Waterproof Foam Insulation

Waterproof foam insulation is specifically designed to completely block water, making it an excellent choice for moisture-prone areas such as basements, foundations, and regions susceptible to flooding. Closed-cell spray foam, particularly polyurethane-based, provides outstanding water resistance by forming a robust, seamless barrier that prevents water and vapour penetration.

To achieve optimal performance, it is essential that installation follows precise techniques, ensuring both durability and long-term protection.

Different types of foam insulation cater to various waterproofing needs, effectively addressing the challenges posed by damp environments. This versatility allows homeowners and builders alike to select the most suitable solution for their specific requirements, ensuring peace of mind and structural integrity in the face of moisture-related issues.

Characteristics of Water-Resistant vs. Waterproof Insulation

Water-resistant and waterproof insulation both play vital roles in protecting buildings from moisture, yet they differ considerably in their ability to manage water exposure.

Water-resistant insulation can withstand brief contact with moisture but doesn't prevent water ingress during full submersion or extended exposure. This type of insulation is designed to resist surface moisture and delay water penetration. However, it can absorb some water over time, which may diminish its effectiveness.

On the other hand, waterproof insulation provides a complete barrier that entirely blocks water from entering, even in situations of flooding or prolonged wet conditions. Materials such as closed-cell spray foam or cellular glass are specifically engineered for this purpose, ensuring they retain their insulating properties regardless of water presence.

Understanding these differences is essential when selecting insulation to match specific environmental moisture risks, ultimately ensuring long-term protection for buildings.

Types of Spray Foam and Their Water Resistance Properties

Closed-cell spray foam provides excellent water resistance, creating a robust moisture barrier that effectively prevents both water vapour and liquid from permeating through. This type of foam utilizes chemicals like polyurethane for strong insulation, providing building envelope protection against water leakage. On the other hand, open-cell foam is more permeable to water vapour and is less efficient at resisting water, making it more suitable for interior applications where moisture exposure is minimal. Understanding these distinctions is crucial when selecting the appropriate type of foam for various insulation requirements, particularly in areas where water resistance is a significant concern.

Closed-Cell Water Resistance

When it comes to spray foam insulation, closed-cell spray foam is notable for its exceptional resistance to water and moisture. Its dense, compact cell structure effectively prevents water absorption and penetration. Water resistance is a key characteristic that makes it suitable for challenging environments. Although it isn't entirely waterproof, it's frequently regarded as waterproof in practical applications due to its ability to repel moisture and dry quickly when temporarily wet. Its low vapour permeance significantly reduces condensation and moisture-related issues. Key features include: - Capable of withstanding flooding without compromising structural integrity - Complies with flood-resistant standards set by relevant authorities - Functions as an efficient vapour barrier at certain thicknesses - Retains its waterproof properties even with prolonged moisture exposure - Adheres strongly to surfaces, preventing water ingress This combination of attributes makes closed-cell spray foam an excellent choice for damp or flood-prone areas in the UK.

Open-Cell Moisture Permeability

Open-cell spray foam is distinguished by its unique structure, which consists of interconnected, open cells that create a soft, flexible material. This design facilitates the passage of moisture vapour, providing a perm rating that indicates good permeability. Its open-cell architecture allows moisture vapour to pass through easily. Due to its open-cell architecture, it can absorb and retain liquid water, in contrast to closed-cell foam, which offers better resistance to moisture. However, it's important to note that open-cell foam isn't waterproof; prolonged exposure to moisture can lead to dampness, increasing the risk of mould or mildew growth. While the material does dry out over time, consistent moisture exposure can diminish its insulation performance. Proper installation and conducive environmental conditions are essential, as any gaps or damage can enhance water ingress.

Rigid Foam Insulation Options and Moisture Compatibility

Rigid foam insulation options differ significantly in their moisture compatibility, which impacts their suitability for various building applications.

Extruded Polystyrene (XPS) features a closed-cell structure, providing excellent moisture resistance with minimal water absorption. This makes it particularly effective in damp environments. XPS is also recognized for its high compressive strength, making it suitable for load-bearing applications.

Expanded Polystyrene (EPS) has a higher water absorption rate, but it remains advantageous in certain below-ground settings where moisture is present.

Polyisocyanurate (Polyiso) can absorb moisture, which may affect its thermal performance over time. However, it can still be a viable option depending on the application.

Both XPS and Polyiso can function as vapour barriers when installed correctly, helping to reduce moisture transfer within building structures.

Understanding the moisture resistance of these materials is crucial for determining their appropriate use.

XPS is particularly suited for damp, below-ground areas, while Polyiso is more effective in above-ground applications.

Choosing the right insulation material based on moisture compatibility ensures better performance and longevity of the building.

Essential Factors for Proper Waterproof Foam Installation

Proper waterproof foam installation begins with meticulous surface preparation and cleaning to ensure optimal adhesion.

It's crucial to apply sealants accurately to joints, cracks, and gaps to prevent water intrusion and maintain a seamless barrier.

Focusing on these essential factors contributes to a robust, effective insulation system that resists moisture and damage.

Surface Preparation Techniques

Surface preparation is a vital step that significantly influences the efficacy of waterproof foam insulation. Properly preparing surfaces ensures that the foam adheres effectively and performs as intended.

