- Blogs

- The Ultimate Guide to Floor Soundproofing in the UK: Materials, Regulations & Best Practices

The Ultimate Guide to Floor Soundproofing in the UK: Materials, Regulations & Best Practices

TLDR: Fed up with noisy floors in your UK home? This guide explains how to tackle both thudding footsteps (impact noise) and voices or TV sounds (airborne noise). Effective floor soundproofing involves understanding the science, choosing the right materials (like dense vinyl, acoustic insulation, and specialist underlays), and installing them correctly – especially sealing all gaps. For many projects, you'll need to meet UK Building Regulations (Approved Document E). Getting it right means a quieter home, but mistakes can be costly, so consider professional advice for complex jobs.

The Quest for Quiet: Understanding Floor Soundproofing in Your UK Home

The desire for a tranquil home environment is universal, yet for many in the UK, unwanted noise is a persistent intrusion. Whether it's the sound of neighbours' footsteps in an adjoining flat, conversations drifting from downstairs, or the general hubbub of a busy household, excessive noise can significantly impact comfort and well-being.

Indeed, sound-related issues are frequently cited as a source of tension between neighbours, particularly in higher-density housing common across the UK, such as flats, terraced, or semi-detached houses. The emotional toll of persistent noise can be substantial, leading to stress, sleep deprivation, and a diminished quality of life.

Anecdotal accounts often describe feelings of upset and even tears due to inescapable noise, or the particular frustration of being disturbed during critical periods of rest, such as when trying to fall asleep. This underscores that the pursuit of effective soundproofing is often driven by a profound need for peace and sanctuary within one's own home, transforming it from a mere technical upgrade into a vital component of domestic well-being. The common aspiration is simply for a "quieter, more peaceful space".

Floor soundproofing, at its core, is about acoustic isolation. This means preventing or significantly reducing the transmission of sound waves through the floor structure, whether that sound is originating from a room below and travelling upwards, or from activities on the floor itself travelling downwards to the space beneath. To effectively address floor noise, it is crucial to understand the two primary types of sound that soundproofing solutions aim to mitigate:

-

Airborne noise: This category includes sounds that travel through the air before impacting the floor structure. Common examples are voices, music, television sounds, and general background noise. These sound waves cause the floor to vibrate, which then radiates sound into the adjacent room.

-

Impact noise: This type of noise is generated by direct physical contact with the floor surface. Footsteps, dropped objects, children playing, or the movement of furniture are typical sources of impact noise. The vibrations from these impacts travel directly through the building's structure.

Many UK properties, especially older conversions or buildings with traditional timber joist floors, are particularly susceptible to problems with both airborne and impact noise transmission. Homeowners or tenants in such properties may find that simple measures, like laying a carpet with a standard underlay, offer some relief from impact noise but do little to prevent airborne sounds from passing through.

This highlights a common challenge: without a clear understanding of these distinct noise types and the fact that they often require different treatment strategies, attempts at soundproofing can be only partially successful or, in some cases, ineffective. Therefore, an early appreciation of these differences is fundamental to setting realistic expectations and selecting comprehensive solutions.

Effective floor soundproofing strategies typically need to address both airborne and impact noise to achieve a satisfactory level of quiet.

The Science of Silence: Key Principles of Effective Soundproofing

A foundational understanding of how sound behaves and how soundproofing works is essential for making informed decisions about materials and installation methods. Without this, efforts to reduce noise can be misguided and ultimately disappointing.

How Sound Travels Through Floors

As established, sound predominantly travels through floor structures in two ways:

-

Airborne Noise: Generated by sources such as speech, music, or televisions, airborne sound waves propagate through the air. When these waves encounter a floor, they cause it to vibrate. These vibrations are then transmitted through the floor structure and radiated as sound into spaces above or below. Airborne sound will readily exploit any cracks, gaps, or weak points in a structure, only being significantly impeded by hard, thick, and massive surfaces.

-

Impact Noise: This results from direct physical impacts on the floor surface, such as footsteps, dropped items, or furniture being dragged. The energy from these impacts creates vibrations that travel directly through the floor assembly and into the building structure, manifesting as noise in adjacent rooms. This is often perceived as the "thudding" or "stamping" noise that causes considerable annoyance.

It is also important to recognise that many real-world noises are a composite of both airborne and impact characteristics. For instance, loud speech involves airborne sound, but heavy footfalls during an animated conversation could also contribute impact noise.

The Four Pillars of Soundproofing

Effective soundproofing relies on several key physical principles, which are often employed in combination:

-

Deflection (Mass and Density): This is one of the most fundamental principles. By adding heavy, dense materials to a floor structure, the energy of sound waves can be blocked or reflected. The greater the mass and density of a barrier, the more difficult it is for sound to pass through it. This principle is particularly effective against airborne noise. All solid materials with a thick consistency and significant weight can contribute to deflecting sound.

-

Absorption: Porous or fibrous materials, such as acoustic mineral wool, work by absorbing sound energy. As sound waves enter these materials, the energy is converted into tiny amounts of heat through friction, thereby reducing the sound that can pass through or be reflected. Absorption is crucial for reducing sound resonance within cavities (like those between floor joists) and for mitigating airborne sound.

-

Decoupling (Isolation): This principle involves creating a separation or break in the structural path that sound can travel along. By isolating one part of a structure from another, the transmission of vibrations is significantly reduced. For example, constructing a "floating floor" that rests on resilient mounts rather than being directly fixed to the subfloor decouples the finished floor from the main structure. While decoupling is often most effectively implemented during the initial construction phase of a building, various retrofit solutions are also available. This principle is highly effective against impact noise and can also enhance airborne sound insulation.

-

Damping: Damping involves using materials that dissipate vibrational energy by converting it into heat. This is often achieved through a technique called Constrained Layer Damping (CLD), where a viscoelastic damping compound is sandwiched between two rigid layers (like plywood). When sound waves cause these panels to vibrate, the damping layer resists this movement, creating shearing forces and friction, which convert the sound energy into heat.

A more advanced, related principle is Thermal Conversion, where specialised materials like certain acoustic membranes are designed to convert sound energy directly into minute amounts of heat energy upon impact.

Soundproofing vs. Sound Absorption

It is vital to distinguish between soundproofing and sound absorption, as these terms are often used interchangeably but refer to different acoustic goals.

-

Soundproofing (or acoustic isolation) aims to block the transmission of sound from one space to another. The primary goal is to prevent noise from entering or leaving a room.

-

Sound Absorption aims to reduce sound reflections and reverberation within a space. Materials like acoustic foam panels or heavy curtains absorb sound waves, improving the acoustic quality and clarity within a room by minimising echoes.

