Thermal Pir Plasterboard

Thermal PIR plasterboard combines a polyisocyanurate foam core with plasterboard facings to deliver superior thermal insulation, fire resistance, and moisture protection. Its low thermal conductivity enables thinner installations while still achieving excellent energy efficiency, making it ideal for internal walls, ceilings, and renovation projects.

Manufactured under strict quality control standards, these panels are designed to ensure durability and safety in line with UK building regulations. Their versatility and high-performance properties make them a popular choice for a wide range of construction applications.

Further details on manufacturing processes, safety features, and expert application guidance can be explored to optimize usage and compliance with current UK building standards.

Composition and Material Structure of Thermal PIR Plasterboard

The composition and material structure of thermal PIR plasterboard are carefully designed to optimize insulation performance while ensuring structural integrity and durability. Its core consists of polyisocyanurate (PIR) foam, produced through a chemical reaction between polyol and isocyanate components, enhanced with a blowing agent that causes foam expansion. This process results in a closed-cell structure filled with gas that exhibits very low thermal conductivity, providing excellent insulation. The PIR foam is bonded to plasterboard facings, which are commonly made of gypsum. These facings may incorporate vapor control layers or composite kraft paper to enhance functionality. The thickness of the board varies, typically ranging from 25 mm to 63 mm for the core and 9.5 mm to 12.5 mm for the facings, creating a balanced, lightweight, and robust construction suitable for a variety of applications. The backing materials also contribute to the overall fire performance and moisture resistance of the plasterboard. Additionally, the thermal efficiency of PIR plasterboard makes it a popular choice for energy-saving building insulation projects.

Achieving Energy Efficiency With Thermal PIR Insulation

Utilizing thermal PIR insulation in building construction significantly enhances energy efficiency by reducing heat transfer across walls, roofs, and floors. Its low thermal conductivity, approximately 0.022 W/mK, provides excellent insulation performance despite requiring only about half the thickness of traditional mineral insulations. Excellent Thermal Performance This efficiency leads to decreased heat loss, subsequently lowering both heating and cooling energy demands, and assists structures in complying with strict UK building energy regulations such as Part L. Moreover, the high thermal performance of PIR insulation supports certification standards like BREEAM and LEED, which recognize sustainable building practices. The slimmer profile of PIR boards also allows for better space optimization within wall assemblies, facilitating quicker installation and reducing overall construction costs. The material’s durability and resistance to moisture ensure sustained energy savings and maintain structural integrity over time. These properties are due in part to its closed-cell structure, which prevents moisture ingress and contributes to long-term thermal stability. Collectively, these advantages make PIR insulation a valuable choice for achieving energy-efficient and environmentally responsible buildings across the UK.

Fire Safety and Regulatory Standards for PIR Plasterboard

Fire safety and regulatory standards for PIR plasterboard are essential considerations to ensure that building occupants are protected from fire hazards while complying with legal requirements. PIR (polyisocyanurate) boards generally meet Group 1 fire rating standards under the UK Building Regulations, making them suitable for most internal walls and ceilings, subject to certain exclusions such as fire escape routes and escape corridors. The fire safety performance of PIR plasterboard is significantly influenced by its material composition and manufacturing process. Foil-faced PIR may achieve Group 2 ratings, but this is only applicable within specific installation contexts. Certification by recognized authorities is mandatory for PIR panels manufactured from 2003 onwards, verifying their compliance with fire safety standards such as those aligned with UK Building Regulations (e.g., BS 476 or EN 13501-1). Uncertified PIR panels pose a significant fire risk, as they may be deemed combustible, increasing potential hazards in the event of a fire. Installation must adhere strictly to fire-rated barrier requirements, ensuring full coverage and proper sealing of joints and penetrations to prevent the spread of fire and smoke. Proper installation practices are critical to maintaining the intended fire safety performance of PIR plasterboard. Regular fire risk assessments and inspections are vital for maintaining long-term fire safety in buildings fitted with PIR plasterboard. Additionally, conducting specific fire resistance testing on panels, especially for cavity barriers and complex constructions, is crucial to verify their structural integrity and fire performance over time. Ensuring compliance with these standards not only safeguards building occupants but also aligns with statutory requirements for fire safety in the UK, promoting safer and more resilient built environments.

Manufacturing Techniques and Quality Assurance Processes

Manufacturing techniques for thermal PIR plasterboard involve precise processes that combine engineered insulation with a structural gypsum core to produce a durable, high-performance panel.

The PIR foam, a rigid, closed-cell plastic with low thermal conductivity, is bonded to 12.5mm gypsum plasterboard using specialized adhesives or mechanical adhesion methods such as dot-and-dab applications.

The PIR core is carefully manufactured through polymerization, ensuring consistent density and stability—both of which are essential for reliable insulation performance. Adhesive bonding techniques are crucial in achieving the required structural integrity and sealing properties.

During production, strict process controls monitor variables such as temperature, humidity, bonding pressure, and contact times, ensuring each panel meets rigorous quality standards.

Quality assurance measures include routine inspections for foam uniformity, dimensional accuracy, bond strength, and the absence of defects.

These procedures guarantee that every panel complies with energy efficiency, durability, and safety standards, making them suitable for effective use in UK construction projects. Advanced manufacturing techniques ensure the panels are produced with high precision and consistency for optimal performance.

Practical Applications in Construction and Building Improvements

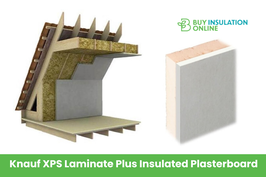

Thermal PIR plasterboard provides versatile solutions for enhancing insulation across a range of construction applications, particularly in internal linings and roof insulation. Its straightforward installation makes it suitable for both new build developments and existing renovation projects, including room-in-the-roof conversions, loft conversions, and cold flat roofing systems. It is capable of significantly reducing heat loss due to its high thermal resistance. This product improves energy efficiency by reducing heat transfer, helping to maintain stable internal temperatures and lowering energy costs. Its lightweight construction facilitates handling and installation, while compatibility with various fixing methods streamlines construction workflows. The integrated vapour control layer prevents moisture-related issues, ensuring long-term durability. Eco-friendly materials and sustainable manufacturing practices underpin its design, aligning with modern environmental standards. Typical applications include space-constrained renovations, home extensions, and internal drylining over masonry structures. Its compliance with UK building standards ensures reliable performance and sustainability, contributing to environmentally responsible construction and enhanced occupant comfort.

Conclusion

Thermal PIR Plasterboard

Thermal PIR plasterboard combines specialized polyisocyanurate insulation with a plasterboard facing, providing high thermal performance and fire safety. Its manufacturing involves precise processes to ensure quality and compliance with safety standards. Proper application in construction enhances energy efficiency and supports regulatory requirements.

Understanding the composition, production methods, and certifications of PIR plasterboard is vital for informed selection and utilization. This knowledge contributes to safer, more sustainable, and cost-effective building practices. Accurate technical understanding of PIR plasterboard is essential for effective implementation and ensuring long-term performance.