- Blogs

- A Comprehensive Guide to Garden Room Insulation in the UK

A Comprehensive Guide to Garden Room Insulation in the UK

TLDR

Core Purpose: Insulation is essential for using a garden room year-round. It keeps the space warm in winter and cool in summer, protects the timber structure from damp and rot, and reduces energy bills.

Key Materials:

PIR (Polyisocyanurate) Boards: Offer the best thermal performance for their thickness, saving valuable internal space. They are a common choice for high-quality, compact garden rooms.

Mineral Wool (Rockwool/Fiberglass): A cost-effective option that provides excellent fire resistance and soundproofing. It requires more thickness than PIR to achieve the same level of insulation.

SIPs (Structural Insulated Panels): A modern construction method where insulation is integral to the building's structure. SIPs provide a strong, airtight building that can be assembled very quickly.

Best Practice is a System: Effective insulation is not just about one material. It requires a complete system: a breather membrane on the outer side of the frame to repel water but allow vapor to escape, and a vapor control layer (VCL) on the inner (warm) side to stop moisture from inside the room from getting into the structure.

UK Regulations Simplified:

Most garden rooms under 30 square meters with no sleeping accommodation are exempt from building regulations, including the strict thermal standards of Part L.

To avoid needing planning permission, most garden rooms must be under 2.5 m tall if they are within 2 m of a boundary.

This regulatory exemption can lead to suppliers offering poorly insulated buildings. Always compare the thermal performance using the U-value (the lower the figure, the better the insulation), not just the thickness of the insulation material.

The Foundation of a Year-Round Garden Room: Understanding Insulation

The modern garden room has evolved far beyond the humble garden shed. Driven by fundamental shifts in how we live and work, such as the rise of remote working and the need for flexible multi-generational living spaces, these buildings are now expected to function as fully fledged extensions of the home. Whether intended as a home office, a creative studio, a gym, or a quiet retreat, a garden room's utility is entirely dependent on its ability to provide a comfortable environment throughout the year. This is where insulation becomes not an optional extra, but a fundamental component of the building's design and value.

The Three Pillars of Insulation Benefits

Properly insulating a garden room delivers three critical benefits that work together to create a high-performing, durable space.

Thermal Comfort & Usability: The primary function of insulation is to maintain a stable and comfortable internal temperature, regardless of the weather outside. It slows the transfer of heat, keeping the space warm and cozy during cold winter months and preventing it from overheating under the summer sun. This transforms the building from a seasonal structure into a genuinely usable space 365 days a year.

Energy Efficiency & Cost Savings: A well-insulated structure is an energy-efficient one. By trapping heat inside during winter, it significantly reduces the amount of energy required for heating. This leads to lower electricity bills and a smaller carbon footprint for the building over its lifetime.

Structural Longevity: Perhaps the most overlooked benefit of insulation is its role in protecting the building itself. A key part of a proper insulation system is moisture management. By controlling the movement of air and water vapor, it prevents condensation from forming within the timber frame. This is crucial for preventing dampness, mold, and the onset of rot, which can compromise the structural integrity of the building over time and ensure its longevity.

Understanding Heat Loss

To appreciate why a comprehensive approach is necessary, it helps to understand where a typical uninsulated building loses heat. A significant amount of heat escapes through the walls (around 35%) and the roof (around 25%), with the remainder lost through the floor, windows, and doors. Therefore, insulating only the walls or the roof is insufficient. A truly effective garden room must be insulated as a complete envelope—floor, walls, and roof—to create a thermally stable and protected environment.

Comparing Insulation Materials for Your Garden Room

When exploring the specifications of different garden rooms, you will encounter various types and thicknesses of insulation. This can be confusing, as suppliers may highlight a thick layer of a certain material, implying it is superior. However, this is not a reliable way to compare performance.

The Great Equaliser: Understanding U-Values

The standard measure for thermal performance in UK construction is the U-value. A U-value measures the rate of heat loss through a building element, such as a wall, roof, or floor. The principle is simple: the lower the U-value, the better the material's performance as an insulator.

Different materials have vastly different thermal properties. For instance, a 50mm thick board of one type of insulation can be significantly more effective than a 100mm thick layer of another. Therefore, instead of comparing thickness, you should always ask for the U-values for the floor, walls, and roof. This allows for a true like-for-like comparison of how well different garden rooms will perform thermally. A reputable supplier will have this information readily available.

In-Depth Material Analysis

The choice of insulation material is not a simple one-for-one swap; it influences the building's cost, internal space, acoustic properties, and construction method. Understanding these trade-offs is key to selecting a garden room that aligns with your priorities.

Rigid Foam Boards (PIR - Polyisocyanurate)

PIR is a high-performance rigid foam insulation. It is manufactured as boards, typically with a foil facing on both sides. Well-known brands that produce PIR include Celotex and Kingspan.

Properties & Benefits:

Superior Thermal Performance: PIR's main advantage is its exceptional thermal efficiency. It provides a very low U-value for its thickness, meaning a relatively thin layer is needed to achieve a high level of insulation. This is ideal for garden rooms, where maximizing internal space within a slim wall profile is often a priority.

Moisture Resistance: The closed-cell foam structure and foil facings make PIR highly resistant to moisture absorption, helping to keep the building's structure dry.

Integrated Vapor Barrier: When the joints between the foil-faced boards are sealed with aluminium tape, the foil layer creates a continuous and effective vapor control layer, an essential component of the building envelope.

Considerations:

Cost: PIR is generally one of the more expensive insulation materials when compared to options like mineral wool.

Installation: To be effective, the rigid boards must be cut precisely to fit snugly between the timber frame studs. Any gaps will create 'thermal bridges' where heat can escape, reducing the overall performance. These gaps must be filled with expanding foam to ensure a continuous insulated layer.

BUY POLYISOCYANURATE INSULATION

Mineral Wool (Rockwool & Fibreglass)

Mineral wool is a general term for fibrous insulation made from either molten rock (often sold as Rockwool) or recycled glass (fiberglass). It is supplied in flexible rolls or semi-rigid slabs, also known as batts.

Properties & Benefits:

Acoustic Insulation: The dense, fibrous structure of mineral wool is excellent at absorbing sound. This makes it a very good choice for garden rooms intended as music studios, recording booths, or offices located in noisy urban environments.

Fire Resistance: Mineral wool is non-combustible and has an extremely high melting point, meaning it will not burn or contribute to the spread of fire. This is a significant safety advantage.

Cost-Effectiveness: It is typically a more affordable option than PIR insulation.

Ease of Installation: The flexible nature of the batts allows them to be easily pushed into place between frame studs, fitting well into irregular spaces.

Considerations:

Thermal Performance & Thickness: Mineral wool is less thermally efficient than PIR. To achieve the same U-value, a much thicker layer is required—often double the thickness. This will result in thicker walls and a reduction in the usable internal floor space of the garden room.

Moisture Management: While the fibers themselves are water-repellent, if the insulation becomes saturated with water due to a leak, it can slump within the wall cavity, and its thermal performance will be severely compromised. It is essential that it is installed as part of a system with correctly fitted protective membranes.

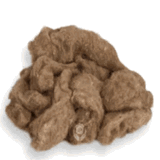

Sheep's Wool

A natural and sustainable alternative, sheep's wool insulation is made from the fleece of sheep and is gaining popularity in eco-conscious construction.

Properties & Benefits:

Sustainability: As a natural, renewable, and biodegradable material, sheep's wool has very low embodied carbon. It requires a fraction of the energy to produce compared to man-made insulations.

Moisture Buffering: Sheep's wool has a unique hygroscopic property, meaning it can naturally absorb and release moisture from the atmosphere without its thermal performance being affected. It can hold up to 35% of its own weight in moisture, helping to regulate humidity and protect the surrounding timber frame from damp. This makes it particularly well-suited to the variable UK climate.

Improved Air Quality: It has the ability to absorb and neutralize certain airborne pollutants, such as volatile organic compounds (VOCs).

Safe Handling: The material is soft and non-irritant, making it safe and pleasant to install without specialized protective gear.

Considerations:

Cost: It is often positioned as a premium product and can be more expensive than both mineral wool and PIR.

Thermal Performance: Its thermal efficiency is comparable to that of mineral wool, meaning it also requires a greater thickness than PIR to achieve an equivalent U-value.

Structural Insulated Panels (SIPs)

SIPs are not simply an insulation material but a complete construction system. A SIP is a composite panel made from a core of rigid foam insulation (typically Expanded Polystyrene - EPS, or the higher-performing PIR) bonded between two structural facings, usually Oriented Strand Board (OSB).22 These panels form the load-bearing walls and roof of the garden room.

Properties & Benefits:

Speed of Construction: SIPs are prefabricated in a factory and delivered to site ready for assembly. This makes the on-site build process exceptionally fast, with a weather-tight structure often erected in just a few days.

Strength and Airtightness: The composite structure is incredibly strong, rigid, and dimensionally stable. The panelised system results in a very airtight building, which minimises heat loss from draughts and reduces thermal bridging.

Predictable Performance: Because the panels are manufactured in a controlled factory environment, the level of insulation and structural performance is highly consistent and predictable.

Considerations:

Cost: The initial material cost for a SIPs kit can be higher than for a traditional timber frame and separate insulation.

Core Material Matters: The overall performance of a SIPs garden room depends heavily on the insulation core used. Cheaper panels may use EPS, which is less thermally efficient. For the best performance, look for SIPs with a PIR core.

Table 1: Comparison of Common Garden Room Insulation Materials

Feature |

PIR Boards |

Mineral Wool |

Sheep's Wool |

SIPs (PIR Core) |

| Thermal Performance | Excellent (Lowest U-value for thickness) | Good (Requires greater thickness) | Good (Requires greater thickness) | Excellent (Airtight system) |

| Acoustic Damping | Fair | Excellent | Very Good | Good |

| Fire Resistance | Combustible core (Fire rating is system-dependent) | Excellent (Non-combustible) | Good (Naturally fire retardant) | Combustible core (Fire rating is system-dependent) |

| Moisture Handling | Excellent (Resistant to moisture) | Good (Must be kept dry) | Excellent (Hygroscopic - buffers moisture) | Excellent (Airtight system) |

| Sustainability | Poor (Oil-based product) | Fair (Recycled content, energy-intensive) | Excellent (Natural, renewable) | Fair (Depends on core material) |

| Relative Cost | High | Low | High | High |

| Best For | Maximising internal space, high thermal efficiency | Soundproofing, fire safety, budget projects | Eco-builds, humidity control | Speed of construction, structural strength |

Best Practices: The 'Building Envelope' System

Achieving a truly insulated garden room is about more than just choosing a material and placing it in the walls. The insulation is only one component of a carefully designed multi-layer system known as the 'building envelope'. The performance and durability of the entire structure depend on each layer being present and correctly installed.1

The Layers of a High-Performance Garden Room Wall

A quality garden room wall is constructed with several layers, working from the outside in:

External Cladding: This is the building's first line of defence against rain and wind. It can be timber, composite, or metal.

Ventilated Cavity: Behind the cladding, vertical battens create an air gap. This cavity is crucial; it allows any moisture that gets behind the cladding to drain away and encourages air to circulate, which helps to keep the main structure dry.

Breather Membrane (The Raincoat): This is a fabric-like membrane wrapped around the outside of the main timber frame. Its job is twofold: it is waterproof to stop any wind-driven rain from reaching the structure, but it is also 'breathable', meaning it allows water vapour from inside the wall to escape outwards. This prevents moisture from becoming trapped within the insulation and timber, which could lead to rot. Its inclusion is a non-negotiable feature for a durable timber building in the UK climate.

Structural Frame & Insulation: This is the core of the wall, typically a timber frame. The chosen insulation (e.g., PIR boards or mineral wool batts) is fitted snugly into the cavities between the timber studs. It is vital that there are no gaps, as these create cold spots, or 'thermal bridges', where heat can pass through the timber instead of the insulation. Any voids should be filled with expanding foam.

Vapour Control Layer (VCL) (The Wetsuit): This is another critical membrane, but it is installed on the warm side (the inside) of the insulation. Its purpose is to stop warm, moist air generated inside the room—from people breathing, boiling a kettle, or from plants—from passing into the colder wall structure. If this moist air were to reach a cold surface inside the wall, it would cool and condense into liquid water, leading to damp and decay. The VCL prevents this. Common materials include high-gauge polythene sheeting or the foil facing on PIR boards. To be effective, all joints and edges must be sealed with the correct tape to form a continuous, airtight barrier.

Internal Finish: The final layer is the internal wall surface, which is typically plasterboard or decorative timber cladding.

Insulating Floors and Roofs

The same principles of a complete, sealed envelope apply to the floor and roof.

Floors: The floor is most commonly insulated with rigid PIR boards fitted between the floor joists, with a typical thickness of 100mm being recommended for good performance. Critically, the floor structure must be protected from ground moisture. If built on a concrete slab, a Damp Proof Membrane (DPM) must be laid underneath the concrete. If built on timber joists, a Damp Proof Course (DPC) must be laid under the timbers where they rest on the foundations.

Roofs: There are two primary methods for insulating a garden room roof:

Cold Roof: This is the most common method. Insulation is fitted between the roof rafters, but a 50mm ventilated air gap is left open above the insulation (between the insulation and the roof deck). This gap allows air to flow from eaves to ridge, carrying away any moisture that might find its way into the roof structure.

Warm Roof: In this design, the insulation is placed on top of the roof deck, outside the main structure. This keeps the entire roof structure 'warm' and can provide superior thermal performance, but it is a more complex and often more expensive construction.

A typical PIR insulation thickness for a garden room roof would be between 75mm and 100mm.

Navigating UK Regulations for Garden Buildings

Understanding the regulatory framework in the UK is essential before buying or building a garden room. There is often confusion between Planning Permission and Building Regulations.

Planning Permission: Governs whether you have the right to build a structure, concerning its size, location, appearance, and use.

Building Regulations: Govern how the structure is built, setting standards for structural integrity, fire safety, energy efficiency, and more.

Permitted Development Rights (Avoiding Planning Permission)

Most garden rooms do not require a formal planning application because they fall under 'Permitted Development Rights'. However, to qualify, the project must meet a strict set of conditions. The key rules for a garden room to be considered permitted development are :

It must not be used for self-contained living or sleeping accommodation.

It must be single-storey with no balconies or verandas.

The maximum height is 2.5m if the building is within 2m of a property boundary.

If more than 2m from a boundary, the maximum eaves height is 2.5m, and the maximum overall height is 4m for a dual-pitched roof or 3m for any other roof type.

It must not, along with other garden buildings, cover more than 50% of the total area of the garden.

It must not be built on land forward of the 'principal elevation' (the front of the house).

Rules are much stricter for properties in Conservation Areas, Areas of Outstanding Natural Beauty (AONBs), National Parks, or for Listed Buildings, where planning permission is more likely to be required.

Building Regulations (The Construction Standards)

This is where the rules regarding insulation lie. However, most garden rooms are exempt from large parts of the Building Regulations based on their size :

Under 15m² internal floor area: Generally exempt from all Building Regulations, except for Part P concerning electrical safety.

Between 15m² and 30m² internal floor area: Also exempt, provided there is no sleeping accommodation AND the building is either positioned at least 1m from any boundary OR is constructed substantially of non-combustible materials.

The Part L Exemption: A Critical Detail for Buyers

The part of the Building Regulations that governs energy efficiency and sets minimum standards for insulation is Part L (Conservation of Fuel and Power). A critical point for any buyer to understand is that detached buildings with an internal floor area of less than 50m², such as most garden rooms, are completely exempt from the requirements of Part L.

The practical implication of this exemption is significant. It means a supplier can legally construct and sell a garden room with very little or poor-quality insulation, as it does not have to meet the same thermal standards as a new house or extension. An unsuspecting buyer might assume their expensive new garden room is built to modern standards, only to find it is cold, damp, and costly to run.

This creates a potential trap where a building is legally compliant but fails to meet the owner's practical needs for year-round comfort. The responsibility, therefore, falls on the buyer to be discerning. It is advisable to seek out suppliers who voluntarily build their garden rooms to a standard that meets or exceeds the requirements of Part L, even though they are not legally obliged to. The proof of this is in the U-values they can provide for their floor, wall, and roof constructions.

Finally, it is important to remember that any electrical installation in a garden room must comply with Part P of the Building Regulations, and the work must be carried out and certified by a qualified electrician.

Table 2: UK Regulations for Garden Rooms at a Glance

| Internal Floor Area | Planning Permission Needed | Building Regulations Approval Needed | Key Considerations |

| Under 15m² | No (if Permitted Development rules are met) | No (except Part P for electrics) | Exempt from Part L insulation standards. |

| 15m² - 30m² | No (if Permitted Development rules are met) | No (except Part P for electrics) | Must contain no sleeping accommodation AND be over 1m from any boundary OR be built of non-combustible materials. Exempt from Part L. |

| Over 30m² | No (if Permitted Development rules are met) | Yes | Full Building Regulations approval is likely required, including compliance with Part L insulation standards |

Final Considerations for Your Insulated Garden Room

Choosing the right insulation for a garden room is a decision that will impact its comfort, running costs, and lifespan for years to come. It requires a balanced approach, weighing up several key factors.

The Balanced Decision

When finalising your choice, consider the project through four lenses:

Budget: Determine your total budget, remembering that while some insulation materials have a higher upfront cost, they can lead to long-term savings on energy bills.

Performance: Decide on the level of thermal and acoustic comfort you require. Use U-values as your primary tool for comparing the thermal performance of different products and suppliers.

Purpose: The intended use of the room should guide your material choice. A sound-sensitive music studio has different priorities from a compact home office where every centimetre of internal space counts.

Compliance: Ensure the size and location of your proposed building comply with Permitted Development rules to avoid the need for planning permission, and always use a qualified electrician for any wiring.

Ultimately, the best-insulated garden rooms are those constructed as a complete, integrated system. Look for a reputable supplier who is transparent about their construction methods, the specific materials they use, and the certified performance data (U-values) of their buildings. An investment in quality insulation is an investment in a comfortable, efficient, and durable space that will serve as a valuable extension of your home for many years.

Legal Disclaimer

The information provided in this article is for general guidance and informational purposes only. It does not constitute professional, legal, or financial advice and should not be relied upon as such. The content does not deal with every important topic or cover every aspect of the topics with which it deals and may not be relevant or appropriate in all circumstances.

Planning permission and building regulation requirements are complex and can vary by local authority and specific site conditions. Before undertaking any construction work or making any financial commitments, you should consult with an appropriately qualified independent professional, such as a chartered building surveyor, architect, or planning consultant, for specific advice tailored to your project. You should also contact your local council's planning and building control departments for definitive information.

You should never attempt any activity that may put you or others at risk or which may cause damage to property. Activities involving gas or electricity must only be carried out by qualified and registered professionals. We accept no responsibility for any loss, damage, or injury that may arise from your use of the information contained in this article.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *