- Blogs

- The Definitive Guide to the Thinnest Wall Insulation for UK Homes

The Definitive Guide to the Thinnest Wall Insulation for UK Homes

TLDR

For projects where preserving interior space is the highest priority, the most effective thin insulation materials are Aerogel and Vacuum Insulation Panels (VIPs). Aerogel offers exceptional thermal performance in a thin, flexible, and breathable format, making it ideal for older, solid-walled properties, but it is very expensive. Vacuum Insulation Panels provide the absolute highest level of insulation for their thickness, but they are rigid, cannot be cut on-site, and are also a premium-cost option. A more common and affordable alternative is thin Polyisocyanurate (PIR) rigid foam board, which offers very good performance. However, PIR is not breathable and requires careful installation to manage moisture and prevent damp issues, particularly in solid walls. The right choice depends on the specific wall construction, budget, and performance requirements, with all work needing to comply with UK Building Regulations.

The Modern Insulation Challenge: Improving UK Homes Without Losing Space

The United Kingdom's housing stock is among the oldest in Europe, with a significant number of properties, particularly those built before the 1920s, constructed with solid walls. These homes are characterful but are notoriously inefficient, losing up to a third of their heat directly through uninsulated walls. This leads to high energy consumption, expensive heating bills, and a less comfortable living environment. For a typical detached house in the UK, effective wall insulation can lead to annual savings of up to £406 on energy bills.

Improving the thermal performance of these buildings is a priority, driven by both financial necessity and increasingly stringent government standards. The challenge, however, lies in the execution. Traditional insulation materials like mineral wool or standard foam boards, while effective, often require substantial thickness to meet modern performance targets. In many UK homes, especially in urban areas where every square metre is valuable, sacrificing 100mm or more of internal floor space per wall is a significant drawback. This creates a direct conflict between the need for energy efficiency and the desire to preserve living space.

This situation has created a growing demand for specialised, high-performance thin insulation solutions. These advanced materials are engineered to provide maximum thermal resistance with a minimal profile, addressing the specific constraints of renovating older properties and maximising usable area in new constructions. The push towards better insulation is not just a matter of personal choice; it is a response to a combination of economic and legislative pressures. Updates to UK Building Regulations, specifically Part L, now mandate higher levels of energy efficiency for both new builds and major renovations. Achieving these new targets with conventional materials can mean building external walls up to 600mm thick. This regulatory push, combined with the direct financial impact of high energy costs, makes thin insulation a critical technology for the future of UK housing.

Key Considerations Before You Insulate

Before selecting an insulation material, it is essential to understand the construction of your home's external walls and the fundamental principles of moisture management. These factors will determine which insulation systems are suitable and which could potentially cause harm to the building's structure.

Solid Walls vs. Cavity Walls

UK homes predominantly feature one of two types of external wall construction:

-

Solid Walls: Typically found in properties built before the 1920s, these walls consist of a single, solid layer of brick or stone. They have no gap and are the primary candidates for either internal or external solid wall insulation.

-

Cavity Walls: Common in homes constructed after the 1920s, these walls are made of two separate layers (or 'leaves') of brick or blockwork with a gap—the cavity—between them. While this article focuses on internal insulation applicable to both wall types, the behaviour of moisture differs significantly between them.

The Critical Role of Breathability (Vapour Permeability)

For owners of older, solid-walled properties, the single most important concept to understand is breathability. Solid brick and stone walls were designed to manage moisture by allowing water vapour to pass through them from the inside out and to evaporate harmlessly. This is known as being 'vapour permeable' or 'breathable'.

Applying a non-breathable (or 'vapour-closed') insulation material, such as a common foil-faced rigid foam board, to the inside of a solid wall can trap this moisture. As warm, moist air from inside the house tries to escape, it passes through the plaster and hits the cold back of the insulation board. Here, it can condense into liquid water—a process called interstitial condensation. Because the foil facing prevents this moisture from escaping, it becomes trapped within the wall structure. Over time, this can lead to serious problems, including damp patches, mould growth, rot in embedded timber floor joists or roof rafters, and frost damage to the brickwork (spalling).

Successful insulation is therefore not just about choosing a product with a good thermal performance value. It is about designing a complete system that works in harmony with the existing building fabric. This system includes the insulation material itself, any necessary vapour control layers, airtightness tapes for sealing joints, a suitable plaster finish, and adequate household ventilation. A failure in any one of these components can compromise the entire installation, regardless of the quality of the insulation board. This shifts the focus from asking "Which product is best?" to the more critical question: "Which system is right for my wall?".

A Guide to High-Performance Thin Insulation Materials

When space is the primary constraint, several advanced materials offer exceptional thermal performance in a very slim profile. These are the leading options available on the UK market, each with distinct properties, benefits, and drawbacks.

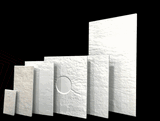

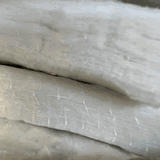

Aerogel Insulation

Often described as "frozen smoke," aerogel is the world's lightest and least dense solid material. It is a highly porous, silica-based substance with an incredibly low thermal conductivity, making it a superb insulator.

-

Performance: Aerogel has one of the lowest thermal conductivity ratings of any commercially available solid insulation, typically around 0.015 W/mK. A single 10mm layer of aerogel blanket can improve the insulation factor of a standard solid wall by as much as 67%.

-

Forms in the UK Market: It is most commonly supplied in two forms. The first is a flexible blanket, where the aerogel is embedded within a fibre matrix (e.g., Spacetherm, Thermablok). The second is as a composite board, where the aerogel blanket is bonded to a carrier board, such as Magnesium Oxide (MgO) board or plasterboard, to create a rigid panel.

-

Key Properties: A crucial advantage of aerogel for older properties is that it is both breathable (vapour permeable) and hydrophobic (it repels liquid water). This allows water vapour to pass through, preventing moisture build-up, while resisting damp from external sources. It is also non-hazardous and available with high fire-resistance ratings.

-

Applications: Its unique combination of thinness, flexibility, and breathability makes it an excellent solution for insulating hard-to-treat solid walls, curved surfaces, and awkward details like window reveals, where it can effectively eliminate thermal bridges.

-

Cost: The primary disadvantage of aerogel is its very high cost, which often places it in the premium category for specialised applications where no other material will suffice.

Vacuum Insulation Panels (VIPs)

Vacuum Insulation Panels represent the pinnacle of thermal performance, offering an insulation value that is typically five to ten times better than conventional materials of the same thickness.

-

Technology: A VIP consists of a microporous core material, usually fumed silica, which is encased and sealed in a gas-tight, multi-layer foil envelope. All the air is then evacuated from the core to create a near-perfect vacuum. This vacuum virtually eliminates heat transfer by convection and gas conduction.

-

Performance: VIPs achieve an outstanding centre-of-panel thermal conductivity, with a lambda value (λ) as low as 0.006 W/mK for the core. This allows for extremely thin insulation solutions that can meet stringent energy efficiency targets.

-

Forms in the UK Market: Leading products include Kingspan OPTIM-R and Recticel Deck-VQ. To protect the delicate vacuum envelope, these panels are often supplied encapsulated within a more robust material, such as a high-density PIR board, which also makes them safer to handle and install on-site.

-

Key Properties: The most significant limitation of VIPs is that they cannot be cut, drilled, or punctured on-site. Any damage to the outer envelope will destroy the vacuum, causing the panel to lose its high-performance insulating properties. This means they must be custom-ordered to the exact dimensions required for a project, demanding meticulous planning and measurement. They are also completely vapour-impermeable.

-

Applications: VIPs are best suited for applications with severe space limitations where the highest possible thermal performance is non-negotiable. They are commonly used on flat roofs, balconies, and terraces to achieve required insulation values without raising floor levels excessively.

-

Cost: Like aerogel, VIPs are a very high-cost, specialist product requiring careful design and professional installation.

Thin Rigid Foam Boards (PIR)

Polyisocyanurate (PIR) is a type of rigid foam insulation that is widely used in UK construction. It provides a practical and cost-effective balance between thermal performance and thickness.

-

Performance: PIR boards offer very good thermal performance, with a typical thermal conductivity of around 0.022 W/mK. This makes them significantly more effective than traditional materials like mineral wool.

-

Forms in the UK Market: PIR is available in a range of thicknesses, with some manufacturers like Unilin (formerly Xtratherm) offering boards as thin as 15mm. A popular format for internal wall insulation is the insulated plasterboard, which combines a layer of PIR insulation with a sheet of plasterboard in a single, easy-to-install panel (e.g., Celotex PL4000).

-

Key Properties: Standard PIR boards are faced with aluminium foil, which acts as a vapour barrier. This means they are not breathable (vapour impermeable). As discussed previously, using these boards on solid walls carries a significant risk of trapping moisture if not detailed correctly with a perfect, continuous vapour control layer and adequate ventilation.

-

Applications: Thin PIR boards are an excellent choice for many internal wall applications, especially in modern homes with cavity walls where internal moisture management is less complex. They are also suitable for solid-walled properties, but only as part of a carefully designed system installed by professionals who understand moisture risk.

-

Cost: Compared to aerogel and VIPs, PIR insulation is a much more moderate and accessible cost option, making it a popular choice for a wide range of projects.

Other Space-Saving Insulation Solutions

Beyond the main high-performance materials, other products can provide a thermal upgrade where space is exceptionally tight or where different properties like breathability and flexibility are required.

Insulating Lining Papers

These are ultra-thin insulation products that are applied to internal walls much like a thick wallpaper. Products like ISO-THERM are typically around 4mm thick and are made from textile-based materials. They are glued to the wall with a special adhesive and work by raising the internal surface temperature of the wall. While their overall contribution to the wall's thermal resistance is modest, they are very effective at combating surface condensation and preventing the formation of mould. They are a good, low-disruption option for providing a noticeable improvement in comfort in small rooms or on localised cold spots.

Sprayed Cork Insulation

Sprayed cork is an innovative and sustainable insulation solution that leverages the natural properties of cork oak trees. The product is a liquid coating containing cork granules mixed with resins, which is sprayed directly onto the wall surface. It dries to form a thin, flexible, and seamless layer. Cork's cellular structure, which contains millions of tiny air pockets, provides both thermal and acoustic insulation. A major benefit is its breathability, allowing moisture to pass through, which makes it suitable for older properties. It is also a renewable resource, as the bark is harvested without harming the tree. Application is a specialist job that must be carried out by approved installers.

Insulating Plasters

For properties with very uneven walls, such as those made from traditional stone, applying rigid insulation boards can be difficult. In these cases, modern insulating plasters offer a practical solution. These systems incorporate insulating aggregates like cork, lime, and clay directly into the plaster mix. The plaster is applied directly to the wall, creating a continuous insulating layer that follows the contours of the surface. These plasters are fully breathable, aligning perfectly with the principles of building conservation. While their thermal performance per centimetre is lower than that of rigid boards, they provide a valuable upgrade without creating moisture traps.

Comparing Your Thin Insulation Options

Choosing the right material involves balancing performance, breathability, installation constraints, and cost. The table below provides a direct comparison of the main high-performance options.

Feature |

Aerogel Blanket/Board |

Vacuum Insulation Panel (VIP) |

Thin PIR Board/Insulated Plasterboard |

| Typical Thickness | 5mm - 20mm | 20mm - 45mm | 15mm - 40mm |

| Thermal Performance | Exceptional | Highest | Very Good |

| Breathability (Vapour Permeable) | Yes | No | No |

| Installation Flexibility | Flexible, can be cut | Rigid, cannot be cut | Rigid, can be cut |

| Indicative Cost | Very High | Very High | Moderate |

| Best Suited For | Heritage properties, solid walls, complex shapes, eliminating thermal bridges. | Projects with extreme space constraints where performance is paramount (e.g., terraces, floors). | General purpose internal insulation, especially in modern cavity-walled homes. |

Best Practices for Installing Internal Wall Insulation

The performance of any insulation material is heavily dependent on the quality of its installation. Poor workmanship can undermine the effectiveness of even the most advanced products and can lead to serious problems.

Surface Preparation

Before any insulation is applied, the existing wall must be sound, clean, and dry. Any underlying issues, such as penetrating damp, rising damp, or damaged brickwork, must be fully resolved. Applying insulation over a damp wall will trap the moisture and worsen the problem.

Airtightness and Continuity

A "fabric-first" approach is essential for effective insulation. This means ensuring the insulation layer is continuous, without gaps. All joints between insulation boards, as well as the junctions where the insulated wall meets the floor, ceiling, and adjacent walls, must be meticulously sealed with appropriate airtightness tapes or sealants. This prevents air leakage, also known as thermal bypass, where cold air can circulate behind the insulation and reduce its effectiveness.

Addressing Thermal Bridges

Thermal bridges are areas where heat can bypass the insulation layer more easily, creating cold spots on the internal surface. Common thermal bridges include the areas around windows and doors (reveals), junctions with uninsulated floors or ceilings, and gaps around electrical sockets or pipework. These areas must be carefully insulated to maintain a continuous thermal barrier. Thin and flexible materials like aerogel strips are particularly well-suited for treating these awkward details.

Fixing Methods

Rigid insulation boards can be fixed to the wall using mechanical fixings or a specialist adhesive. A common method is 'dot and dab', where dabs of adhesive are applied to the back of the board. However, this method can leave air gaps behind the insulation, which can lead to air movement and compromise thermal performance. A better practice is to apply a continuous bead of adhesive around the perimeter of the board and across its centre to minimise air circulation.

Professional Installation

While simpler systems like insulating lining paper may be within the scope of a competent DIYer, high-performance insulation systems demand a high level of skill and knowledge. For materials like VIPs, or for any project involving the insulation of solid walls where moisture management is critical, professional installation by experienced and reputable contractors is strongly recommended. Poor installation by inexperienced companies has been identified as a cause of significant problems, including structural damage.

Understanding UK Building Regulations

In the UK, any significant building work, including the installation of wall insulation, must comply with the Building Regulations. For energy efficiency, the relevant section is Approved Document L (Conservation of fuel and power).

Introduction to Part L

Part L of the Building Regulations for England sets the legal minimum standards for the energy performance of buildings. There are two volumes: Volume 1 covers dwellings, and Volume 2 covers buildings other than dwellings. These regulations were updated in 2022 as an interim step towards the Future Homes Standard, which will come into effect in 2025.

When Do the Regulations Apply to Renovations?

For existing homes, the regulations typically apply when a "thermal element" (like a wall, roof, or floor) is being added or replaced, or when a significant proportion of an existing element is being renovated. This includes work such as:

-

Adding internal or external wall insulation to more than 50% of an individual wall's surface.

-

Renovating more than 25% of the total external surface area of the building (e.g., by applying new cladding or dry-lining).

-

Building an extension.

-

Converting a previously unheated space (like a garage) into a habitable room.

Target U-values for Walls

The performance of a building element is measured by its U-value, which indicates the rate of heat transfer throughit. A lower U-value means better insulation. Part L specifies target U-values that must be achieved. For renovation work on existing dwellings, the key targets for walls are:

-

Internal or External Wall Insulation: The insulated wall should achieve a U-value of 0.30 W/m²K or better.

-

New or Replacement Wall (e.g., in an extension): The wall must achieve a more stringent U-value of 0.18 W/m²K or better.

These targets provide a clear benchmark for the level of performance that your insulation project should aim to meet.

Making an Informed Decision

Choosing the thinnest insulation for your walls involves navigating a series of important trade-offs between performance, space, cost, and building physics. There is no single "best" material; the right solution is entirely dependent on the specific context of your property.

The highest-performing materials, Aerogel and Vacuum Insulation Panels, offer remarkable space-saving potential but come with a significant financial investment. They represent the cutting edge of insulation technology and are often the only viable solution for the most challenging projects. More conventional thin materials like PIR boards provide a more affordable route to achieving excellent thermal performance, but their lack of breathability means they must be used with caution and expertise, particularly in older solid-walled homes where moisture management is paramount.

The final decision should be based on a thorough assessment of your property. Consider its age, the type of wall construction, your budget, and the specific performance targets you need to meet, such as those dictated by Building Regulations. Given the potential for costly mistakes, especially those related to damp and moisture, seeking advice from a qualified professional, such as a retrofit assessor or an experienced architect or builder, is a wise investment. Recent government warnings about poor quality installations highlight the importance of selecting reputable, knowledgeable installers who understand the building as a whole system, rather than simply applying a product. By carefully considering all these factors, you can make an informed choice that will improve the comfort and efficiency of your home for years to come.

Legal Disclaimer

The information contained in this article is provided for general information purposes only. It does not constitute professional, technical, legal, or financial advice and should not be relied upon as such. The application of building regulations and construction techniques will vary depending on the specific circumstances of each project. Laws, regulations, and standards are subject to change and may not be fully reflected in this content.

You should not act, or refrain from acting, on the basis of any information contained in this article. We strongly recommend that you seek tailored advice from a qualified and insured professional, such as an architect, surveyor, structural engineer, or specialist insulation contractor, before undertaking any building work or making any decisions related to your property. No liability is accepted for any errors or omissions in the content of this article, or for any loss or damage, including indirect or consequential loss or damage, arising from the use of or reliance on the information provided.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *