- Blogs

- Installation of Cavity Wall Ties in Masonry Walls

Installation of Cavity Wall Ties in Masonry Walls

The proper installation of cavity wall ties in masonry walls is of utmost importance. While getting the design, specifications, and details right is crucial, the quality and accuracy of the installation are equally vital to ensure the long-term performance of a building's walls.

This becomes particularly critical as modern construction often requires wide cavities to accommodate necessary insulation thickness, as outlined in the 2021 editions of Approved Document L Volume 1 and 2.

It's worth highlighting that improper specification or installation can result in moisture infiltration or even structural failure of the masonry wall panels. To uphold Building Regulation 7(1), which demands skilled work with suitable materials, referencing Approved Document Regulation 7 and the BS 8000 series for on-site craftsmanship details is recommended.

It's a standard practice to adhere to the manufacturer's instructions or guidance when installing cavity wall ties, especially if they are specialized products. However, some general rules for installation should be followed unless the manufacturer suggests an alternative method.

Please note that this article pertains solely to buildings where the top floor is under 18m from the lowest external ground level.

Accurate Wall Tie Specification

Choosing the right wall tie for the specific situation is crucial. Any deviation from the specified wall tie should only be approved by the designer or structural engineer after a careful assessment of the product's suitability.

Compatibility with retaining clips for partial fill cavity insulation is essential, and consulting the manufacturer is advisable.

When in doubt, it's important to verify the specification with the designer.

The cavity wall tie specifications for smaller buildings can be found in Paragraph 2C19 and Table 5 of Approved Document A.

These specifications indicate that austenitic stainless steel and type 1, 2, 3, or 4 ties in accordance with BSI PD 6697:2010 should be used.

For separating and external cavity walls' sound transmission resistance, refer to the guidance in Paragraphs 2.18-2.24 of Approved Document E to ensure appropriate cavity wall tie selection.

Considerations for Thermal Performance and Wall Ties

Wall ties can impact the thermal performance of external walls, potentially influencing U-value calculations. These calculations should follow the methods in BR443 from the BRE. According to BR443, U-values might need adjustments if wall ties penetrate insulation layers (see Annex F of BS EN ISO 6946). However, BS EN ISO 6946 permits the exclusion of wall ties from thermal calculations if:

- Wall ties cross an empty cavity.

- Specialist wall ties with thermal conductivity below 1 W/m·K are used.

- Total corrections are under 3% of the uncorrected U-value.

In other cases, wall tie effects should be factored into U-value calculations. Correction involves knowing thermal conductivity, cross-sectional area, quantity per square meter, and insulation thickness penetrated.

In the absence of specifics, BR443 provides approximate thermal conductivity (λ) values:

- Mild steel: λ=50 W/m·K.

- Stainless steel: λ=17 W/m·K. Refer to manufacturer data for non-steel wall ties.

Likewise, BR443 offers indicative wall tie cross-sectional areas:

- Double triangle (4 mm diameter): 12.5 mm².

- Vertical twist (20 × 4 mm): 80 mm².

Proper Wall Tie Installation

BS 8000-3 offers installation standards for cavity wall ties in masonry construction. Familiarity with these recommendations by designers, installers, site managers, and construction verifiers is crucial to prevent potential failures.

