- Blogs

- A Comprehensive Guide to Foam and Rubber Pipe Insulation in the UK

A Comprehensive Guide to Foam and Rubber Pipe Insulation in the UK

TLDR

Insulating pipes is a critical measure for energy conservation, frost protection, and condensation control in UK properties. The primary materials used are flexible Nitrile Rubber and Polyethylene (PE) foam for general domestic applications, robust EPDM rubber for outdoor use, and high-performance Phenolic foam for specialised building services where efficiency and fire safety are paramount. The effectiveness of any insulation material is entirely dependent on correct installation; a snug fit and the meticulous sealing of all joints and seams are essential to create a continuous thermal barrier. All work must comply with UK regulations, principally Building Regulations Part L and the British Standard BS 5422:2023, which set the minimum standards for thermal performance and fire safety.

Introduction to Pipe Insulation in the UK![]()

The Function and Benefits of Insulating Pipes

Pipe insulation, often referred to as pipe lagging, serves several vital functions within a building's heating and plumbing system. Its installation is one of the most cost-effective ways to improve the energy efficiency and resilience of a property. The primary benefits include:

Energy Conservation: For hot water pipes, insulation significantly minimises heat loss as water travels from the boiler or hot water cylinder to the tap or radiator. This ensures hot water arrives at the outlet faster and with less energy wasted in maintaining its temperature. For chilled water systems, insulation limits heat gain, reducing the energy load on cooling equipment.

Frost Protection: In unheated areas such as lofts, garages, and external locations, pipework is vulnerable to freezing during cold weather. Insulation slows down the rate of heat loss from the water inside the pipes, providing crucial protection against freezing and the subsequent risk of burst pipes and water damage. It is important to recognise that insulation postpones freezing but cannot prevent it indefinitely in prolonged sub-zero conditions.

Condensation Control: On cold and chilled water pipework, a correctly installed insulation system keeps the outer surface temperature of the insulation above the dew point of the surrounding air. This prevents condensation from forming, which is essential for avoiding moisture damage to surrounding structures, mould growth, and Corrosion Under Insulation (CUI).

Personnel Protection: Insulating pipes that operate at very high temperatures, such as steam lines, protects individuals from accidental burns and scalds.

Acoustic Control: Certain types of foam insulation possess sound-absorbing properties. They can help to dampen the noise generated by water flow and vibrations within the pipework, contributing to a quieter indoor environment.

The most effective strategy is to view pipe insulation not as a single product but as a complete system. The objective is to create an unbroken thermal envelope around all components of the heating and plumbing network. A single uninsulated valve or a small section of exposed pipe can act as a significant thermal bridge, allowing heat to escape and undermining the performance of the entire insulated system. A holistic approach that includes pipes, bends, junctions, valves, and hot water tanks delivers compounding benefits far greater than a piecemeal application.

Key Areas in a Property Requiring Pipe Insulation

To maximise effectiveness, insulation should be prioritised in specific locations where pipes are most vulnerable to heat loss or freezing.

Lofts and Roof Spaces: Pipes running through unheated lofts are particularly at risk. Modern loft floor insulation is designed to keep heat in the living space below, which means the loft itself becomes colder and pipes are more susceptible to freezing.

Boiler and Cylinder Pipework: All primary pipes that connect the boiler to the hot water storage cylinder, and those that distribute hot water from the cylinder, should be thoroughly insulated to minimise standing heat losses within the core of the heating system.

Central Heating Pipes: Central heating pipework should be insulated as it passes through unheated areas like underfloor voids or garages to ensure that the maximum amount of heat is delivered to the radiators rather than being lost along the way.

External Pipework: Any pipework located outside the building's main insulated structure requires robust, weather-resistant insulation. This includes condensate drain pipes from modern condensing boilers, which can freeze and cause the boiler to shut down, and pipes leading to outside taps.

Initial Considerations: Choosing the Correct Size

The performance of pipe insulation is critically dependent on achieving a correct and snug fit. Two measurements are fundamental:

Pipe Diameter: The internal bore of the insulation tube must precisely match the external diameter of the pipe. If the insulation is too loose, it creates an air gap between the pipe and the insulation. This trapped air can lead to convection currents, which significantly reduces the thermal performance of the insulation.

Insulation Wall Thickness: The thickness of the insulation material itself is a primary determinant of its thermal resistance. A thicker wall generally provides better insulation. The required thickness depends on the specific application—for example, the thickness needed for frost protection is typically greater than that for simple domestic heat retention—and must meet the minimum standards set by UK regulations.

A Detailed Review of Pipe Insulation Materials

The UK market provides a specialised portfolio of pipe insulation materials. The selection process is not about finding a single "best" product, but about conducting a needs analysis for the specific pipework and choosing the material whose properties profile—covering thermal performance, fire safety, moisture resistance, UV stability, and cost—is the optimal match for that application. Using the wrong material, such as an unprotected foam outdoors, can lead to rapid degradation and system failure.

Nitrile Rubber Foam (Flexible Elastomeric Foam - FEF)

Properties: Nitrile rubber is a highly flexible, synthetic rubber with a closed-cell structure. These non-interconnected cells are filled with a blowing agent, making the material inherently resistant to water vapour ingress, which is its defining characteristic. Its flexibility makes it easy to install around complex bends and fittings. It also offers good resistance to oils and various chemicals.

Thermal Performance: This material provides good thermal insulation, with a thermal conductivity typically in the range of 0.033 to 0.036 W/mK. It is highly effective for controlling condensation and reducing energy losses in both hot and cold water systems.

Fire Performance: In the UK, nitrile rubber insulation is commonly available with a Euroclass fire rating of B/BL-s3, d0. The 'B' or 'BL' signifies a very limited contribution to fire. However, the 's3' rating indicates significant smoke production, while 'd0' means no flaming droplets are produced during combustion. The term "Class O", from the old British Standard, is still used colloquially but has been superseded by the Euroclass system.

Applications: It is widely used for insulating hot and cold water services, chilled water lines, heating systems, and HVAC ductwork. Its excellent moisture resistance makes it a prime choice for preventing condensation and the associated risk of corrosion.

Leading UK Brands: Armacell is the most recognised manufacturer, with its Armaflex range being synonymous with this material type.

BUY NITRILE RUBBER PIPE INSULATION

EPDM Rubber Foam ![]()

Properties: EPDM (Ethylene Propylene Diene Monomer) is another synthetic rubber, but it possesses a saturated polymer backbone. This chemical structure gives it superior resistance to heat, UV radiation, and ozone compared to other rubber types. This makes it exceptionally durable for outdoor applications where other materials would quickly perish. Like nitrile, it has a closed-cell structure and excellent water resistance.

Thermal Performance & Temperature Range: EPDM foam operates effectively across an extremely wide temperature range, typically from −50?C up to +150?C. This makes it suitable for high-temperature applications such as solar thermal hot water pipes.

Fire Performance: Specific products can offer good fire resistance with the added benefit of low smoke density.

Applications: EPDM is the primary choice for any external pipework, solar heating systems, and applications in harsh industrial environments due to its outstanding weather and chemical resistance. While nitrile rubber can be used outdoors, it must be protected with a specialised UV-resistant paint (e.g., Armafinish) or a protective cladding system; EPDM does not require this additional protection.

Polyethylene (PE) Foam

Properties: This is a lightweight, flexible, and highly cost-effective closed-cell foam insulation. It is known for being rot-proof, non-hydroscopic (it does not readily absorb moisture), and odourless.

Thermal Performance & Temperature Range: PE foam offers good thermal performance, with a thermal conductivity value around 0.034 W/mK. It is suitable for a broad temperature range, typically from

−45?C to +105?C, and can provide a degree of acoustic insulation by dampening flow noises in pipes.

Fire Performance: The fire rating of PE foam can vary significantly between products. Basic, economy-grade products may only achieve a Euroclass E rating, indicating a high contribution to fire. It is essential to check the specific fire classification of any PE foam product before specification or installation.

Applications: Due to its low cost and ease of installation, PE foam is very common for domestic plumbing and heating applications, particularly for DIY projects. It is well-suited for insulating standard 15 mm, 22 mm, and 28 mm copper or plastic pipes in accessible locations like lofts and underfloor spaces.

Leading UK Brands: Well-known brands in the UK include Climaflex and Armacell's Tubolit range.

Phenolic Foam

Properties: Phenolic foam is a rigid, closed-cell thermoset insulation. Its standout characteristic is being one of the most thermally efficient insulation materials commonly available for any given thickness. It has a very high percentage of closed cells (over 90%) and is manufactured with a factory-applied foil vapour barrier jacket, giving it excellent resistance to moisture.

Thermal Performance: It offers excellent thermal conductivity, with values as low as 0.025 W/mK. This high performance means that a thinner section of phenolic foam can achieve the same level of insulation as a much thicker section of other materials, making it ideal for situations where space is limited.

Fire Performance: Phenolic foam demonstrates superior fire and smoke performance. Products are often rated BL-s1, d0 under the Euroclass system. This is a best-in-class rating for a combustible insulation material, indicating a very limited contribution to fire ('BL'), very low smoke production ('s1'), and no flaming droplets ('d0').

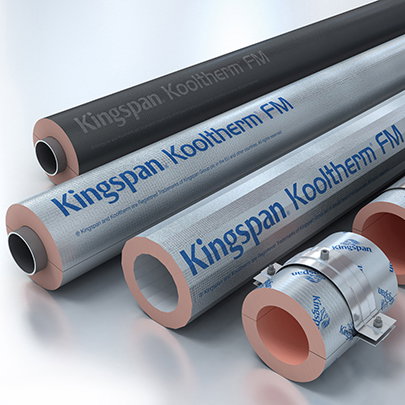

Applications: It is primarily used in high-specification building services and HVAC applications, often in commercial, public, and industrial buildings where superior thermal performance and fire safety are non-negotiable requirements.

Leading UK Brands: Kingspan is the dominant manufacturer in this category with its Kooltherm pipe insulation range.

Comparative Analysis of Common UK Pipe Insulation Materials

Material Type |

|

UV/Weather Resistance |

Flexibility |

Typical Euroclass Fire Rating |

Primary UK Application |

|

| Nitrile Rubber Foam | −50C to +110C | Poor - requires protection (paint/cladding) | High | B/BL-s3, d0 | General purpose HVAC, hot/cold water services, condensation control. | |

| EPDM Rubber Foam | −50C to +150C | Excellent | High | Varies by product | External pipework, solar heating systems, high-temperature applications. | |

| Polyethylene (PE) Foam | −45C to +105C | Poor - not for outdoor use | High | Can be as low as E | Cost-effective domestic heating and plumbing, DIY projects. | |

| Phenolic Foam | −50C to +110C | Good (with foil face) but requires additional protection outdoors | Low (Rigid) | BL-s1, d0 | High-performance building services, commercial HVAC, where space is limited. |

Best Practices for Installation

The performance of any pipe insulation material is fundamentally dependent on the quality of its installation. A poorly fitted product with gaps and unsealed joints will fail to provide the intended thermal and moisture protection.

Preparation and Tools

Essential Tools: A sharp utility knife or a specialised insulation knife is crucial for achieving clean, precise cuts. A measuring tape and a marker pen are needed for accuracy. For cutting accurate angles for bends and junctions, a mitre box is a highly recommended and valuable tool.

Surface Preparation: Before applying any insulation, the pipe surface must be thoroughly cleaned. It should be free of any dust, dirt, oil, or moisture. This is particularly important when using self-adhesive strips or contact adhesives, as any contamination will compromise the bond and prevent a proper seal.

Safety: The heating or cooling system should always be shut down and at ambient temperature before installation begins. When working with certain materials like mineral wool, appropriate personal protective equipment (PPE), including gloves, goggles, and a dust mask, should be worn.

Fitting and Sealing Straight Pipes ![]()

The installation process is fundamentally about creating and maintaining a perfect, continuous vapour barrier around the pipe. For cold and chilled water lines, the primary function of the insulation is to keep its outer surface temperature above the dew point of the surrounding air, preventing condensation. The closed-cell structure of foam and rubber provides the first line of defence, but the joints are the weak points. Any unsealed gap creates a pathway for warm, moist air to reach the cold pipe surface, causing condensation, potential CUI, and mould growth. Every cut, seam, and joint must be meticulously sealed to ensure the integrity of this vapour barrier.