Many homeowners mistakenly believe that materials designed for sound absorption, such as thin foam panels or even cardboard egg cartons, will effectively soundproof a floor against noise from neighbours. However, such materials typically lack the necessary mass or decoupling properties to significantly block sound transmission between rooms.

While sound absorption can play a complementary role in a comprehensive acoustic strategy (e.g., reducing reverberation within a room that has a soundproofed floor), the focus of floor soundproofing is predominantly on isolation. Understanding this distinction is crucial for selecting appropriate materials and methods, thereby avoiding wasted expenditure and effort on solutions that are not fit for the primary purpose of blocking noise.

The success of any floor soundproofing project ultimately depends on correctly identifying the dominant type of noise (airborne, impact, or both) and then applying the relevant scientific principles through carefully selected materials and installation techniques. For example, simply adding mass to a floor might help with airborne noise but could be insufficient for severe impact noise if the principle of decoupling is not also addressed. A mismatch between the problem and the applied principles will invariably lead to less than optimal results.

Your Toolkit for a Quieter Floor: Essential Soundproofing Materials in the UK

A wide array of materials is available for floor soundproofing, each with specific properties suited to tackling different aspects of noise transmission. Effective solutions often involve a combination of these materials, working together as a system.

Heavyweights for Mass & Density (Primarily Airborne Noise, some Impact Damping)

These materials primarily work on the principle of deflection by adding significant mass to the floor structure.

-

Mass Loaded Vinyl (MLV):

- Description: MLV is a thin, dense, and flexible material, typically made from vinyl impregnated with high-mass elements like barium sulphate. It is highly effective at blocking airborne noise and can also contribute to reducing impact noise due to its damping properties. Its primary function is to add substantial mass to a surface with minimal thickness. Some advanced acoustic membranes, like Acoustiblok, operate on a thermal conversion principle, converting sound energy into trace heat, while standard MLV relies more on deflection.

- Properties: Its flexibility allows it to be used on various surfaces, including curves. It is generally durable and resistant to mould and mildew, and can be layered with other materials for enhanced performance.

- Installation: Typically installed directly onto the subfloor, beneath underlays or the final floor finish. It can also be incorporated into wall and ceiling assemblies. It is cut to fit and usually secured with adhesive.

- UK Availability & Cost: Various brands are available. Indicative costs can range from £50 to £120 per square metre. Products like MuteBarrier™ are available in different weights, for example, 5 kg/m² offering up to 22dB reduction, and 10 kg/m² offering up to 28dB reduction in specific test conditions.

-

Dense Boards (OSB, Plywood, Particle Board, Fire Board, Cement Particle Board):

- Description: Standard construction boards like Oriented Strand Board (OSB), plywood, particle board, and cement particle board can contribute to soundproofing by adding mass to a floor structure. Fire-rated boards often have increased density, which can also be beneficial.

- Application: Commonly used as a subfloor material or as a structural layer in a floating floor system, providing a solid base for other soundproofing treatments.

Champions of Absorption & Damping (Airborne Noise in Cavities, Impact Noise Reduction)

These materials excel at soaking up sound energy or reducing vibrations.

-

Acoustic Mineral Wool (Rock Wool, Stone Wool, Fibreglass):

- Description: These are typically open-cell, fibrous insulation materials made from molten rock, slag, or glass. Their structure is highly effective at absorbing sound energy and converting it into heat, reducing airborne sound transmission and cavity resonance. Examples include Rockwool RWA45, Isover APR, and QuietFibre Stone Wool.

- Application: Ideal for filling the void between timber floor joists to absorb airborne sound travelling through the cavity. It is strongly recommended to install some form of insulation between joists if possible.

- Properties: Besides acoustic benefits, mineral wool also provides excellent thermal insulation. Most products have a high fire safety rating (e.g., Euroclass A1). When handling fibreglass, appropriate protective gear should be worn as it can be an irritant.

- UK Availability & Cost: Widely available in various densities and thicknesses (commonly 25mm to 100mm). Material costs can range from approximately £25 to £50 per square metre for installed systems. Raw material prices vary; for example, 100mm acoustic mineral wool can range from around £4 to £14 per square metre (excluding VAT) depending on brand and specification.

-

Soundproof Underlays (Rubber, Cork, Felt, Specialist Foam):

- Description: These are resilient layers placed directly beneath the final floor finish (e.g., laminate, wood, carpet, tiles). Their primary function is to cushion impacts and absorb impact noise energy, preventing it from transmitting into the structure below.

- Types & Properties:

- Rubber underlays are particularly effective for impact noise reduction.

- Cork is a natural and sustainable option, also good for impact sound.

- Felt is often used in combination with other materials in composite underlays.

- Specialist acoustic foam underlays can offer high performance, such as MuteMat® OSF 750-10, which has a density of 750kg/m³, is 10mm thick, and can provide up to 23dB impact sound reduction under specific test conditions. Another example is Sonic Gold 5mm underlay, quoted with a 25dB impact sound reduction. Some underlays also incorporate a damp-proof membrane.

- Application: Installed directly onto the subfloor or over an intermediate soundproofing layer like MLV.

- UK Availability & Cost: Prices vary significantly based on material and performance. For example, a 5mm Sonic Gold underlay might cost around £2.20 per square metre, while higher performance specialist underlays will be more expensive.

Masters of Decoupling (Impact and Airborne Noise Reduction)

Decoupling materials create a physical separation to break the path of sound vibrations.

-

Resilient Bars (Resilient Channels):

- Description: These are thin, profiled metal channels designed to be fixed to timber joists (for ceilings below a noisy floor) or wall studs. The new surface (e.g., acoustic plasterboard or other dense boards) is then fixed to the resilient bars, creating a mechanical separation from the main structure. The corrugated design of the bar acts like a spring, isolating the new surface.

- Application: Primarily used to create a "floating" ceiling or wall surface, significantly reducing both impact and airborne sound transmission.

- Installation: Bars are fixed perpendicular to joists or studs. It is critical that screws fixing the surface material only penetrate the resilient part of the bar and do not touch the joists/studs, as this would create an acoustic bridge and compromise performance.

- UK Availability & Cost: Available from specialist suppliers, typically costing around £4 to £6 per 3-metre length.

-

Acoustic Hangers / Isolation Clips (Mounts):

- Description: These are engineered components, often made from steel with a resilient rubber or elastomeric element. They provide a more robust method of decoupling than resilient bars and are used to suspend ceilings or support wall framing. MuteClip is an example of such a product.

- Application: Suitable for applications requiring a higher degree of sound isolation, particularly for low-frequency noise, often used in ceiling assemblies below a problematic floor.

