Insulated Plasterboard Thicknesses

Insulated plasterboard thicknesses vary depending on their intended use, typically ranging from about 9.5mm for lightweight ceiling panels to over 80mm for high-performance fire-resistant or thermal panels. Common configurations combine a 12.5mm plasterboard with insulation layers between 25mm and 62.5mm thick, which influence the overall thermal performance and space requirements of a building. Thicker boards generally offer better insulation properties but require more substantial fixing methods and take up additional space.

When selecting the appropriate insulated plasterboard, it is important to consider both the thermal requirements and the available space within the building design. For interior wall insulation, standard panels are often sufficient, but for external applications or areas needing enhanced fire resistance, specific thicker or specialized boards are recommended.

For detailed guidance and to ensure an optimal choice for your insulation needs, consulting relevant building regulations and technical specifications is advised. This will help you identify the most suitable thickness and type of insulated plasterboard for your project.

Common Thickness Ranges and Their Uses

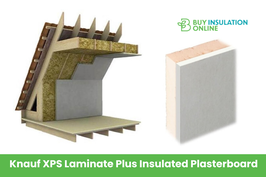

Insulated plasterboard thicknesses are primarily determined by their intended application and performance requirements, with standard ranges tailored to specific functional needs. Typically, 12.5mm plasterboard is used for general dry lining and plastering, providing a balance of strength and finish quality. For ceilings or areas requiring lightweight materials, 9.5mm boards are common, facilitating easier handling and reducing load. Insulated boards used in retrofit or high-performance settings generally feature insulation layers ranging from 25mm to 62.5mm, resulting in total thicknesses from approximately 37.5mm to over 75mm. Thicker options, such as those exceeding 80mm, serve specific environments, like improved fire resistance or superior thermal performance. Manufacturers like Celotex offer a range of sizes, with total thicknesses corresponding to insulation layer increments, aiding in selecting suitable boards for diverse building needs. An important consideration is that thermal insulation requirements vary significantly based on climate and building standards, influencing the choice of thickness. INCREASED THICKNESS of insulated plasterboard enhances thermal performance and fire resistance, making them ideal for demanding environments.

How Thickness Influences Thermal Performance

Increasing the thickness of insulated plasterboard directly enhances its thermal resistance. A thicker layer of insulation material provides a more substantial barrier to heat transfer, effectively lowering the U-value of the wall assembly. More insulation layers can improve overall energy efficiency.

Thicker boards, particularly those made from materials such as phenolic foam or PIR, enable lower U-values. This results in reduced heat loss and maximizes energy efficiency within buildings.

The thermal conductivity of insulation materials affects the required thickness; materials with lower conductivity, such as phenolic foam (~0.018 W/mK), can achieve better insulation performance with thinner profiles.

While increasing thickness boosts insulation efficiency, it may also reduce internal space. Careful consideration is needed during design and renovation projects to balance thermal benefits with spatial constraints.

Thicker insulation layers also help minimize thermal bridging at fixings or structural components, creating more continuous insulation and improving the overall thermal performance of the building envelope.

Considerations for Installing Different Thicknesses

Considerations for Installing Different Thicknesses of Insulated Plasterboard

The choice of insulated plasterboard thickness must consider several practical installation factors, as these impact both the approach and safety protocols required during fitting. Thinner boards, around 25mm, are ideal for confined spaces and often require high-performance materials such as PIR to maintain thermal efficiency without compromising space. Using the right insulation material can improve energy savings and fire safety, aligning with building regulations.

When opting for thicker boards, typically between 50mm and 75mm, adjustments to existing fixtures such as electrical sockets or switches are necessary. Mechanical fixings are also recommended, especially when attaching these boards to walls prone to moisture exposure, to ensure secure and durable fixing. Proper fixing techniques are essential to accommodate the increased weight and prevent future issues like sagging or detachment.

Proper wall preparation is crucial prior to installation. Ensuring the surface is stable, dry, and free of debris helps achieve a better bond and reduces the risk of issues such as sagging or detachment over time. Selecting the appropriate insulation thickness helps ensure compliance with standards like BS 5422:2009 and supports effective thermal insulation.

Thicker boards impart additional weight, which in turn demands more robust fixing solutions to prevent movement or damage. Handling heavier boards requires proper tools and techniques to ensure safety and secure attachment during installation. Moreover, the choice of thickness can influence the acoustic and thermal performance, which should align with the specific requirements of the space.

Furthermore, the type of wall, relevant building regulations, and potential moisture risks play significant roles in determining suitable thickness. Selecting the appropriate board thickness ensures compliance with regulations and guarantees optimal thermal performance and durability.

Conclusion

Choosing the appropriate insulated plasterboard thickness depends on specific insulation requirements, available space, and installation conditions. Thicker boards generally provide enhanced thermal performance, helping to reduce heat loss and improve energy efficiency. However, they can also decrease the internal room dimensions, which may not be suitable for all projects. Conversely, thinner options tend to be easier to install and preserve more interior space but might offer less insulation value.

It is important to assess these factors carefully to ensure effective thermal management and structural compatibility. Proper measurement and planning help in selecting the most suitable plasterboard thickness, balancing insulation performance with practical considerations. By understanding the influence of board thickness on U-Values, energy efficiency, and building durability, installers can make informed decisions that contribute to creating well-insulated, sustainable, and comfortable environments.