Application: After measuring the pipe's outer diameter and selecting the correct insulation bore size, cut the insulation tube to the required length. Open the insulation along its pre-cut slit and fit it over the pipe. It is important not to stretch or pull the material, as this reduces its wall thickness and compromises its insulating capability. The insulation should be pushed onto the pipe, ensuring it closes snugly without gaps.

Sealing Seams and Joints: For self-sealing products, peel away the protective backing tapes and press the two adhesive faces firmly together along the entire length of the seam. For non-adhesive insulation, a specialised contact adhesive (such as Armaflex 520) should be used. Apply a thin, even film of adhesive to both faces of the slit, allow it to become tack-dry (when it feels tacky to a fingernail but doesn't transfer), and then press the faces firmly together under compression. Where two lengths of insulation meet (a butt joint), the ends should be pushed together firmly and the joint must be sealed with a suitable tape, such as a matching foil tape for foil-faced products or a proprietary insulation tape for foam products.

Fabricating Fittings

Dealing with bends and junctions is a craft that requires precision to maintain the integrity of the insulation system.

90-Degree Sharp Bends: The standard professional method is to create a mitred bend. Using a mitre box, cut the ends of two separate insulation tubes at a 45-degree angle. Fit these onto the pipe so that the two 45-degree cut faces meet perfectly at the centre of the bend, forming a neat 90-degree corner. This joint must then be securely sealed with tape.

90-Degree Curved Bends: For more gradual, sweeping bends, a different technique is used to avoid kinking the insulation. Instead of a single cut, a series of small V-shaped notches are cut into the insulation on the inside radius of the bend. This allows the tube to flex around the curve smoothly. The cuts should then be taped over to ensure a complete seal.

T-Junctions: Insulating a T-junction involves fabricating a "fish mouth" joint. First, on the main piece of insulation that runs straight through the junction, a 90-degree wedge is cut out at the point where the branch pipe meets. Then, on the end of the insulation piece for the branch pipe, two opposing 45-degree cuts are made to form a point. This pointed end is then fitted snugly into the 90-degree wedge on the main run. All three resulting seams must be carefully and thoroughly taped to create a complete seal.

Insulating Valves and Flanges

While it is possible to fabricate complex covers for valves and flanges from insulation sheet material, a more practical and common solution is to use pre-fabricated, removable insulation jackets. These are especially useful for components that require periodic access for maintenance or inspection. These jackets typically consist of an outer layer of durable material like silicone-coated glass fibre cloth, an infill of insulation, and are secured with simple velcro fastenings and pull cords for easy removal and re-fitting.

UK Standards and Regulations for Pipe Insulation

The specification and installation of pipe insulation in the UK are governed by a framework of Building Regulations and British Standards. This framework has evolved from a simple "good practice" approach to a more sophisticated, data-driven engineering model. Compliance now involves selecting and installing a specified, tested, and verifiable insulation system that meets quantifiable targets for both thermal efficiency and fire safety.

Understanding BS 5422:2023 - The Method for Specifying

BS 5422 is the cornerstone British Standard that provides the method for specifying thermal insulation for pipes, ducts, and vessels. It is not a law in itself, but it is referenced by the Building Regulations and provides the technical guidance needed to comply with them. It covers a wide range of objectives, including energy conservation, frost protection, condensation control, and personnel safety.

A critical principle within the standard is that the application requiring the greatest thickness of insulation takes precedence. For instance, if the thickness required to prevent condensation on a chilled water pipe is 25 mm, but the thickness required to limit heat gain is only 20 mm, the 25 mm thickness must be used.

The standard underwent a major update in 2023, introducing several key changes:

Simplification of Tables: The numerous tables within the standard were revised and simplified, with separate tables for copper and steel pipes being consolidated.

Adoption of Euroclass Fire Ratings: The old UK-specific "National Class" fire ratings were officially replaced with the European standard (Euroclass) system, as defined in BS EN 13501-1.

Enhanced Performance Levels: Tables from the government's Energy Technology List (ETL) were incorporated as optional 'enhanced' performance tables, allowing specifiers to design systems that exceed the minimum requirements for greater energy savings.

District Heating Tables: New, more demanding tables were added specifically for the insulation of secondary district heating systems.

