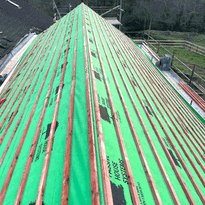

Waterproof Roof Insulation

Waterproof roof insulation comprises materials such as XPS, EPS, and Polyiso, which are specifically designed to prevent moisture ingress while providing effective thermal resistance.

XPS, or extruded polystyrene, boasts high moisture resistance due to its closed-cell structure, making it particularly durable in damp environments.

EPS, or expanded polystyrene, is a more cost-effective option but does offer slightly less water resistance.

Polyiso, or polyisocyanurate, delivers strong insulation properties; however, it may be less moisture-resistant unless it has undergone special treatment.

The combination of these materials, when installed correctly, enhances the overall durability of roofs and offers robust water protection. Understanding how these systems work together can significantly improve building performance and longevity.

Types of Waterproof Roof Insulation Materials

There are various types of waterproof roof insulation materials, each tailored to meet distinct roofing requirements and environmental conditions.

Rigid foam board insulation comprises options such as Expanded Polystyrene (EPS), Extruded Polystyrene (XPS), and Polyisocyanurate (Polyiso). R-value measures the insulation's resistance to heat transfer, and higher values indicate better insulation performance. EPS is lightweight, durable, and cost-effective, making it particularly suitable for warm flat roofs, although its thermal resistance is lower than that of other rigid foam options.

XPS offers greater density, high compressive strength, and superior moisture resistance, making it appropriate for both warm and cold roof applications, but it's generally more expensive. These rigid foam boards deliver excellent thermal resistance and longevity, making them a popular choice for roof and attic installations.

The selection of the most suitable type hinges on specific climate conditions, insulation requirements, and budget considerations, ensuring a roof that's both functional and contributes to a sense of belonging.

Key Properties of Polyisocyanurate (Polyiso)

Polyisocyanurate (Polyiso) is distinguished among roof insulation materials due to its exceptional performance characteristics, merging robust thermal resistance with durability.

This rigid foam insulation is primarily composed of methylene diphenyl diisocyanate (MDI) and features a unique chemical structure formed from polyols and isocyanurate rings.

Polyiso provides one of the highest thermal resistance values available per inch, significantly aiding in energy efficiency. Its closed-cell foam structure ensures low thermal conductivity, maintaining effective insulation over time.

The insulation boards are typically laminated with facers such as aluminium foil or kraft paper, which enhance their strength and resistance to moisture.

With commendable compressive strength, Polyiso is capable of resisting deformation and mechanical damage. Its reliable waterproof properties make it an ideal option for roof insulation, particularly in applications requiring water resistance. Additionally, the manufacturing process involves higher-temperature reactions than those used for standard polyurethane, resulting in a denser and more fire-retardant foam.

Advantages of Expanded Polystyrene (EPS) Panels

Expanded polystyrene (EPS) panels are a highly regarded option for roof insulation, providing a cost-effective solution that enhances energy efficiency. Their water-resistant and robust characteristics ensure that they perform admirably even in challenging weather conditions, retaining their insulation properties over time. EPS contains tiny air pockets, which contribute to its excellent thermal insulating properties and moisture resistance. Furthermore, EPS panels are lightweight and straightforward to install, which aids in minimising construction time and reducing labour costs. Due to their exceptional thermal performance, EPS panels contribute significantly to lowering energy bills, making them an appealing choice for homeowners and builders alike. Their versatility allows for various applications, from residential to commercial projects, highlighting their adaptability in the construction sector. The durability of EPS panels also means they require minimal maintenance, adding to their long-term value.

Cost-Effective Insulation Option

Despite requiring a higher initial investment, expanded polystyrene (EPS) panels provide a cost-effective insulation solution in the long term. These panels significantly reduce heating and cooling expenses due to their excellent thermal resistance, with an R-value typically ranging from R-3.6 to R-4.2 per inch. By lowering energy bills and minimising dependence on costly HVAC systems, EPS panels contribute to ongoing financial savings.

Installation is straightforward and efficient, owing to their lightweight construction, which reduces labour costs and project duration. The durability of EPS panels allows them to withstand moisture, mould, and pests, leading to lower maintenance and replacement expenses over time. Furthermore, EPS retains its insulating properties for decades, making it a sustainable choice for energy efficiency.

Benefit |

Description |

Impact |

| Cost Savings | Reduces energy bills | Long-term financial relief |

| Easy Installation | Lightweight and quick | Fewer labour costs |

| Durability | Resists moisture and pests | Less maintenance |

Water-Resistant and Durable

Water-resistant and durable properties make EPS panels particularly valuable in insulation applications. The closed-cell structure of EPS limits water penetration as the cells are filled with air, causing water to bead on the surface rather than soak in. Its waterproof cell walls significantly reduce water absorption, although tiny channels between beads may permit minimal moisture entry over time. EPS remains stable in high humidity and resists damage from water, salt, and alkali solutions, maintaining both its strength and insulation performance. EPS's closed-cell design also contributes to its excellent thermal insulation properties, making it a reliable choice for various environments. Surface treatments can further enhance durability in challenging environments. The lightweight design of EPS makes it ideal for roofing systems, foundations, and outdoor applications, providing consistent thermal insulation regardless of moisture exposure. These qualities ensure that EPS insulation remains reliable, helping structures stay protected from moisture damage for years to come.

Easy to Install

Installing EPS panels is a straightforward process, thanks to their uncomplicated surface preparation requirements.

It's essential to thoroughly clean the surfaces by removing dirt, dust, debris, and any moisture. If the surface is uneven, utilising levelling compounds can help establish a flat area. Prior to placing the new panels, it's necessary to remove any existing insulation or incompatible materials. Applying a primer can enhance the bonding of the adhesive. A clean and dry surface ensures better adhesion and long-lasting insulation performance.

Accurate measurements are crucial to ensure the correct quantity and fit of the panels. For precise shapes, panels can be cut using utility knives or saws. Adhesive should be applied evenly with trowels or spreaders, ensuring a strong bond with minimal air gaps.

Panels should be placed closely together and can be reinforced with screws, nails, or framing supports to enhance stability.

Sealing the joints with tape or foam is important to prevent air leaks, making the installation both efficient and reliable.

Water-Resistant Features of Extruded Polystyrene (XPS)

Extruded polystyrene (XPS) boasts impressive water-resistant properties, primarily due to its closed-cell structure and hydrophobic materials.

These attributes effectively prevent moisture from penetrating the foam, ensuring that the insulation remains dry and functional over time.

XPS is characterised by its low water absorption and limited vapour permeability, which contribute to its long-lasting performance in various applications.

Furthermore, its durability in damp conditions makes XPS a dependable choice for roofing and below-ground uses, where effective insulation is crucial.

Water Resistance Capabilities

The closed-cell structure of extruded polystyrene (XPS) is fundamental to its exceptional water resistance capabilities. This tightly packed arrangement creates small, sealed pockets of air fully surrounded by polystyrene, making it notably difficult for water to penetrate. Water conducts heat effectively, which further enhances XPS’s performance in moisture-prone environments. The extrusion process results in a homogeneous foam with fewer pathways for moisture compared to expanded polystyrene (EPS), which is produced through bead moulding and contains open voids. Moreover, polystyrene is inherently hydrophobic, meaning it effectively repels water. When combined with its closed-cell design, this significantly restricts water absorption. XPS is known to absorb a minimal amount of water after immersion, thereby demonstrating its outstanding resistance to moisture. These properties make XPS particularly suitable for waterproofing applications, especially in scenarios where exposure to damp conditions is a concern. Its durability and reliability make it an excellent choice for various construction and insulation projects requiring effective moisture control.

Durability in Moisture

The water resistance of extruded polystyrene (XPS) is closely linked to its durability when exposed to moisture over time. The continuous extrusion process creates a homogeneous, closed-cell structure with no gaps, effectively preventing water from penetrating at cell boundaries. Each cell is fully enclosed by polystyrene walls, which significantly enhances its ability to repel water. This manufacturing process also results in fewer defect sites, which further contributes to XPS's water-resistant qualities. The closed-cell nature, combined with hydrophobic polystyrene, ensures that moisture is kept at bay, reinforcing its resistance to the elements. Furthermore, XPS boasts a high compressive strength, enabling it to endure heavy loads without deforming, thus maintaining its waterproof characteristics. While XPS may absorb some moisture over extended periods, appropriate installation techniques and surface choices can help mitigate moisture accumulation. This attention to detail is crucial for ensuring the long-term durability of XPS in environments where moisture is a concern.

Role and Benefits of Cover Boards in Roofing

Cover boards play a crucial role in roofing systems by providing a stable and resilient surface for membrane installation. They enhance water runoff, helping to prevent ponding at seams or roof penetrations, and protect the underlying insulation from damage caused by foot traffic, tools, or maintenance activities. Various types of cover boards are available, each suited for specific applications. Certain cover boards are designed to resist hail, offering the density and flexibility needed to allow hail to bounce off rather than embedding itself into the insulation. Furthermore, they serve as a fire barrier, reducing the flammability of insulation and slowing the spread of fire, which contributes to overall safety. In addition to these protective features, cover boards improve wind uplift resistance, enhancing the roof's adherence and enabling the use of fewer fasteners. They also provide additional thermal resistance, which aids in maintaining insulation performance and energy efficiency.

Benefits of Spray Foam Insulation for Waterproofing

Spray foam insulation provides significant advantages for waterproofing roofing systems. One of its primary benefits is the ability to create a robust, impermeable moisture barrier. Closed-cell spray foam effectively prevents water from penetrating the roof surface and maintains its effectiveness even in the event of flooding, ensuring long-term integrity.

Unlike open-cell foam, closed-cell options serve as a dependable water stop. Proper installation is essential to guarantee that the foam completely seals all surfaces against water intrusion.

The key benefits include:

Establishing a durable, waterproof barrier that resists moisture and mitigates the risk of water damage.

Reducing the likelihood of mould growth by sealing cracks and obstructing potential water entry points.

Improving insulation performance and energy efficiency through a continuous, moisture-resistant layer.

These factors collectively safeguard the roof and the structure for many years to come.

Comparing Thermal Resistance Among Insulation Options

Different insulation options offer varying levels of thermal resistance, which significantly influence their effectiveness in reducing heat transfer through a roof.

Fibreglass batts provide an economical solution for basic insulation requirements, delivering reliable performance in many situations.

Spray polyurethane foam (SPF) boasts a higher thermal resistance, offering excellent insulation with its continuous coverage that effectively minimises gaps and thermal bridging.

Rigid foam boards, particularly polyisocyanurate, are ideal for confined spaces, providing substantial thermal resistance and ensuring efficient insulation.

Metal roofs, while typically exhibiting lower thermal resistance, can reflect radiant heat when treated with reflective finishes, contributing to cooler indoor environments.

Fire Safety and Durability Considerations

Fire-resistant materials are essential for safeguarding roof insulation from heat and flames. Options such as mineral-based or specially treated foam materials enhance safety.

Additionally, improved durability features, including UV-resistant coatings and moisture barriers, help sustain the insulation's performance over time. By integrating these fire safety measures with robust design elements, roofs can better endure environmental stresses while minimising fire risks.

It is crucial to consider these factors when selecting roofing materials, as they contribute significantly to the overall safety and longevity of the structure.

Prioritising fire resistance alongside durability ensures that roofs not only perform effectively but also provide peace of mind for homeowners and builders alike.

Fire-Resistant Material Options

Choosing the appropriate insulation materials for roofs involves balancing fire safety with durability. Numerous options provide excellent fire resistance, contributing to the overall protection of buildings.

Rockwool (Mineral Wool): This insulation boasts a high melting point, preventing it from aiding in fire spread. It's versatile and environmentally friendly, being made from natural or recycled materials.

Fibreglass: Renowned for its non-combustible characteristics, fibreglass offers good thermal performance as well as soundproofing benefits. Its lightweight and moisture-resistant properties make it suitable for a variety of roof types.

Phenolic Foam: This material exhibits low flammability and can endure high temperatures. It's effective in resisting smoke and toxic gases, enhancing occupant safety during a fire.

These insulation options help ensure that your roof remains secure and durable over the long term.

Enhanced Durability Features

To ensure that roof insulation remains effective over time, it's crucial to focus on both its fire safety features and its durability under various conditions.

High-quality materials such as XFP Polyiso and expanded polystyrene are designed to resist moisture, thereby minimising the risks of water damage and condensation that can compromise insulation effectiveness.

The proper utilisation of air control membranes and treated materials plays a significant role in managing moisture flow, which in turn protects the integrity of the insulation.

Furthermore, durable insulation must be able to withstand physical stresses, including foot traffic and structural settling.

Materials such as Lightweight Insulating Concrete and elastomeric membranes are known for their resistance to wear, UV rays, and chemicals, significantly extending their lifespan.

Compatibility with waterproof membranes, such as PVC or TPO, ensures seamless protection against the elements.

Regular inspections and prompt repairs are vital in maintaining waterproofing, ensuring that the roof remains durable and effective for years to come.

Cost Implications and Installation Factors

The costs associated with waterproof roof insulation can vary significantly based on several important factors.

Material selection has a considerable impact on overall expenses. For instance, foam insulation can range widely in price, with specialised materials often commanding higher costs.

Installation costs are influenced by the size and complexity of the roof, as well as regional labour rates. Larger or more intricate roofs typically require additional time and expertise for installation.

Moreover, potential long-term savings should be taken into account. Although premium insulation methods may involve higher initial costs, they often lead to reduced energy bills and lower maintenance requirements over time.

When considering waterproof roof insulation, it's essential to weigh these factors carefully to make an informed decision that balances upfront investment with future savings.

Selecting the Right Waterproof Insulation System

Selecting the appropriate waterproof insulation system is crucial and requires an understanding of the various types available, as well as how they correspond to specific roofing requirements.

Closed-cell spray foam is known for its excellent water resistance, superior sealing capabilities, and high thermal performance. This makes it an ideal choice for regions that are particularly susceptible to moisture.

Rigid foam boards, such as Polyiso and XPS, offer durable waterproofing along with commendable insulation properties. Polyiso boasts the highest thermal resistance, while XPS is recognised for its robust water resistance.

On the other hand, open-cell spray foam, while more flexible, tends to absorb water easily, rendering it less suitable for waterproofing applications. Perlite cover boards are lightweight and fire-resistant, yet they may be less durable in wet conditions.

The selection of the right system is influenced by several factors, including water resistance, insulation requirements, durability, and compatibility with existing roofing materials.

Choosing the right waterproof insulation system ensures long-term performance and comfort, fostering a sense of security and belonging for homeowners and building occupants alike.

Conclusion

Choosing the appropriate waterproof roof insulation is crucial and should be tailored to the specific requirements of each project. Familiarising oneself with the properties, advantages, and costs of materials such as Polyiso, EPS, and XPS can aid in making well-informed decisions.

Incorporating cover boards can enhance both performance and durability. When selecting insulation systems, it is essential for property owners and builders to consider factors such as thermal resistance, fire safety, and budget. This careful consideration will ensure reliable protection and energy efficiency for many years to come.