Kingspan Plasterboard

Kingspan plasterboard features a high-performance, fiber-free rigid phenolic core offering excellent thermal insulation with low conductivity, making it suitable for internal walls and ceilings in both new construction and refurbishment projects. It provides high fire safety standards, durability, and ease of installation, utilizing adhesive or mechanical fixings. Designed for efficiency and environmental sustainability, these panels support modern, eco-conscious building practices. Further sections will provide comprehensive guidance on installation procedures, suitable applications, and the overall construction benefits of Kingspan plasterboard.

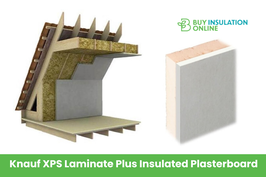

Overview of Kingspan Insulated Plasterboards

Kingspan insulated plasterboards are advanced building materials designed to combine insulation, vapor control, and surface finishing within a single unit. These panels feature a fiber-free, rigid thermoset phenolic core that delivers exceptional thermal performance, with low thermal conductivity values around 0.018-0.019 W/mK. The core utilizes environmentally friendly blowing agents with zero ozone depletion potential and low global warming potential, supporting sustainable construction practices. To ensure durability and stability, the core is fixed either mechanically or adhesively to plasterboard panels. These often include low-emissivity foil or tissue-based vapor barriers on the reverse side, enhancing vapor control and thermal efficiency. The panels are manufactured to precise standards to ensure consistency and ease of installation. Standard dimensions are 2400mm by 1200mm, with thickness options typically ranging from 37.5mm to over 92.5mm, making them adaptable for various insulation requirements across both new build and retrofit projects. Additionally, many of these panels incorporate environmentally friendly materials to reduce their carbon footprint and support sustainable constructions.

Key Features and Benefits of Kingspan Models

The key features and benefits of the various Kingspan plasterboard models are primarily defined by their advanced insulation capabilities, stringent fire safety standards, ease of installation, and robust structural performance.

Kingspan’s insulation cores, such as phenolic and Kooltherm, offer high thermal resistance, which helps to reduce energy consumption and improve overall comfort by minimizing thermal bridging and supporting efficient building envelopes. Their boards, like the Kingspan K118 Single Board, feature a low lambda value of 0.019 W/mK, demonstrating their superior thermal performance and thermal conductivity. Fire safety is reinforced through certifications such as Euroclass C-s1 and d0 and the utilization of non-combustible, fiber-free cores that limit the release of toxic fumes during fires.

The boards are designed for straightforward installation using conventional fixing methods, with custom sizes and tapered edges that enhance joint finishing and decrease installation time. Their durability, dimensional stability, and compatibility with standard finishing materials ensure long-lasting performance, making them suitable for a variety of internal wall and ceiling applications across the UK.

Installation Considerations and Best Practices

Effective installation of plasterboard demands meticulous surface preparation and strict adherence to recommended procedures to guarantee structural integrity and optimal performance. Surfaces should be dry, stable, and free from moisture ingress to prevent compromising insulation and plasterboard stability.

Precise marking of guidelines on floors, ceilings, and walls ensures correct positioning.

When cutting sheets, allow approximately 15 mm shorter than the overall height to accommodate expansion and enable sealing. Minor irregularities in the substrate should be addressed by adjusting the thickness of adhesive dabs or performing minor chasing to smooth out uneven areas.

A clearance gap of 15 mm at the base of walls must be maintained and subsequently sealed to ensure airtightness.

Adhesive should be applied in continuous bands at 300 mm centers, ensuring that no bridging occurs over joints and covering at least 20% of the back face of each sheet.

Mechanical fixings should complement the adhesive application; they must be correctly positioned to prevent damage and provide stability, with at least two fixings per sheet.

Adhering to these best practices will help achieve a durable, well-finished plasterboard installation suitable for various UK building applications. Incorporating proper support and insulation techniques further enhances system performance and safety.

Applications and Market Relevance

Applications of Kingspan plasterboard are wide-ranging within both residential and commercial construction, playing a vital role in improving thermal efficiency and reducing energy consumption.

It's mainly utilized for internal wall insulation on masonry and timber-framed structures, enabling energy efficiency upgrades without compromising interior space. The ease of installation and compatibility with various building systems further contribute to its popularity in building insulation applications.

In commercial buildings, its swift installation and high-performance insulation properties make it highly valued for projects that require rapid completion. Its moisture-resistant surface also aids in maintaining durability in diverse environmental conditions, which is essential for long-term performance.

The product is particularly suitable for refurbishment work, where minimal disruption is essential, and in new builds that must meet strict regulations for low U-values. Its advanced materials, such as a low thermal conductivity core and moisture-resistant surface, support durability and excellent thermal performance over the long term.

These features make Kingspan plasterboard the preferred choice among builders, developers, and retrofit specialists dedicated to sustainable and energy-efficient construction practices.

Additionally, it is compatible with various construction methods and can be easily integrated into existing wall assemblies to enhance overall building performance.

Conclusion

Kingspan plasterboards provide excellent insulation performance combined with straightforward installation, making them ideal for a variety of construction projects across the UK. Their key features include high thermal efficiency, fire resistance, and compatibility with different building standards.

Proper installation is essential and involves following the manufacturer’s guidelines to ensure optimal performance and safety. By selecting the appropriate plasterboard type and adhering to best practices, builders can enhance energy efficiency and structural integrity. This supports long-term durability and helps to meet regulatory requirements in both commercial and residential applications.