Eps Insulation

EPS insulation is a lightweight and durable material composed of expanded polystyrene with a closed-cell structure that traps air, providing excellent thermal insulation. It is widely utilized in construction for walls, floors, attics, and other applications due to its high energy efficiency, water-repellent properties, and ease of handling.

Although environmentally resistant, EPS waste can persist for centuries and presents challenges for recycling. However, ongoing technological advancements support sustainable management strategies. Continued exploration of this material reveals effective methods to maximize its benefits and reduce environmental impacts, ensuring EPS remains a valuable component in environmentally conscious building practices within the UK.

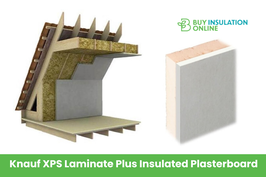

Properties and Applications of EPS Insulation

Polyurethane foam insulation, particularly expanded polystyrene (EPS), is widely recognized for its effective thermal insulating properties and versatile applications. Its closed-cell structure, containing 98% trapped air, results in very low thermal conductivity, making EPS an excellent insulator that maintains consistent thermal performance even in temperature fluctuations. Efficient Installation and Cost Savings EPS significantly enhances energy efficiency in buildings by reducing both heating and cooling costs. It helps stabilize indoor temperatures, thereby lowering greenhouse gas emissions. Its water-repellent qualities enable it to retain insulating capabilities in moist environments, preventing deterioration over time. Lightweight and durable, EPS is simple to handle, transport, and install, fitting seamlessly into various construction projects. Its adaptability allows for customization into different shapes and sizes, meeting insulation requirements across attics, walls, and floors in residential, commercial, and specialized applications. Additionally, its fire-resistant properties make it a safe choice for many building projects, providing peace of mind alongside thermal benefits.

Environmental Considerations and Challenges of EPS Waste

Although EPS insulation provides significant benefits in thermal performance and ease of handling due to its lightweight nature, it also presents notable environmental challenges and waste management concerns that require careful consideration. EPS waste remains in the environment for hundreds of years, breaking down into microplastics that threaten marine and terrestrial ecosystems. Its low density means it often accumulates in landfills and natural habitats, posing ongoing disposal problems.

Key environmental issues associated with EPS include:

Its resistance to biodegradation makes cleanup efforts difficult and increases the risk of environmental contamination. The material can persist in ecosystems long after disposal.

Inappropriate disposal, especially through incineration, releases toxic gases such as dioxins and other harmful pollutants, contributing to air pollution and health hazards. Additionally, unregulated disposal practices exacerbate the environmental impact.

The limited recycling infrastructure in the UK restricts effective waste recovery. This often results in increased volumes of EPS ending up in landfills, further straining waste management systems.

Contaminated EPS waste complicates recycling processes, reducing the potential for reuse and raising costs for waste treatment facilities.

Advances in chemical recycling technology are ongoing, offering potential solutions to convert EPS waste back into styrene monomers for reuse, which could significantly reduce environmental impact. chemical recycling solutions could transform disposal practices

Addressing these challenges requires comprehensive waste management strategies, including the development of specialized recycling solutions, increased awareness among consumers and industry, and policies that promote proper disposal and repurposing of EPS waste. Implementing such measures can help minimize the environmental footprint of EPS and protect delicate ecosystems.

Recycling Methods for EPS and Their Effectiveness

Recycling methods for EPS involve a variety of processes aimed at reducing waste volume, recovering valuable materials, and lowering environmental impact.

Mechanical recycling is one of the most common approaches. It involves shredding EPS foam into small pieces, which are then melted and molded into new products such as packaging, insulation panels, or other utilitarian items. This process helps to maximize the reuse of existing materials and minimize landfill waste.

In-house techniques often include grinding and de-dusting to produce finer particulates. These are frequently sold for soil amendment purposes or for manufacturing applications, further extending the material’s lifecycle.

Chemical recycling employs the use of solvents or heat to break down the polymer chains of EPS. This method facilitates the extraction of useful chemicals or enables the production of new polystyrene with similar quality to the original. Chemical recycling can also treat contaminated or complex waste streams, making it a versatile option.

Pyrolysis is another method utilized, where EPS is heated in the absence of oxygen to convert it into gases, oils, and char. These by-products can be used as fuels or raw materials for other industries, thereby significantly reducing landfill volumes.

Additionally, composite regeneration involves blending recycled EPS with virgin materials. This approach supports sustainable product manufacturing whilst maintaining quality standards and product performance.

Throughout all methods, effective removal of contaminants is essential. Achieving high levels of purity enhances recycling efficiency and ensures that the recycled materials meet the required standards for further use.

These recycling techniques, when applied correctly, play a vital role in managing EPS waste responsibly and supporting sustainable practices across the UK.

Industry Practices and Recycling Statistics in the U.S

The waste management sector within the United States has made considerable advances in establishing practices and expanding recycling infrastructure to effectively handle expanded polystyrene (EPS) waste.

Industry investments currently exceed 170 million pounds (approximately £149 million), with facilities increasingly focused on integrating post-consumer recycled EPS into new manufacturing processes, thereby supporting a more circular economy. The emphasis on environmental sustainability is driving innovation and capacity expansion across the sector.

Recycling capacity across North America is close to 35 million kilograms (about 77 million pounds), with a further 68 million kilograms (around 150 million pounds) in planning stages, indicating ongoing growth within the sector.

Most of this progress occurs within business-to-business channels, where specialized systems diverted 28 million kilograms (approximately 61 million pounds) of post-consumer EPS in 2022.

This volume represented a recycling rate of around 31%, reflecting significant developments in waste diversion efforts.

Despite facing increased volumes—approximately 76,600 tonnes (168.6 million pounds)—and technological advancements such as densifiers boosting capacity by 150%, participation in curbside recycling programs remains limited.

Recycling success largely occurs through business-to-business systems and alternative drop-off channels, not curbside programs. This underscores the need for continued outreach and infrastructure improvements to boost public participation.

Promoting Sustainability Through Improved EPS Management

Promoting sustainability through improved EPS management involves implementing comprehensive strategies that maximize recycling efficiency, reduce waste, and support environmentally responsible practices.

EPS insulation is 100% recyclable and can be repurposed into new products, significantly reducing landfill waste and fostering a circular economy. Advances in recycling technology ensure effective reprocessing of EPS, conserving raw materials and lowering energy consumption during manufacturing processes. Recycling EPS reduces the need for new raw materials, which helps in conserving natural resources and decreasing the environmental footprint of production activities. Additionally, the development of recycling facilities specifically designed for EPS contributes to streamlined waste management and recycling efforts.

Recycling used EPS extends its life cycle and aligns with green building standards, thereby supporting sustainable construction practices.

Proper management of EPS enhances building energy efficiency by reducing heating, cooling, and overall energy usage, which in turn decreases greenhouse gas emissions.

Furthermore, EPS’s ability to be molded with minimal waste and transported efficiently further contributes to resource conservation.

These integrated efforts promote environmentally responsible development and offer tangible benefits for industries and communities committed to sustainability, helping to create a more sustainable future for the UK.

Conclusion

Effective management of EPS insulation involves understanding its properties and applications, recognizing environmental challenges related to waste, and utilizing appropriate recycling methods. Industry practices vary, with ongoing efforts to improve recycling rates and reduce landfill accumulation. Implementing improved collection and processing techniques, alongside promoting sustainability, can significantly mitigate environmental impact. By integrating these strategies, stakeholders can enhance the reuse of EPS waste and uphold environmental responsibility, ensuring that the benefits of EPS insulation are balanced with responsible waste management and ecological preservation.