-

Floating Floor Systems:

- Description: A floating floor is a construction where the finished floor surface is separated from the structural subfloor by a resilient layer. This "floats" the floor, isolating it from vibrations. This can be achieved using layers of padding or foam, resilient battens laid over the subfloor with a new deck on top, or by using specialist acoustic overlay boards that incorporate a resilient layer.

- Application: Highly effective for reducing impact noise and also beneficial for airborne sound insulation.

The Unsung Heroes (Sealing and Finishing)

These materials are crucial for ensuring the overall integrity of a soundproofing system.

-

Acoustic Sealants & Caulks:

- Description: These are flexible, non-hardening sealants specifically designed to fill gaps and joints in soundproofing constructions.

- Importance: Sound, particularly airborne sound, will find any small openings to leak through. Acoustic sealant is essential for sealing perimeters of floors and walls, around service penetrations (pipes, cables), and at joints between materials to maintain the acoustic integrity of the assembly. Even the best soundproofing materials can be compromised by unsealed gaps. While an important complementary product, acoustic caulk alone will not soundproof a room.

- Cost: Typically £5 to £20 per linear metre for the applied bead.

-

Acoustic Putty, Tapes & Bands:

- Description: Acoustic putty is used for sealing around electrical boxes and other small penetrations. Specialist acoustic tapes and bands can be used for sealing joints between boards or providing a resilient break at junctions.

It becomes clear that there is no single "magic bullet" material for floor soundproofing. The most effective solutions almost invariably involve a system of carefully chosen, compatible materials that work together to address the specific noise types, floor construction, and desired level of performance. Relying on a single product, especially for complex noise issues, is a common oversight that often leads to unsatisfactory results. The principles of adding mass, absorbing sound, decoupling structures, and meticulous sealing all play a role, and different materials excel in different areas.

Furthermore, while high-performance specialist materials can achieve excellent results, significant improvements in sound insulation can often be realised with more budget-friendly options, provided they are installed correctly and as part of a thoughtfully designed system. The cost of materials can vary widely, from relatively inexpensive mineral wool to premium MLV products.

However, it is crucial to be wary of products marketed as simple, standalone solutions for complex noise problems, such as "soundproof paint" or "soundproof wallpaper." While these might be listed among general soundproofing materials, expert assessments suggest they are generally ineffective for achieving meaningful soundproofing against typical noise complaints in dwellings and can be considered a waste of resources if substantial noise reduction is the goal. The focus should always be on proven principles and materials that contribute to a robust soundproofing assembly.

To help navigate these choices, the following table provides a comparison of key floor soundproofing materials:

Table 1: Comparison of Key Floor Soundproofing Materials

| Material Type | Primary Noise Type Addressed | Key Advantages | Typical Installation Areas | Estimated Cost Guide (UK) |

| Mass Loaded Vinyl (MLV) | Airborne (primarily), Impact | High mass in thin profile, flexible, good for adding density | Under flooring, within floor/wall/ceiling assemblies | £50 - £120 / m² |

| Acoustic Mineral Wool | Airborne, Cavity Resonance | Excellent sound absorption, thermal co-benefits, fire resistant | Between timber joists, in stud wall/ceiling cavities | £25 - £50 / m² (installed system estimate); material ~£4-£14 / m² |

| High-Density Rubber Underlay | Impact | Good impact absorption, durable, can be laid under various floor finishes | Directly under hard flooring (laminate, wood), or carpet | Varies, e.g., £2-£10+ / m² |

| Resilient Bars (for ceilings/walls) | Airborne, Impact | Decouples surface from structure, space-saving, cost-effective decoupling | Ceilings below noisy floors, walls | £1.30 - £2.00 / m (approx.) |

| Acoustic Overlay Boards | Impact, Airborne | Combines mass and resilient layer, direct fix to subfloor, some meet Part E | Over existing timber or concrete subfloors | £25 - £60+ / m² |

| Acoustic Sealant | Airborne (leakage) | Seals gaps and perimeters, maintains acoustic integrity, flexible | Around perimeters, penetrations, joints in soundproof assembly | £5 - £20 / linear metre |

Note: Costs are indicative and can vary based on brand, specification, quantity, and supplier. Performance (dB ratings) depends on the specific product and the overall system it's part of.

Best Practices: Installing Floor Soundproofing Like a Pro in the UK

Successful floor soundproofing is not just about choosing the right materials; correct installation is paramount. Even the best products can underperform if not fitted according to established best practices. This section outlines key installation techniques for common UK floor types.

General Preparation for All Floor Types

Before commencing any soundproofing work, thorough preparation is essential:

-

Clear and Clean: The floor area must be cleared of all furniture and obstacles. The existing floor surface should be thoroughly cleaned, and any existing floor coverings like carpet or old underlay should be removed to expose the subfloor. This ensures a smooth, sound base for the new soundproofing materials.

-

Inspect and Seal: Carefully inspect the subfloor for any existing gaps, cracks, or holes, particularly around the perimeter, where pipes or services pass through, and between floorboards. These must be sealed meticulously with a good quality acoustic sealant or appropriate fillers. Making the existing surface as airtight as possible is a crucial first step.

Tackling Timber Floors

Timber joisted floors are prevalent in many UK homes, from Victorian terraces to more modern constructions, and they often present challenges for both airborne and impact noise.

-

The Aim: For timber floors, the goal is usually to address both airborne sound (e.g., voices, TV from rooms below or above) and impact sound (e.g., footsteps from the room above).

-

Approach 1: Insulating Between Joists

- This is widely considered one of the most effective and straightforward ways to reduce airborne sound transmission in either direction through a timber floor.

- Material: Acoustic mineral wool (e.g., Rockwool, Isover, Knauf) is the material of choice. It should be cut to slightly larger than the width of the joist cavity and friction-fitted snugly between the joists, ensuring there are no gaps. The full depth of the joist cavity should ideally be filled.

- Benefits: The mineral wool absorbs airborne sound waves travelling through the cavity and also helps to damp resonance within the void.

-

Approach 2: Treating Above Existing Floorboards

- This approach involves adding soundproofing layers on top of the existing floorboards or subfloor. It will inevitably lead to some increase in floor height, which must be considered.

- Materials:

- Soundproof Underlays: High-density rubber, cork, felt, or specialist acoustic foam underlays can be laid directly onto the floorboards, beneath the final floor finish. These are particularly effective at reducing impact noise.

- Mass Loaded Vinyl (MLV): Sheets of MLV can be laid over the floorboards, often beneath an acoustic underlay or a new flooring layer. This adds significant mass to combat airborne noise.

- Acoustic Overlay Boards: These are specialist boards designed for direct application over existing subfloors. Products like cement particle boards (e.g., STS TG4 Acoustic Flooring Board) or other dense boards typically combine mass with a resilient layer to tackle both airborne and impact noise.

