Waterproof Closed Cell Foam

Waterproof closed cell foam is a robust insulation material characterised by its dense, sealed-cell structure, which offers exceptional resistance to water. Its tightly compacted cells prevent water infiltration and significantly reduce vapour transmission, making it an ideal choice for environments susceptible to dampness or flooding.

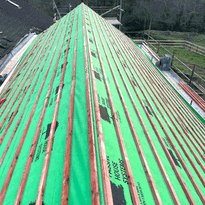

This insulation solution is both durable and long-lasting, and it can be easily applied in various areas of a building, including walls, roofs, and floors. When installed correctly, the waterproof properties are enhanced, while regular maintenance helps to ensure ongoing effectiveness over time.

Discover how this versatile foam can safeguard structures from moisture damage, creating a more resilient and comfortable environment. Whether used in residential or commercial projects, waterproof closed cell foam is a wise investment for protecting properties against the challenges posed by water.

Understanding the Composition and Basic Traits of Closed Cell Foam

Closed cell foam is a type of insulation material produced through a specific chemical process that yields a dense and durable structure. It primarily consists of two components: an “A” component (isocyanate) and a “B” component (resin). The resin is formulated with polyols, catalysts, blowing agents, fire retardants, and surfactants. When these components are combined, a chemical reaction takes place, resulting in rapid expansion and the formation of foam. This leads to tightly packed, closed cells made from polymer walls that trap gases within. The closed-cell structure imparts strength, rigidity, and high density to the foam, showcasing an impressive thermal resistance. The gas trapped inside the cells enhances insulation properties, making closed cell foam highly effective for thermal insulation. The durability of closed cell foam allows it to resist compression and maintain its shape, making it an excellent choice for insulation and sealing applications where strength and protection are paramount. Its properties make it particularly suitable for a variety of uses in construction, automotive, and marine sectors, helping to create energy-efficient and well-sealed environments.

Waterproofing Capabilities and How It Compares to Other Materials

Waterproofing is a significant advantage that distinguishes closed cell foam from numerous other insulation materials. Its tightly packed, sealed cell structure renders it highly water-resistant, creating a seamless barrier against moisture when correctly applied. This effectively prevents water penetration and reduces the risk of mould, mildew, and rot.

In comparison to open-cell foam, which readily absorbs water, closed cell foam absorbs considerably less, making it an excellent choice for various applications. Other materials, such as extruded polystyrene (XPS) and polyisocyanurate (Polyiso), also demonstrate good resistance to water; however, closed cell foam is noted for its superior durability and mechanical strength when exposed to moisture.

It is essential to note that while closed cell foam is resilient, prolonged immersion can compromise its integrity. Therefore, effective drainage and moisture management are crucial in wet environments to maintain its performance.

The Role of Water Vapor Resistance in Building Applications

Water vapour resistance plays a crucial role in building applications by controlling the movement of moisture through walls, floors, and roofs.

The cellular structure of closed cell foam contains fully sealed cells, creating an impermeable network that limits the passage of water vapour. Its low perm values indicate a high resistance to vapour transfer, often negating the need for additional vapour barriers.

By minimising both inward and outward vapour diffusion, closed cell foam effectively prevents condensation, which can lead to issues such as mould, mildew, and rot within building assemblies.

This material also helps to keep insulation dry, thereby maintaining its effectiveness and supporting long-term durability. Its ability to resist water vapor transmission is a key factor in maintaining building integrity.

In colder climates, thicker layers of closed cell foam serve as reliable vapour barriers, ensuring that buildings remain dry and protected from moisture-related complications.

The importance of proper moisture management in construction can't be overstated, as it significantly contributes to the overall health and longevity of a building.

Practical Uses of Closed Cell Foam in Flood-Prone and Moist Environments

In flood-prone and damp environments, the practical application of closed cell foam offers significant benefits for enhancing resilience and durability. Its high resistance to floodwater, classified by FEMA as Class 5, ensures that structures can withstand wetting and drying cycles without sustaining damage. This classification indicates its superior waterproof qualities compared to other materials. Moreover, closed cell foam can be easily cleaned to eliminate harmful contaminants, thereby reducing repair time and associated costs. Its seamless, water-impermeable surface prevents floodwater from trapping debris or bacteria, promoting a healthier environment. Key applications include: - Sealing walls and floors to prevent water intrusion in basements or crawl spaces. - Insulating roof decks to enhance wind resistance and avert leaks during storms. - Reinforcing foundations and slab areas to improve flood recovery, minimising long-term damage. Utilising closed cell foam in these ways not only enhances the integrity of buildings in challenging conditions but also contributes to more efficient maintenance and longevity.

Durability and Longevity: What to Expect With Proper Installation

When correctly installed, closed-cell foam can provide exceptional longevity, often lasting well beyond 15 years, and in some cases, up to several decades with top-quality spray foam. Proper installation is crucial to ensure the foam remains waterproof, maintains its shape, and resists wear and tear. Conversely, inadequate application can lead to premature deterioration and diminished effectiveness. The durability and long-term performance of closed-cell foam largely hinge on meticulous installation and regular maintenance. Additionally, understanding the factors that affect foam lifespan can help in optimising its durability over time. Therefore, investing in skilled professionals for installation and adhering to maintenance guidelines is essential for maximising the benefits of this insulation material.

Resistance to Water Damage

Properly installed closed-cell foam offers robust resistance to water damage, making it a durable choice for various construction applications. Its dense structure significantly reduces water absorption, typically absorbing less than 1% by volume, functioning more as a water-resistant barrier than as a moisture-retaining material. This low absorption rate makes it especially effective in preventing water infiltration in high-humidity or flood-prone areas. Key benefits include:

Maintaining structural integrity during flooding, as recognised by relevant building regulations as flood-resistant material.

Reducing the risks of mould, mildew, rot, and bacteria growth due to its waterproof characteristics.

Preserving insulation performance over time by preventing water-related deterioration and moisture accumulation.

While prolonged exposure to standing water can eventually compromise the foam, correct installation, protective coatings, and effective moisture management greatly enhance its longevity.

This resilience makes closed-cell foam a dependable option for both indoor and outdoor applications, provided it's installed correctly and maintained appropriately.

Proper Installation Importance

Proper installation of closed-cell foam is crucial for ensuring its longevity and effectiveness. To achieve strong adhesion, it's essential that surfaces are clean, dry, and devoid of dust, oils, or debris. It's also vital to complete any electrical and plumbing rough-ins prior to application to avoid complications later on. Maintaining temperatures between 15°C and 27°C with low humidity is beneficial for the foam to cure correctly, thereby minimising any potential bonding issues. When applying the foam, it's advisable to make passes no thicker than 5 centimetres to reduce the risk of fire hazards and ensure high quality. Temperatures outside this range can impair curing, leading to compromised performance. Careful cutting around openings is important for achieving full coverage and eliminating voids. Additionally, using protective masking can help prevent overspray from damaging finishes. Properly sealing the work environment and handling equipment correctly further enhances the foam's durability, ensuring it performs reliably over its lifespan.

Long-Term Material Performance

With proper installation, closed-cell foam insulation can last for many decades, making it a robust choice for building insulation. Its resilience enables it to endure environmental challenges when maintained correctly.

Notable benefits include:

Flood resistance, which helps maintain structural integrity during flooding events.

An expected lifespan significantly exceeding that of fibreglass or cellulose insulation.

Strong moisture resistance, which prevents mould growth and decay in damp environments.

Closed-cell foam generally has a longer lifespan than open-cell foam. However, exposure to saltwater, ultraviolet rays, or physical damage may impact its longevity.

Regular inspections and protective measures, such as vapour barriers and pest deterrents, can help extend its lifespan.

When properly cared for, closed-cell foam provides dependable, long-term insulation that enhances value and energy efficiency in buildings.

Safety Considerations and Variations for Different Environments

Safety considerations for closed cell foam vary depending on the environment in which it's installed. During the installation process, the chemicals released can cause skin irritation or respiratory issues if appropriate protection isn’t used. It's crucial for trained professionals to wear full-face respirators and chemical-resistant gloves, while ensuring adequate ventilation during and after application. Occupants should avoid the area for 24 to 72 hours to prevent exposure to fumes. Although closed cell foam offers superior fire resistance compared to open cell foam, it remains combustible and must comply with fire safety standards set out by relevant authorities. Environmental factors also play a significant role in safety. In humid or damp areas, moisture can become trapped if the foam isn’t installed correctly, potentially leading to damage. Proper installation practices significantly reduce the risk of off-gassing and ensure safety and long-lasting performance for all users. A thorough evaluation of the environment is essential to ensure safety and achieve long-lasting performance for all users. Proper planning and adherence to safety guidelines can help mitigate risks associated with the application of closed cell foam.

Key Factors for Maximizing Waterproof Performance and Maintenance

To achieve optimal waterproof performance from closed-cell foam, it's essential to understand its inherent properties and maintain them effectively over time. Proper application, routine inspections, and diligent upkeep are crucial. Closed-cell foam's density and tightly packed cell structure contribute significantly to its water resistance. Key factors include:

Quality Installation Practices

Ensuring a seamless and well-cured foam application is vital in preventing water ingress.

Routine Inspections

Regularly examine the foam for any signs of damage, punctures, or compression that could compromise its water resistance.

Environmental Management

Avoid standing water, clean surfaces regularly, and safeguard the foam from UV exposure and abrasion.

By adhering to these guidelines, you can preserve the water-repelling qualities of closed-cell foam and extend its durability.

When properly maintained, it provides a dependable, long-lasting waterproof barrier that satisfies safety requirements and quality standards.

Conclusion

Closed cell foam provides exceptional waterproofing, making it a perfect choice for areas prone to moisture. Its robust resistance to water vapour, combined with its durability and versatile uses, guarantees long-lasting performance when installed correctly.

Understanding the safety requirements and maintenance tips is essential to maximise its lifespan. By selecting the appropriate type and ensuring proper installation, users can depend on closed cell foam to effectively safeguard structures in flood-prone and damp environments. This ensures continued performance over time with minimal upkeep required.