- Blogs

- A Comprehensive Guide To Internal Wall Insulation Using Vapour Barrier Insulated Plasterboard In The United Kingdom

A Comprehensive Guide To Internal Wall Insulation Using Vapour Barrier Insulated Plasterboard In The United Kingdom

TLDR

Internal wall insulation using thermal laminate plasterboard is a highly effective solution for improving the energy efficiency of the UK housing stock, particularly solid wall properties where external insulation is not feasible. This guide provides a technical overview of material choices including polyisocyanurate, phenolic foam, and expanded polystyrene cores, alongside a detailed analysis of moisture management under current building standards. The report outlines professional installation procedures for both the adhesive direct bonding and timber battening methods, with a specific focus on maintaining the continuity of the vapour control layer. Regulatory compliance under the updated Part L 2022 and 2025 standards is discussed, providing practitioners with the necessary data to achieve target thermal transmittances while mitigating the risks of interstitial condensation through robust sealing and the application of intumescent putty pads.

The Evolution Of Thermal Standards In The United Kingdom Housing Sector

The domestic building landscape in the United Kingdom presents a specific set of challenges for thermal performance. A substantial proportion of the current housing stock was constructed prior to the introduction of modern building regulations, leaving millions of properties with solid masonry walls that offer little resistance to heat transfer. These structures often contribute significantly to the national carbon footprint and result in high operational costs for occupants. Internal wall insulation has become a primary strategy for addressing these deficiencies, especially in urban environments or conservation areas where the external appearance of the building cannot be altered.

The shift toward internal wall insulation necessitates a deep understanding of how thermal upgrades affect the hygrothermal behaviour of existing walls. When insulation is added to the interior face of a masonry wall, the original structure remains at a lower temperature throughout the winter months because it is no longer heated by the internal environment. This change in the thermal profile increases the potential for moisture within the air to reach its dew point at the interface between the new insulation and the original wall.

To address these risks, the industry has transitioned toward the use of thermal laminate plasterboards. These products integrate a high-performance insulation core with a gypsum-based facing and, crucially, a vapour control layer. This multi-layered approach allows for a faster installation process while providing the necessary protection against moisture migration. The technical specifications of these boards have evolved alongside the UK building regulations, moving from basic polystyrene-backed products to advanced phenolic foams capable of achieving stringent thermal targets with minimal loss of internal floor area.

Material Science Of Thermal Laminate Insulation Cores

The selection of an insulation core is the most significant decision in the design of an internal wall insulation system. Each material possesses distinct thermal conductivities, moisture resistance profiles, and fire performance characteristics. In the UK market, the options are generally categorised into four types: polyisocyanurate, phenolic foam, expanded polystyrene, and extruded polystyrene.

Polyisocyanurate Core Characteristics

Polyisocyanurate, or PIR, is a thermoset plastic produced as a foam and used as rigid insulation. It is currently the most popular choice for residential retrofits in the United Kingdom due to its balanced performance and cost-effectiveness. PIR is typically manufactured with a closed-cell structure, which provides a high resistance to water vapour and liquid moisture.

Most PIR laminates used in the UK, such as those from the Celotex PL4000 range or the Unilin XT/TL series, are faced with a multi-layer aluminium foil on both sides. This foil facing serves a triple purpose. It functions as a high-performance vapour control layer, it provides a radiant heat reflective surface, and it adds structural rigidity to the foam core. The thermal conductivity of PIR is generally around 0.022 W/mK, which allows for a relatively slim profile while meeting standard building control requirements.

Phenolic Foam Performance

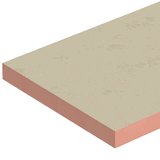

Phenolic foam represents the highest level of thermal efficiency available in a rigid board format. It is produced through a chemical reaction that creates an extremely fine cell structure. Phenolic cores, such as those found in Kingspan Kooltherm K118 or Unilin Safe-R boards, offer a thermal conductivity as low as 0.018 W/mK.

This superior efficiency is particularly advantageous in UK terrace houses or flats where room dimensions are limited. By using a phenolic core, designers can achieve the same thermal resistance as PIR with a thinner board, thereby preserving valuable internal living space. These boards are also factory-bonded to a vapour control layer, often consisting of a composite foil or glass tissue, and are designed for both mechanical and adhesive fixing.

Polystyrene Options

Expanded Polystyrene is the most cost-decisive option. It is a lightweight, easy-to-handle material with a thermal conductivity of approximately 0.038 W/mK. While it provides an improvement over uninsulated walls, the thickness required to meet modern standards is significantly greater than that of PIR or phenolic alternatives. EPS boards often lack an integrated foil vapour barrier, necessitating the application of a separate vapour control layer or the use of specialised vapour-resistant variants.

Extruded Polystyrene offers a more robust alternative to EPS. It is a closed-cell material with higher compressive strength and superior resistance to moisture. XPS laminates are frequently chosen for applications where dampness is a potential concern, such as in basements or at the base of walls where capillary rise might occur.

Technical Data Comparison For Insulation Cores

| Material Type | Thermal Conductivity (W/mK) | Common Thickness Range (mm) | Vapour Resistance |

| Phenolic Foam | 0.018 - 0.020 | 32.5 - 112.5 | Very High (Foil Faced) |

| Polyisocyanurate | 0.022 | 27.5 - 122.5 | High (Foil Faced) |

| Extruded Polystyrene | 0.029 - 0.030 | 27.0 - 55.0 | High |

| Expanded Polystyrene | 0.038 | 22.0 - 112.5 | Low/Moderate |

Understanding Vapour Dynamics and Condensation Risks

The primary risk associated with internal wall insulation is interstitial condensation. This occurs when water vapour from the internal environment diffuses through the wall finish and insulation, reaching a cold surface within the wall where it turns into liquid water. In the UK, where winter temperatures frequently drop below the dew point of internal air, this is a significant concern for the longevity of the building fabric.

The Role Of The Vapour Control Layer

A vapour control layer is a material with high vapour resistance installed on the warm side of the insulation. Its purpose is to limit the amount of moisture that can pass from the room into the wall structure. In thermal laminate boards, this is usually achieved by the aluminium foil backing of the insulation core.

The effectiveness of a vapour control layer is measured by its vapour resistivity. For most foil-faced PIR and phenolic boards, the resistivity is extremely high, often exceeding 100 MNs/gm. This ensures that only a negligible amount of moisture can penetrate the board. However, the integrity of the system depends entirely on the continuity of this layer. Any breach, such as an unsealed joint or a cut for an electrical socket, allows vapour to bypass the protection through a process known as vapour convection.

The Impact Of BS 5250:2021 On IWI Practice

The British Standard BS 5250, the Code of Practice for Managing Moisture in Buildings, underwent a major revision in 2021. This update moved away from the simplistic Glaser method of calculating condensation risk toward a more holistic assessment. The standard acknowledges that in traditional solid-walled buildings, an impermeable vapour barrier can sometimes prevent the masonry from drying out toward the inside if it becomes wet from rain penetration.

In modern construction or standard refurbishments, the use of vapour-closed insulation remains the dominant approach. However, for heritage buildings or structures with high exposure to wind-driven rain, the current guidance suggests that capillary-active or vapour-open systems might be lower risk. Practitioners should evaluate each project individually to ensure the moisture strategy aligns with the specific building's hygrothermal behaviour.

Regulatory Framework And Thermal Targets Under Part L

Compliance with the Building Regulations is mandatory for any significant renovation of a thermal element in the UK. Approved Document L provides the specific targets for thermal transmittance, or U-values, which measure the rate of heat loss through a square metre of a building element.

Current U-value Requirements

The 2022 updates to Part L introduced stricter targets for both new builds and existing dwellings. These standards are expected to remain the baseline as the industry transitions toward the Future Homes Standard in 2025.

| Application | Target U-value (W/m2K) | Threshold U-value (W/m2K) |

| New Build Domestic Walls | 0.18 | N/A |

| New Elements in Existing Dwellings | 0.18 | N/A |

| Refurbishment of Existing Walls | 0.30 | 0.70 |

| Extensions (Area Weighted) | 0.28 | N/A |

The target for refurbishing an existing wall is 0.30 W/m2K. If achieving this value is not technically feasible or would not provide a 15-year payback on the investment, the regulations allow for a higher U-value, provided it is the best achievable and is no worse than the threshold value of 0.70 W/m2K.

Achieving Compliance In Practice

To reach the 0.30 W/m2K target on a standard 225mm solid brick wall, a common specification involves approximately 62.5mm of high-performance insulated plasterboard. If a property requires the 0.18 W/m2K target, the thickness of PIR insulation usually needs to increase to approximately 125mm.

While thicker insulation provides greater energy savings, there is a diminishing return. Research indicates that the first 100mm of insulation provides the most significant reduction in heat loss. Beyond this point, the cost of materials and the loss of internal floor space often outweigh the incremental gains in thermal performance.

The Direct Bonding Installation Method

Commonly referred to as dot and dab, direct bonding is a fast and effective method for installing insulated plasterboard onto solid masonry walls. It is particularly useful in refurbishments where the original wall may not be perfectly plumb or level.

Preparation Of The Substrate

Before application, the wall surface must be checked for stability. Any loose render or paint should be removed, and the surface should be clean and dry. In some cases, a bonding agent or a coat of PVA mixed with water is applied to the wall to control suction. This ensures that the masonry does not extract moisture from the adhesive dabs too quickly, which would result in a weak bond.

Adhesive Application For Airtightness

The distribution of adhesive is critical not only for structural support but also for thermal performance. To prevent air from circulating behind the insulation—a phenomenon known as thermal bypassing—a continuous bead of adhesive should be applied around the perimeter of each board. Additionally, continuous beads should be placed around any openings for windows, doors, or electrical services.

The dabs themselves should be approximately 50mm to 75mm wide and 250mm long. Standard practice for a 2400mm x 1200mm sheet involves three vertical rows of dabs, covering at least 22% of the total board area. This ensures a secure bond while allowing for the necessary adjustments to be made using a spirit level or straight edge.

Mechanical Security

While the adhesive provides the primary bond, modern safety standards recommend the use of supplementary mechanical fixings. For insulated plasterboard, it is standard to use at least two fire-rated mechanical fixings per board after the adhesive has set. In some specifications, up to six fixings per sheet are required to ensure the boards remain secure in the event of a fire. These fixings should be driven flush with the surface of the plasterboard and then covered during the jointing process.

Mechanical Fixing To Timber Battens Or Studs

Mechanical fixing is the preferred method for walls that are excessively damp or where a larger cavity is needed for plumbing and electrical services. This method involves the construction of a timber frame or the installation of vertical battens onto which the boards are screwed.

Batten Configuration and Moisture Protection

Timber battens should have a minimum width of 47mm and a depth of 25mm. To prevent moisture from the masonry wall from transferring into the timber, a strip of damp-proof course (DPC) should be installed behind each batten. Battens are typically fixed at 600mm horizontal centres, ensuring that the edges of each insulated plasterboard sheet are fully supported.

Installation Procedure

The boards are positioned against the battens and secured using drywall screws. These screws must be long enough to penetrate at least 25mm into the timber. It is essential to start the installation from a corner or a window reveal to ensure alignment. The boards should be lightly butted together to minimize the size of the joints.

To maintain the continuity of the vapour barrier in this system, the timber frame must be sealed at the floor and ceiling junctions. This prevents air movement within the cavity, which could carry moisture to the cold masonry. If the wall is particularly uneven, the battens can be packed out to create a level surface for the boards.

Detailed Sealing And Vapour Barrier Continuity

The integrity of the vapour control layer is the single most important factor in the long-term success of an internal wall insulation project. Small gaps in the barrier can lead to significant moisture accumulation.

Joint Treatment and Foil Taping

In a standard drylining installation, board joints are covered with scrim tape and finished with jointing compound. However, this does not create a vapour-tight seal. For a robust vapour barrier, all joints between foil-faced boards should be sealed with high-quality aluminium foil tape. The tape should be applied to the foil face of the boards before any final plaster finish is applied. This ensures that the vapour control layer is continuous across the entire wall surface.

Sealing The Perimeters

The junctions between the insulated boards and other building elements are common points of failure. At the floor junction, a gap of 10mm to 15mm should be left to prevent capillary moisture from the floor from reaching the plasterboard. This gap should be filled with a flexible, moisture-resistant sealant. At the ceiling junction, the boards should be butted tight and sealed with foil tape or a compatible sealant to prevent warm air from entering the wall cavity.

Managing Service Penetrations with Putty Pads

Electrical sockets and switches present a challenge for both airtightness and vapour control. Cutting a hole for a back box creates a direct path for air and vapour to move into the cavity behind the insulation.

The Application Of Intumescent Putty Pads

Putty pads are a non-setting, flexible material designed to be moulded around the back of an electrical socket box. They are primarily used to maintain the fire rating of a wall, but they also provide an excellent vapour and air seal. When a socket is installed in an insulated wall, the putty pad should be wrapped around the exterior of the plastic or metal box before it is fixed into the board.

| Benefit of Putty Pads | Technical Mechanism |

| Vapour Control | Creates a non-porous seal around the back of the socket box. |

| Fire Safety | Expands under heat to fill the penetration and stop the spread of smoke. |

| Acoustic Performance | Increases the mass of the penetration, reducing sound transfer. |

| Airtightness | Prevents convection currents through the electrical conduit. |

By using putty pads, installers can ensure that the vapour barrier remains effective despite the presence of numerous electrical outlets. This is particularly important in rooms with high moisture levels, such as kitchens, where multiple sockets are often located on external walls.

Space Optimisation And Corner Details

One of the practical difficulties of internal wall insulation is the impact on room dimensions. Careful planning of corner and reveal details can help minimize this impact while maintaining thermal performance.

Window and Door Reveals

Window reveals are often too narrow to accommodate the full thickness of the insulated plasterboard used on the main wall. In these instances, a thinner board, such as a 22mm or 27.5mm laminate, is used to provide some thermal improvement without obstructing the window frame or preventing the window from opening. It is critical to ensure that the vapour barrier is continuous from the main wall into the reveal. This is achieved by overlapping the boards at the corner and sealing the junction with foil tape or expanding foam.

Internal And External Corners

At internal corners, the first board should be installed and the second board butted against it. The joint should be sealed with foil tape before the corner is finished with standard joint tape. For external corners, the insulation cores should be mitred or butted tightly to ensure there is no gap in the thermal layer. A metal or plastic corner bead is then used to protect the edge and provide a clean finish for plastering.

Financial Considerations And Economic Viability

The cost of internal wall insulation is a significant factor for UK homeowners. While it is generally more affordable than external wall insulation, the total project cost must be balanced against the anticipated energy savings.

Average Costs for UK Installations

The total cost of a project depends on the choice of material and the complexity of the room. A room requiring the relocation of radiators, skirting boards, and electrical points will be more expensive to insulate than a simple, clear wall.

| Component | Estimated Cost (per m2) |

| Basic EPS Insulated Plasterboard | £28.00 - £33.00 |

| PIR Insulated Plasterboard (37.5mm) | £34.00 - £42.00 |

| Phenolic Insulated Plasterboard (K118) | £60.00 - £95.00 |

| Professional Labour (Installation) | £15.00 - £30.00 |

| Skimming and Finishing | £10.00 - £15.00 |

On average, a professional installation of internal wall insulation in the UK costs between £40 and £100 per square metre. For a standard three-bedroom semi-detached house, the total cost for insulating all external walls internally can range from £6,000 to £10,000.

Payback and Incentives

Internal wall insulation can save a household significant amounts on their annual heating bill, often between £300 and £700 depending on the property type and current energy prices. In many cases, the investment pays for itself within 10 to 15 years. Additionally, various government grants, such as the Energy Company Obligation (ECO4) scheme, may be available to help offset the costs for eligible households, particularly those in lower-income brackets or living in the most energy-inefficient homes.

Future Trends In The UK Insulation Market

The insulation industry in the United Kingdom is currently undergoing a period of rapid innovation. As the 2025 Future Homes Standard approaches, the focus is shifting toward even higher levels of performance and lower environmental impact.

Advanced Insulation Technologies

We are seeing a slow but steady increase in the use of ultra-thin materials such as vacuum insulation panels and aerogel-infused boards. These materials offer thermal conductivities significantly lower than phenolic foam, potentially allowing for walls to be insulated with only 20mm to 30mm of material while meeting high thermal standards. Although currently expensive, these technologies are likely to become more common as the demand for space-efficient retrofits grows.

Sustainability and Circular Economy

The embodied carbon of insulation materials is becoming a key consideration for many specifiers. There is a growing interest in boards that use recycled content or bio-based materials. Manufacturers are also working to reduce the Global Warming Potential of the blowing agents used in the production of PIR and phenolic foams. The transition toward a circular economy will likely see more products designed for easier removal and recycling at the end of a building's lifespan.

Professional Summary And Final Recommendations

Internal wall insulation using vapour barrier insulated plasterboard is a technically sound and economically viable method for upgrading the UK's older housing stock. By integrating the insulation and the vapour control layer into a single product, it simplifies the construction process while providing essential protection against moisture damage.

The success of these systems depends on the correct selection of materials and the meticulous execution of details. PIR and phenolic cores offer the best thermal performance for the thickness, making them the standard choice for most UK projects. Regardless of the material chosen, the continuity of the vapour barrier must be the priority during installation. Sealing joints with foil tape and using putty pads for electrical services are essential steps that must not be overlooked.

As the UK continues its journey toward net-zero, the role of internal wall insulation will only become more prominent. By following professional standards and staying informed about the latest regulatory changes, practitioners can deliver high-quality thermal upgrades that provide lasting benefits for homeowners and the environment alike.

UK Legal Disclaimer

The information provided in this report is for general guidance and informational purposes only. It does not constitute a technical specification or professional advice. Building regulations, material suitability, and safety requirements can vary significantly depending on the specific characteristics of a property and local authority guidelines. All thermal calculations and moisture risk assessments must be performed or verified by a qualified professional, such as a chartered surveyor, structural engineer, or certified retrofit coordinator, before any construction work begins. This content should not be used to specify materials or installation methods for any particular project. No responsibility is accepted for any errors, omissions, or any loss or damage resulting from the use of this information. All work must be carried out in accordance with current UK Building Regulations and Health and Safety legislation.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *