Plaster Board Insulation

Plasterboard insulation utilizes a range of materials, such as PIR, polystyrene-backed, phenolic, and moisture-resistant boards, to enhance thermal efficiency, regulate humidity, and provide fire resistance within building interiors. These materials offer various benefits, including space-saving qualities, lightweight installation, and durability, making them suitable for walls, ceilings, and humid areas. Proper installation involves preparing surfaces, cutting boards to the required size, and sealing joints effectively to maximize performance. Understanding these options to meet specific project requirements will become clearer with further guidance.

Types of Plasterboard Insulation Materials

What are the main types of plasterboard insulation materials used in construction and renovation projects

They include PIR (Polyisocyanurate) insulated plasterboard, which features rigid closed-cell foam plastic known for excellent thermal insulation, with a thermal conductivity of around 0.022 W/mK. This type is favored in space-saving applications such as new builds or renovation projects.

Polystyrene-backed plasterboards, primarily EPS (expanded polystyrene) and XPS (extruded polystyrene), offer lightweight and cost-effective solutions. XPS especially provides superior moisture resistance, making it suitable for areas prone to damp.

Phenolic insulated plasterboard, manufactured from phenolic foam, is notable for its high thermal efficiency, with a very low thermal conductivity of about 0.019 W/mK. Its slim profile makes it ideal where space conservation is a priority.

Additionally, HP+ boards combine reliable performance with moisture and fire resistance at moderate thicknesses. This versatility makes them suitable for various internal insulation applications.

These materials are widely used across the UK for their durability, thermal properties, and suitability for different building needs. Understanding insulation performance helps in selecting the appropriate plasterboard for specific projects.

Functional Benefits and Practical Applications

The functional benefits of plasterboard insulation materials directly impact their suitability for specific construction and renovation projects, as these advantages determine overall building performance and occupant comfort. Acoustic insulation properties help minimize noise transmission between rooms by absorbing and dampening sound vibrations, making spaces quieter and more suitable for bedrooms, offices, or healthcare environments. The material’s low thermal conductivity contributes to energy efficiency by maintaining consistent indoor temperatures and reducing heating or cooling demands. Moisture resistance, particularly with gypsum cores and water-resistant facings, prevents mold growth and structural deterioration in humid environments such as kitchens and bathrooms. Additionally, plasterboard is lightweight, facilitating quick and straightforward installation, while its smooth surfaces support various finishing options, making it versatile for both commercial and residential applications. Lightweight construction materials These combined benefits ensure durability, ease of maintenance, and enhanced occupant well-being. Furthermore, the moisture-resistant versions of plasterboard are vital in humid areas, helping to prevent issues related to dampness and mold that can compromise indoor air quality.

Installation Considerations and Best Practices

Proper installation of plasterboard insulation demands careful planning and adherence to best practices to ensure optimal performance and safety. Wall surfaces must be clean, dry, stable, and flat to prevent bonding issues and moisture accumulation. Insulated plasterboard should be stored flat and handled carefully to prevent damage before installation. For solid brick, block, or rendered walls that are free from moisture risks, the dot and dab adhesive method offers an effective bonding solution. Avoid using adhesives on surfaces prone to dampness or on timber and steel frames; instead, employ mechanical fixings such as screws or metal fasteners, spaced appropriately, to secure the panels firmly. Boards should be cut approximately 15 mm shorter than the wall height to accommodate expansion and any structural movement. Sealing gaps and joints with quality sealant or caulk enhances airtightness and reduces thermal bridging. Incorporating the use of thermal bridging minimization techniques during installation contributes to better overall insulation performance. Combining adhesive with mechanical fixings during installation provides increased stability and safety and ensures the long-term integrity of the insulation system. Handling materials with care during installation prevents damage and preserves the quality of the finished surface. Following these guidelines will help achieve a safe, durable, and effective insulation solution suitable for UK building standards.

Performance Categories and Industry Brands

Assessing the performance categories of plasterboard insulation involves understanding their specific qualities and how these qualities serve different building needs. These qualities include thermal efficiency, fire resistance, moisture resistance, acoustic performance, and impact resistance.

Thermal efficiency varies among products, with thermal conductivities (K-values) typically ranging from 0.018 to 0.035 W/m·K. These values directly influence energy savings and thermal comfort within buildings.

Fire-resistant boards adhere to rigorous standards such as BS EN 520 and EN ISO 1182:2010, offering high safety levels for both commercial and residential applications.

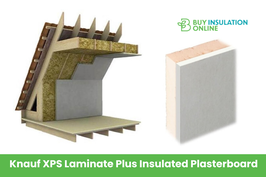

Industry brands such as Gyproc and Knauf and their key product lines—like Gyproc ThermaLine PIR, Knauf XPS Laminate Plus, and Gyproc SoundBloc—provide specialized solutions to meet thermal, moisture, and acoustic requirements.

Products like Knauf Insulation's glass mineral wool and rock mineral wool have unique fire-resistant properties that enhance safety in various construction scenarios.

These products work seamlessly together to create reliable, system-wide solutions suited to various building types and needs.

Conclusion

Selecting the appropriate plasterboard insulation requires an understanding of various material types, their functional benefits, installation procedures, and performance standards. Careful consideration of industry brands and performance categories ensures the best thermal and acoustic performance while maintaining cost-effectiveness and durability. Proper installation techniques are essential to maximize efficiency and safety. Overall, a comprehensive knowledge of these factors enables informed decision-making, resulting in improved building comfort, energy efficiency, and compliance with relevant standards and regulations.