Insulated Plasterboard Wickes

Wickes offers a selection of insulated plasterboards designed to enhance thermal efficiency in both residential and commercial buildings by incorporating insulation materials such as PIR, phenolic foam, or extruded polystyrene within the board. These boards are available in a variety of sizes and thicknesses, with some featuring moisture-resistant vapour barriers suitable for use in bathrooms and kitchens. Proper installation involves ensuring surfaces are clean and flat, making precise cuts, and securely fixing the boards using appropriate adhesives and battens. Continued guidance will provide detailed instructions to optimize performance and ensure effective insulation.

Overview of Wickes Insulated Plasterboard Options

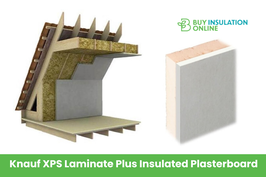

Wickes offers a comprehensive range of insulated plasterboards designed to meet diverse thermal insulation requirements for internal walls and ceilings. These boards feature various insulation cores, including PIR, XPS, EPS, and phenolic foam, each selected for their specific performance characteristics. Insulated plasterboards are bonded wallboards with an insulation core made from materials such as EPS, phenolic foam, and XPS. Standard boards combine drywall with pre-bonded insulation cores, enabling straightforward and efficient installation. Moisture-resistant variants incorporate vapour barriers and are suitable for high-humidity areas such as bathrooms or kitchens. Phenolic foam boards, such as Kingspan K118, provide low thermal conductivity and combine insulation with vapour control within a single unit, making them ideal for tighter space requirements and enhanced thermal performance. Other options include Knauf’s thermal laminate boards, which are bonded with EPS for high compressive strength and eco-friendliness. These insulated plasterboards are available in common dimensions of 2400 mm x 1200 mm and with thicknesses ranging from 22 mm to 50 mm, catering to a broad spectrum of insulation needs. They're designed to deliver precise specifications for durability, ease of installation, and thermal performance, ensuring suitability for both residential and commercial applications across the UK. Additionally, the incorporation of mineral wool as an insulation core option offers excellent fire resistance and acoustic properties, making these boards suitable for a variety of building projects.

Key Features and Benefits of Wickes Insulated Plasterboards

An important benefit of Wickes insulated plasterboards is their enhanced thermal performance, which can reduce heat loss through walls by up to 25 percent. This is achieved through their construction, which combines plasterboard with high-quality insulation cores such as PIR, phenolic foam, or extruded polystyrene. The boards typically have low thermal conductivity values, around 0.018 to 0.033 W/mK, enabling excellent insulation properties that help lower energy bills. Some variants of Wickes insulated plasterboards are designed with moisture-resistant features, including vapour barriers, making them suitable for humid environments like bathrooms and kitchens. Others offer acoustic benefits, contributing to noise reduction and creating more comfortable internal spaces. These boards simplify installation by integrating insulation and plasterboard into a single panel, significantly reducing labor time and effort. They're available in a variety of thicknesses to suit specific thermal and moisture control needs, supporting sustainable building practices by decreasing reliance on heating systems and reducing the overall carbon footprint. They are also recyclable, supporting environmentally friendly construction.

Installation Tips and Best Practices for Wickes Insulated Plasterboards

Proper installation of Wickes insulated plasterboards requires careful attention to surface preparation, measurement, and fixing procedures to ensure optimal thermal performance and structural stability. The wall surface must be clean, dry, and flat to maximize adhesive bonding and screw fixation. A flat surface is essential for proper adhesion and alignment. Accurate measurement and precise cutting of panels are essential. Maintain a gap of approximately 15mm from floor to ceiling to accommodate expansion and facilitate fitting.

When fixing vertical battens, mark their positions at a maximum of 600mm centers, ensuring they're level and secure. Horizontal battens should be positioned at key locations around openings and other critical points. Support the boards temporarily with packing strips until the adhesive and fixings are fully set. Incorporating proper insulation materials can significantly improve thermal efficiency and climate control in your project.

Apply adhesive in a continuous bead along the length of each board, combining this with mechanical fixings spaced between 150mm and 300mm along the edges and between 300mm and 600mm across the panels. Use fixings that are flush with the surface to prevent distortion. Ensure joints are tightly butted and sealed thoroughly with appropriate foam and sealant to achieve the best thermal and airtight performance.

Paying close attention to these steps will help ensure a high-quality finish, enhancing the insulation’s effectiveness and the overall integrity of the wall assembly.

Conclusion

Wickes insulated plasterboards offer an effective solution for enhancing wall insulation through straightforward installation procedures. Their key features include high thermal performance, ease of handling, and compatibility with standard building methods, making them suitable for both commercial and residential projects. Proper installation—comprising accurate measurements, secure fixing, and careful sealing—ensures optimal performance and durability. By adhering to manufacturer guidelines and best practices, you can achieve energy efficiency and improved indoor comfort across various construction settings.