Kingspan Insulated Plasterboard

Kingspan Insulated Plasterboard combines insulation and plasterboard into a single, factory-made panel, streamlining internal wall installation by reducing both time and labour requirements.

Constructed with a high-performance phenolic foam core and a gypsum-based surface, it provides excellent thermal efficiency, fire safety, and moisture resistance. This innovative system is compatible with standard fixing methods and suitable for a wide range of building types, supporting UK energy efficiency and safety standards.

Further guidance on installation techniques and environmental benefits is available, helping ensure proper application and maximizing sustainability.

Key Features and Benefits of Kingspan Insulated Plasterboard

Kingspan insulated plasterboard provides an array of key features designed to enhance building performance and simplify installation processes.

By integrating insulation and plasterboard into a single board, it reduces installation time and effort, eliminating the need for separate components and streamlining the construction timeline. The boards are supplied in standard dimensions of 2400mm by 1200mm, which facilitates handling on-site and ensures compatibility with most insulation requirements, thereby minimising on-site adjustments.

The built-in drylining system enables precise and swift internal wall finishing, while factory pre-bonded construction decreases labour complexity and reduces the potential for incorrect installation. This integrated approach supports seamless construction workflows and promotes a cleaner, more efficient build process.

The core, made of fibre-free rigid phenolic foam, boasts a low thermal conductivity of 0.018 W/mK. This significantly enhances thermal efficiency by reducing heat transfer, making it highly suitable for external wall applications as well. Which helps to lower energy consumption.

Collectively, these features promote quicker, more efficient builds while delivering improved thermal performance and ease of handling—all tailored to meet the needs of construction projects across the UK.

Understanding the Composition and Thermal Performance

The composition of Kingspan insulated plasterboard is carefully engineered to combine high-performance insulation with practical surface characteristics, ensuring both thermal efficiency and ease of installation. Its core features a fibre-free, rigid phenolic foam material that provides excellent thermal insulation, with a thermal conductivity around 0.018 to 0.019 W/mK, making it one of the most efficient insulation products available in the UK. The front surface incorporates a 12.5mm tapered edge gypsum-based plasterboard, compatible with standard finishing materials for easy decoration. The reverse side is fitted with a low-emissivity foil face, which helps to reduce radiative heat transfer and improve overall thermal performance. Manufactured using environmentally responsible blowing agents with zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP), the product maintains durability and moisture resistance over time. This ensures consistent thermal performance throughout the lifespan of the building, supporting energy efficiency and sustainable construction practices. The phenolic core's high thermal resistance also contributes to achieving stringent thermal insulation standards and reduces energy consumption for heating and cooling. Additionally, the foil surface can serve as part of a continuous air barrier, enhancing airtightness when properly sealed.

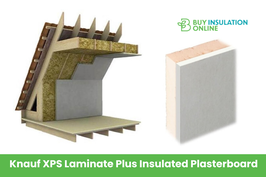

Installation Techniques and Compatibility With Building Systems

Proper installation of insulated plasterboard requires careful adherence to techniques that ensure both structural stability and thermal performance. To achieve this, the following key points are essential:

Use a continuous adhesive band around walls and openings, combined with adhesive dabs covering at least 20% of the board area, to secure the boards effectively.

Fix boards with mechanical fixings such as drywall screws or galvanized nails once the adhesive has set. Ensure two fixings are applied per board, positioned approximately 15 mm from edges and at mid-height for optimal support.

Centre boards over timber or metal framing, employing noggins where joints are unsupported. Fixings should be spaced at 300 mm centers on internal walls and approximately 200 mm at external corners to provide additional stability.

Maintain dry, stable surfaces free from dust and moisture. Accurate markings are crucial for precise alignment, and any gaps should be sealed with appropriate sealants to ensure airtightness.

Using high-performance insulation like wood fibre insulation can further improve a building's moisture management and thermal performance, complementing proper fixing and sealing techniques.

Adhering to these guidelines will help in achieving a durable and thermally efficient installation compatible with UK building systems.

Versatile Applications for Residential and Commercial Projects

Insulated plasterboard systems offer highly adaptable solutions for both residential and commercial building projects. By integrating insulation and drylining into a single, streamlined system, they reduce material usage and installation times. These boards are suitable for masonry walls and timber framing, featuring a low-conductivity phenolic core with a foil-backed surface, which delivers excellent thermal performance across a variety of applications.

In residential settings, insulated plasterboards effectively enhance indoor comfort, decrease heating costs, and help preserve interior aesthetics by maintaining external facades.

For commercial buildings, they support energy efficiency standards and optimize space utilization, particularly during renovation projects. Their moisture resistance and vapour control features make them ideal for environments such as schools, offices, and retail spaces.

Fire Safety, Environmental Ratings, and Longevity

How do Kingspan insulated plasterboards perform in terms of fire safety, environmental impact, and durability. These products are developed with strict UK standards in mind, offering robust safety features and sustainability credentials.

Fire safety: Kingspan Kooltherm K118 achieves a Euroclass B rating, indicating limited combustibility. It's designed with fire-resistant coatings and complies with fire safety regulations, including BS EN 13501-1 tests for heat, smoke, and flame spread. Proper installation practices, such as the inclusion of cavity barriers, are essential to maintain optimal fire safety standards. Additionally, Kingspan products are manufactured using fire-resistant thermoset formulations, which provide enhanced safety margins in the event of a fire. The products are also non-ventilated and do not contribute to smoke propagation, further supporting fire safety.

Environmental impact: These boards are engineered for energy efficiency through low thermal conductivity characteristics. They've low embodied energy and are certified for recyclability via Environmental Product Declarations and third-party assessments, contributing positively to environmental sustainability. They are also developed with environmentally friendly processes that align with global sustainability goals, such as reduced ozone depletion and low GWP emissions.

Durability: Manufactured using advanced phenolic foam, the boards are moisture resistant and require minimal maintenance. Incorporating vapour control layers, they promote a long-lasting and stable performance, ensuring they withstand the test of time in various environments. These materials are also resistant to thermal ageing, maintaining their insulation properties for at least the lifetime of the building.

Additional features: Ensuring safety and sustainability also involves adhering to best installation practices. Proper detailing and the use of cavity barriers help minimise fire risks while safeguarding environmental standards, leading to a reliable, safe, and environmentally responsible insulation solution. Taking into account the Euroclass fire safety ratings during design and installation helps optimize safety throughout the product's lifespan.

Conclusion

In conclusion, Kingspan insulated plasterboard provides a dependable solution for improving the thermal performance of buildings through its high-quality composition and versatile application options. Its correct installation is essential and should follow recommended techniques to ensure safety and compatibility with existing structural elements. Furthermore, its fire safety features, environmental ratings, and durability support the long-term performance of buildings. Utilising this product enables professionals in the UK to achieve greater energy efficiency and meet safety standards, making it a practical choice for both residential and commercial construction projects.