Plasterboard Thermal Insulation

Insulated plasterboard combines traditional plasterboard panels with integrated insulation, often produced from materials such as PIR, XPS, or EPS, to enhance the thermal performance of walls. The installation process involves cleaning the surfaces, marking out guides, leaving appropriate expansion gaps, and fixing the panels securely using adhesive or mechanical fasteners to ensure stability and optimal insulation effectiveness. This method helps to reduce heat transfer, lower energy costs, and improve indoor comfort levels. Ongoing research highlights how the choice of materials and installation techniques can influence the long-term efficiency and suitability of insulated plasterboard for various environments across the UK.

Types and Materials of Insulated Plasterboard

Insulated plasterboard is available in a variety of types and materials, each designed to meet specific performance criteria for thermal efficiency, durability, and moisture resistance.

Polyisocyanurate (PIR) plasterboard features a rigid foam core with an exceptionally low thermal conductivity of approximately 0.022 W/mK. This makes it highly suitable for applications requiring high-performance insulation within slim profiles, helping to maximize internal space while maintaining effective thermal performance. It is also highly fire-resistant and retains its insulating properties even at elevated temperatures.

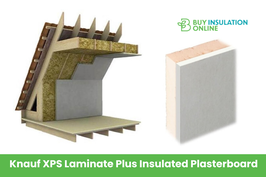

Extruded polystyrene (XPS) plasterboard utilizes a dense foam core that offers excellent moisture resistance and high compressive strength. It's particularly suitable for use in damp environments, such as bathrooms or external walls, where moisture management is critical.

Expanded polystyrene (EPS) plasterboard comprises lightweight beads of polystyrene pressed together to form a board. It provides moderate insulation properties at a more affordable price point but offers less resistance to moisture compared to XPS. EPS boards are often utilized in interior wall insulation where moisture levels are less problematic.

In addition to these foam-based options, gypsum-based plasterboards can be combined with foam inserts or specialized coatings to enhance fire resistance or provide better soundproofing capabilities.

There are also specialized boards designed for specific conditions, such as high-moisture environments or fire-resistant applications, offering tailored solutions to meet diverse building requirements.

Choosing the appropriate type of insulated plasterboard depends on the specific needs of the project, including factors such as thermal performance, moisture exposure, and fire safety requirements.

Installation Techniques for Thermal Insulated Plasterboard

Proper installation of thermal insulated plasterboard necessitates careful preparation and the application of correct techniques to achieve optimal performance. Prior to installation, surfaces should be clean, dry, and level, with any loose paint, dust, or debris thoroughly removed to ensure effective bonding and fixing. Clean, dry, and level surfaces help prevent issues such as poor adhesion or future deformation of the plasterboard. Vertical guides should be marked at 1200 mm intervals on both the floor and ceiling to facilitate accurate panel alignment. Panels should be cut to leave a 15 mm gap around the edges to allow for thermal expansion and contraction. Adhesive fixing involves applying a continuous bead or a ‘dot and dab’ pattern of adhesive to the backside of the plasterboard. During installation, panels must be pressed firmly against the wall or ceiling to remove air pockets and achieve proper contact. It's essential to allow the adhesive to become tacky before fitting the panels into position to maximize bonding strength. In cases where surfaces are unsuitable for adhesive fixing, mechanical fixings such as screws or nails should be used. These fixings must be spaced correctly to prevent sagging and to maintain the structural integrity of the plasterboard. These mechanical fixings help to distribute weight evenly and ensure secure attachment over time. Throughout the process, a spirit level should be used continually to check that panels are installed plumb and level. Joints should be sealed carefully to create a seamless surface, and small gaps should be left at joints and edges for finishing compounds or skim coats. These steps help ensure both the structural stability of the installation and the effectiveness of the thermal insulation. Following these guidelines will lead to a durable, well-insulated finish that meets UK building standards and performance expectations.

Benefits for Energy Efficiency and Cost Savings

Thermal insulated plasterboard provides a practical and effective solution for enhancing the energy efficiency of buildings in the UK. By significantly reducing heat transfer through walls, ceilings, and floors, it helps maintain a comfortable indoor environment year-round.

The product combines plasterboard with insulating materials, such as expanded polystyrene (EPS), creating a high-performance barrier that minimises heat loss—an issue that accounts for up to 25% of heat escaping through walls in homes. Incorporating high-quality EPS insulation further enhances thermal resistance. The use of [high-performance insulation materials improves overall effectiveness and durability. Reducing heat loss through enhanced insulation decreases the need for heating and cooling systems to work as hard, leading to a notable decrease in energy consumption. This results in lower energy bills and supports environmentally responsible building practices by reducing carbon emissions.

Furthermore, installing insulated plasterboard offers a cost-effective way to improve thermal performance. The integration of insulation and finishing layers means fewer materials and less labour are required compared to traditional separate insulation and plastering projects.

As a result, it not only provides an immediate cost saving but also contributes to long-term financial benefits through reduced energy bills and increased building efficiency.

Conclusion

In conclusion, selecting the appropriate insulated plasterboard requires an understanding of different materials and installation techniques, as these directly influence thermal performance and energy efficiency. Proper choice and meticulous installation can significantly enhance insulation levels, reduce energy consumption, and lower ongoing costs. Adhering to recommended best practices ensures maximum effectiveness and durability, making insulated plasterboard a practical and reliable solution for thermal management across a variety of building projects. This structured approach guarantees consistent insulation performance while effectively supporting energy conservation objectives in the UK.