Waterproof Insulating Sealant

Waterproof insulating sealants are specially formulated to prevent water ingress while providing insulation. These products are composed of materials such as silicone, polyurethane, or elastomeric blends. They offer exceptional flexibility, durability, and resilience against adverse weather conditions and temperature fluctuations.

Commonly utilised around windows, roofs, pipes, and foundations, these sealants play a crucial role in averting leaks and enhancing energy efficiency. Proper application is essential for long-lasting protection, and selecting the appropriate type for your specific environment can significantly improve their effectiveness.

With numerous options available, understanding the distinct properties of each sealant can assist you in identifying the best solution to meet your needs. Whether for domestic or commercial purposes, ensuring the right choice will provide peace of mind and safeguard your property against the elements.

Composition and Material Types of Waterproof Sealants

Waterproof sealants are composed of a range of materials, each tailored for specific applications and environments. Polyurethane-based sealants are formed through the reaction of polyol and isocyanate, resulting in a robust, flexible polymer that resists abrasion and vibration. Butyl rubber-based sealants, crafted from synthetic rubber, are notably sticky and offer strong water resistance, making them ideal for sealing gaps. Silicone-based sealants are renowned for their flexibility and high-temperature resistance, providing excellent waterproofing properties. Acrylic-based sealants, made from acrylic polymers, are primarily used indoors as they're paintable and offer moderate water resistance. Elastomeric blends combine resilient elastomers that adhere well to metals, cables, and insulations, while also showcasing high dielectric strength, rendering them versatile for various sealing requirements. Understanding the specific composition of each material type helps in selecting the most suitable sealant for different conditions and ensures effective waterproofing. Choosing the right waterproof sealant is essential for ensuring long-lasting protection against moisture and environmental factors.

Functional Properties and Benefits

The functional properties of waterproof sealants are vital for safeguarding structures and materials from environmental deterioration. They establish watertight barriers that prevent water from penetrating through cracks, seams, and joints. Definition of Waterproof Sealants For instance, they:

Form dense, closed-cell structures that offer superior resistance to moisture, making them ideal for high-humidity areas such as bathrooms or basements.

Protect metal surfaces from moisture, thereby reducing rust and corrosion, which extends the lifespan of components.

Seal gaps and cracks to enhance energy efficiency by minimising drafts, helping to maintain comfortable indoor temperatures.

Retain flexibility and adhere strongly to various surfaces, including glass, metal, and wood, ensuring enduring protection against weathering and chemicals.

These attributes contribute to the durability and energy efficiency of structures, making them less susceptible to damage, and fostering a sense of security and belonging.

Common Application Areas and Usage Scenarios

Common application areas for waterproof insulating sealants are diverse, spanning both residential and industrial settings.

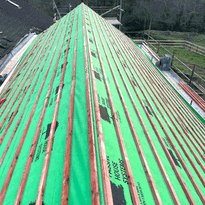

In domestic environments, they play a crucial role in protecting areas such as bathrooms and kitchens by sealing around sinks, baths, and tiles to prevent water leaks and the growth of mould. Additionally, they contribute to improved energy efficiency by sealing windows and doors, and safeguarding roofs and gutters from rainwater exposure. Silicone-based sealants are especially popular in these applications due to their UV resistance and elasticity. Foundations and basements also benefit from waterproofing to avert dampness and structural damage.

In industrial and commercial spaces, waterproof sealants are essential for sealing metal roofs, pipelines, and tanks, ensuring durability in challenging conditions. Outdoor applications include sealing roof vents, pipe joints, and exposed woodwork. Repair scenarios often involve filling cracks, stopping leaks, and maintaining existing seals, making these sealants a versatile choice for ongoing maintenance and preservation.

Their adaptability and effectiveness make them invaluable in both residential and commercial settings across the UK.

Performance Characteristics and Strengths

Waterproof insulating sealants are renowned for their robust bonding capabilities and flexibility, enabling them to conform to various surfaces and accommodate movements without cracking or diminishing in effectiveness. Their longevity is also crucial, as they withstand weathering, UV exposure, and temperature fluctuations, ensuring sustained performance over time. Recognising these essential characteristics is vital for selecting the appropriate sealant for diverse applications where reliability and resilience are paramount. Additionally, many of these sealants are formulated with UV-resistant compounds that help prevent degradation under prolonged sunlight exposure, further enhancing their durability.

Bonding and Flexibility

Bonding and flexibility are essential performance features of waterproof insulating sealants. They form strong, durable bonds that resist peeling and cracking, ensuring long-lasting protection.

These sealants adhere effectively to a variety of surfaces, including glass, metal, ceramic, wood, and concrete.

Imagine a sealant:

Sticking firmly to a wet window frame during a rainstorm, preventing leaks.

Maintaining a seamless bond across a concrete joint that shifts with temperature changes.

Stretching to accommodate building movement without breaking.

Remaining elastic under the hot sun or cold winter, which helps prevent cracks.

This flexibility enables the sealant to adapt to movement and environmental factors, thereby extending its lifespan. Proper bonding and flexibility foster a sense of security by ensuring a tight, waterproof seal in every situation.

In the UK, where weather conditions can change rapidly, the reliability of these sealants is paramount for maintaining the integrity of structures and protecting against moisture ingress.

Durability and Resistance

The durability and resistance of waterproof insulating sealants play a crucial role in their performance over time, particularly in diverse environmental conditions. Waterproof sealants, such as closed-cell spray foam, are designed to resist moisture and water intrusion, boasting a low level of vapour permeance that makes them effective vapour barriers. Maintaining proper installation practices ensures their continuous effectiveness. Advanced liquid rubber sealants exhibit minimal water absorption rates, which contributes to their exceptional waterproofing capabilities. Polyurethane and silicone sealants offer robust, weather-resistant seals that can endure rain, wind, UV rays, and fluctuations in temperature, ensuring they maintain their integrity for many years. These sealants cure rapidly, bond effectively to damp surfaces, and resist chemical degradation, which supports long-term resilience. When applied correctly, they serve as a formidable defence against condensation, water damage, and general wear, establishing them as reliable options for lasting waterproof insulation in a variety of settings.

Advantages and Limitations of Different Formulations

Different sealant formulations present a variety of advantages and limitations that make them suitable for specific applications.

Silicone sealants, for instance, are particularly renowned for their:

High flexibility and elongation, which allow them to accommodate building movements without cracking.

Exceptional water-blocking properties, effectively preventing mould growth.

Strong adhesion to materials such as masonry, metal, and glass.

Stability across a wide range of temperatures, maintaining consistent performance.

Nonetheless, they do have certain drawbacks, including poor adhesion to some substrates without appropriate priming, limited paintability, a higher cost compared to other options, and a tendency to attract dirt.

Sealant Compatibility with Surfaces is an essential factor to consider when choosing silicone to ensure long-lasting performance in all environments.

Understanding these benefits and restrictions is essential for users in the UK when selecting the right sealant for their projects.

This knowledge ensures that waterproofing is both effective and durable, meeting the specific needs of the application.

Longevity and Durability of Waterproof Insulating Sealants

Waterproof insulating sealants are engineered to endure for many years, yet their longevity is influenced by various factors. Proper application, environmental conditions, and the specific type of sealant all significantly affect durability.

Silicone sealants are known for their impressive resilience against moisture and UV rays, often lasting for two to three decades. Polyurethane sealants are robust and can endure for a longer period, while acrylic sealants typically require reapplication every few years due to their comparatively lower durability.

Epoxy sealants, when maintained correctly, can provide a lifetime of protection. Durability of silicone sealant Lasts 20 to 25 years when applied correctly and shows exceptional resistance to moisture, UV rays, and temperature fluctuations. Environmental factors such as temperature fluctuations, sunlight exposure, and humidity levels can impact the ageing process of sealants. Regular inspections, appropriate maintenance, and selecting the right formulation tailored to specific conditions are essential practices.

These measures ensure that sealants continue to safeguard surfaces effectively and provide peace of mind over time.

Conclusion

Waterproof insulating sealants are vital for safeguarding surfaces against moisture and fluctuations in temperature. Their varied formulations and materials render them appropriate for a wide array of applications, providing robust performance and long-lasting durability. These sealants not only deliver effective insulation and sealing advantages but also require careful selection based on particular requirements and environmental conditions.

In essence, waterproof insulating sealants enhance the longevity of structures and avert potential damage, making them indispensable in numerous construction and repair contexts. Choosing the right type guarantees reliable, enduring protection against water ingress, ensuring that both residential and commercial properties remain secure and well-maintained.