Insulated Plasterboard 22MM

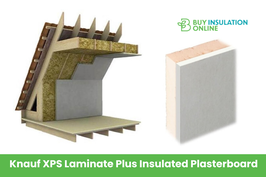

Insulated plasterboard with a thickness of 22mm combines a standard plaster surface with an integrated layer of insulation, typically a 12.5mm expanded polystyrene core bonded to gypsum board. This design enhances thermal performance by reducing heat transfer, thereby supporting energy efficiency and improving fire safety due to its non-combustible core.

Proper installation of 22mm insulated plasterboard involves preparing the surface, applying adhesive correctly, and ensuring secure fixing to the substrate. Achieving an effective airtight seal and proper insulation setup is essential for maximum performance. When installed correctly, this system can optimize building energy efficiency, making it a sustainable choice for modern construction projects across the UK.

Attributes and Benefits of the 22mm Insulated Plasterboard

The 22mm insulated plasterboard provides notable attributes that enhance both the thermal performance and safety of internal walls. Its construction features a 9.5mm gypsum wallboard bonded to 12.5mm expanded polystyrene insulation. This results in a U-value of approximately 0.28 W/m²K, which effectively reduces heat transfer and helps lower energy costs. The low thermal conductivity of polystyrene offers excellent resistance to heat flow, aiding in maintaining warmer indoor environments during colder months. Its overall thickness boosts insulation capacity while conserving space, making it particularly suitable for buildings where space is limited. Furthermore, the gypsum core is non-combustible, granting the board a Class 0 fire rating and restricting the spread of flames. These attributes ensure the board complies with safety standards and contribute to creating a more energy-efficient and secure internal environment. Incorporating fire-resistant materials such as these enhances building safety by slowing fire spread and protecting occupants.

Installation Strategies and Tips for Optimal Performance

Proper installation of insulated plasterboard is vital to maximize its thermal performance and safety benefits. It requires meticulous attention to preparation, adhesion, fixing, handling, and finishing procedures. Below are essential guidelines to ensure a high-quality installation:

Surface Preparation

Begin by ensuring all surfaces are clean, dry, and flat. Remove any protrusions, dust, or debris that may impede adhesion. Take accurate measurements and make precise cuts, allowing small gaps to accommodate slight expansion and contraction in the material. A well-prepared surface promotes better adhesion and a more uniform finish. Note that properly prepared surfaces can also help prevent issues like mold growth or thermal bridging. Ensuring that the substrate is compatible with adhesive systems is crucial for performance.

Adhesive Application

Apply the adhesive in continuous beads or as dot-and-dab, depending on the manufacturer's specifications. Ensure the spread is even across the entire surface area of the plasterboard. Allow the adhesive to become tacky before fixing the panels, which helps prevent slippage and ensures a strong bond.

Fixing and Securing

Align the panels carefully using guidelines or a spirit level to ensure a straight and level finish. Press the panels firmly into place to promote good contact with the adhesive. Secure each panel with appropriate fixings, such as screws or nails, maintaining the recommended minimum distances from edges and at regular intervals across the panel. This ensures stability and reduces the risk of movement or cracking over time. Proper fixing techniques also contribute to the overall durability of the installation.

Handling and Cutting

Handle the panels with care during cutting and installation to prevent damage to the insulation core. Use sharp tools and support the panel during cutting to avoid breakage or undue stress. Proper handling preserves the integrity of the insulating material and ensures a tighter, more effective installation.

Finishing

Once fitted, check that the panels are level and flush. Fill any gaps or misalignments with suitable filler and ensure fixings are flush with the surface. Allow adequate curing time for adhesives and fillers before proceeding with plastering or finishing coats. Inspect all screw fixings for flushness and add sealant or tape as required to achieve a seamless, professional appearance. A well-executed finish not only enhances aesthetics but also improves energy efficiency. Incorporating joint systems, such as membranes or tapes, further enhances airtightness and reduces thermal bridging.

Environmental Impact and Regulatory Standards Compliance

Environmental impacts of insulated plasterboard primarily stem from its manufacturing processes, material composition and end-of-life disposal, all of which influence its overall sustainability profile.

During production, approximately 12 kg of CO? is emitted per sheet over its lifespan. These emissions mainly originate from gypsum extraction, manufacturing, and landfill waste.

Increasing the recycled gypsum content from 10.5% to 25% can marginally reduce emissions by conserving virgin resources. Using recycled materials helps lower environmental impact.

Transport distances for waste and recycled materials play a significant role in environmental footprints; shorter transport routes help lower associated emissions.

The long lifespan of the product reduces the frequency of replacement, thereby decreasing overall material use and energy consumption.

In addition, the product complies with fire safety regulations, with core materials that are free from chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs).

These materials feature low Global Warming Potential (GWP) and zero Ozone Depletion Potential (ODP), supporting adherence to environmental standards.

Recycling gypsum and minimising waste contribute positively to circular economy principles and help reduce landfill impact, further enhancing the sustainability credentials of insulated plasterboard in compliance with UK environmental regulations.

Furthermore, the manufacturing process incorporates eco-friendly innovations that reduce chemical emissions and enhance overall environmental performance.

Conclusion

In summary, the 22mm insulated plasterboard offers an effective combination of thermal performance and structural stability, making it a versatile choice for various construction projects across the UK. Proper installation is essential, including the correct securing techniques and joint treatments, to ensure optimal durability and insulation efficiency.

Adherence to environmental and safety standards is also crucial, as it helps minimise ecological impact and ensures compliance with relevant regulations. By understanding the key attributes of this product and following recommended installation practices, users can achieve energy-efficient, compliant, and long-lasting wall systems that meet modern building requirements effectively.