Fire Safety and Euroclass Ratings (BS EN 13501-1)

The Euroclass system provides a standardised, Europe-wide classification for the reaction to fire of construction products. A typical rating for pipe insulation is expressed in three parts, for example, B-s3, d0.

Main Class (A1 to F): This indicates the material's combustibility. A1 is non-combustible (e.g., stone wool), while F is easily flammable. Foamed plastics like nitrile rubber and phenolic foam typically fall into the B or C categories, signifying a limited contribution to fire.

Smoke Production (s1, s2, s3): This part of the rating relates to the amount of smoke produced during combustion. 's1' is low smoke, 's2' is medium, and 's3' indicates high or significant smoke production.

Flaming Droplets (d0, d1, d2): This indicates whether the material produces flaming droplets or particles when burning. 'd0' means no droplets, 'd1' means some, and 'd2' means a considerable amount.

BS 5422:2023 specifies that for buildings other than dwellings, insulation assemblies should achieve at least Class B-s3, d2. For dwellings, the requirement is Class C-s3, d2 or better.

Building Regulations Part L (Conservation of fuel and power)

Part L of the Building Regulations for England sets the legal minimum standards for the energy performance of buildings. It is supported by statutory guidance in the form of Approved Documents. Volume 1 covers Dwellings, and Volume 2 covers Buildings other than dwellings.

Key Requirements for Dwellings (Volume 1): The regulations are designed to limit heat loss from building services. The guiding principle is that heat loss from pipes is only permitted where that heat is 'always useful'—that is, it contributes to heating the occupied living space. Therefore, primary circulation pipes for heating and domestic hot water must be insulated wherever they pass through unheated spaces like lofts, garages, or unheated voids. Pipes connected to a hot water cylinder should also be insulated for at least the first metre from the cylinder.

Key Requirements for Buildings other than Dwellings (Volume 2): The requirements for commercial and public buildings are more stringent. The guidance specifies maximum permissible heat loss levels (given in Watts per metre, W/m) for heating pipework, which must not be exceeded. Cooled pipework must also be insulated along its entire length to limit heat gain.

Conclusion

The selection and installation of foam and rubber pipe insulation are fundamental aspects of creating an energy-efficient, safe, and durable building in the UK. The choice of material is not a matter of a simple quality hierarchy but a technical decision driven by the specific demands of the application. Flexible polyethylene and nitrile rubber foams offer cost-effective and practical solutions for general domestic heating and plumbing. For external or high-temperature applications, the superior UV and heat resistance of EPDM rubber make it the appropriate choice. In high-specification commercial projects where thermal efficiency and fire performance are critical, rigid phenolic foam provides an optimal solution.

The ultimate performance of any of these materials, however, is entirely conditional on the quality of the installation. A meticulous approach, focused on achieving a snug fit and creating a continuous, perfectly sealed thermal and vapour barrier at all seams, bends, and junctions, is paramount. Failure to do so will compromise the system and negate the benefits of the insulation.

All specification and installation work must be carried out in accordance with the latest UK standards, principally the methodology set out in BS 5422:2023 and the legal requirements of Building Regulations Part L. Adherence to this regulatory framework ensures not only legal compliance but also the delivery of buildings that are safer, more resilient, and consume less energy.

Legal Disclaimer

The content on this page is provided for general information only. While we try to make sure that the information is accurate, up to date and free from any bugs, we cannot promise that it will be. Furthermore, we cannot promise that the information will be fit or suitable for any purpose. Any reliance that you may place on the information on this site is at your own risk. You should not use this content as a basis for specifying materials or undertaking building work without seeking independent, professional advice from a suitably qualified and experienced person, such as a building services engineer, a qualified plumber, or a building control body.

To the extent permitted by law, we exclude all conditions, warranties, representations, or other terms which may apply to this site or any content on it, whether express or implied. We will not be liable to any user for any loss or damage, whether in contract, tort (including negligence), breach of statutory duty, or otherwise, even if foreseeable, arising under or in connection with the use of, or inability to use, this site; or use of or reliance on any content displayed on this site.

We assume no responsibility for the content of any websites linked on this site. Such links should not be interpreted as an endorsement by us of those linked websites. We will not be liable for any loss or damage that may arise from your use of them.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *