Best Insulated Plasterboard

The best insulated plasterboard for your project will depend on specific needs, with a focus on thermal performance, moisture resistance, and fire safety. Premium options such as Kingspan Kooltherm K118 and Celotex PL4000 provide low U-values and excellent moisture resistance, making them versatile for a range of applications.

When selecting insulated plasterboard, consider factors such as the foam core material, thickness, and any additional features like vapor barriers. These elements influence suitability and performance in particular building environments.

Choosing reputable brands is important to ensure durability and compliance with UK standards.

For comprehensive advice tailored to your specific construction requirements, consulting a knowledgeable supplier or industry expert can provide guidance on the most suitable products for your project.

Types of Insulated Plasterboard and Their Features

Insulated plasterboard products are available in a variety of types, each designed to meet specific insulation, moisture, fire, or soundproofing requirements. Their features reflect these specialized functions, offering suitable options for different building scenarios.

PIR (Polyisocyanurate) boards utilize rigid foam cores combined with plasterboard faces. They provide high thermal performance, with thermal conductivity characterized by low U-values, making them ideal for internal walls where efficient heat retention is essential. PIR boards are also lightweight and easy to handle, facilitating quick installation and reducing labor costs.

XPS (Extruded Polystyrene) boards feature moisture-resistant, dense foam cores supported by smooth plasterboard surfaces. They offer excellent durability and structural strength, particularly in areas exposed to damp conditions, making them suitable for use in basements and exterior applications.

EPS (Expanded Polystyrene) boards are lightweight and economically priced, laminated with plasterboard. While they meet basic insulation needs, they tend to be less resistant to moisture compared to XPS or PIR options and are best suited for less demanding environments.

Vapor-control boards incorporate thicker gypsum layers with integrated vapor barriers. These boards help prevent condensation within wall assemblies, especially in humid environments, contributing to overall building durability and comfort.

Specialist boards are designed to cater to specific requirements such as moisture resistance, fire protection, or soundproofing. These boards are tailored for applications where particular building standards must be met, ensuring safety, comfort, and compliance. Additionally, some types of insulated plasterboard can incorporate fire safety features to enhance building safety in compliance with regulations.

Understanding the features of each type of insulated plasterboard allows for informed choices that enhance the thermal efficiency, durability, and safety of UK buildings.

Factors to Consider When Choosing Insulated Plasterboard

Selecting the appropriate insulated plasterboard requires careful consideration of several factors that directly impact its performance and suitability for specific building projects. Key aspects to evaluate include thermal performance, where boards with low U-values and high K-values offer improved energy efficiency by minimizing heat transfer. Thermal conductivity is a critical measure, with lower values indicating better insulation properties. Thicker boards can provide enhanced insulation benefits but may reduce internal space, which is particularly relevant in retrofit applications where space preservation is important. Moisture and vapor management are also vital; foil-backed boards act as vapor barriers, helping to prevent condensation and mold growth within the construction. Choosing boards with water-resistant properties can further enhance their effectiveness in damp environments. Fire resistance is another critical factor, and choosing boards with recognized safety ratings ensures compliance with UK building regulations and enhances safety. Cost considerations and ease of installation shouldn't be overlooked, as premium insulating materials typically deliver superior performance but at higher upfront costs. Furthermore, integrated solutions that combine insulation with finishing layers can streamline installation processes, minimize disruption, and improve the overall durability of the finished wall.

Leading Brands and Recommendations for Different Application Needs

The choice of leading brands and specific product recommendations is essential to ensure that insulated plasterboard meets the diverse requirements of various building applications. Reputable manufacturers such as Kingspan, Celotex, Gyproc, Ecotherm, and Knauf offer specialized solutions tailored to different project needs.

For instance, Kingspan Kooltherm K118 provides exceptional thermal performance suitable for internal wall insulation, helping to achieve low U-values and improved energy efficiency. The Celotex PL4000 series is ideal for use in moisture-prone environments due to its moisture-resistant properties. These brands produce boards with low lambda values, ensuring high insulating performance. Ecotherm Eco-Liner is particularly well-suited for retrofit applications involving solid walls, offering a straightforward installation with effective insulation. Gyproc ThermaLine Super combines thermal insulation with vapor control, making it a versatile choice for a range of building types. Selecting the right insulation material is crucial for optimizing energy savings and durability.

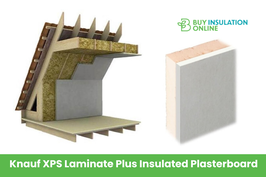

Meanwhile, Knauf insulated boards are recognized for their sustainability and versatility across different applications.

These brands deliver products that feature a variety of beneficial properties, including low K-values for superior insulation performance, moisture resistance, and environmentally friendly options.

Selecting the most appropriate product depends on specific project requirements, such as thermal efficiency, moisture management, and sustainability considerations.

Conclusion

Selecting the appropriate insulated plasterboard requires careful consideration of various types, such as foil-faced, foil-backed, or fibre-reinforced options, each offering different thermal, acoustic, and moisture-resistant properties. Evaluating factors like insulation performance, compatibility with existing structures, and specific application needs ensures optimal results. Consulting reputable brands and adhering to installation guidelines can enhance durability and energy efficiency. A thorough, informed approach guarantees a choice that aligns with both functional and environmental objectives, promoting long-term performance.