thermal resistance among foam board options. It performs particularly well in moderate climates and often comes with foil facings, which assist in reflecting radiant heat, thereby enhancing insulation performance. Additionally, the durability and appropriate thickness of these boards depend on the project’s specific load-bearing requirements and material strength, impacting the long-term performance of the insulation. Additional variants include polyurethane boards and customised panels tailored with specialised features such as fire resistance or soundproofing capabilities. The choice of foam board insulation depends on the specific requirements of the building project, considering factors like moisture exposure, structural strength, thermal performance, and any specific safety or acoustic considerations.

Understanding R-Values and Thermal Performance

Understanding K-values and the thermal performance of foam board insulation requires an examination of how effectively these materials resist heat transfer, as indicated by their thermal transmittance ratings. The K-value measures a material’s rate of heat transfer per unit area and temperature difference, with lower values signifying better insulation performance. [R-values are essential for assessing overall insulation quality. For example, polyisocyanurate foam offers approximately 0.022 W/m²K per centimetre, while extruded polystyrene (XPS) typically has a K-value around 0.031 W/m²K. Graphite-enhanced expanded polystyrene (EPS) can achieve even lower K-values, around 0.020 W/m²K. However, these initial ratings can change over time; some foam boards experience increases in their K-values due to ageing or environmental exposure, which diminishes their insulating efficacy. Thermal ageing can cause deterioration in foam insulation materials, impacting their long-term performance. Temperature also influences the thermal performance of foam insulations. XPS tends to maintain or slightly improve its insulating properties in colder conditions, whereas polyisocyanurate (polyiso) may experience a slight decline in efficiency at lower temperatures. Understanding these factors is essential for selecting insulation materials that will maintain optimal performance over time, help reduce energy costs, and ensure compliance with UK building regulations and standards. Proper selection and application of foam insulation require considering both the initial thermal performance and how it may evolve throughout the lifespan of the building, ensuring consistent energy protection and comfort.

Moisture Resistance and Durability of Foam Boards

Moisture resistance is a vital aspect in determining the durability of foam board insulation, as exposure to water can jeopardise both its structural integrity and insulating performance. Extruded Polystyrene (XPS) boards, with their homogeneous closed-cell structure, demonstrate very low water absorption, typically between 0.1% and 0.3% by volume. This makes them highly resistant to moisture ingress. Conversely, Polyisocyanurate (Polyiso) and Expanded Polystyrene (EPS) absorb more moisture—up to 3%—which can weaken their insulating properties and create conditions conducive to mould growth if water penetrates the insulation over time. Water resistance varies significantly depending on the type of foam board used. Proper installation is essential to optimise moisture resistance, including sealing seams and edges to prevent water infiltration, particularly in areas where foam boards are exposed to damp conditions. Additionally, selecting foam boards with improved moisture barriers can further enhance their performance in moist environments. When suitably protected from moisture, foam boards can have a lifespan exceeding 50 years, maintaining their performance and structural stability over time.

Application Areas, Environmental Impact, and Cost Considerations

Foam board insulation is widely utilised across various construction applications due to its effective thermal properties and ease of installation. It's commonly used in residential walls, particularly beneath cladding or in basements, to enhance thermal resistance. Additionally, it's employed in commercial roofing systems with rigid foam panels.

Its suitability extends to insulating foundations and areas below ground level, although performance can vary depending on the specific product type.

From an environmental perspective, the use of blowing agents such as CFCs and HCFCs in the manufacturing process has raised concerns due to their high global warming potential. Disposal of foam boards in landfill sites presents further challenges, as harmful chemicals can be released during degradation. Using environmentally friendly foam insulation materials can mitigate some of these impacts and promote sustainability.

These environmental impacts underscore the importance of sourcing foam insulations made with greener alternatives, such as recycled materials or less harmful blowing agents.

When considering costs, initial expenses differ based on the type of foam used, but these are often offset by long-term energy savings through improved insulation. Proper installation and the utilisation of recycled foam products can enhance both economic and environmental outcomes, contributing to more sustainable building practices.

Conclusion

Choosing the appropriate foam board insulation requires careful consideration of factors such as type, thermal resistance, moisture resistance, and environmental impact. Understanding these characteristics ensures optimal thermal performance, durability, and suitability for specific applications. While cost remains an important factor, prioritising quality and environmental considerations promotes long-term efficiency and sustainability.

Making informed decisions based on detailed technical knowledge improves insulation effectiveness, ultimately contributing to energy efficiency and the structural integrity of building projects.