-

Approach 3: Creating a Floating Floor

- This is a more disruptive and complex method but offers a high level of sound insulation, particularly for impact noise.

- It involves creating a new floor deck (e.g., chipboard or plywood) that is isolated from the existing joists or subfloor. This can be achieved by:

- Laying a resilient layer (e.g., specialist acoustic foam or rubber matting) over the subfloor, with the new deck installed on top.

- Fixing resilient timber battens over the existing floor structure, with the new deck then secured to these battens. This creates a service void, which can also be insulated with mineral wool. This method will raise the floor height more significantly.

-

Combining Approaches: For optimal performance on timber floors, a combination of methods is often best. For instance, installing acoustic mineral wool between the joists and then adding an acoustic overlay board or a combination of MLV and a high-performance underlay on top of the floorboards can provide excellent all-round sound insulation.

Conquering Concrete Floors

Concrete floors are common in many newer UK builds, particularly in flats and apartment blocks. Dense concrete slabs (typically 150mm thick or more) can offer good inherent airborne sound insulation. Therefore, the primary aim when soundproofing concrete floors is often to improve impact sound insulation, which can still be a significant issue. If the concrete slab is relatively thin or has structural weaknesses, treatment for airborne noise may also be necessary.

-

Method 1: Screed with Acoustic Underlays (Approved Document E Floor Type 2)

- This involves pouring a sand-cement screed (typically 50-75mm thick) over a specialist resilient acoustic underlay that is laid on top of the structural concrete slab. An example of such a system is Robust Detail E-FC-4, which uses IsoRubber Base beneath a screed on precast concrete planks.

- Critical Detail: It is absolutely vital that the screed does not make direct contact with either the base concrete slab or any of the surrounding (flanking) walls. Any such contact will create an acoustic bridge, allowing vibrations to bypass the resilient layer and potentially causing sound insulation tests to fail. Resilient flanking strips must be installed around the perimeter of the floor at the wall junctions before the screed is poured. The resilient underlay material itself should be overlapped and taped at joints according to manufacturer instructions.

-

Method 2: Resilient Overlay Floor Coverings (Approved Document E Floor Type 1)

- These are specialist acoustic underlay systems designed to be bonded directly to the top of the concrete slab or a bonded screed, with the final floor finish then applied over them. Examples include Robust Details systems E-FC-9 and E-FC-10.

-

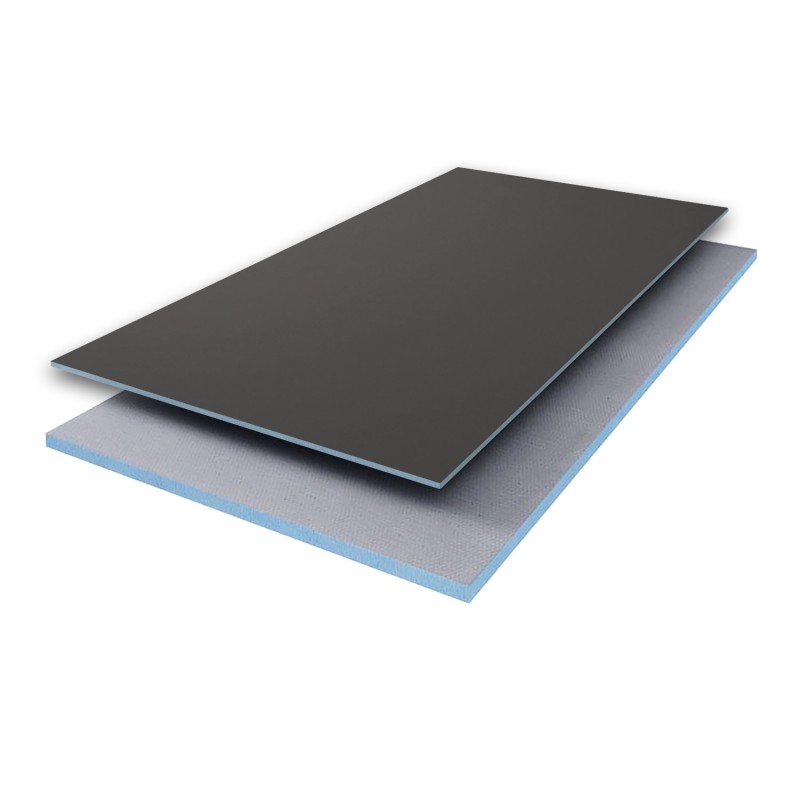

Method 3: Acoustic Overlay Boards

- These offer a "dry" alternative to a wet screed system. They typically consist of a dense board material (such as cement particle board, plywood, or MDF) with a resilient layer (e.g., foam or felt) pre-bonded to the underside. These are laid directly onto the concrete slab.

-

Method 4: Resilient Timber Battens

- This method can provide the highest level of acoustic performance, especially for impact sound. Resilient timber battens, or proprietary cradle and batten systems, are laid over the concrete slab. These battens incorporate a resilient layer or support. A new floating floor deck, typically chipboard, is then installed on top of the battens. If a higher performance is desired, this can be achieved with a cementitious board along with the chipboard. The void created between the battens can be used for services and can also be filled with acoustic mineral wool to further enhance performance. This system will result in a significant increase in finished floor height (often 60mm to 90mm).

The choice of soundproofing method is heavily influenced by the existing floor construction. Timber joist floors and concrete slab floors present different acoustic challenges and lend themselves to different solutions. UK housing stock is diverse, encompassing everything from historic buildings with original timber floors to modern apartment blocks with concrete structures. Therefore, generic advice is often insufficient; solutions must be tailored to the specific construction type to be effective and practical.

Critical Considerations for All Installations

Regardless of the floor type or materials chosen, certain principles are universally critical for successful soundproofing:

-

Sealing Gaps – The Non-Negotiable Step:

- As airborne sound will readily pass through even the smallest unsealed gaps or cracks, meticulous sealing is paramount.

- All perimeters where the floor meets walls, around any pipes or services that penetrate the floor, and any joints between soundproofing materials must be thoroughly sealed with a flexible acoustic sealant. This prevents sound leakage that could otherwise undermine the entire soundproofing effort.

-

Addressing Flanking Transmission:

- Flanking transmission refers to sound that bypasses the main soundproofed floor assembly by travelling along indirect paths, such as adjoining walls, structural connections, or through cavities. It is a major, and often underestimated, cause of soundproofing failure. Even a perfectly treated floor can seem ineffective if significant flanking noise is present.

- Common flanking paths in UK homes include:

- Timber joists that run through or into party walls.

- Continuous cavity walls that allow sound to travel between dwellings.

- Noise travelling through window reveals, especially in buildings with cavity external walls.

- Unsealed electrical sockets or service penetrations in walls.