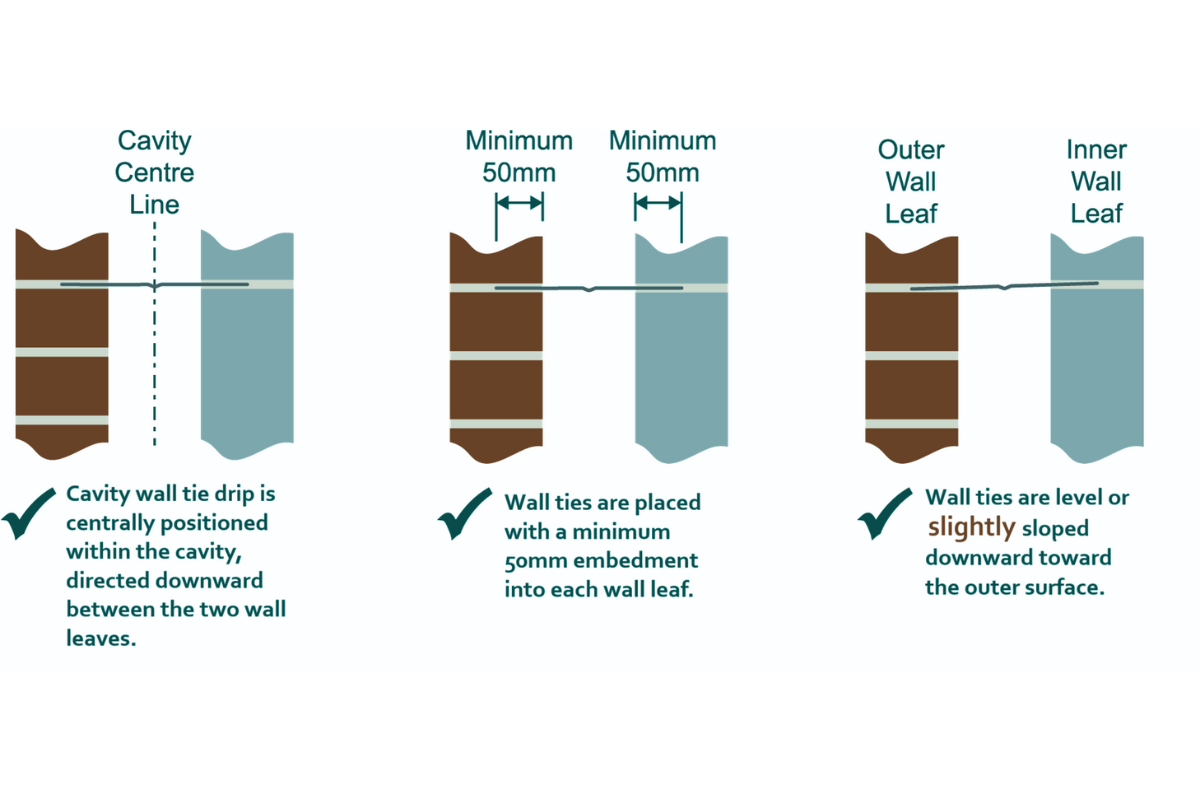

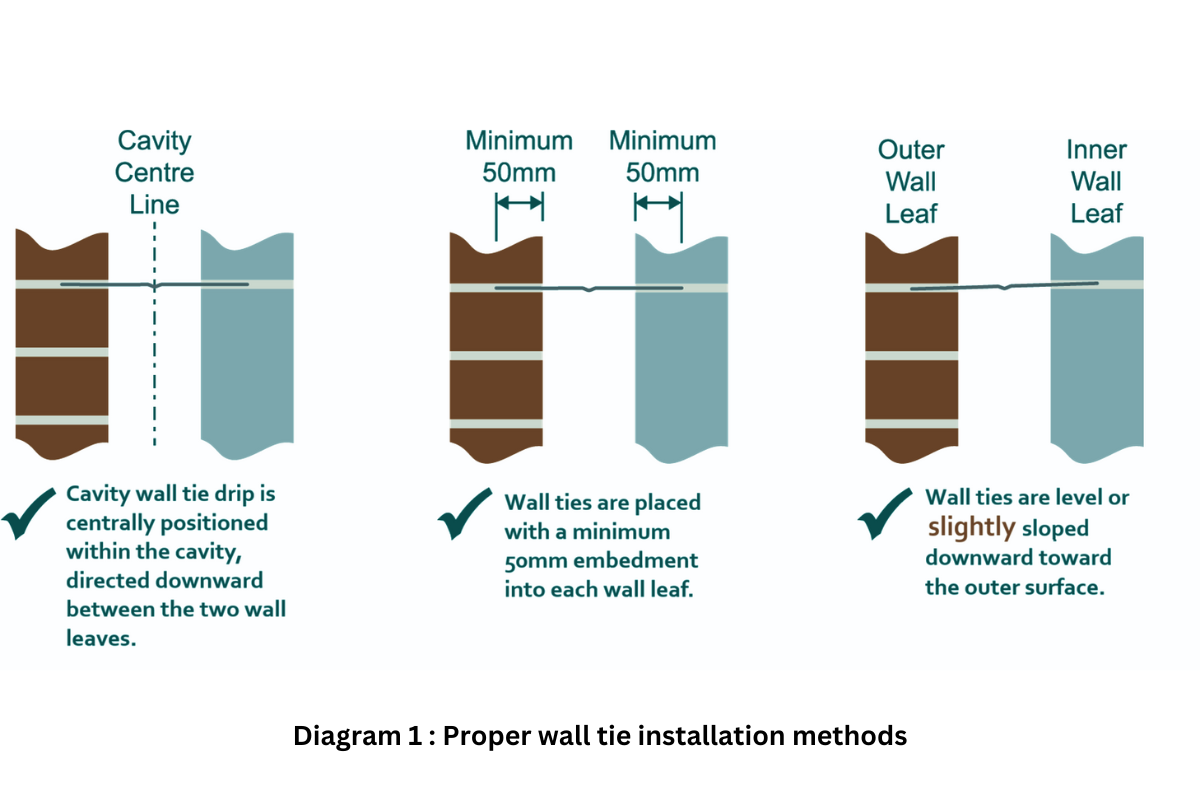

During installation, follow Diagram 1 for proper positioning:

During installation, follow Diagram 1 for proper positioning:

- Center the drip within the cavity, pointing downwards.

- Maintain level placement or a slight downward slope toward the outer leaf (avoid sloping towards the inner leaf).

- Ensure at least 50mm embedment into each masonry leaf, complying with Table 5 of Approved Document A. Some ties may need greater embedment, so adhere to the manufacturer's instructions, especially for proprietary or specialized products. Given the prevalence of larger cavities for enhanced insulation per Part L of Building Regulations, tie length should align with minimum embedment guidelines.

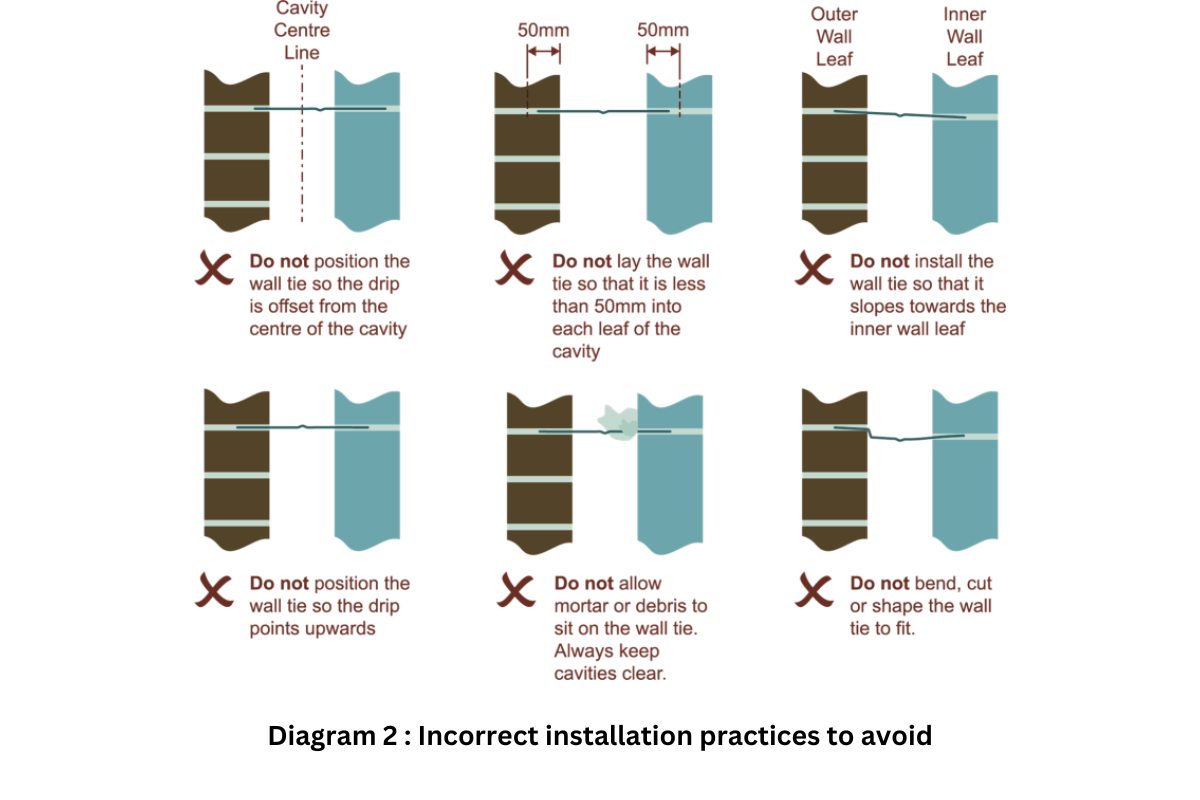

Diagram 2 highlights incorrect installation practices to avoid:

- Drip shouldn't deviate from the cavity's center line unless permitted by manufacturers.

- Wall tie must extend into each leaf by at least 50mm.

- Wall tie shouldn't slope towards the inner leaf.

- Drip shouldn't point upwards unless approved by the manufacturer.

- Prevent mortar or debris from bridging the cavity on ties. Keep cavities clear.

- Don't bend, cut, or shape ties without the manufacturer's guidance.

