Thermal Plasterboard

Thermal plasterboards are specialized wall panels designed to improve the thermal performance of building structures. Their cores are primarily composed of gypsum, which is reinforced with mineral fibres and fire-resistant additives such as boric acid. These components enhance fire safety, stability, and durability, making them suitable for various construction applications.

Incorporating insulation materials such as expanded polystyrene (EPS) within the boards significantly boosts energy efficiency. This integration helps in reducing heat transfer, stabilizing indoor temperatures, and lowering heating costs. Thermal plasterboards can be utilized on walls, ceilings, or floors across a range of building projects.

Many thermal plasterboards also incorporate vapour barriers to control moisture levels and prevent condensation issues within the building fabric. Understanding how the composition of these boards influences their performance and ease of installation is important for ensuring optimal building performance and longevity. Further detailed information is available regarding their specific components and applications.

Composition and Core Materials of Thermal Plasterboard

Thermal plasterboard mainly comprises a core material based on gypsum, specifically calcium sulphate dihydrate, which is heated to eliminate water content and then ground into a fine powder for manufacturing purposes. This core provides the board with its essential structural integrity, typically with a density ranging from 800 to 1,000 kg/m³, balancing durability and weight. The composition often includes hydratable calcium sulphate, making up between 55% and 92% of the core. This component contributes significantly to fire resistance and dimensional stability, ensuring the material performs reliably under various conditions. Reinforcement materials, such as mineral or refractory fibres, are incorporated at low percentages—generally between 0.1% and 5%—to enhance the mechanical strength and fire-protective qualities of the plasterboard. Additionally, boric acid is added in concentrations of 1% to 4%, which further improves fire resistance and reduces shrinkage during ignition, supporting fire-resistant properties and maintaining performance over time. Gypsum's mineral form plays a crucial role in the core's overall performance and fire-resistant properties, making it an essential component of thermal plasterboard.

Enhancing Energy Efficiency With Insulated Boards

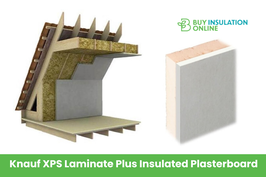

Insulated plasterboards, such as Warmline EPS, greatly enhance building energy efficiency by offering high thermal resistance, which reduces heat transfer through walls and diminishes energy loss. This increased insulation helps to maintain stable indoor temperatures throughout the year, leading to a decrease in reliance on heating and cooling systems. Incorporates high-quality EPS insulation to minimize heat loss, which contributes to long-term energy savings and lower utility bills for property owners. As a result, properties can achieve heating cost savings of up to 25%, supporting both lower operational expenses and sustainability efforts. The improved thermal performance also lessens the internal energy demand on HVAC systems, potentially extending their operational lifespan and reducing maintenance costs. Furthermore, by minimizing thermal bridging and preventing draughts, insulated plasterboards deliver consistent indoor comfort in both winter and summer. This thermal performance combined with quick installation benefits makes insulated boards a practical and effective solution for enhancing building efficiency across the UK.

Practical Applications and Installation Advantages

Thermal plasterboard provides a flexible and effective solution for enhancing insulation in a range of building types throughout the UK. It acts as a reliable thermal barrier for walls, ceilings, and floors in both residential and commercial properties.

Its practical uses include application during new builds, renovation projects, and retrofit installations where improved insulation is essential.

The boards can be directly fixed onto existing brick walls, which helps minimize space loss compared to traditional insulation methods. They're also suitable as overboarding material, making upgrades within layered wall systems straightforward and less disruptive.

Embedded metallized foil layers within the boards serve as vapour barriers, effectively preventing condensation and safeguarding the structural integrity of the building.

One of the key installation advantages of thermal plasterboard is its lightweight nature, which simplifies handling and accelerates the fitting process. Its compatibility with non-specialist tools makes it accessible for both professional builders and DIY enthusiasts.

Additionally, using thermal plasterboard contributes to energy efficiency improvements by reducing heat loss and maintaining more consistent indoor temperatures. The ease of installation, combined with its versatility, results in faster, more cost-effective construction and renovation projects, contributing to improved energy efficiency across a variety of UK building scenarios.

Conclusion

Thermal plasterboard provides an efficient solution for improving building insulation in the UK, combining specialized core materials with excellent insulating properties to boost energy efficiency. Its simple installation process and compatibility with various construction approaches make it suitable for both new builds and refurbishment projects. By choosing the right types and ensuring proper installation, users can effectively minimise heat loss and reduce energy consumption. This material’s durability and performance establish it as a dependable option for creating cost-effective, sustainable, and comfortable indoor environments.