Insulated Plasterboard Sheets

Insulated plasterboard sheets combine a plasterboard core—typically gypsum pressed between heavy-duty paper—with an integrated rigid foam insulation layer such as PIR, EPS or XPS. These sheets offer enhanced thermal performance for walls, floors, and ceilings, making them an effective solution for improving energy efficiency in buildings.

Standard sizes generally include dimensions like 2400mm by 1200mm, with thicknesses ranging from 22mm up to over 110mm, depending on the specific insulation requirements. The selection of thickness and insulation type allows for customization to meet various thermal and acoustic performance targets.

Installation involves careful surface preparation, accurate measurement, and precise fitting to minimize gaps and maximize thermal continuity. Sealing joints properly with appropriate tape or sealant is important to optimize energy efficiency and protect against moisture ingress. Handling insulated plasterboard sheets with care ensures the integrity of the insulation and plaster face remains intact.

Continuing development of these materials provides detailed specifications and best practice guidelines for their effective use. Proper installation ensures their thermal benefits are fully realized, contributing to more comfortable, energy-efficient internal environments.

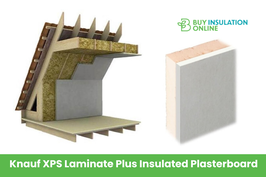

Types and Composition of Insulated Plasterboards

Insulated plasterboards are specialized building materials designed to combine the functionalities of standard plasterboard with integrated thermal insulation, resulting in a single, streamlined component suitable for internal wall or ceiling construction. These boards typically feature a plasterboard core, usually gypsum pressed between heavy-duty paper, bonded with a rigid foam insulation layer such as PIR, EPS, or XPS. Provides thermal insulation for walls, floors, or ceilings, making them highly effective for energy-efficient building design. PIR, or polyisocyanurate, offers high thermal efficiency and moisture resistance, with low thermal conductivity (around 0.022 W/mK). EPS, expanded polystyrene, is lightweight and cost-effective, making it a popular choice for many projects. XPS, extruded polystyrene, provides greater water resistance and is denser, which can be beneficial in certain applications. Some insulated plasterboards include vapor control membranes, adding extra moisture protection to help prevent condensation issues within indoor environments. The foam insulation is glued to the plasterboard, creating an integrated sheet that simplifies installation and reduces thermal bridging, thereby enhancing the energy efficiency of building structures. Using these boards can significantly improve the thermal performance of internal walls and ceilings, contributing to a comfortable indoor climate while maintaining a clean and efficient construction process. Incorporating insulation materials can also help comply with building regulations related to energy efficiency.

Standard Sizes and Thickness Variations

What are the typical physical dimensions of insulated plasterboard sheets used in construction

The most common sizes include 2400mm x 1200mm, 3600mm x 1200mm, and 3000mm x 1200mm. These sheets typically come in widths of either 600mm or 1200mm, designed to align with standard stud spacings and wall heights in UK construction.

The 2400mm x 1200mm sheet is particularly popular due to its ease of handling and compatibility with UK installation practices. Variations in thickness range from approximately 22mm up to over 110mm, reflecting different thermal and structural requirements. Thinner boards, around 22-25mm, are suitable for limited space applications, while thicker boards — up to 112.5mm — offer enhanced thermal insulation properties.

The choice of size and thickness also impacts manufacturing processes and overall project costs, influencing material efficiency and labor time.

Choosing the appropriate size and thickness is essential, as it directly influences installation efficiency, thermal performance, and the suitability of the product for specific project needs.

Thermal Performance and Energy Efficiency

Thermal performance and energy efficiency in insulated plasterboard primarily depend on its construction, materials used, and installation techniques. These factors influence the material’s ability to minimize heat transfer through walls and ceilings.

Insulated plasterboard combines standard plasterboard with a rigid insulation layer, offering basic to moderate thermal resistance. The thermal performance is largely determined by the type and thickness of the insulation material. Materials such as PIR boards provide higher thermal resistance per millimeter compared to EPS or XPS boards. The insulating core also contributes significantly to the overall R-value, enhancing thermal efficiency. Integrating additional cavity insulation can further enhance overall thermal performance, especially when combined with high-quality installation methods.

Reducing heat transfer by approximately 20-25% helps to maintain comfortable indoor temperatures throughout the year, which in turn reduces heating and cooling costs. Proper installation, combined with good building practices such as airtight sealing, can optimize energy efficiency and ensure compliance with UK energy standards and building regulations.

Installation Techniques and Practical Applications

Effective installation of insulated plasterboard necessitates meticulous attention to preparatory work, fixing techniques, and handling procedures to guarantee optimal performance and longevity. Initially, wall surfaces should be thoroughly inspected to ensure they're clean, dry, and flat. Any irregularities or moisture should be addressed using suitable leveling compounds or waterproofing solutions. Visual inspection ensures surface readiness, which is crucial for a secure and effective installation. Incorporating proper pipe insulation strategies can also prevent issues related to condensation and external environmental damage on the installed system.

Accurate measurement and clearly marked guidelines are essential for precise alignment and fitting of panels. The selection of the installation method will depend on the type of wall—dot and dab for smooth surfaces, continuous adhesive for enhanced airtightness, or mechanical fixings for ceilings and uneven areas.

Panels should be cut carefully using a utility knife, leaving approximately 15 mm of expansion gap around edges to accommodate movement. During installation, panels must be supported to prevent sagging while adhesive sets.

Fixings, such as screws or staples, should be applied at consistent intervals to reinforce the panels' stability. Joints between panels need to be securely taped and sealed to prevent air infiltration, thereby maintaining the material’s thermal efficiency. Proper handling and installation techniques are vital to achieve a durable, effective insulated plasterboard system.

Environmental Impact and Safety Considerations

Considering the widespread adoption of insulated plasterboard, it's important to evaluate its environmental impact and safety considerations to ensure sustainable and secure building practices.

Insulated plasterboard reduces a building’s carbon footprint by lowering heating demand through superior thermal insulation, often combining materials that minimize resource consumption. Natural insulation options, such as hemp or wool, support carbon-neutral or negative products, further reducing CO? emissions over time. Properly selected materials and recycling practices can limit landfill waste, especially when boards incorporate recycled fibers. Recycling practices can help to minimize environmental impact and promote sustainability. Research indicates that using recycled content in manufacturing can significantly reduce environmental impact. Safety also involves fire performance; PIR insulation, for example, often meets strict fire standards to enhance safety. Correct installation, handling, and moisture control are essential to prevent hazards like mould, ensuring good indoor air quality.

Conclusion

Insulated plasterboard sheets provide a dependable solution for improving thermal performance in UK construction projects through careful selection of types, sizes, and installation methods. Understanding their composition, variations, and environmental impacts is essential to ensure optimal application and energy efficiency. Precise installation techniques and considerations for safety and environmental sustainability are crucial for achieving the best results. When used correctly, these boards can significantly enhance building insulation, contribute to energy savings, and support sustainable construction practices, making them a valuable component in modern architecture and renovation efforts.