First and foremost, surfaces must be clean, dry, and devoid of dust, grease, oil, or loose debris. Techniques such as vacuuming, sweeping, or wiping with a damp cloth can help eliminate any particles.

For wooden surfaces, it's crucial that the moisture content is kept below the acceptable threshold, and sanding can create a textured surface that enhances bonding.

When dealing with metal and concrete, it's essential to ensure that there are no flaking or weak layers present. This often necessitates thorough cleaning or the use of wire brushing to prepare the surface.

Additionally, removing old, loose paint and any contaminants such as oils or residues is critical for achieving a secure attachment.

Paying close attention to surface details guarantees a durable and waterproof insulation that can withstand various environmental challenges.

Proper surface preparation is also vital for ensuring that the expanding foam does not degrade prematurely or lose its seal over time.

Sealant Application Strategies

Applying sealant correctly is a crucial step in ensuring that waterproof foam remains in place and functions as intended. Controlling the application environment is essential; maintain the ambient temperature close to room temperature for optimal foam expansion and curing, while ensuring good ventilation to facilitate proper curing. To protect surrounding surfaces, use masking tape or plastic sheets to prevent any potential damage. It's advisable to avoid application during periods of high humidity or windy conditions, as these factors can hinder adhesion. Additionally, applying foam from the bottom upwards promotes even coverage and helps to prevent sagging. Filling gaps up to 40% allows space for expansion and reduces the risk of overflow. Proper preparation and technique are vital for long-lasting waterproofing. Utilising appropriate applicators and layering the foam with adequate curing time in between layers ensures a secure, waterproof seal. When sealant is applied properly, it creates a durable barrier that enhances the effectiveness of insulation.

Long-Term Durability and Maintaining Waterproofing Effectiveness

Over time, the durability of waterproof foam insulation is significantly influenced by environmental conditions and proper maintenance. When applied correctly, spray foam can offer a lifespan of many decades due to its inherent moisture resistance and capacity to withstand temperature fluctuations. The dense structure of closed-cell foam effectively minimises water absorption, ensuring long-lasting performance even in damp conditions. Chemical stability allows the foam to resist deterioration caused by prolonged exposure to moisture, prolonging its effective service life. However, exposure to ultraviolet (UV) rays and heat can lead to brittleness if the foam isn't adequately protected. Environmental factors such as saltwater, high humidity, and varying temperatures can compromise the waterproof qualities of the foam. To maintain its effectiveness, it's crucial to conduct regular inspections, carry out prompt repairs, and employ protective coverings.

Here are some key maintenance strategies:

Apply UV-protective coatings or coverings to shield the foam.

Inspect for cracks or damage every six months to ensure early detection of issues.

Repair any small problems immediately to prevent water ingress.

Utilise vapour barriers and drainage systems to manage moisture effectively.

Avoid physical damage by refraining from drilling or cutting into the foam.

Application Areas and Best Practices for Waterproof Foam

Waterproof foam is widely utilised across various applications to protect structures from moisture damage while enhancing energy efficiency.

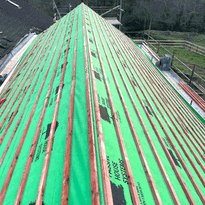

It's particularly suitable for insulating basement walls, foundation slabs, exterior walls, and roofs, especially in challenging weather conditions.

Crawl spaces, rim joists, and high-humidity areas such as bathrooms and kitchens greatly benefit from its moisture-blocking capabilities, effectively preventing the growth of mould and minimising condensation.

In regions prone to flooding and in marine environments, waterproof foam acts as a barrier against water intrusion and vapour transmission.

For outdoor applications, employing closed-cell spray foam that comes with UV protective coatings ensures enduring waterproofing.

Proper surface preparation and skilled installation are crucial to avoid voids and guarantee strong adhesion.

Adhering to the manufacturer's guidelines regarding thickness is essential for establishing a dependable barrier that enhances both insulation quality and structural integrity.

Advantages of Spray Foam Insulation in Moisture-Prone Environments

Spray foam insulation presents numerous significant advantages in environments where moisture can be a persistent issue. Its formulation from inert polymers renders it highly resistant to mould and mildew, ensuring that it doesn't provide a food source for these harmful organisms. This characteristic creates an unfavourable environment for mould growth by effectively preventing moisture accumulation in walls and crawlspaces.

Furthermore, closed-cell spray foam serves as an exceptional water barrier, sealing cracks and halting both airborne and liquid water from infiltrating. It also boasts a high thermal resistance, which helps to maintain stable indoor temperatures and reduces the risk of condensation forming.

The durability of spray foam ensures long-lasting protection against water damage, pests, and structural stress, making it an ideal choice for moisture-prone areas.

The benefits include:

Resistance to mould and mildew development

Impermeability to water, effectively preventing leaks

Consistent indoor temperature maintenance

Long-term resilience in damp conditions

Enhanced structural integrity in vulnerable regions

Conclusion

Waterproof foam insulation provides dependable moisture protection when installed and maintained correctly. It is important to understand the various types available, their levels of water resistance, and the appropriate application areas to ensure optimal performance.

Selecting the right type of foam insulation and adhering to best practices can significantly enhance its durability, particularly in environments that are susceptible to moisture.

In summary, waterproof spray foam insulation offers an effective solution that helps to prevent mould, structural damage, and energy loss. This makes it a valuable choice for maintaining dry, insulated spaces over time.