Wall Tie Spacing

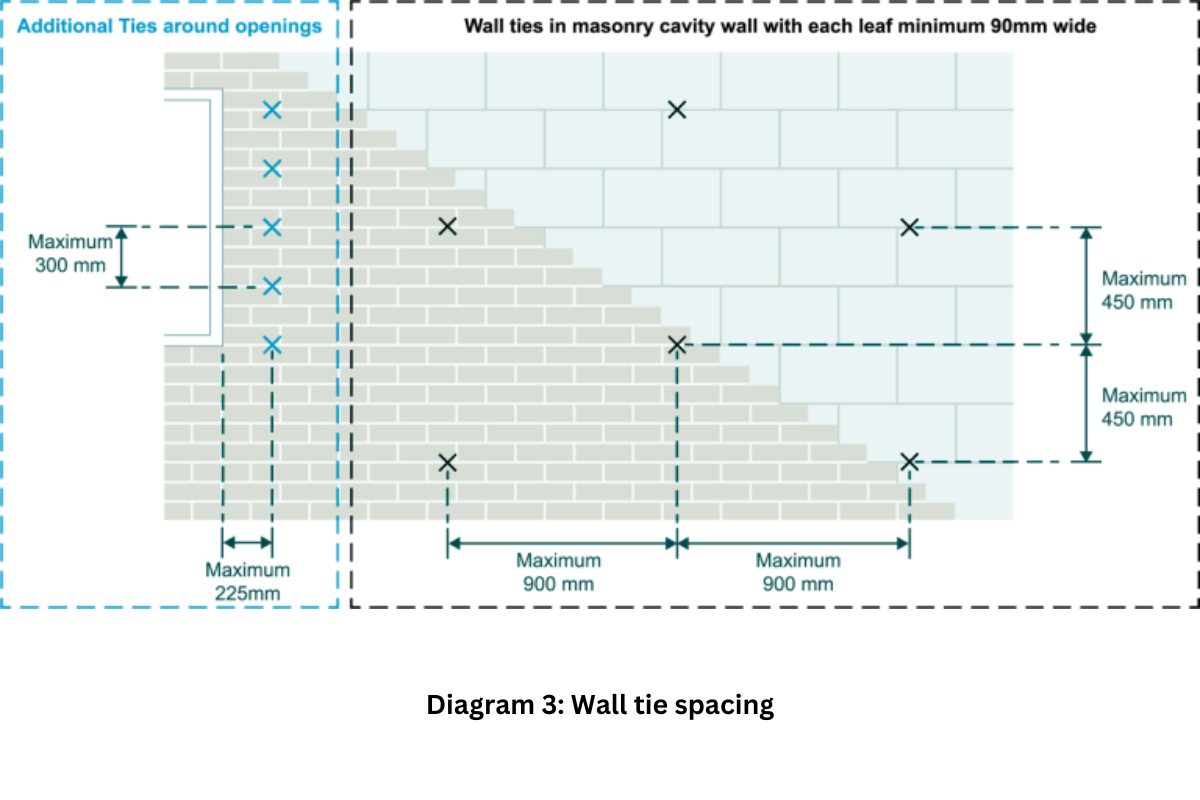

Always adhere to approved design specifications. For masonry walls with both leaves at least 90mm, follow Approved Document A and BS 8000-3 recommendations:

- Maximum horizontal spacing: 900mm.

- Maximum vertical spacing: 450mm (see Diagram 3). Alternatively, ensure a minimum of 2.5 ties/m².

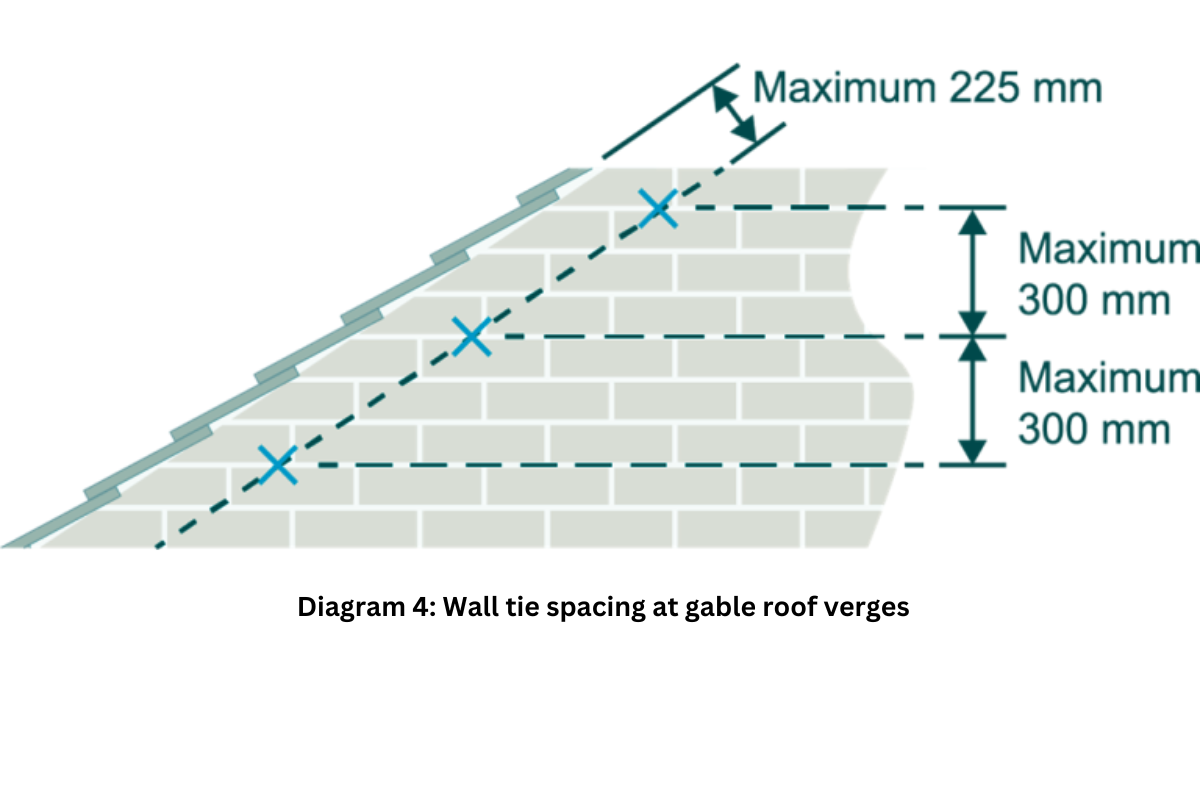

Maintain vertical spacing of no more than 300mm, and keep within 225mm from vertical edges of openings, roof verges (see Diagram 4), and movement joints.

When uncertain, consult the designer and site manager, and confirm with the Local Authority Building Control if deviations from approvals are considered.

Frequently Asked Questions

Q: What is the purpose of cavity wall ties?

A: Cavity wall ties are used to connect the inner and outer leaves of a masonry cavity wall, providing stability and strength to the wall.

Q: How do I know if I need to replace my wall ties?

A: Signs of wall tie failure may include bulging or cracking in the walls, or if you notice that the ties are corroded or damaged. A professional assessment can determine if replacement is necessary.

Q: What length of wall tie should I use in my masonry wall?

A: The length of the wall tie required will depend on the width of the cavity. It is important to use a tie suitable for the specific cavity width in order to ensure proper installation.

Q: What types of wall ties are available?

A: There are several types of wall ties available, including cavity wall ties, timber frame ties, and remedial ties for replacement purposes. The type of wall tie needed will depend on the specific requirements of the wall and the construction method.

Q: How many wall ties do I need per square meter of wall?

A: The number of wall ties required per square meter of wall will depend on the type of wall tie and the specific requirements of the wall. Generally, a guideline of 2.5 wall ties per square meter is often used.

Q: How do I install cavity wall ties?

A: The installation of cavity wall ties should be carried out by a professional who is familiar with the correct installation methods and has the necessary tools. The spacing and positioning of the ties is crucial for a successful installation.

Q: Can I replace wall ties myself?

A: It is recommended to leave the replacement of wall ties to professionals who have the expertise and experience in this specific area. They will ensure that the correct wall ties are used and that the installation is done properly.

Q: Are wall ties used in buildings with cavity walls?

A: Yes, wall ties are commonly used in buildings with cavity walls to provide structural stability and maintain the integrity of the wall system.

Q: What is the purpose of cavity wall insulation?

A: Cavity wall insulation is used to reduce heat loss through the walls and improve energy efficiency. It is typically installed in the cavity between the inner and outer walls.

Q: How are wall ties manufactured?

A: Wall ties are typically manufactured from materials such as stainless steel or galvanized steel. They are designed to be strong and durable, capable of withstanding the forces and loads placed upon them in a masonry wall system.

Conclusion:

In summary, meticulous installation of cavity wall ties in masonry walls is paramount to the long-term performance of buildings. With evolving construction demands, such as accommodating insulation requirements according to the 2021 editions of Approved Document L Volume 1 and 2, precise installation becomes even more critical. Deviating from proper specifications or installation practices can lead to moisture issues and potential structural instability in masonry wall panels. Building Regulation 7(1) underscores the need for skilled workmanship and material suitability, supported by Approved Document Regulation 7 and BS 8000 series guidance. Following manufacturer instructions and general installation principles helps manage the challenges of modern construction effectively.

Furthermore, considering the thermal impact of wall ties, as outlined in BR443 and BS EN ISO 6946, underscores the importance of accurate U-value calculations. Attention to factors like thermal conductivity and cross-sectional area ensures the integration of wall ties aligns with thermal performance goals. Adhering to the installation standards set by BS 8000-3 is essential, ensuring proper positioning, spacing, and compliance with manufacturer guidelines. In this evolving construction landscape, collaborative efforts among designers, installers, site managers, and regulatory bodies are vital to achieving seamless execution and upholding both design integrity and regulatory compliance. Ultimately, meticulous cavity wall tie installation remains a cornerstone for building durability, energy efficiency, and occupant satisfaction.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *