Polystyrene Sheet Insulation

Polystyrene sheet insulation, commonly available as EPS (expanded polystyrene) or XPS (extruded polystyrene), offers excellent thermal resistance, moisture resistance, and durability. These qualities make it suitable for a wide range of applications, including walls, roofs, foundations, and more.

EPS is lightweight, cost-effective, and environmentally friendly. It is easy to handle and install, making it a popular choice for many construction projects. Its good insulating properties help reduce heat loss and improve energy efficiency in buildings.

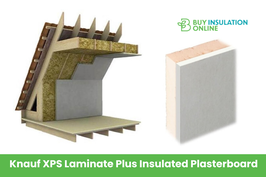

XPS provides greater compressive strength and moisture resistance compared to EPS. This makes it especially beneficial in demanding environments such as below-ground foundations or areas prone to higher moisture levels. Its durability ensures long-lasting performance in such applications.

Proper handling and installation of polystyrene sheet insulation are crucial. Care must be taken to prevent damage during transportation and fitting, as dents or cracks can compromise insulation performance. Correct installation techniques not only enhance thermal efficiency but also help prevent issues such as air gaps or moisture ingress, which could reduce the lifespan of the insulation.

In addition, using suitable jointing and sealing methods ensures that the insulation maintains continuous thermal barriers, contributing to the overall energy efficiency of the building.

Understanding the limitations of polystyrene insulation is also important. While it is highly effective as a thermal barrier, it can be susceptible to certain chemical interactions or degradation if exposed to high temperatures or direct sunlight for extended periods. Therefore, it should be properly protected and installed according to manufacturer guidelines.

This versatile material's properties, combined with proper handling and installation, optimize its performance, ensuring long-term benefits in energy conservation and structural integrity. Continuing will further detail best practices and considerations for maximizing the effectiveness and lifespan of polystyrene sheet insulation in UK building projects.

Thermal Performance and Energy Efficiency

Polystyrene sheet insulation enhances a building's thermal performance and supports energy efficiency by primarily doing so through its low thermal conductivity, which typically ranges between 0.034 and 0.038 W/mK. Materials such as extruded polystyrene (XPS) offer higher thermal resistance thanks to their denser cell structure, effectively reducing heat transfer. Furthermore, expanded polystyrene (EPS) insulation, with its favorable U-value performance, maintains consistent thermal properties over time, unlike some materials affected by thermal drift. This stability helps buildings sustain comfortable indoor temperatures, reducing the need for excessive heating or cooling. As a cost-efficient solution, polystyrene insulation minimizes energy consumption, supports climate control, and enhances overall energy efficiency in both new builds and renovations. Proper installation techniques can also minimize thermal bridging, further improving insulation performance. This contributes to long-term environmental benefits and lower running costs.

Moisture Resistance and Durability

Polystyrene sheet insulation demonstrates notable resistance to moisture owing to its inherently closed-cell structure. This structure comprises small, sealed pockets of air that effectively limit water absorption.

Both Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are highly resistant to water penetration, making them suitable for use in environments with high humidity or occasional water exposure.

While neither material is completely waterproof, EPS and XPS significantly minimize moisture-related problems such as mold, mildew, and rot. This helps to maintain the long-term durability of the insulation system.

EPS, in particular, retains between 95 and 97 percent of its thermal performance after prolonged exposure to moisture. It also preserves its structural integrity even under environmental stresses such as freeze-thaw cycles.

Manufacturing quality, cell structure uniformity, and surface treatments influence water-resistant and waterproof characteristics. Surface treatments can further enhance moisture resistance, providing reliable insulation performance over time across various construction applications.

Versatile Applications in Construction

The versatile applications of polystyrene sheet insulation in construction showcase its adaptability across a broad spectrum of structural and environmental requirements. It's widely utilized in residential buildings for walls, roofs, foundations, and floors due to its excellent thermal efficiency, which helps to maintain stable indoor temperatures and reduce energy consumption. Building and Construction Furthermore, expanded polystyrene (EPS) is employed as geofoam in commercial projects, providing lightweight stability in the construction of roadways, slopes, and embankments. Its buoyant properties also make it suitable for flotation in marinas and pontoon structures, offering structural support while minimizing weight. Additionally, EPS's shock-absorbing qualities render it ideal for packaging delicate items and original equipment manufacturer (OEM) components, thereby decreasing the risk of damage during transit. Its environmental sustainability benefits also include recyclability and energy-efficient production processes, reinforcing its appeal in eco-conscious projects. These varied applications highlight polystyrene sheet insulation as a practical and sustainable choice for enhancing construction efficiency across the UK.

Environmental Impact and Sustainability

Considering the environmental impacts of insulation materials is crucial for promoting sustainable construction practices, especially as awareness of ecological footprints continues to grow. Expanded polystyrene (EPS) insulation emits less carbon dioxide, consumes less energy during manufacturing, and has a significantly lower ozone depletion potential compared to extruded polystyrene (XPS). Its global warming potential and water usage are also notably lower, making it a more environmentally responsible choice for building projects.

Moreover, EPS panels offer long-lasting insulation properties, with effective performance lasting up to 50 years. This extended lifespan reduces the need for frequent replacements, thereby conserving resources over time. However, it is important to recognise that EPS does pose environmental challenges. It contributes substantially to plastic pollution, as it persists in landfills for centuries and can contaminate oceans, breaking down into tiny microplastics that threaten marine ecosystems. It floats on water, facilitating worldwide dispersal via waterways, which accelerates ecological damage.

Recycling options for EPS do exist, but the rates of post-consumer recycling remain low due to collection and processing difficulties. Furthermore, the low recycling rates highlight the importance of considering both the efficiency benefits and the environmental footprint when choosing insulation materials. Ensuring responsible use and disposal practices can help mitigate some of the associated environmental concerns.

Aspect |

Benefits |

Challenges |

| Carbon footprint | Produces lower emissions during manufacturing compared to XPS | Difficult disposal and long decomposition period in landfills |

| Water consumption | Uses less water during production | Potential to pollute oceans via microplastics |

| Durability & lifespan | Up to 50 years, reducing the frequency of replacements | Recycling rates are limited and hindered by contamination issues |

Important Considerations and Limitations

While polystyrene foam insulation offers valuable thermal properties and ease of installation, several important limitations must be carefully considered before selecting it for construction projects.

Temperature Restriction: Both EPS (expanded polystyrene) and XPS (extruded polystyrene) have maximum service temperatures of approximately 75°C (165°F). This limits their suitability in high-temperature environments or applications involving significant heat exposure, such as around certain industrial equipment or exposed flues.

Fire Safety: Polystyrene foam is flammable and can emit toxic fumes when burning. The use of polystyrene insulation must comply with stringent safety standards and building regulations, often requiring the inclusion of fire retardants and protective coverings to minimise fire risks.

Material Durability: EPS is generally less durable over time; it may suffer from deterioration, cracking, or shrinkage, which can reduce its insulating effectiveness. XPS offers higher compressive strength and durability but can still face issues under sustained heavy loads or prolonged environmental stress.

Installation Challenges: Installing EPS boards can be complex, as they often require meticulous hanging procedures to prevent movement. They're also prone to cracking and shrinkage if not handled carefully. Additionally, factory ageing of EPS boards is necessary to ensure product quality, which can complicate scheduling and logistics during construction.

Considering these factors will help ensure the appropriate application and long-term performance of polystyrene foam insulation in UK building projects.

Conclusion

Polystyrene sheet insulation provides reliable thermal performance, resistance to moisture and a versatile option for various construction projects. Its environmental impact is influenced by responsible sourcing and disposal practices, highlighting the importance of sustainable considerations. Users should be aware of its limitations, such as potential damage during handling and environmental concerns related to its production and disposal, to ensure optimal use.

Careful selection and correct installation of polystyrene sheets can enhance energy efficiency and improve the durability of buildings. When used appropriately, it supports sustainable building practices and helps achieve effective insulation solutions. A thorough understanding of these factors ensures informed decisions in choosing the right insulation materials for UK projects.