- Mitigation strategies include:

- Using resilient flanking strips at all floor-to-wall junctions to create a break between the flooring system and the walls.

- Sealing around joists where they enter walls with mortar or acoustic sealant.

- In severe cases, treating the flanking walls themselves with soundproofing measures may be necessary.

- Installing cavity stops (e.g., dense mineral wool) within external wall cavities around window reveals.

-

Avoiding Acoustic Bridging:

- An acoustic bridge (or sound bridge) is any rigid connection that allows sound vibrations to bypass a sound-isolating layer or component, effectively short-circuiting the soundproofing.

- Common examples include screws that are too long and pass through a resilient layer into the fixed structure, mortar droppings creating a solid link in a cavity, or a floating screed touching the surrounding walls.

- Acoustic bridging is a frequent cause of sound insulation test failures and must be diligently avoided through careful design and installation.

Flanking transmission, in particular, warrants special attention. Many soundproofing projects focus solely on the direct path of sound through the floor, only for the occupants to find that noise is still a problem because it is travelling via these alternative routes. This is especially true in older UK properties with shared structural elements or continuous cavities. Addressing these flanking paths is often what separates a moderately successful soundproofing job from a truly effective one, and it's a key area where expert understanding can make a significant difference.

While many simpler soundproofing measures, such as laying an acoustic underlay or installing mineral wool between joists (if accessible), can be undertaken by a competent DIY enthusiast, achieving compliance with UK Building Regulations for more complex systems, or where Pre-Completion Testing is mandatory, often benefits from professional expertise. The intricacies of acoustic design, material selection for specific decibel targets, and the avoidance of common pitfalls like acoustic bridging and unaddressed flanking paths can be challenging. Investing in professional installation or, at the very least, expert advice can prevent costly mistakes, ensure regulatory compliance, and ultimately lead to a more successful outcome.

Buy Acoustic Floor Insulation

Staying Compliant: Navigating UK Soundproofing Regulations & Standards

For many floor soundproofing projects in the UK, particularly those involving new builds, conversions, or significant refurbishments, compliance with national Building Regulations is a legal requirement. The key document governing sound insulation is Approved Document E (Resistance to the passage of sound).

Introduction to Approved Document E

Approved Document E is a part of the Building Regulations for England and Wales that provides practical guidance on how to meet the regulatory requirements for sound insulation in buildings. Its primary purpose is to ensure that dwellings provide occupants with reasonable resistance to sound from other parts of the same building and from adjoining buildings, thereby enhancing comfort, privacy, and well-being. Given that noise is a common source of disputes between neighbours, these regulations play an important role in maintaining amenity.

The scope of Approved Document E is broad and applies to:

- New-build houses and flats.

- Buildings undergoing a "material change of use," for example, when a single large house is converted into multiple flats.

- Alterations to pre-existing premises and refurbishments, although the specific application and requirements may vary. The general principle is that any alteration work should not make the sound insulation performance worse than it was before.

- The document covers the performance of separating walls, floors, and stairs between dwellings, as well as internal walls and floors within a dwelling.

Key Requirements of Approved Document E for Floors

Approved Document E is divided into sections, with the main requirements relevant to floors being:

-

Requirement E1: Protection against sound from other parts of the building and adjoining buildings. This deals with sound insulation between separate dwellings (e.g., between flats).

-

Requirement E2: Protection against sound within a dwelling-house, etc. This addresses sound insulation between rooms within the same dwelling (e.g., between a bedroom and a living room).

To meet these requirements, separating floors must achieve specific minimum levels of performance for both airborne and impact sound insulation. These are expressed in decibels (dB):

-

For purpose-built dwellings (New Builds):

- Airborne sound insulation: Floors must achieve a weighted standardised level difference, corrected for low-frequency sound, of at least 45 dB.

- Impact sound insulation: Floors must achieve a weighted standardised impact sound pressure level of no more than 62 dB (lower values indicate better performance for impact sound).

-

For dwellings formed by a material change of use (Conversions/Refurbishments):

- Airborne sound insulation: Floors must achieve at least 43 dB.

- Impact sound insulation: Floors must achieve no more than 64 dB.

The inclusion of the factor (a low-frequency spectrum adaptation term) for airborne sound is important as it accounts for noise sources with significant low-frequency content, such as amplified music or home cinema systems, which are common in modern living.

The slightly more relaxed performance standards for conversions compared to new builds acknowledge the inherent practical difficulties and structural constraints often encountered when working with existing buildings. However, it is crucial to remember that these are minimum standards. For enhanced occupant comfort and to minimise potential noise complaints, aiming for performance levels that exceed these minimums is often advisable, particularly where budget and construction constraints allow. Achieving only the bare minimum required by regulations may not always translate to a subjectively "quiet" environment for residents.

Proving Compliance with Approved Document E

There are two primary routes to demonstrate compliance with the sound insulation requirements of Approved Document E for floors:

-

Pre-Completion Testing (PCT):

- This is the default method for demonstrating compliance for most new builds and conversions, unless the Robust Details scheme is used.

- PCT involves on-site sound insulation tests carried out on completed separating floors (and walls) by an accredited testing body before the building is signed off by Building Control.

- The tests measure the actual airborne sound insulation and impact sound insulationzzzzzzzzzzzzzz achieved by the constructed elements.

- The results of these tests are then submitted to the local authority's Building Control department as evidence of compliance. A typical testing regime for a small to medium-sized development might include two airborne floor tests and two impact floor tests, alongside wall tests.

-

The Robust Details Scheme (RDs):

- Robust Details offer an alternative to Pre-Completion Testing, but only for new, attached dwellings (i.e., new houses and flats that adjoin each other). The scheme is not applicable for extensions, conversions of existing buildings, or detached properties.

- The scheme is administered by Robust Details Ltd., a non-profit distributing organisation. Developers who wish to use this route register their plots with Robust Details Ltd. and then construct the separating elements (walls and floors) strictly in accordance with specific, pre-tested and certified construction designs known as "Robust Details".

- These details specify the exact materials (often proprietary products) and construction methods to be used. Examples of floor Robust Details include E-FC-4 (which features IsoRubber Base resilient layer under a screed on precast concrete planks and is one of the most frequently used details), E-FC-5, E-FC-6 (other screed on resilient layer systems for concrete floors), and E-FC-9, E-FC-10 (resilient overlay floor coverings for concrete floors).

- The main benefit of using Robust Details is that, if the construction is carried out exactly as specified and registered, it avoids the need for PCT, thereby saving time and reducing the risk of costly test failures and remedial work.

- Crucially, any deviation from the specified Robust Detail, such as substituting a specified proprietary product for another, will invalidate the registration for that plot, and Pre-Completion Testing will then be required. It is therefore essential that contractors are fully aware of the specific requirements of the Robust Detail being used and adhere to them meticulously.

