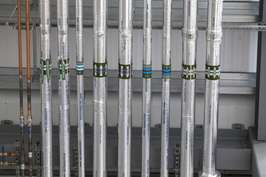

Insulated Pipe Sleeves

Insulated pipe sleeves are protective barriers designed to safeguard pipes in various environments. Constructed from materials such as carbon steel, stainless steel, PVC, rubber, or fiberglass, these sleeves are customized to meet specific environmental conditions and piping requirements.

Their primary functions include providing thermal insulation to minimize heat loss and maintain temperature integrity. Additionally, insulated pipe sleeves help to reduce noise arising from fluid flow, and they protect pipes from corrosion and physical damage caused by external factors.

To ensure optimal performance, proper installation is essential. This involves accurate measurement of pipe dimensions, securing the sleeves firmly to prevent movement, and sealing any gaps effectively to maintain insulation integrity. Routine maintenance checks are also important to identify and address potential issues early, thereby extending the lifespan of the insulation system.

A comprehensive understanding of these factors enhances knowledge of how insulated pipe sleeves contribute to improved efficiency and safety across a range of applications. Whether in industrial, commercial, or infrastructural settings, well-installed insulation not only preserves pipe functionality but also supports regulatory compliance and operational durability.

Types and Materials of Insulated Pipe Sleeves

When selecting insulated pipe sleeves, it's essential to understand the various types and materials available, each designed to meet specific application requirements and environmental conditions.

Common materials include carbon steel, valued for durability and resistance to corrosion, and stainless steel, which offers superior corrosion resistance suitable for high-moisture environments.

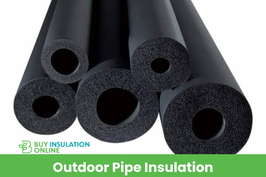

PVC provides a lightweight and cost-effective option with good chemical resistance, making it suitable for less demanding applications.

Rubber supplies flexibility, often utilized in sleeves or gaskets, enabling easier installation around complex pipe configurations.

Fiberglass excels in heat resistance and thermal insulation, making it ideal for high-temperature environments.

Appreciating the properties of these materials assists users in selecting the most appropriate sleeve tailored to their project's needs, ensuring optimal performance, longevity, and compatibility with specific piping systems.

Understanding how fire safety standards influence material choices can help ensure compliance and safety during installation and operation.

Advantages of Using Insulated Pipe Sleeves

Insulated pipe sleeves offer substantial benefits by enhancing the efficiency, safety, and dependability of piping systems. They're particularly effective in reducing heat loss during the conveyance of hot water or steam, which minimizes the energy required to sustain desired temperatures. This leads to improved energy efficiency and notable cost savings for users. Proper installation of these sleeves is crucial to ensure maximum insulation performance and long-term durability. By decreasing heat loss, insulated sleeves also lessen the operational burden on heating systems, contributing to longer equipment lifespan and reduced maintenance requirements. Additionally, using acoustic pipe wrap or similar soundproofing materials can further minimise noise transmission from pipes, improving overall comfort. Furthermore, they bolster safety by preventing pipes from freezing, lowering condensation risks, and minimising issues related to moisture accumulation. Insulated sleeves make a positive environmental impact as well, by decreasing overall energy consumption and reducing greenhouse gas emissions. Their protective barrier shields pipes from external damage and corrosion, helping to maintain consistent performance over time.

Installation, Maintenance, and Safety Considerations

Proper installation, maintenance, and safety of insulated pipe sleeves are essential to ensuring their long-term performance and the safety of personnel handling them. During installation, professionals must measure pipes accurately, cut the sleeves to the correct length using suitable tools, and carefully wrap them around the pipe. Ensuring correct alignment and sealing any gaps in accordance with manufacturer instructions is crucial. Securing the sleeve with tape or adhesive helps prevent movement during operation. A final inspection should be carried out to verify proper placement and the integrity of the insulation. Using proper insulation techniques is vital to maximize thermal efficiency and prevent future issues such as deterioration or heat loss. Regular maintenance involves inspecting the sleeves for any signs of damage, cleaning them using appropriate materials, and repairing or replacing worn or damaged sleeves following clear guidelines. Safety measures include using fire-resistant materials where appropriate, ensuring moisture barriers are intact to prevent deterioration, and avoiding installation near electrical components to reduce risks. Proper handling and installation procedures help to minimise hazards, extend the lifespan of the insulation, and support the safe and reliable operation of piping systems.

Conclusion

Selecting the correct insulated pipe sleeve is essential to meet the specific demands of your project. Consider factors such as the compatibility of materials, environmental conditions, and thermal performance to ensure optimal insulation. Proper installation is crucial for effective thermal management, and routine maintenance helps uphold safety and efficiency over time.

It is important for professionals to adhere to safety guidelines during installation to prevent potential hazards. By understanding the various types of insulated pipe sleeves and their respective benefits, users can make well-informed decisions. This ensures the longevity, safety, and optimal operation of piping systems in a wide range of industrial and commercial settings across the UK.