The Robust Details scheme provides a degree of predictability for developers of new housing, but its strict adherence requirements mean it is less flexible. For individuals or smaller developers undertaking conversions or major refurbishments where Part E applies, Pre-Completion Testing is the more common compliance pathway. This places a strong emphasis on getting the acoustic design and installation right from the outset, as failing PCT can lead to expensive and disruptive remedial work.

Relevant British and International Standards for Testing

The sound insulation tests conducted for PCT, and indeed the development of Robust Details, are based on standardised measurement procedures. Key standards include:

-

BS EN ISO 140-7:1998: "Acoustics. Measurement of sound insulation in buildings and of building elements. Field measurements of impact sound insulation of floors." This standard (though noted as withdrawn by BSI, it remains referenced in some scopes like SITMA's) specifies methods for on-site measurement of impact sound insulation using a standardised tapping machine to simulate footsteps.

-

BS EN ISO 10140 series: This series of standards covers laboratory measurement of sound insulation of building elements. For example, BS EN ISO 10140-2:2021 deals with the laboratory measurement of airborne sound insulation. While these are primarily for laboratory testing of products and systems, the data generated informs design and regulatory requirements.

-

BS EN ISO 717-2: "Acoustics. Rating of sound insulation in buildings and of building elements. Impact sound insulation." This standard is used to convert the frequency-dependent results obtained from impact sound insulation measurements (e.g., using BS EN ISO 140-7) into the single-number quantity required by Approved Document E.

Consequences of Non-Compliance

Failure to comply with the sound insulation requirements of the Building Regulations can have serious consequences:

-

Costly Remedial Work: If a building fails Pre-Completion Testing, the local authority Building Control body will not sign off the project. This will necessitate potentially expensive and disruptive remedial work to improve the sound insulation to the required standard, followed by re-testing.

-

Legal Action and Fines: Under the Building Safety Act 2022, which has introduced stricter enforcement for building regulation compliance, violations can lead to significant penalties, including potentially unlimited fines and additional daily fines until compliance is achieved.

-

Post-Occupation Issues: Even if a building is signed off, ongoing noise issues can lead to complaints from occupants. Local authorities have powers under legislation such as the Noise Act 1996 (for excessive noise) and the Environmental Protection Act 1990 (for statutory noise nuisance) to take action against noise problems in residential properties after they are occupied.

To provide a clear summary of the performance targets, the following table outlines the minimum sound insulation requirements for floors in dwellings as per Approved Document E:

Table 2: Approved Document E – Minimum Sound Insulation Performance for Floors in Dwellings (UK)

| Dwelling Type | Performance Standard | Required Value (dB) |

| Purpose-built new dwellings | Airborne sound insulation (minimum) | ≥45 dB |

| Impact sound insulation (maximum) | ≤62 dB | |

| Dwellings formed by material change of use | Airborne sound insulation (minimum) | ≥43 dB |

| Impact sound insulation (maximum) | ≤64 dB |

Source: Based on information from Approved Document E guidance.

Common Floor Soundproofing Pitfalls in the UK (And How to Avoid Them)

Despite the availability of effective materials and guidance, floor soundproofing projects can sometimes fall short of expectations. Understanding common pitfalls is key to avoiding them and achieving a successful outcome.

-

Choosing the Wrong Materials for the Noise Type or Floor Structure:

- A frequent error is failing to match the soundproofing materials to the specific type of noise being addressed (airborne vs. impact) or to the existing floor construction (timber joist vs. concrete slab). For example, using only a thin acoustic foam underlay designed for minor impact noise reduction will do little to combat loud airborne music from a neighbour below. Similarly, applying materials suited for timber floors to a concrete slab without considering its unique properties can be ineffective.

- Another aspect of this is using materials that are simply not designed for or capable of providing significant sound insulation, such as standard household items like mattresses, cardboard egg cartons, or relying solely on "soundproof paint" or "soundproof wallpaper" for anything more than negligible acoustic effect. These quick fixes rarely deliver meaningful results for common noise complaints.

-

Acoustic Bridging – Short-Circuiting Your Soundproofing:

- Acoustic bridging occurs when a rigid connection allows sound vibrations to bypass the soundproofing material or system, effectively creating a shortcut for sound. This can drastically reduce the performance of even the most sophisticated soundproofing installations, particularly those relying on decoupling.

- Common causes include screws that are too long and connect an isolated layer (like plasterboard on resilient bars used for ceilings) back to the main structure, mortar droppings in a cavity creating a solid link, or a floating screed making direct contact with surrounding walls.

- Avoidance requires meticulous attention during installation, ensuring correct fixing lengths, maintaining clear cavities, and using appropriate isolation strips at junctions. Acoustic bridging is a common reason for failing Pre-Completion Tests.

-

Ignoring or Underestimating Flanking Transmission:

- Flanking transmission, where sound travels via indirect paths around the soundproofed element, is a critical and often overlooked issue. Even if a floor is treated to a high standard, noise can still be a problem if it finds its way through adjoining walls, structural connections, or shared cavities.

- As noted previously, common flanking paths in UK properties include joists running into or through party walls, continuous wall cavities, and unsealed service penetrations.

- To avoid this, potential flanking paths must be identified and treated. This may involve sealing gaps meticulously, using flanking isolation strips at floor/wall junctions, treating window reveals, or even applying soundproofing measures to the flanking walls themselves in severe cases.

-

Poor Installation and Unsealed Gaps:

- The general quality of installation is crucial. Even the best materials will be ineffective if improperly installed.

- Leaving gaps around the perimeter of the floor, around pipes, or between sheets of soundproofing material will allow sound to leak through, significantly compromising performance. Materials must be fitted correctly, ensuring full coverage and proper adhesion or fixing as per manufacturer guidelines.

- Meticulous sealing of all joints and penetrations with acoustic sealant is non-negotiable.

-

Misunderstanding Decoupling Principles (e.g., with Resilient Bars):

- Decoupling systems like resilient bars (often used for ceilings or walls) rely on correct installation to function. Common errors include fixing the surface material (like plasterboard) directly to the joists through the resilient bar (instead of only to the bar's flexible flange), installing bars at incorrect centres, or allowing the isolated surface to touch rigid surrounding structures. Such mistakes negate the decoupling effect and render the system ineffective.

-

Relying on a Single Product for All Problems:

- Complex noise issues, especially those involving both significant airborne and impact sound, rarely have a single-product solution. Expecting one material to perform all functions (mass, absorption, decoupling, damping) effectively is unrealistic.

- A layered approach, using a system of compatible materials chosen to address the specific principles of soundproofing required, is almost always more effective.

-

Neglecting Professional Advice for Complex Situations or Compliance:

- While some simpler soundproofing tasks can be DIY projects, attempting complex installations or those requiring compliance with Building Regulations (like Approved Document E) without sufficient knowledge or experience can lead to failure, wasted money, and potential legal issues.

- For challenging noise problems, or when regulatory compliance and testing are involved, consulting with an acoustic professional or an experienced builder specialising in soundproofing early in the process is a wise investment.

Many soundproofing failures are not due to faulty materials but rather to a lack of understanding of fundamental acoustic principles and the critical importance of meticulous installation. The way materials are combined and installed, with careful attention to details like sealing all air paths and preventing acoustic bridges or flanking routes, is just as important, if not more so, than the inherent properties of the materials themselves.

The appeal of "quick fixes" or seemingly inexpensive materials often proves to be a false economy, particularly when dealing with the significant noise problems common in some UK housing types. Products like "soundproof paint" or thin decorative wallpapers, while perhaps offering marginal acoustic absorption, do not provide the substantial sound insulation needed to block intrusive neighbour noise or meet regulatory standards. Investing time in understanding the problem and applying proven, systematic solutions is far more likely to lead to a satisfactory and lasting reduction in noise.

Making the Right Choice: Tailoring Your Floor Soundproofing Solution

With a grasp of soundproofing principles, materials, installation techniques, and regulatory requirements, the next step is to tailor a solution to the specific circumstances of a UK home. There is no universal "best" way to soundproof a floor; the optimal approach is highly contextual.

Key Factors to Consider

Before deciding on a strategy, several factors must be carefully evaluated:

-

Type of Noise: Is the primary concern airborne noise (e.g., voices, music from downstairs), impact noise (e.g., footsteps from an overhead flat), or a combination of both? Clearly establishing the aim of the soundproofing is the first vital step.

-

Your Floor Construction: Is the floor of timber joist construction, or is it a concrete slab? This is a fundamental determinant of the most suitable soundproofing methods.

-

Severity of the Noise: Is the noise a minor irritation, or is it causing significant disruption and distress? The level of intervention required will depend on the intensity of the problem.

-

Budget: Soundproofing solutions can range from relatively inexpensive DIY measures to more costly professional installations. A realistic budget must be established, balancing cost against the desired level of performance.

-

DIY vs. Professional Installation: An honest assessment of one's DIY skills, available time, and the complexity of the proposed solution is necessary. If compliance with Approved Document E is required, professional involvement is often advisable, if not essential.

-

Room Height Constraints: Some soundproofing solutions, particularly those involving deep floating floors, resilient batten systems, or thick overlay boards, will result in a reduction in room height. This must be acceptable for the space in question.

Common Scenarios and Suggested Approaches (UK Focused)

Here are some common noise scenarios encountered in UK homes and potential soundproofing approaches:

-

Scenario 1: Reducing Footstep Noise from the Flat Above (Timber Floor Construction)

- If you are in the flat above (source of the noise): The most effective treatment is at the source. Focus on reducing impact transmission by installing high-performance acoustic underlays (e.g., dense rubber, specialist foam) beneath the floor finish. Consider using MLV for added mass. If a hard floor finish (like laminate or wood) is desired, a robust acoustic underlay is critical. A good quality carpet with a thick, dense underlay will always provide significant impact sound reduction. Acoustic overlay boards can also be very effective.

- If you are in the flat below (receiver of the noise): Treating the problem from below is more challenging and generally less effective than treating it at the source. If cooperation from the upstairs neighbour to treat their floor is not possible, options include installing a decoupled ceiling in your flat. This typically involves using resilient bars or acoustic hangers to suspend new layers of acoustic plasterboard (often two layers with staggered joints) from the existing joists, with acoustic mineral wool installed in the cavity created.

-

Scenario 2: Reducing TV/Music Noise from the Flat Below (Timber Floor Construction)

- This is primarily an airborne noise issue. The focus should be on adding mass to your floor and ensuring airtightness.

- If accessible (either by lifting your floorboards or from the ceiling below), install acoustic mineral wool snugly between the floor joists.

- On top of your floorboards, consider laying MLV followed by dense acoustic overlay boards or a new layer of chipboard/plywood with a good quality acoustic underlay and final floor finish.

- Meticulously seal all gaps and perimeters with acoustic sealant.

-

Scenario 3: Soundproofing a Concrete Floor in a New Conversion (to meet Approved Document E)

- This will require a system designed to meet the specific airborne and impact sound insulation targets for conversions (typically ≥43 dB DnT,w?+Ctr? and ≤64 dB LnT,w′?).

- Refer to the solutions for concrete floors discussed previously, such as a floating screed over a specialist resilient layer (e.g., Approved Document E Floor Type 2), or the use of high-performance acoustic overlay boards or resilient batten systems.

- Crucially, ensure all flanking details are correctly addressed (e.g., perimeter isolation strips) to prevent acoustic bridging.

- Plan for Pre-Completion Testing (PCT) to demonstrate compliance.

-

Scenario 4: Improving Soundproofing in a Dedicated Home Cinema Room (Timber Floor)

- This requires a comprehensive approach to achieve high levels of sound isolation, preventing noise from disturbing the rest of the house and ensuring good internal room acoustics.

- Consider a "room within a room" concept if possible. For the floor, this might involve:

- Acoustic mineral wool between the joists.

- A decoupled subfloor system, perhaps using resilient battens to create a floating floor.

- Multiple layers of dense materials on the floating deck, such as two layers of chipboard or plywood with a constrained damping layer or MLV sandwiched between them.

- Careful attention to sealing all perimeters and addressing potential flanking transmission into adjoining walls and the ceiling.

The Importance of a Holistic Approach

While this guide focuses on floor soundproofing, it is important to remember that sound can travel through all elements of a building's structure. If noise is a significant problem, simply treating the floor in isolation may not be sufficient. Weak points in walls, ceilings, doors, and even windows can compromise the overall sound insulation of a room. A holistic assessment of all potential sound paths may be necessary for complex situations.

The optimal floor soundproofing solution is rarely a one-size-fits-all package. It requires a careful assessment of the specific noise problem, the construction of the building, the desired level of improvement, and practical constraints like budget and allowable changes to floor height. UK residents face a variety of housing types and noise challenges, and navigating these variables to arrive at an effective solution is key.

For significant noise issues, or particularly when compliance with Building Regulations like Approved Document E is mandatory and Pre-Completion Testing will be required, investing in professional acoustic advice at an early stage can be invaluable. An acoustic consultant can help diagnose the precise nature of the noise problem, recommend the most appropriate and cost-effective solutions, and provide design details that will help ensure a successful outcome and avoid costly trial-and-error or failed inspections. The technicalities of decibel targets, testing procedures, and the nuances of acoustic design can be complex for a layperson, making expert guidance a prudent investment.

Maintaining Your Peace: Long-Term Care for Soundproofed Floors

Once a floor soundproofing system has been installed, some simple measures can help to ensure its long-term effectiveness and preserve the peace and quiet achieved.

-

Routine Inspections: Periodically, it is good practice to inspect the soundproofed floor area, especially if any new or unexpected noises start to become apparent. Look for any visible signs of wear and tear, such as cracks developing in the floor finish that might indicate movement, or damage to skirting boards that could affect perimeter seals.

-

Maintaining Seals: The acoustic sealant used around the perimeter of the floor and at any service penetrations is critical to the performance of the soundproofing system. Over time, sealant can sometimes shrink, crack, or pull away from surfaces due to building movement or drying. Check these seals periodically and reapply acoustic sealant if any damage or gaps are found to maintain an airtight barrier.

-

Care with Floor Coverings: If floor coverings (such as carpet, laminate, or engineered wood) are replaced at a later date, care must be taken to avoid damaging the underlying soundproofing layers or acoustic underlays. Ensure that any new fixings (e.g., carpet gripper rods) do not compromise the integrity of floating floor systems or create new acoustic bridges. When choosing new floor coverings, remember that soft, thick materials like carpet with a good quality underlay will always contribute positively to reducing impact noise.

-

Awareness During Subsequent Structural Changes: If further renovation or alteration work is undertaken in the property, be mindful of how these changes might affect the existing floor soundproofing. For example, installing new pipework that penetrates the soundproofed floor, or altering adjoining walls, could create new paths for sound if not managed correctly. Ensure that any breaches of the soundproofing layers are properly reinstated and sealed.

While robustly designed and correctly installed floor soundproofing solutions are generally durable and require minimal ongoing maintenance, their long-term effectiveness can be compromised by physical damage, degradation of seals, or unmanaged subsequent alterations to the building. A degree of awareness and occasional simple checks can help to preserve the initial investment and ensure that the benefits of a quieter home environment are enjoyed for many years to come.

Glossary of Key Soundproofing Terms (UK Context)

Understanding the terminology used in discussions about soundproofing can be helpful. Here are definitions for some key terms relevant in the UK context:

-

Airborne Noise: Sound that travels through the air, such as voices, music, or television sound.

-

Impact Noise: Sound generated by direct physical contact with a structure, such as footsteps on a floor or dropped objects.

-

Decibel (dB): A logarithmic unit used to express the intensity of a sound or the power level of an electrical signal. In acoustics, it's used to quantify sound pressure levels and sound insulation performance.

-

DnT,w?+Ctr? (Weighted Standardised Level Difference + Spectrum Adaptation Term): The single-number quantity used in UK Building Regulations (Approved Document E) to rate the airborne sound insulation of a separating element like a floor or wall. It includes a correction (Ctr?) for low-frequency sound sources. Higher values indicate better airborne sound insulation.

-

LnT,w′? (Weighted Standardised Impact Sound Pressure Level): The single-number quantity used in UK Building Regulations (Approved Document E) to rate the impact sound insulation of a floor. Lower values indicate better impact sound insulation.

-

Approved Document E: The part of the Building Regulations for England (with similar provisions in Wales) that deals with resistance to the passage of sound. It sets out minimum performance standards for sound insulation in dwellings.

-

Flanking Transmission (Flanking Noise): Sound that bypasses a soundproofed element (like a floor) by travelling along indirect paths, such as adjoining walls, structural connections, or through cavities.

-

Decoupling: The process of mechanically separating elements of a structure to prevent or reduce the transmission of sound vibrations from one part to another.

-

Mass Loaded Vinyl (MLV): A dense, flexible, vinyl-based material used to add mass to structures to block airborne sound.

-

Acoustic Mineral Wool: Fibrous insulation material (e.g., rock wool, stone wool, fibreglass) used for its sound-absorbing properties, typically installed in cavities like those between floor joists.

-

Resilient Bars (Resilient Channels): Profiled metal channels used to decouple surface materials (like plasterboard or other dense boards) from the main structure (joists or studs), improving sound insulation, typically in wall or ceiling applications.

-

Floating Floor: A floor construction where the finished floor surface is separated from the structural subfloor by a resilient layer, thus "floating" and reducing impact sound transmission.

-

Pre-Completion Testing (PCT): On-site sound insulation tests carried out on separating floors and walls in new builds and conversions to demonstrate compliance with Approved Document E.

-

Robust Details (RDs): A scheme providing pre-tested and certified construction details for separating walls and floors that, if followed precisely for new attached dwellings, can be used as an alternative to Pre-Completion Testing to meet Approved Document E requirements.

This glossary aims to demystify some of the technical jargon frequently encountered when researching or implementing soundproofing solutions. A clear understanding of these terms can make the information more accessible and empower individuals to make more informed decisions, which is particularly valuable given the regulatory and scientific language involved in UK soundproofing standards and practices.

Conclusion: Investing in a Quieter Future for Your UK Home

Effectively soundproofing a floor is a multifaceted undertaking that goes beyond simply choosing a particular material. It requires an understanding of the types of noise being addressed, the fundamental principles of how sound travels and how it can be blocked or reduced, and the specific construction of the floor in question.

As this guide has detailed, a systematic approach – encompassing appropriate material selection, meticulous installation with careful attention to sealing gaps, and a crucial awareness of potential flanking transmission paths – is paramount to achieving significant and lasting noise reduction.

For many projects in the UK, particularly those involving new constructions or changes of use, compliance with the sound insulation requirements of Building Regulations, chiefly Approved Document E, is a legal necessity. Navigating these regulations, understanding the performance targets for airborne and impact sound, and knowing the routes to demonstrating compliance (whether through Pre-Completion Testing or the Robust Details scheme for eligible new builds) are essential components of a successful project.

Investing in effective floor soundproofing is more than just a home improvement project; it is an investment in enhanced comfort, improved well-being, better relationships with neighbours, and potentially an increase in property value. The peace and quiet gained from a well-soundproofed home can transform daily life, reducing stress and creating a more tranquil and productive living environment.

While some simpler soundproofing measures can be tackled by competent DIYers, the complexities of achieving high levels of sound insulation, or meeting stringent regulatory standards, often warrant professional expertise. Consulting with acoustic specialists or experienced builders at an early stage can prevent costly mistakes, ensure that solutions are tailored effectively to the specific problem, and provide the best chance of creating the quieter future that so many UK homeowners and residents seek.

Ultimately, a well-considered and properly executed floor soundproofing solution can bring profound and lasting benefits to any home.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *